Electrothermal film heater and assembly method thereof

An electric heating film and heater technology, which is applied in the field of household appliances, can solve problems such as complex operation procedures, high difficulty in wiring electric heating diaphragms, and low assembly efficiency of electric heating diaphragms, so as to improve installation efficiency and avoid electrical safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

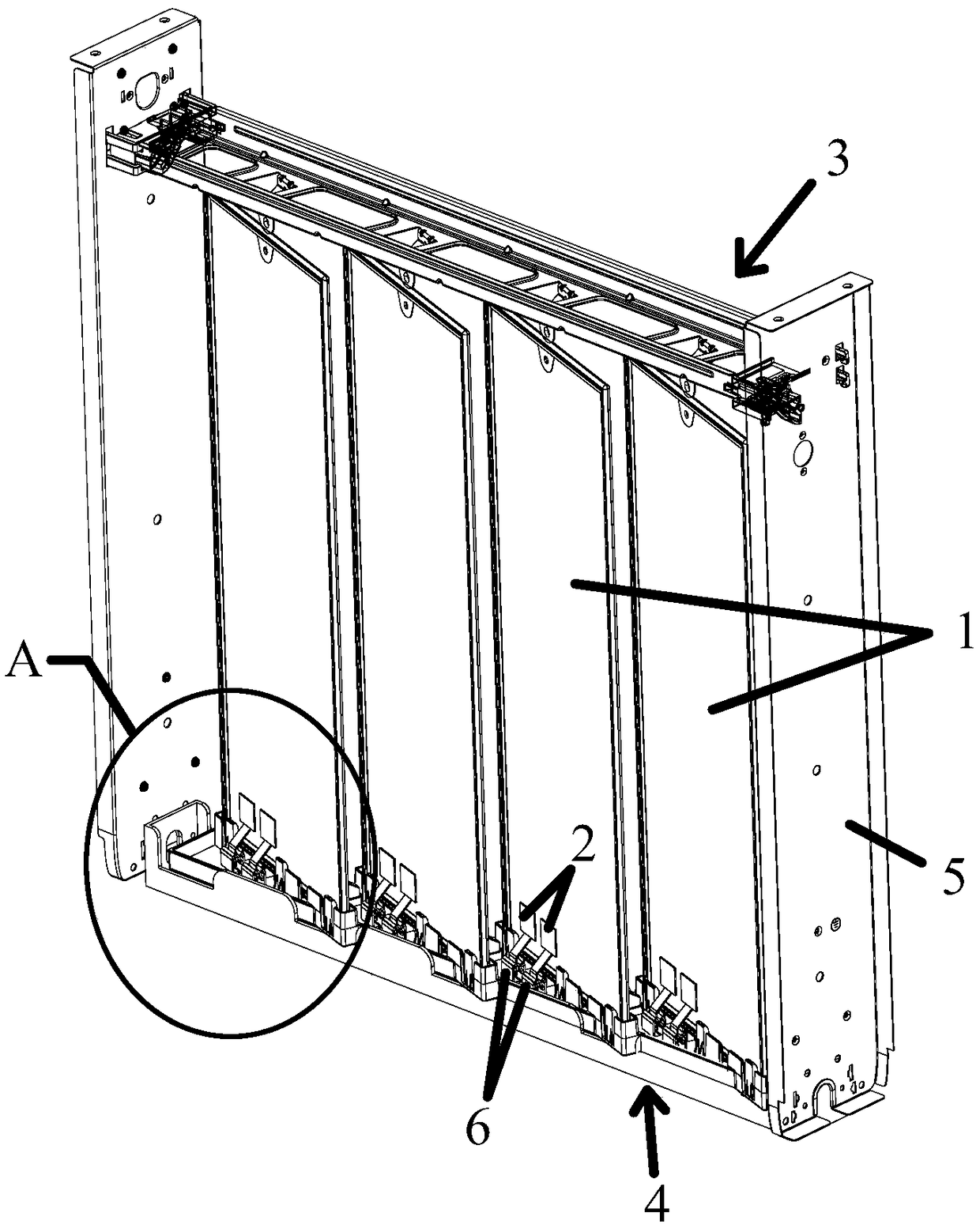

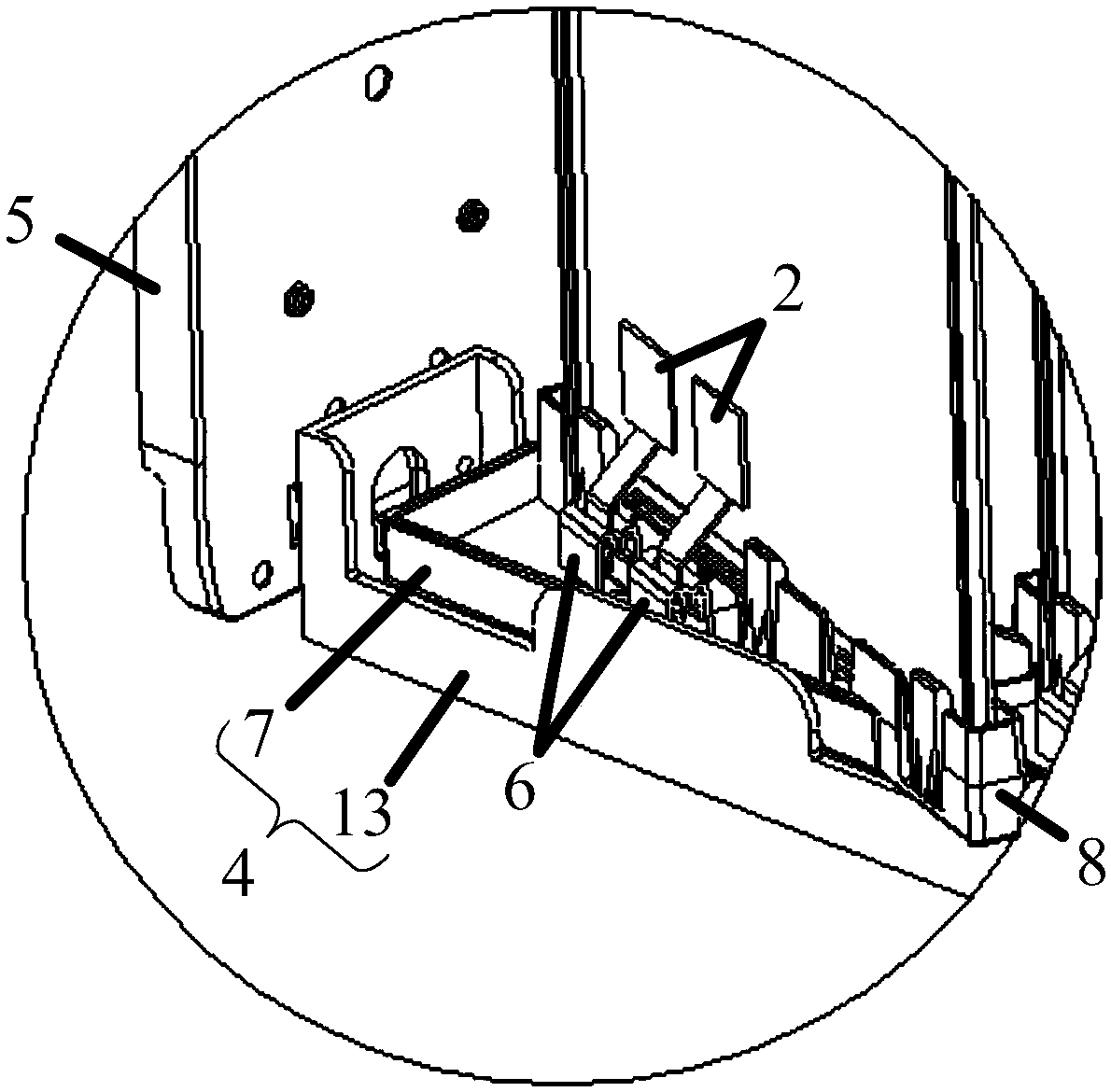

[0052] This embodiment provides an electric heating film heater, such as Figure 1 to Figure 3 shown, which includes

[0053] An electrothermal diaphragm 1, the lower end of which is provided with a terminal 2;

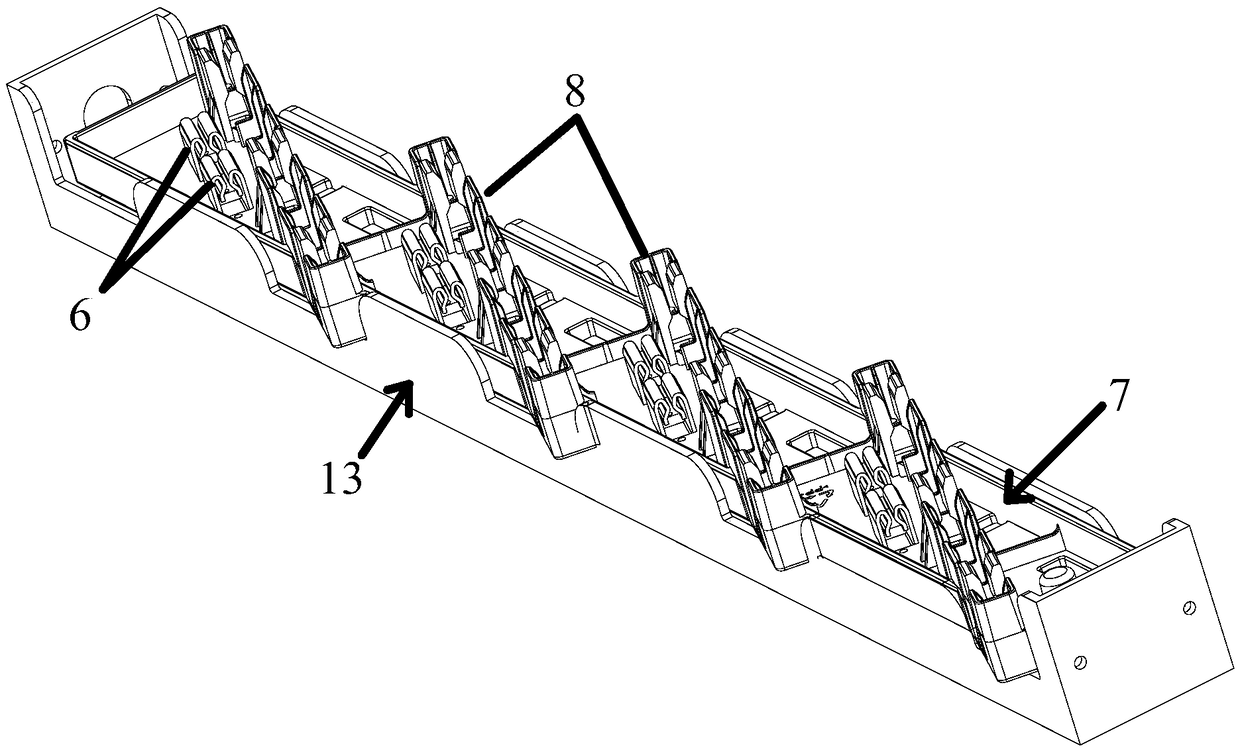

[0054] Socket body 7, such as Figure 4 with Image 6 As shown, the socket main body 7 is provided with a card slot 8 matching the shape of the lower end of the electrothermal film 1, and the lower end of the electrothermal film 1 is inserted into the card slot 8 to connect with the socket. The main body 7 is clamped and connected, and the installation of the electric heating diaphragm can be completed by inserting the electric heating diaphragm into the card slot. There is no need to assemble parts such as porcelain seats, porcelain sleeves, screws and nuts, which greatly reduces the installation of the electric heating diaphragm Difficulty, one worker can complete the above work independently and quickly, greatly improving the installation efficiency and in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com