Drawing equipment and method for curvilinear profile pultrusion production based on differential drawing rate

A kind of traction equipment and profile technology, which is applied in the field of curvilinear profile pultrusion production traction equipment to achieve the effect of simple use of equipment and clear movement principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

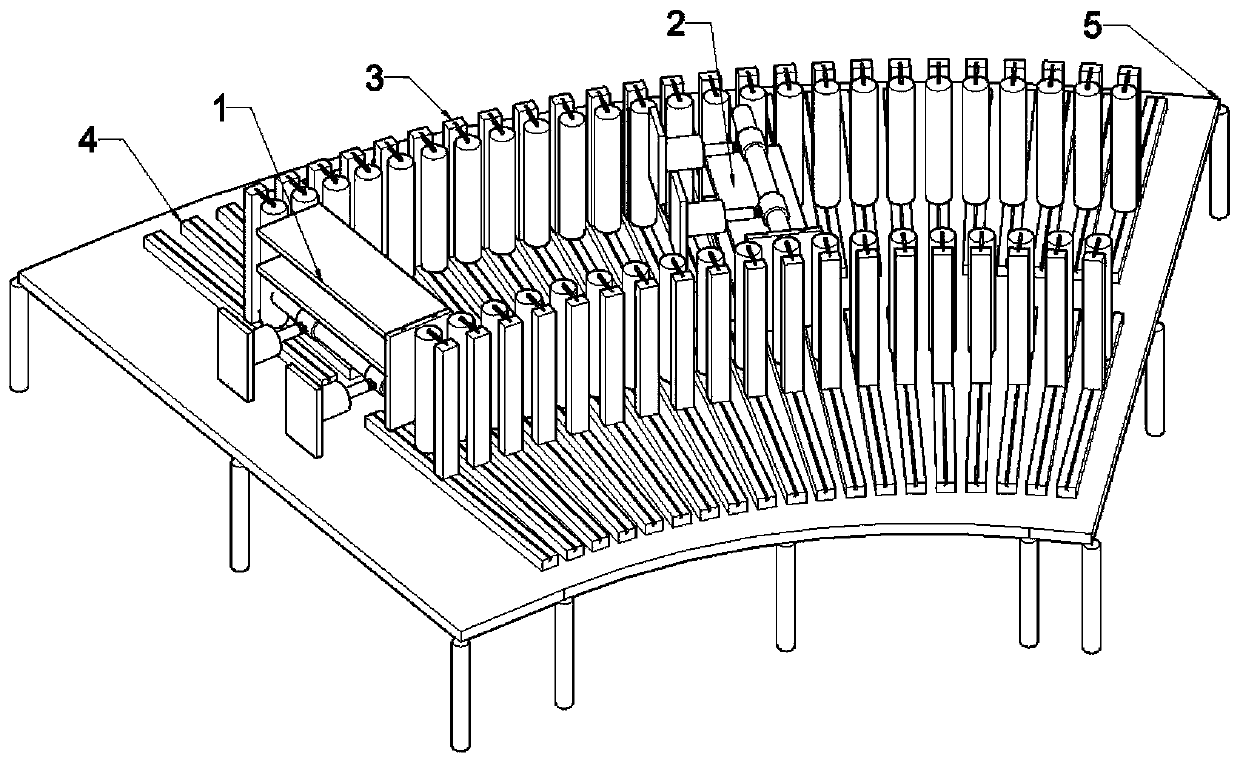

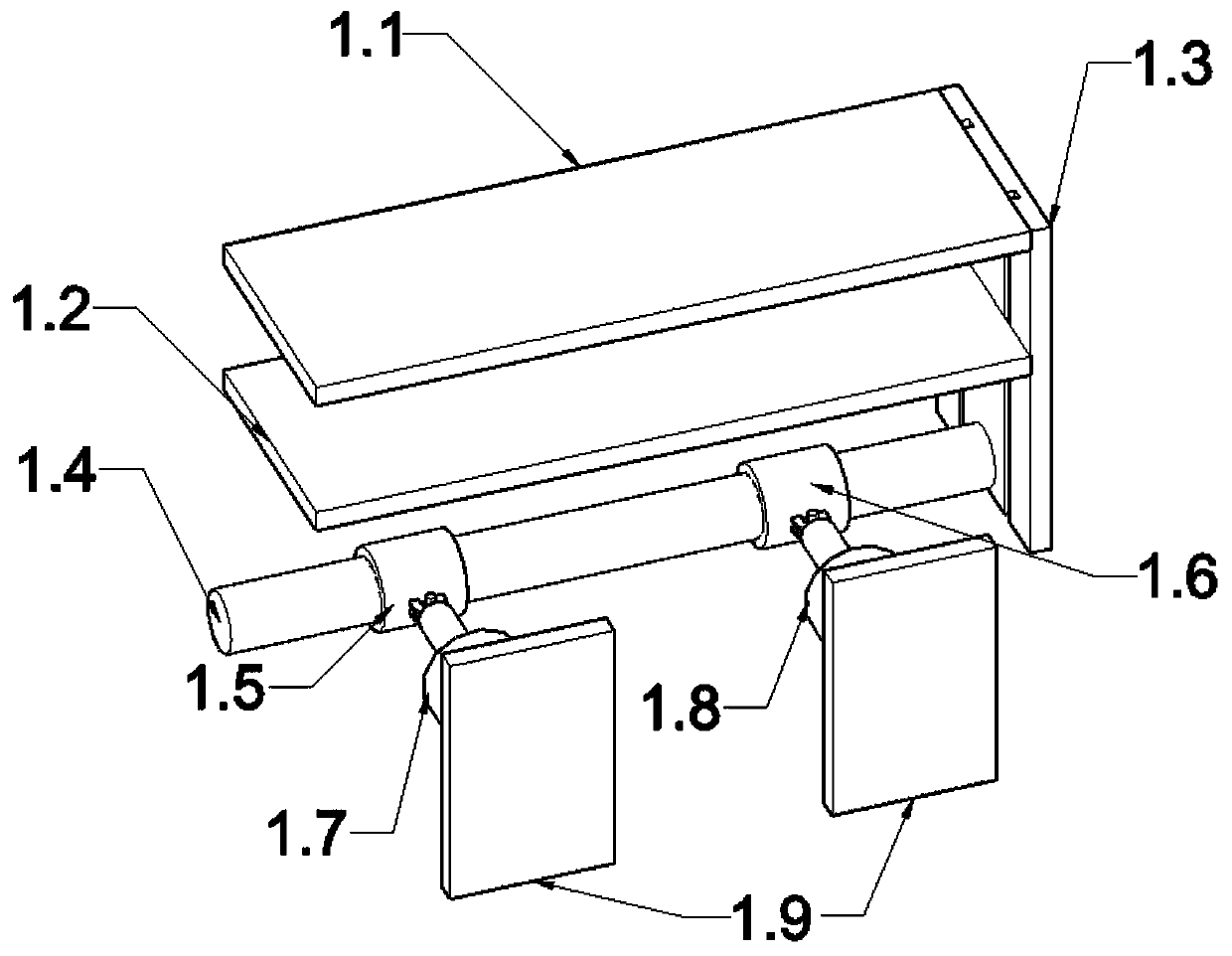

[0024] Such as figure 1 As shown, the present invention includes a first pulling chuck 1 , a second pulling chuck 2 , rollers 3 , slide rails 4 and a frame 5 . The first drawing chuck 1 is located at the exit of the curing mold, the first drawing chuck 1 and the second drawing chuck 2 are distributed along the same arc interval, the two ends of the first drawing chuck 1 and the second drawing chuck 2 There are rollers 3 respectively, and the rollers 3 are installed on the slide rail 4 to form a track to limit the movement direction of the traction chuck. The slide rail 4 is distributed in a fan shape, and the roller 3 can reciprocate linearly along the slide rail 4 to adjust the circular curve track of the radius. Driven by the jack, the first drawing chuck 1 and the second drawing chuck 2 move along the track formed by the rollers 3, and the rollers 3 and slide rails 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com