Patents

Literature

46results about How to "Avoid positional interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

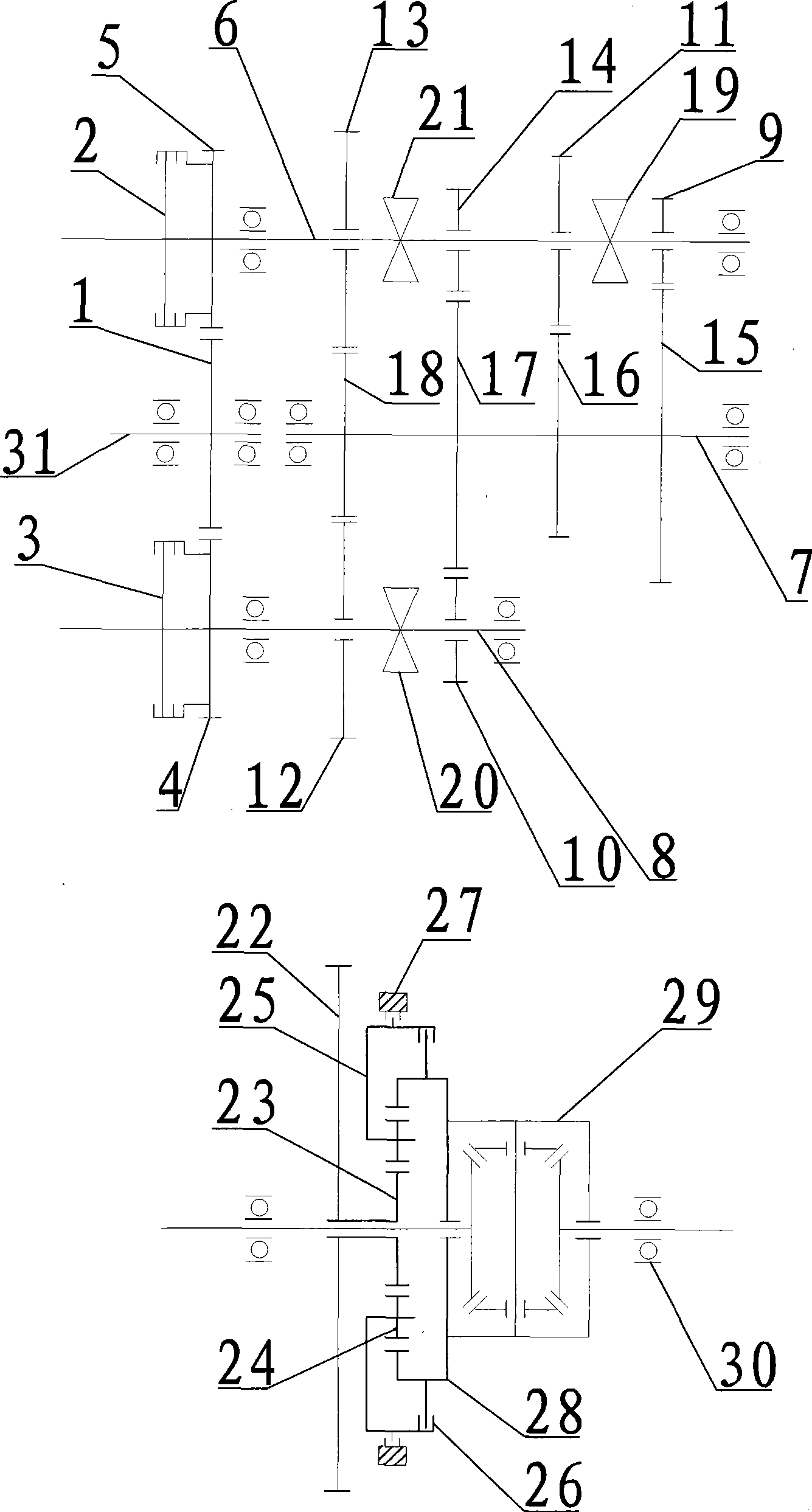

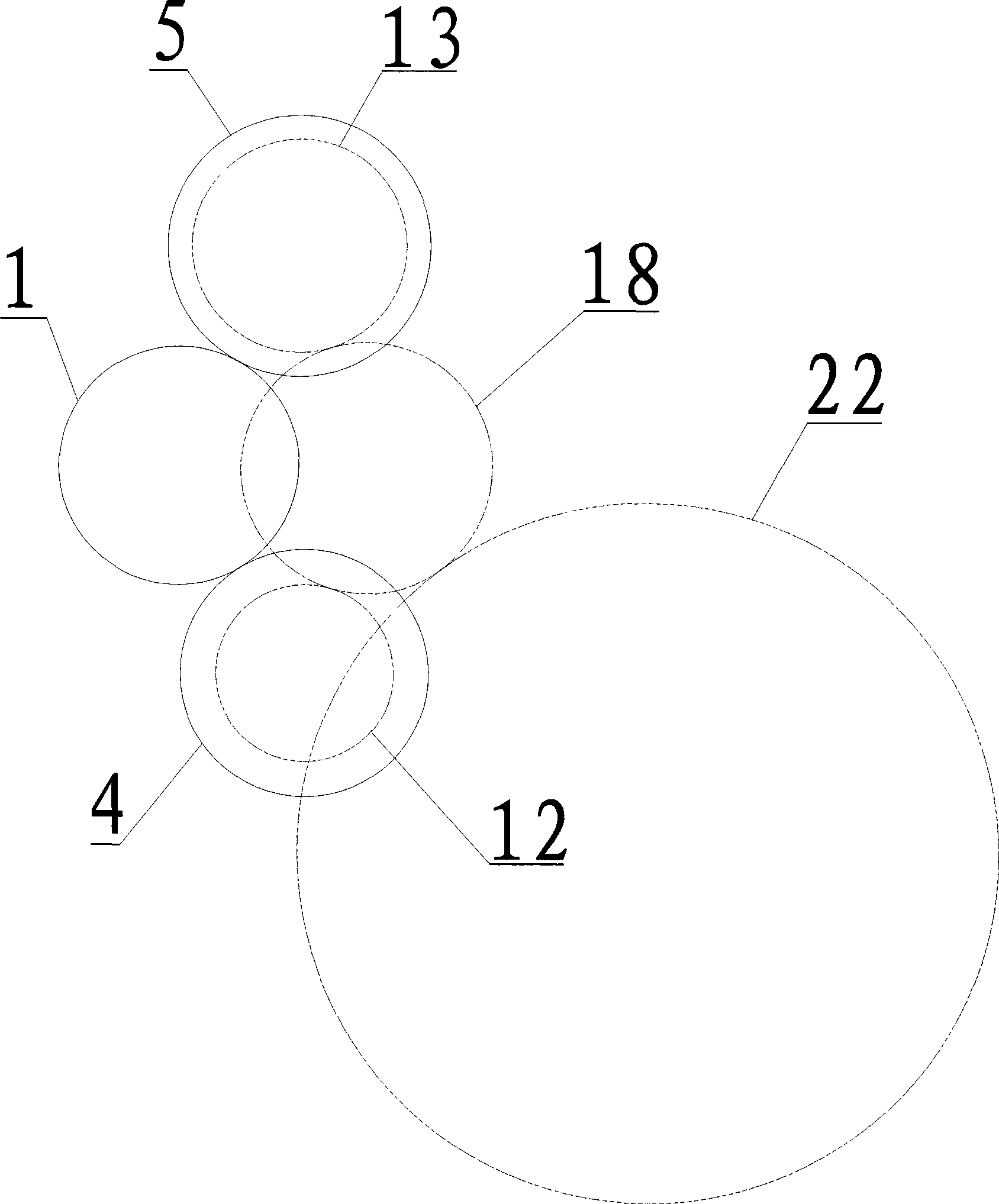

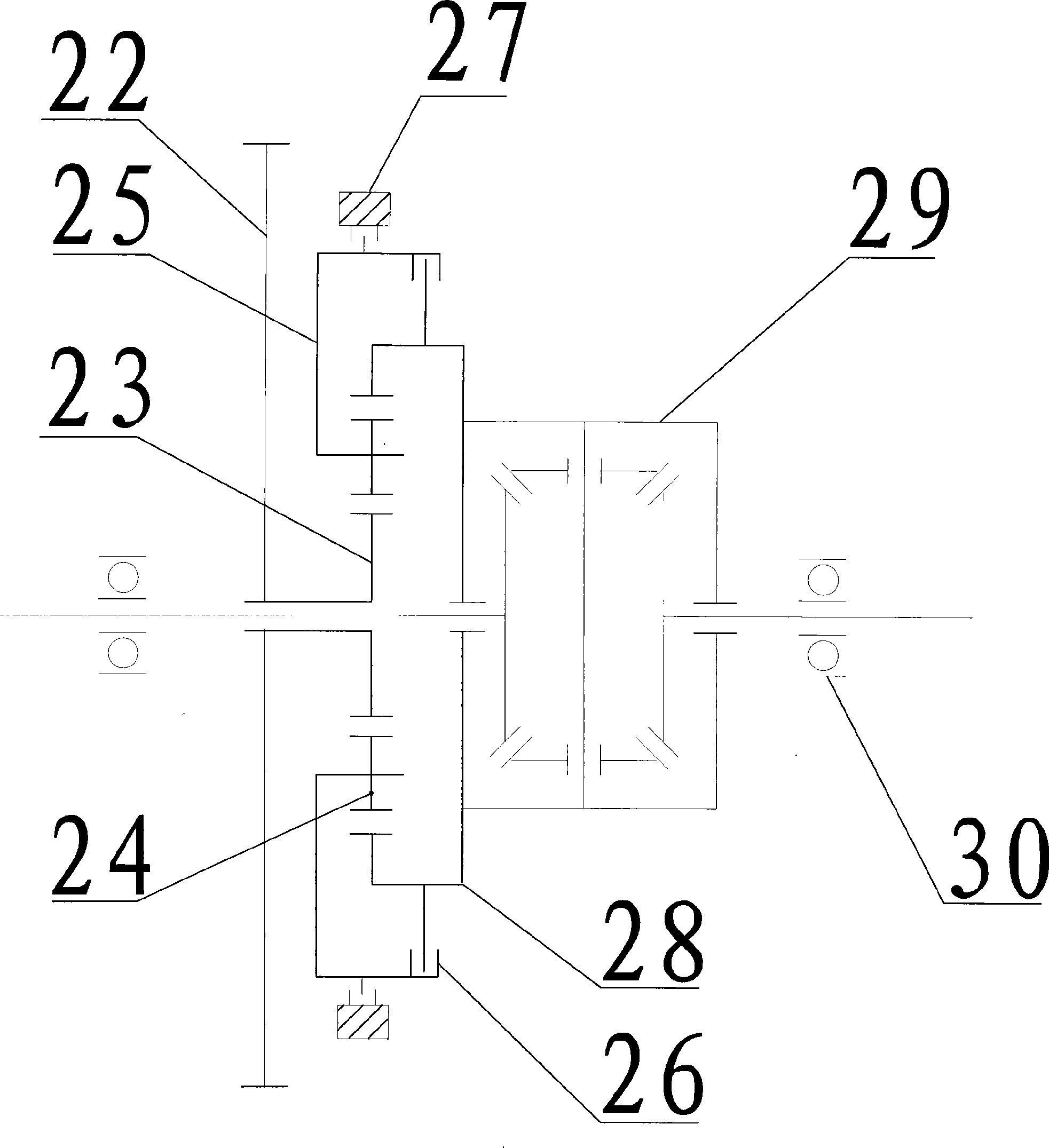

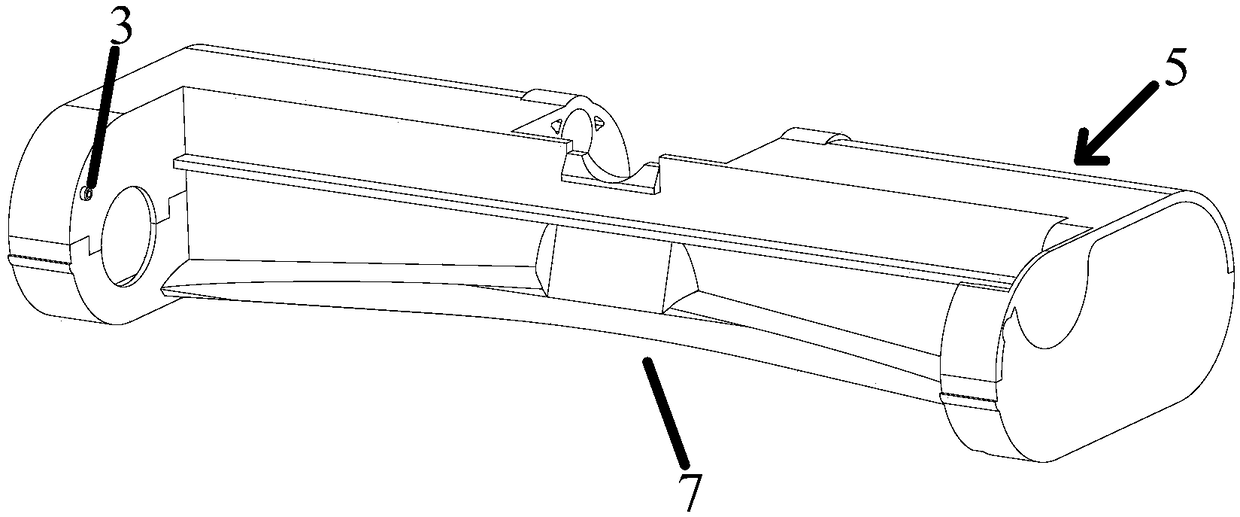

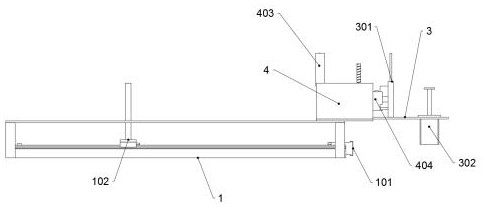

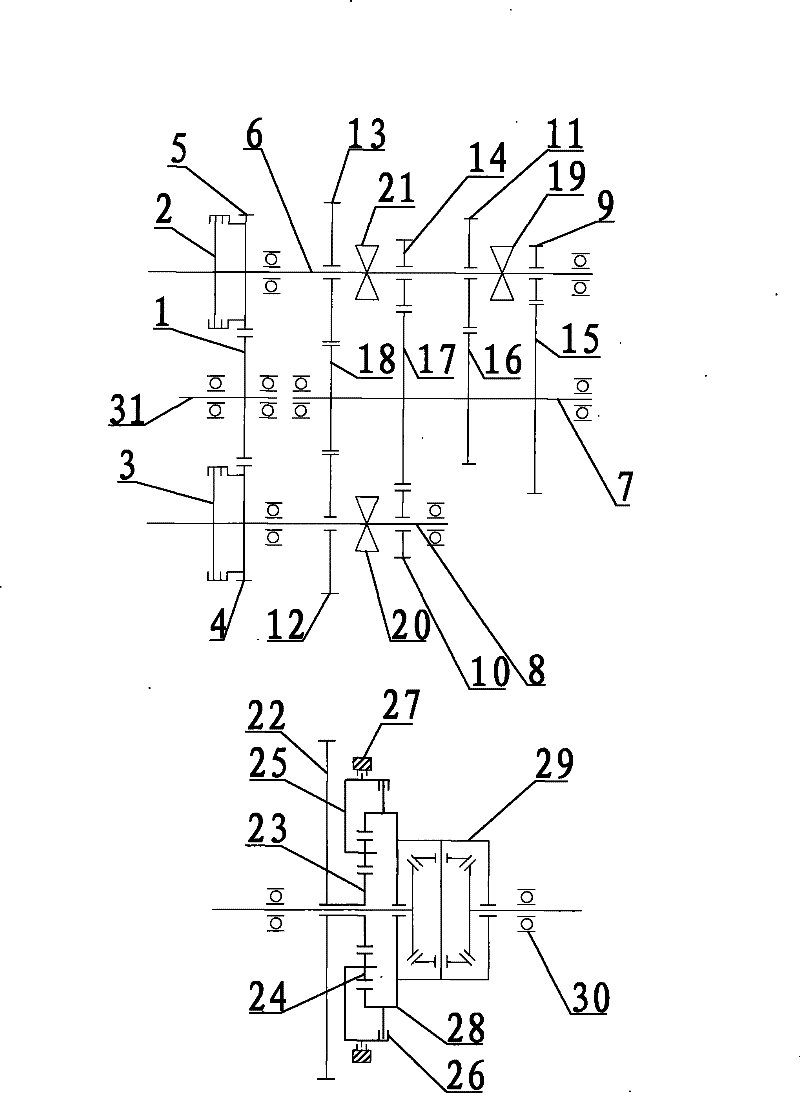

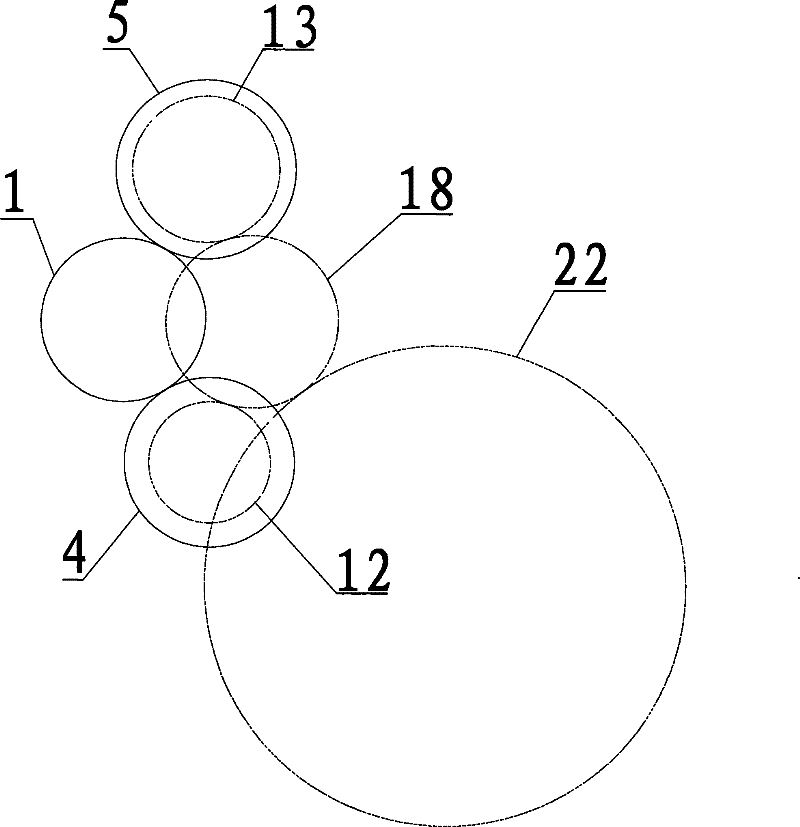

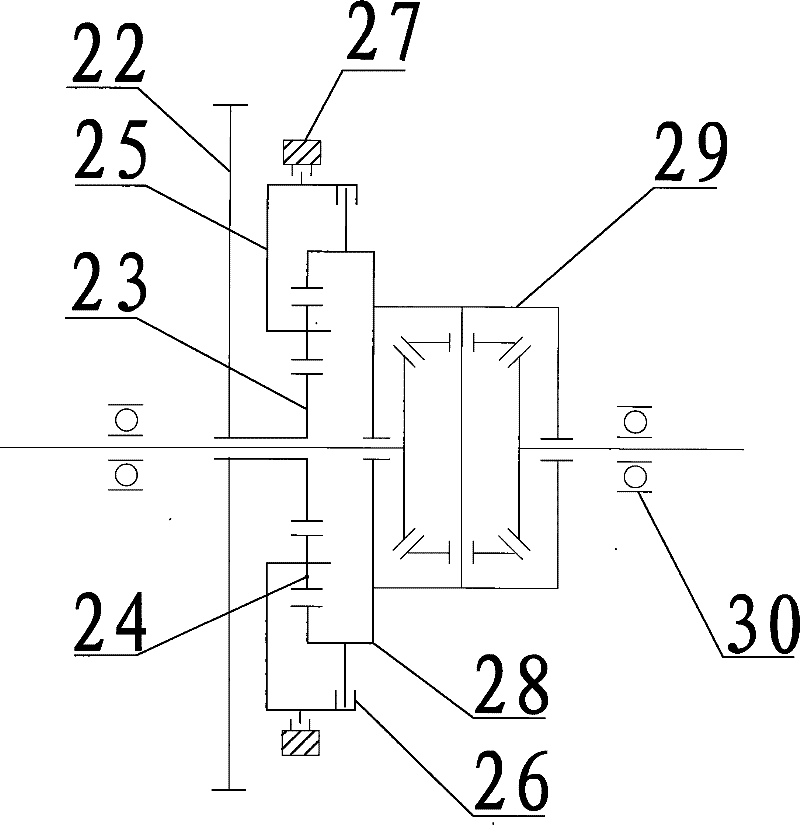

Double clutch automatic speed transmission

ActiveCN101424328ASave spaceEasy to arrange and useToothed gearingsGearing detailsAutomatic transmissionGear wheel

The invention relates to a double-clutch automatic speed changer, which comprises an input shaft (31), an input shaft gear (1), a first auxiliary shaft (6), a second auxiliary shaft (8), an intermediate shaft (7), a power output device, at least one odd-shift gear pair, at least one even-shift gear pair, a first clutch (2) fixed on the first auxiliary shaft (6) and a second clutch (3) fixed on the second auxiliary shaft (8). The speed changer is characterized in that the power output device comprises a differential (29) and a planetary mechanism fixedly connected with the differential (29). The speed changer has the advantages that the speed changer is small in gear quantity, small in axial length, light in weight and easier to arrange and use in small-size front-wheel driven cars.

Owner:CHONGQING TSINGSHAN IND

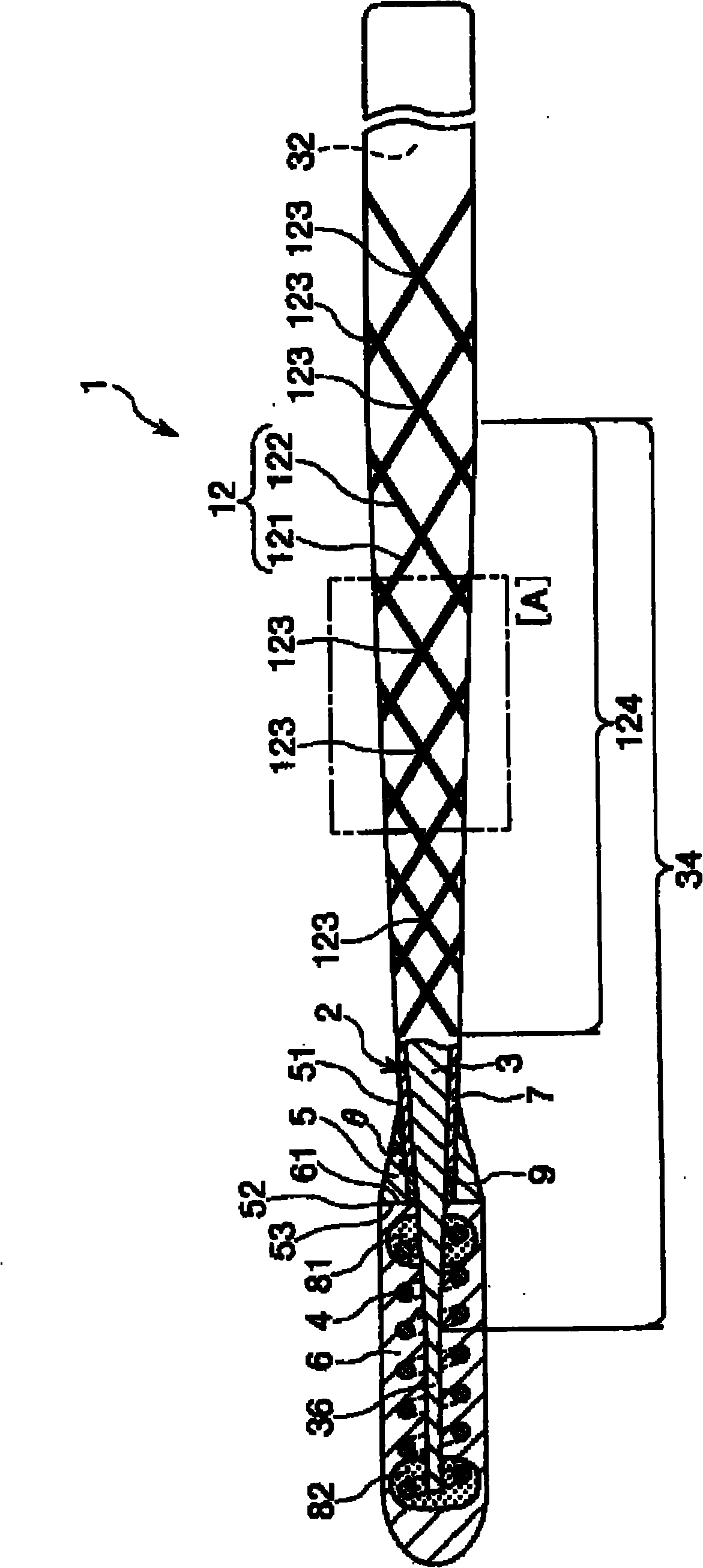

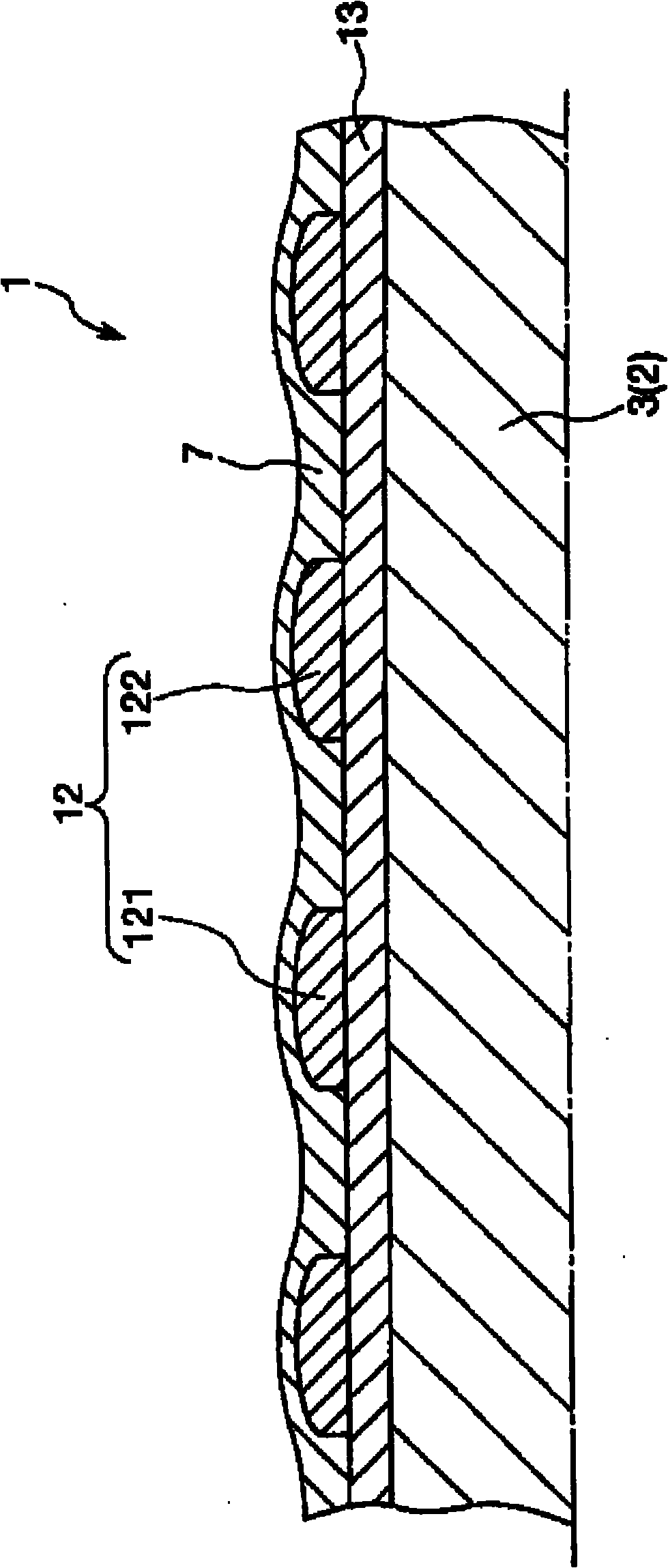

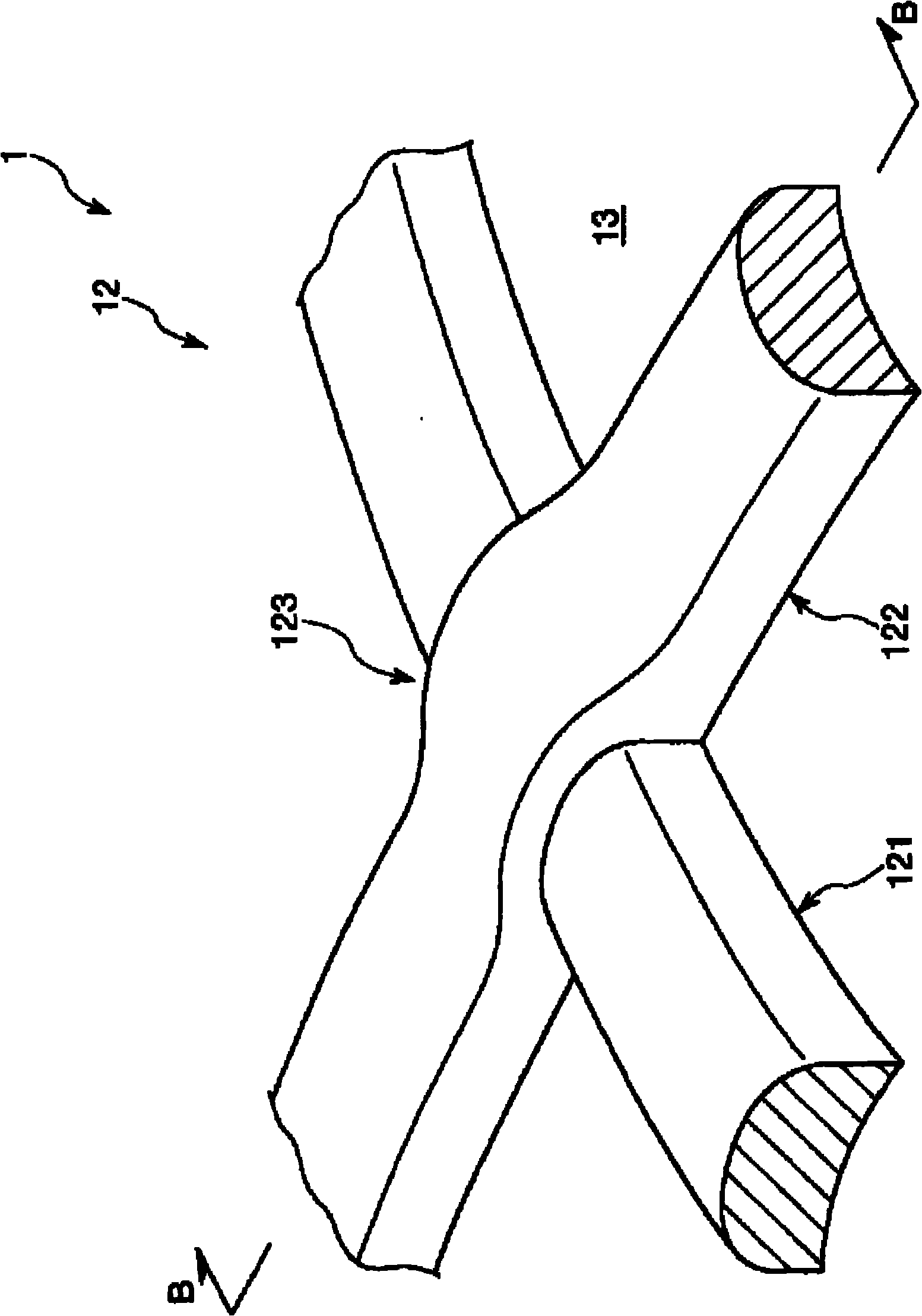

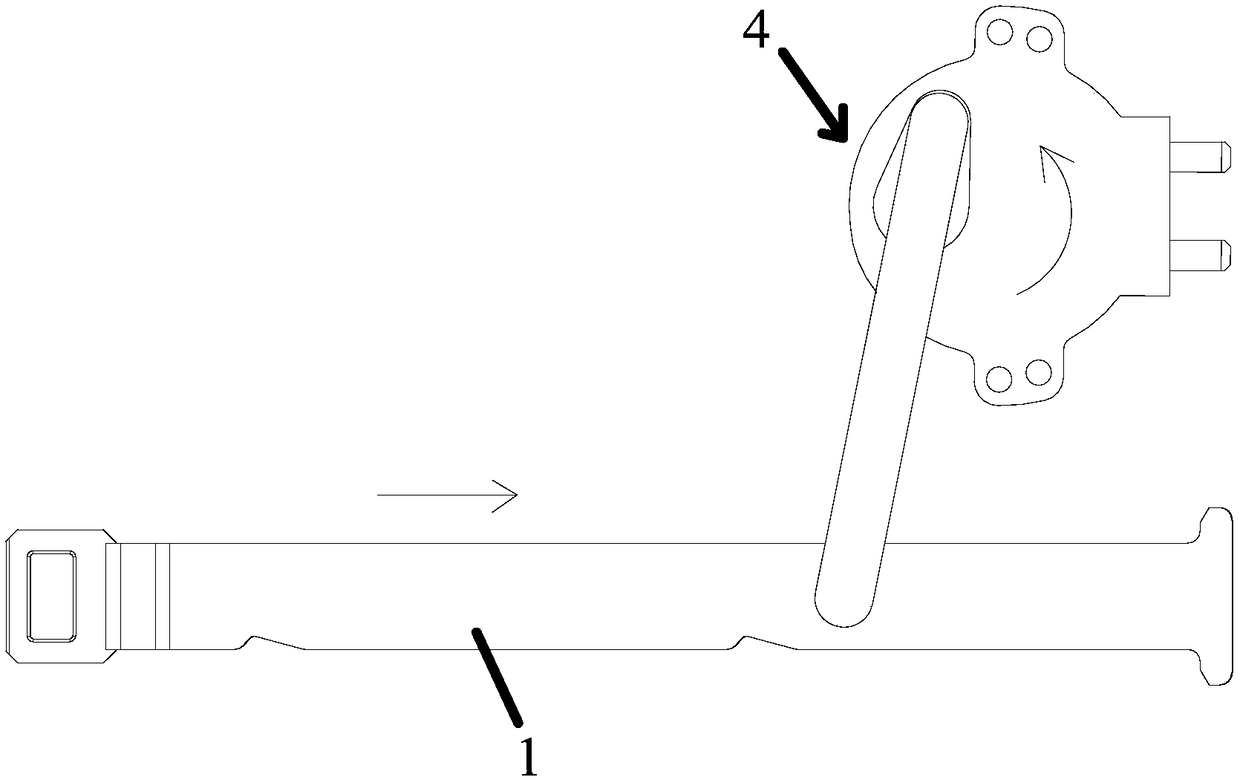

Guide wire

Provided is a guide wire, which comprises a lengthy wire body, and a marker disposed in at least the tip side portion of the wire body all over the circumference and having a function to indicate the position of the wire body in a living body. The marker is formed into a lattice shape as a whole by causing a first filament portion and a second filament portion to intersect with each other at a plurality of portions. Moreover, the intersecting portions of the first filament portion and the second filament portion are formed in plurality in the marker. Noting a predetermined one of those intersecting portions, therefore, the predetermined intersecting portion looks, as if it moves radially of the guide wire, when the guide wire is turned on its axis. Thus, it is possible to confirm reliablythat the guide wire has been turned.

Owner:TERUMO KK

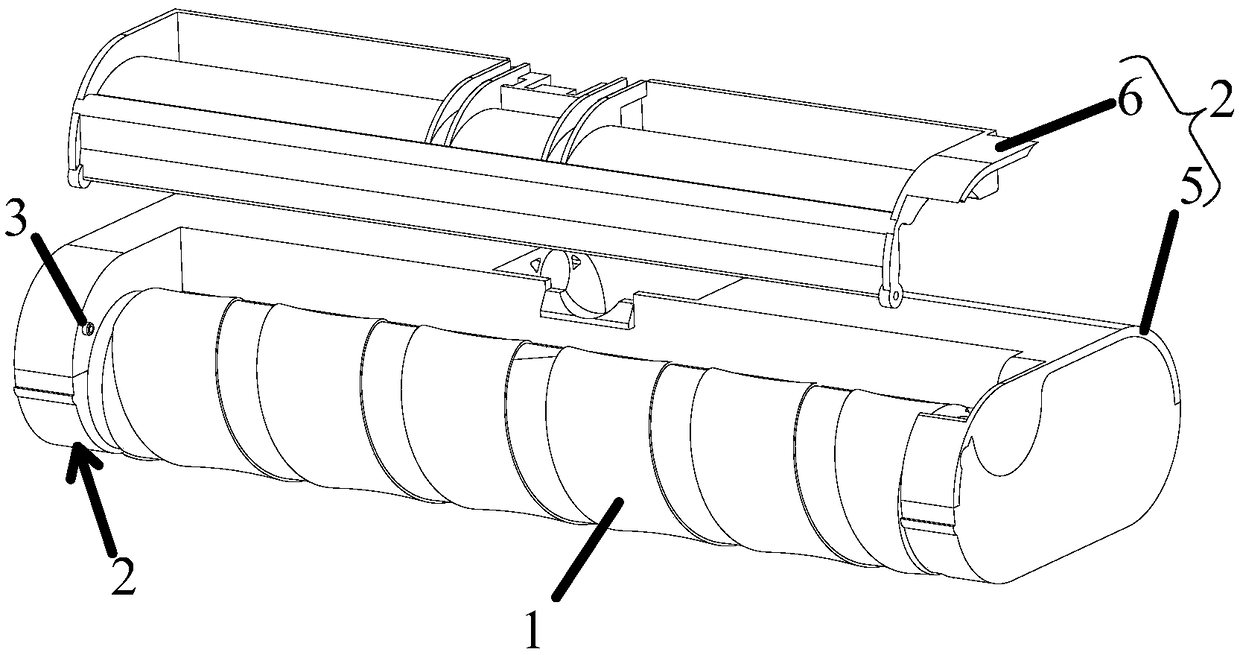

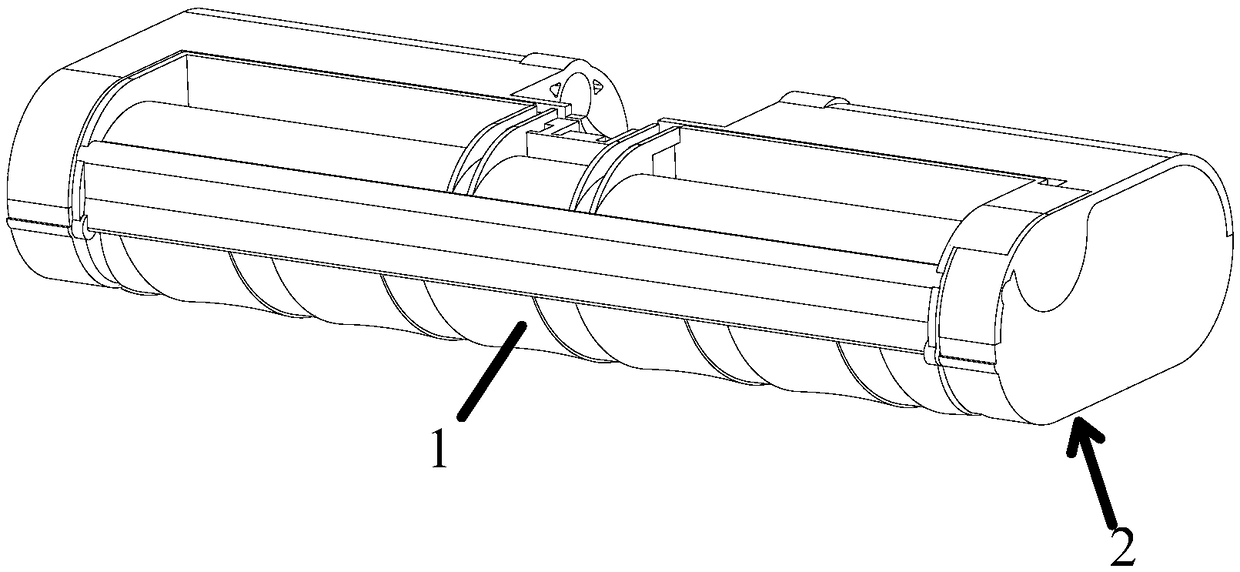

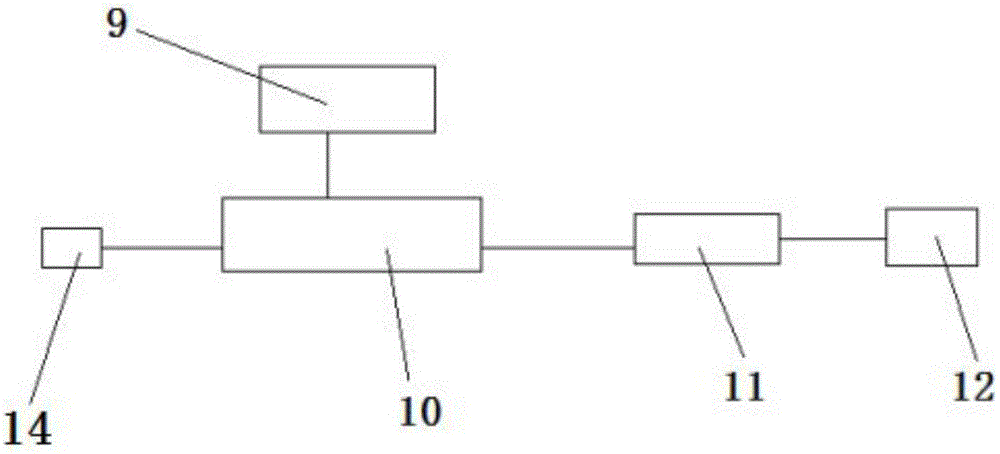

Cleaning head with a water spraying function and a wet vacuum cleaner having the cleaning head

PendingCN109171549AReduce manufacturing costsIncrease the cleaning areaSuction nozzlesEngineeringMechanical engineering

The invention discloses a cleaning head with a water spraying function and a wet vacuum cleaner with the cleaning head. The cleaning head with the water spraying function comprises a wiping head, a housing, and a water spraying mechanism, wherein the wiper head is accommodated in the housing; the water spraying mechanism includes a nozzle positioned at a side wall position of an inner cavity of the housing and disposed toward the wiper head and a liquid supply line communicating with the nozzle; and the nozzle is positioned outside an outer contour of the wiper head. The cleaning head with a water spraying function solves the problems that the spray head of the prior art cleaning head cannot be arranged on the outside of the wiper head, and the spray head cannot spray the liquid onto the part of the wiper head close to the inner wall of the shell, and the wiper head has a dry part, and cannot be uniformly wetted, thus leading to poor cleaning ability of the wiper head and even scratches on the cleaned surface.

Owner:GREE ELECTRIC APPLIANCES INC

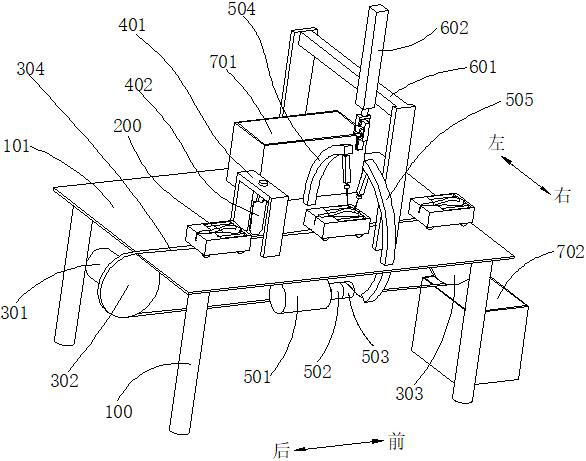

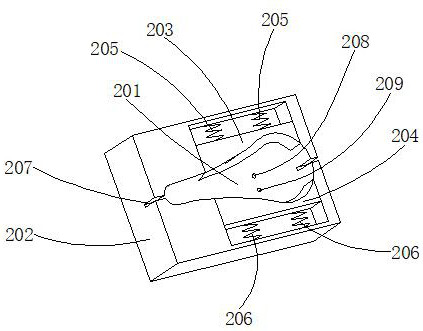

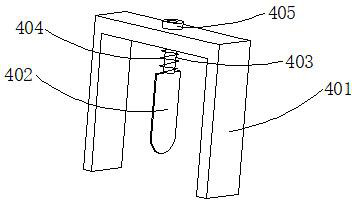

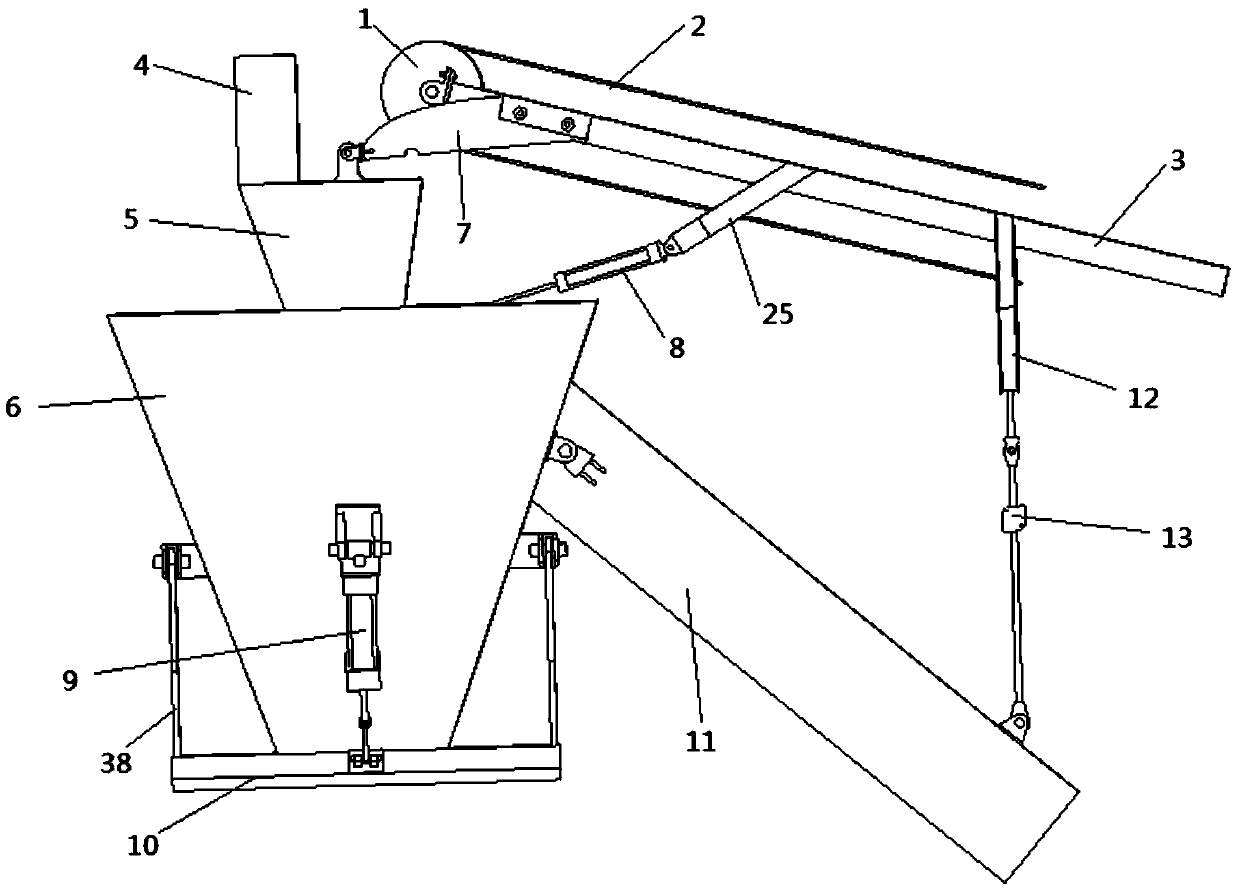

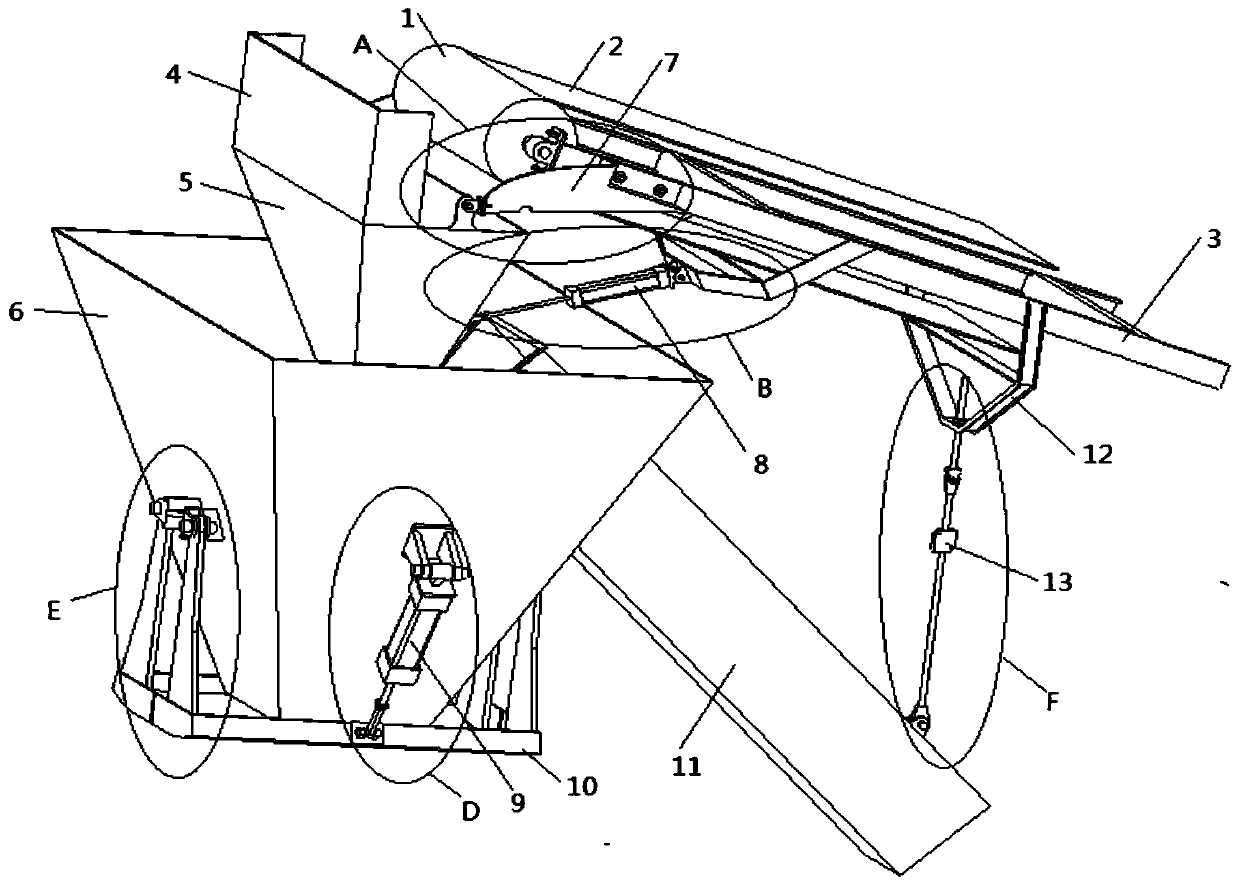

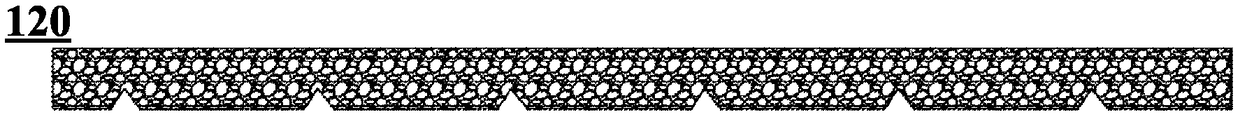

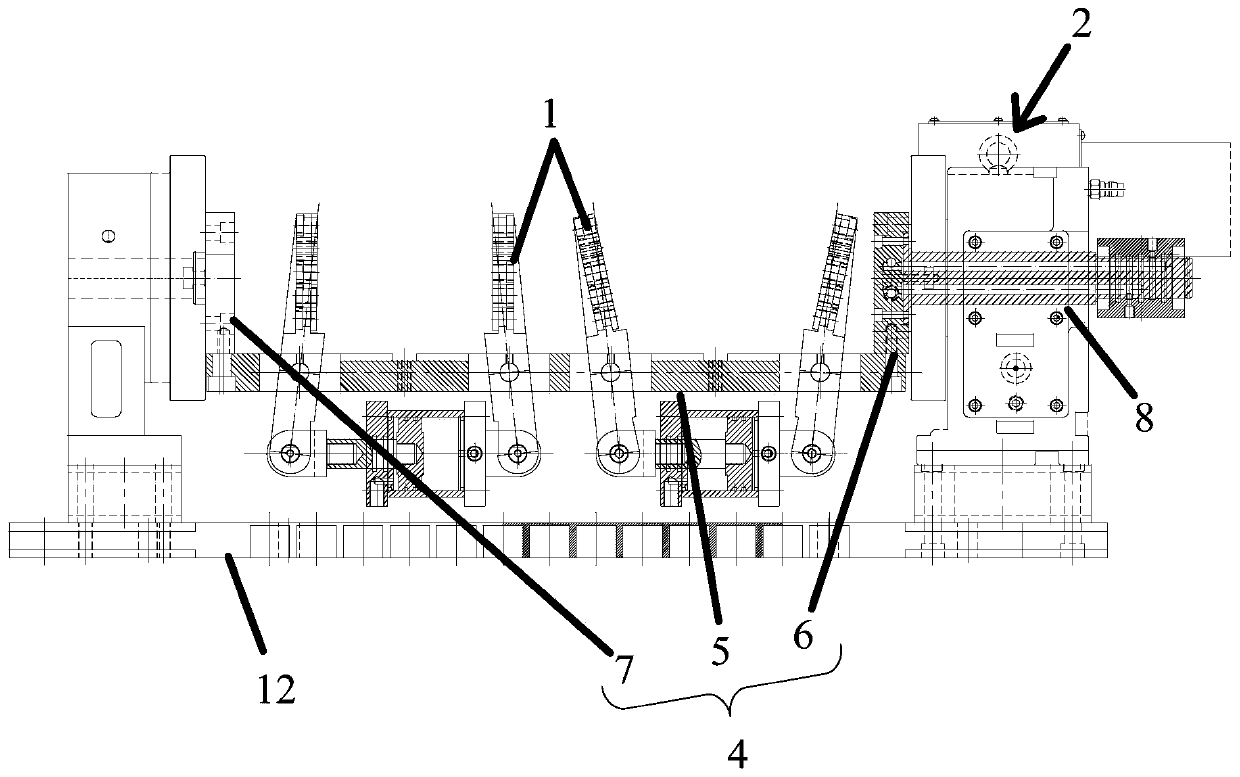

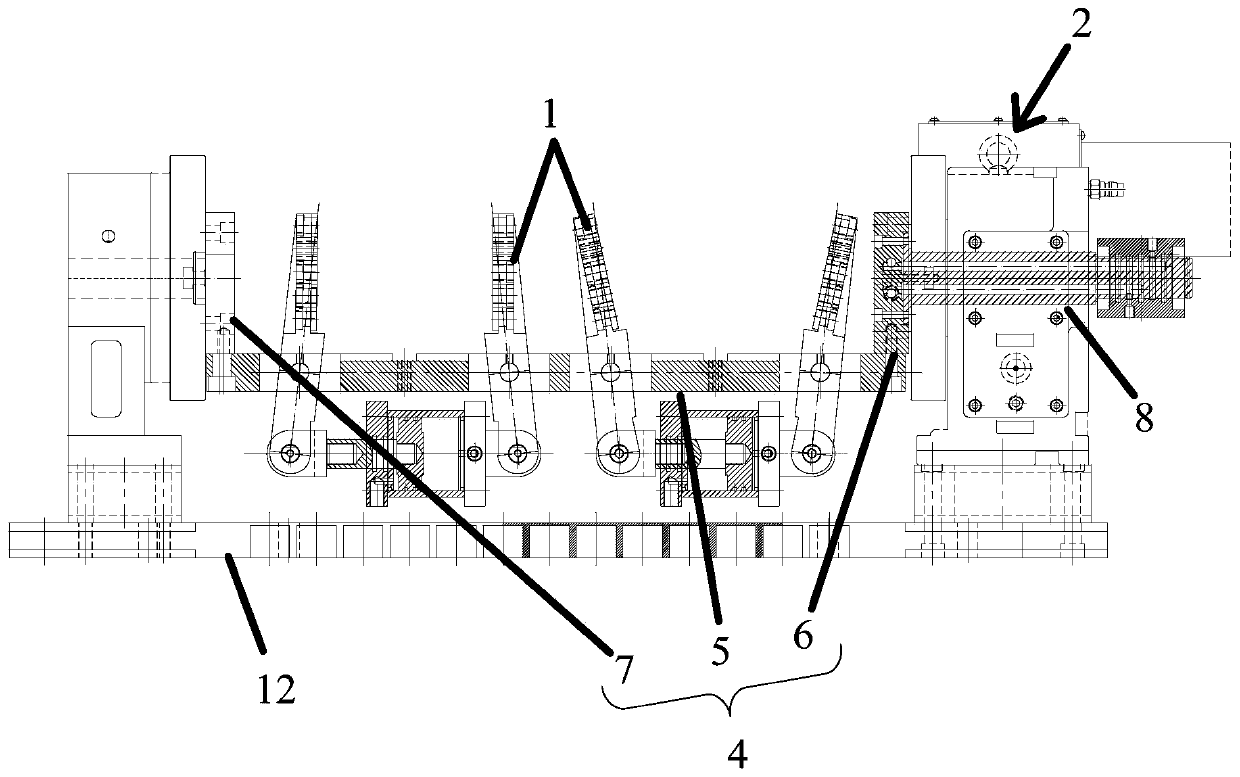

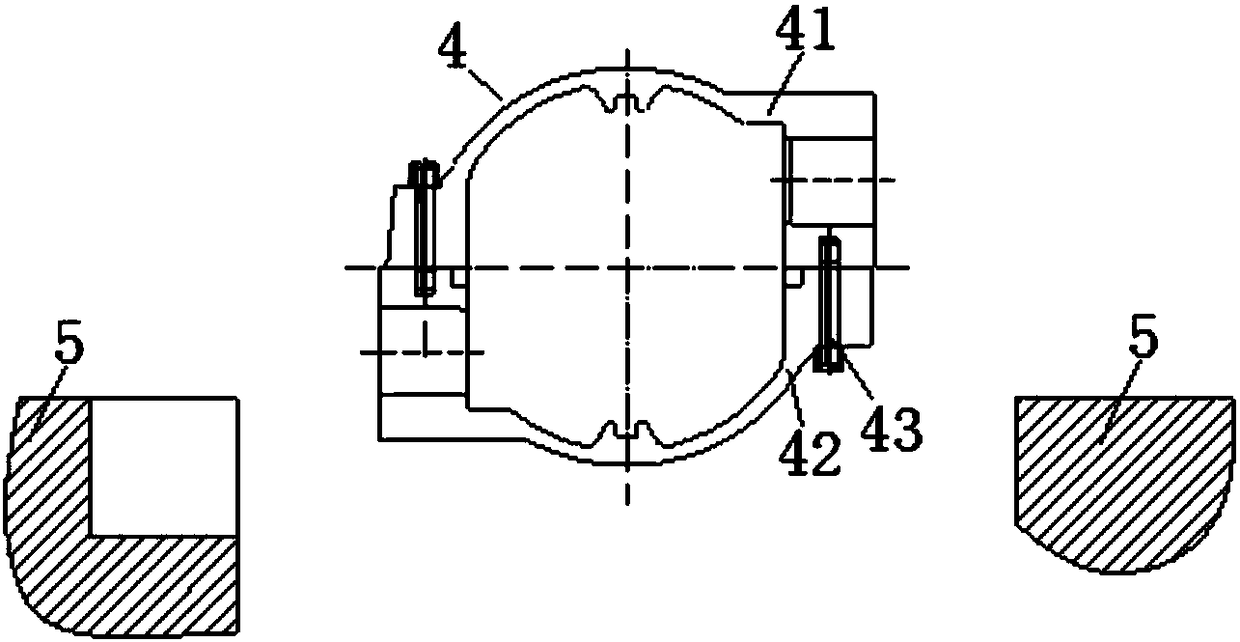

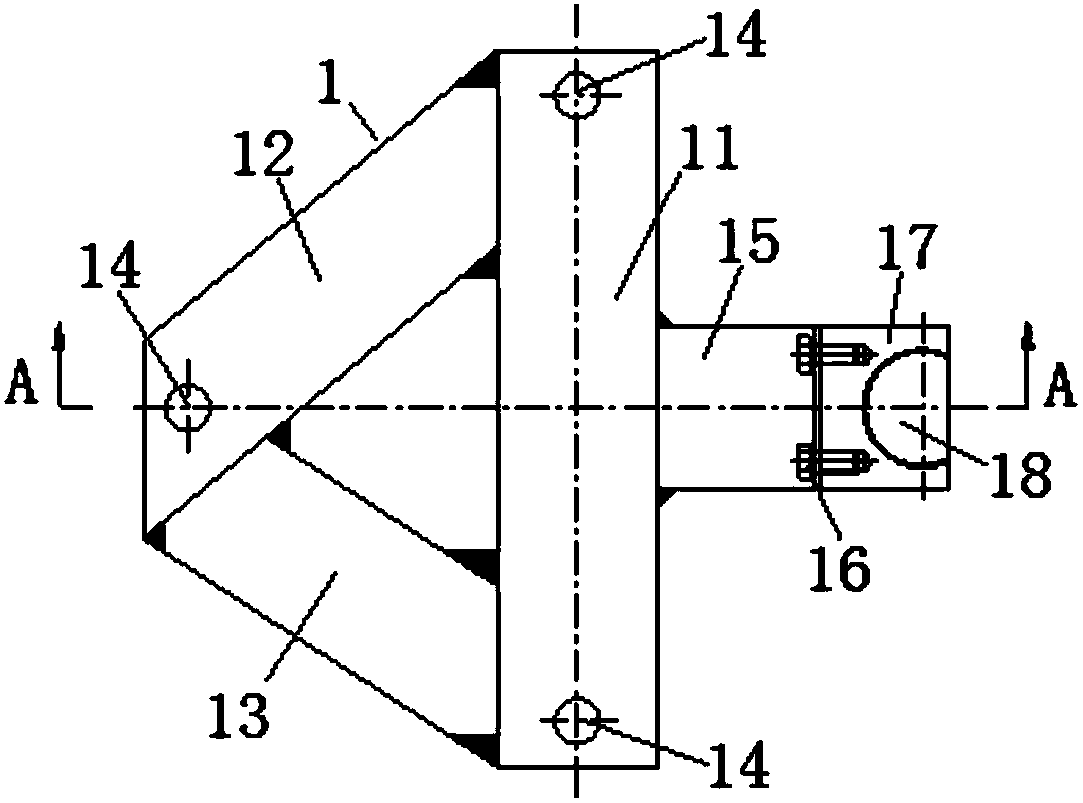

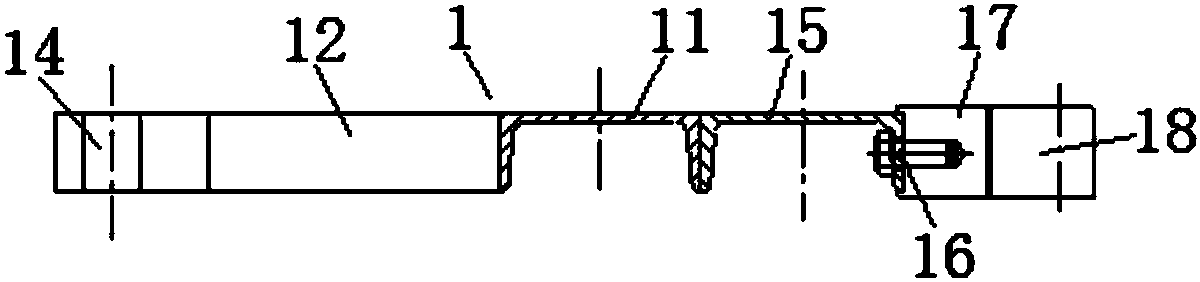

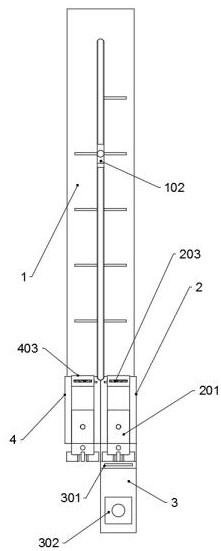

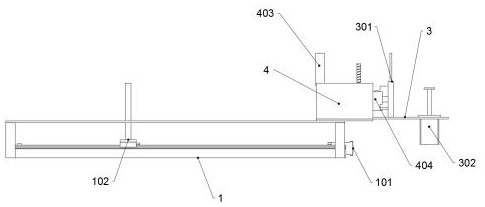

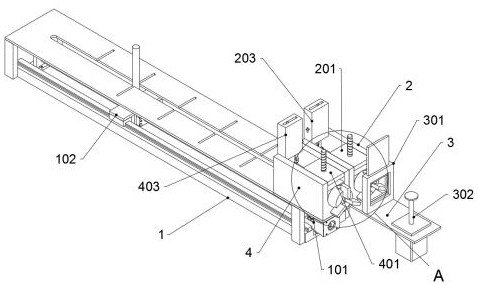

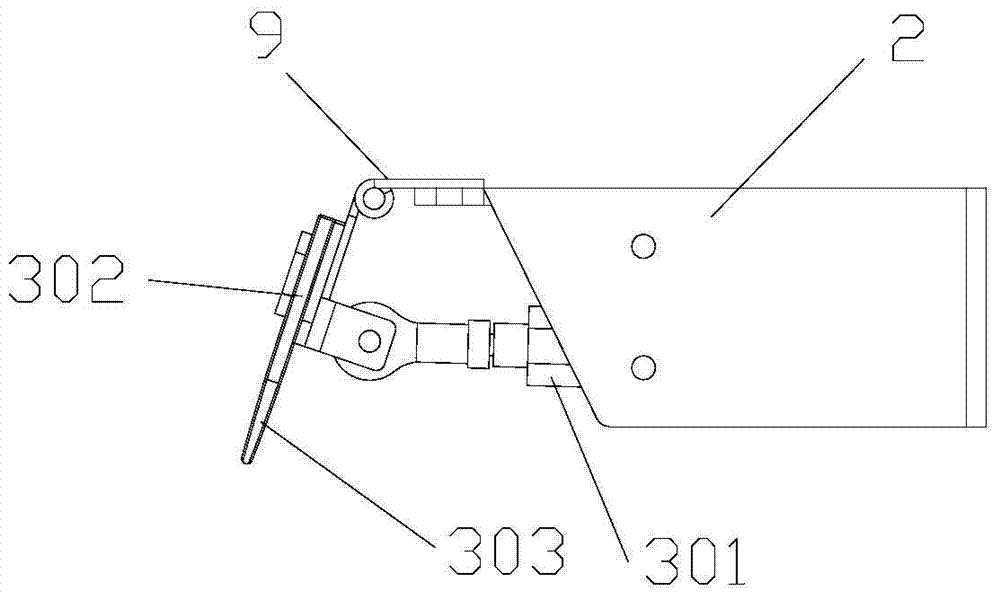

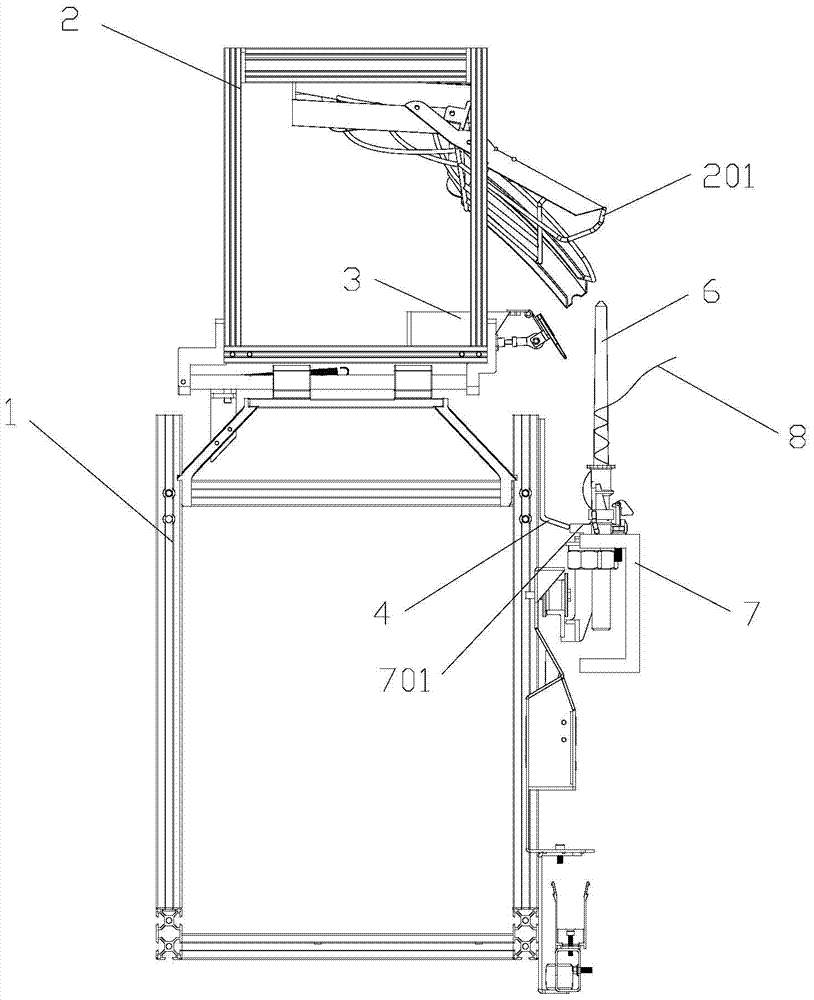

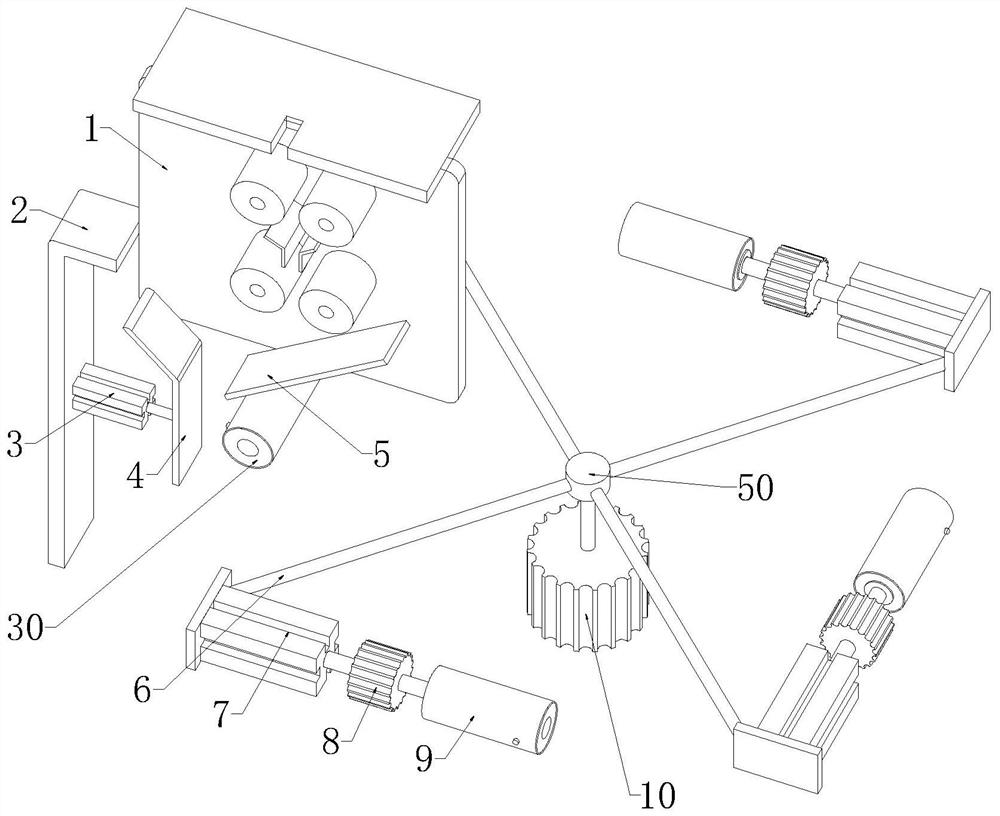

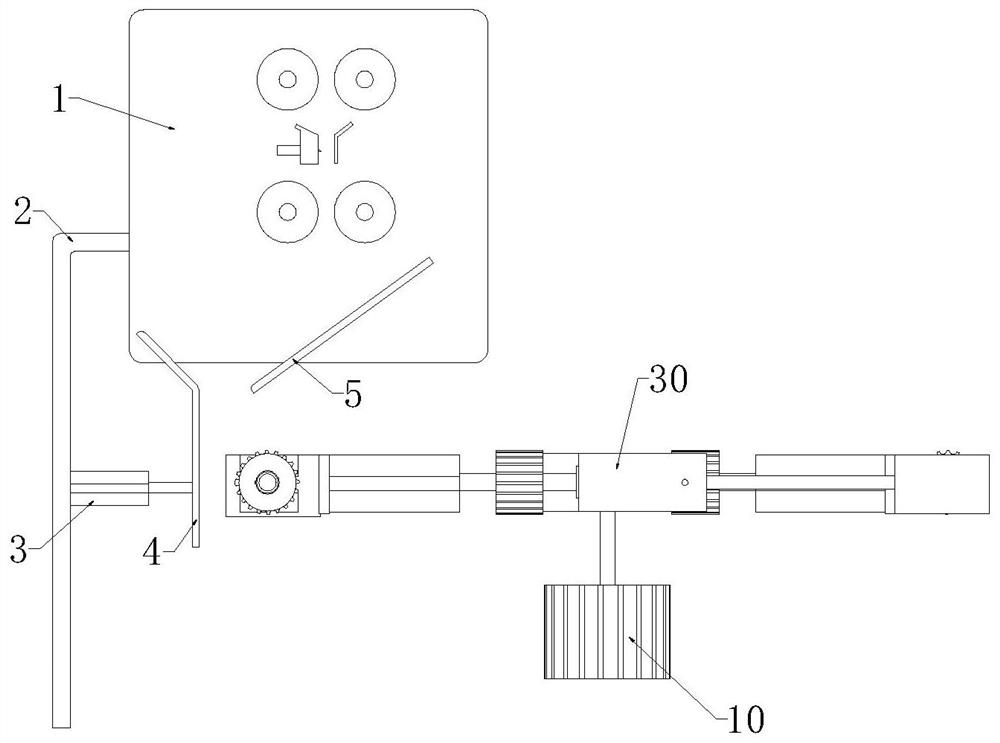

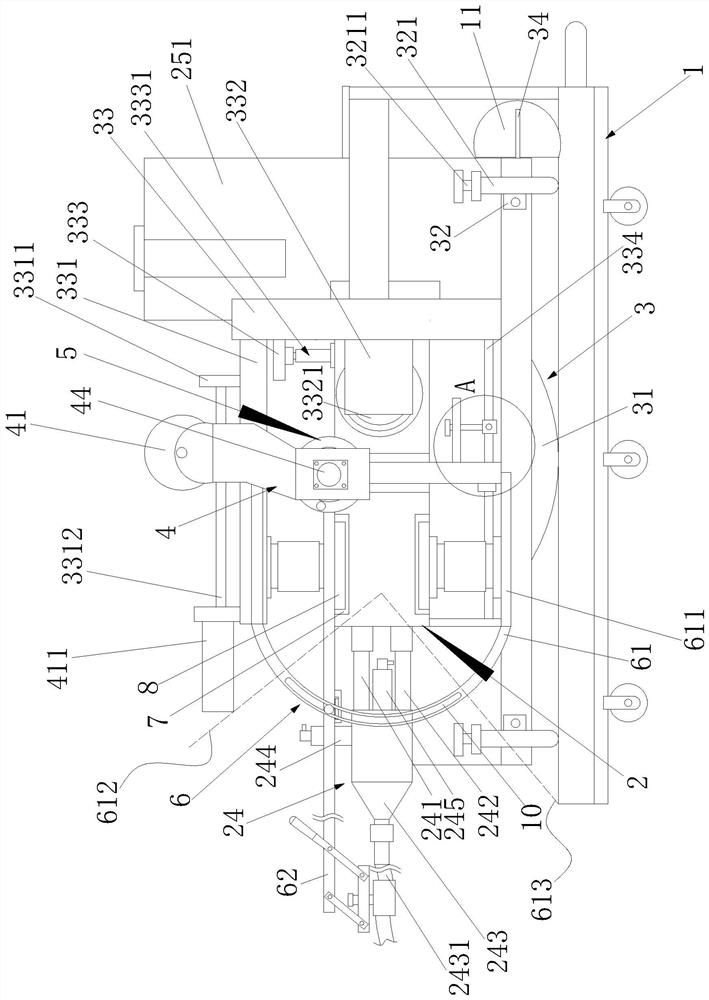

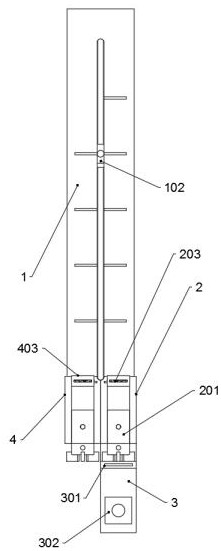

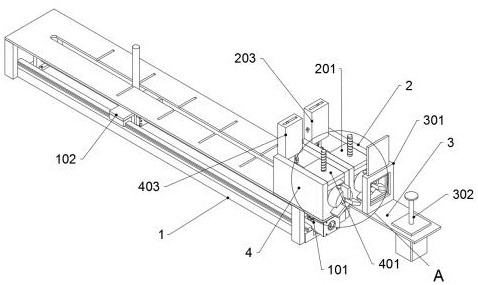

Chicken leg boning equipment

InactiveCN111887285ASimple structureEasy to operatePoultry deboningPoultry transferring/conveying devicesAnatomyEngineering

The invention discloses chicken leg boning equipment. The chicken leg boning equipment comprises a rack, a circulating conveying module, a dissection module, a breaking-off module, a gripping module and a plurality of traveling blocks, wherein the circulating conveying module, the dissection module, the breaking-off module and the gripping module are all mounted on the rack, the traveling blocks are sequentially mounted on the circulating conveying module and are driven by the circulating conveying module to do reciprocating circulating motion, and a cavity for placing a chicken leg is formedin each traveling block; and the breaking-off module comprises a guiding driving unit, a left telescoping unit and a right telescoping unit, the left telescoping unit and the right telescoping unit are separately inserted into the corresponding chicken leg from the two sides of an incision during outstretching, the guiding driving unit is used for drawing the two telescoping units after the left telescoping unit and the right telescoping unit outstretch, and thus, the two telescoping units can swing towards mutual-outlying directions so as to break off the corresponding chicken leg from the incision and expose chicken leg bones. The chicken leg boning equipment is simple in structure and good in boning effect.

Owner:从海彬

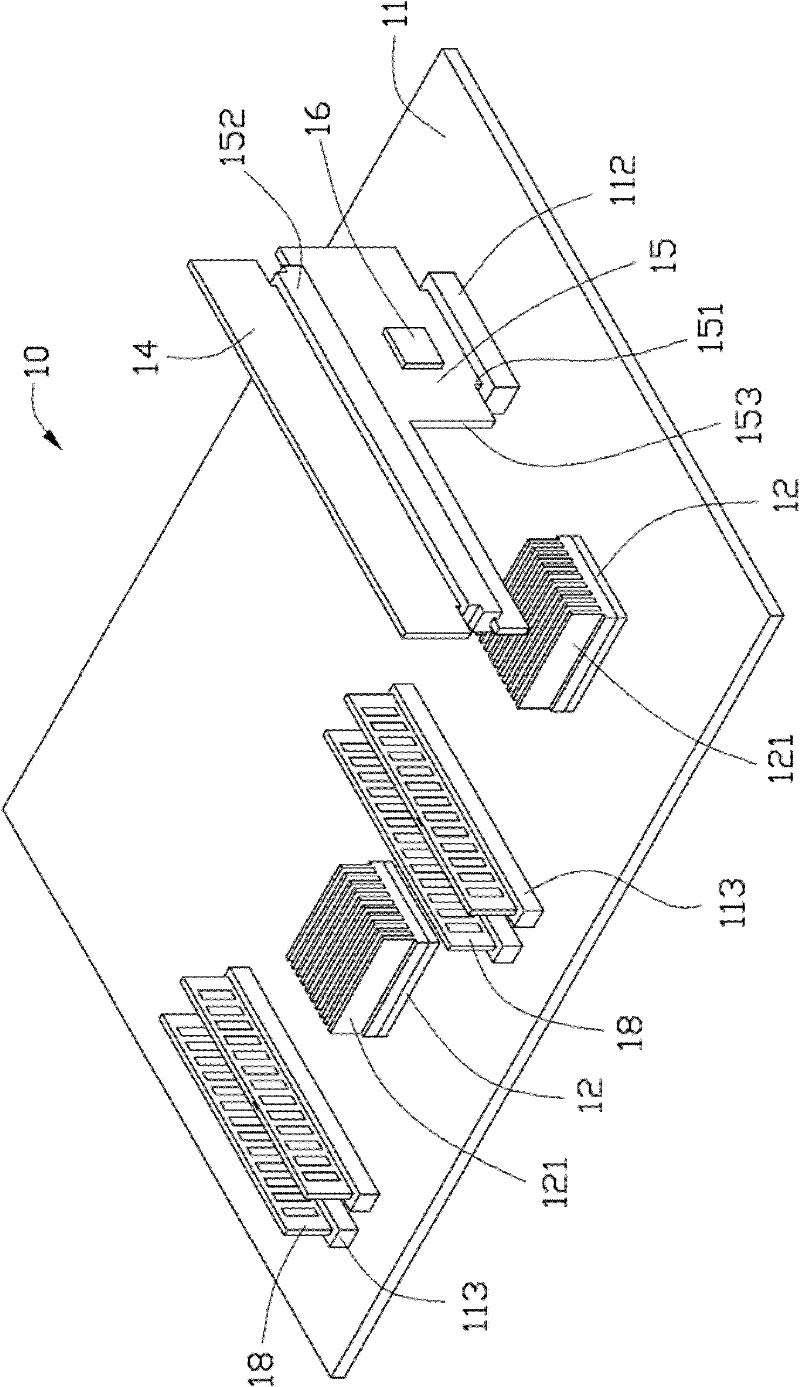

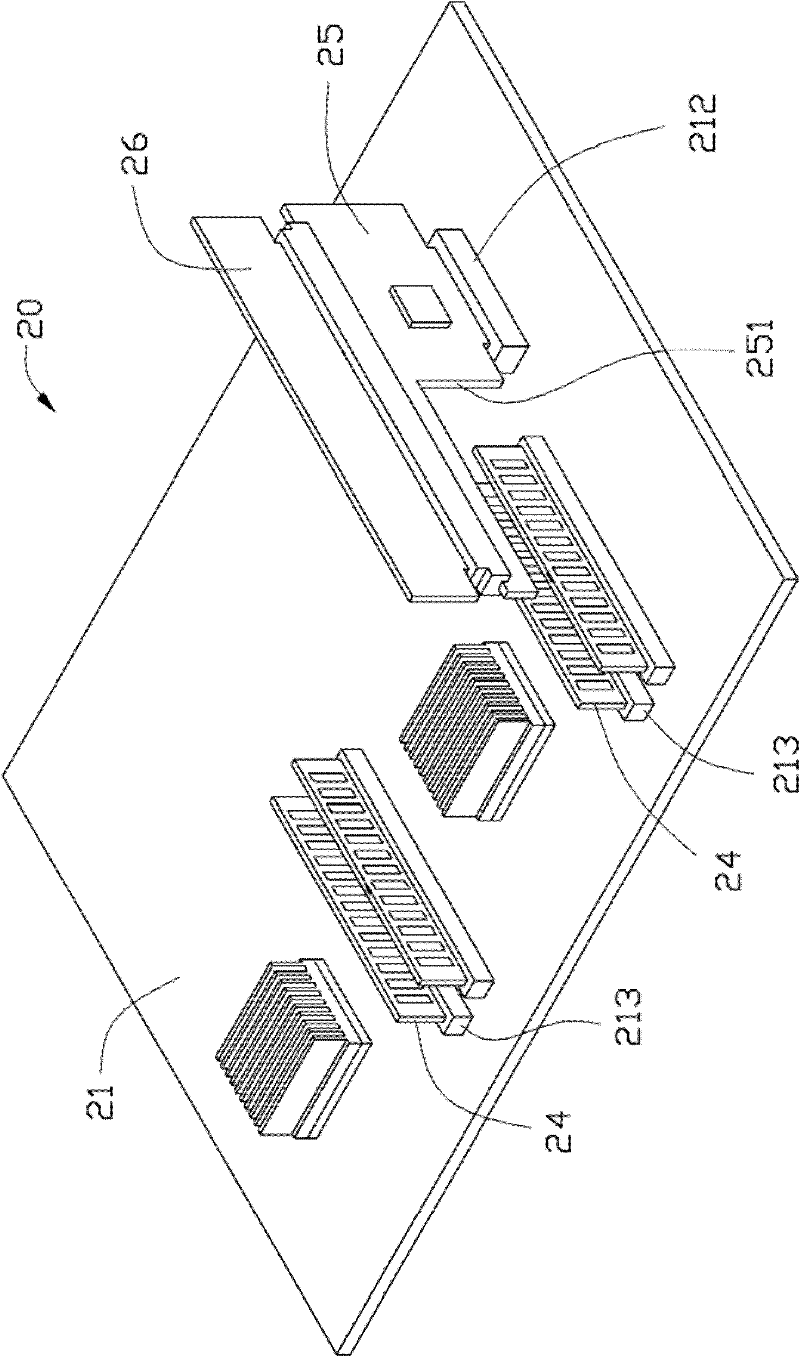

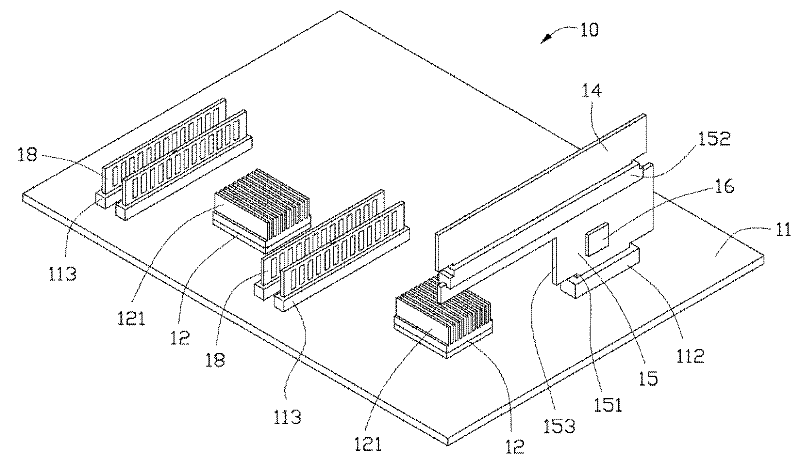

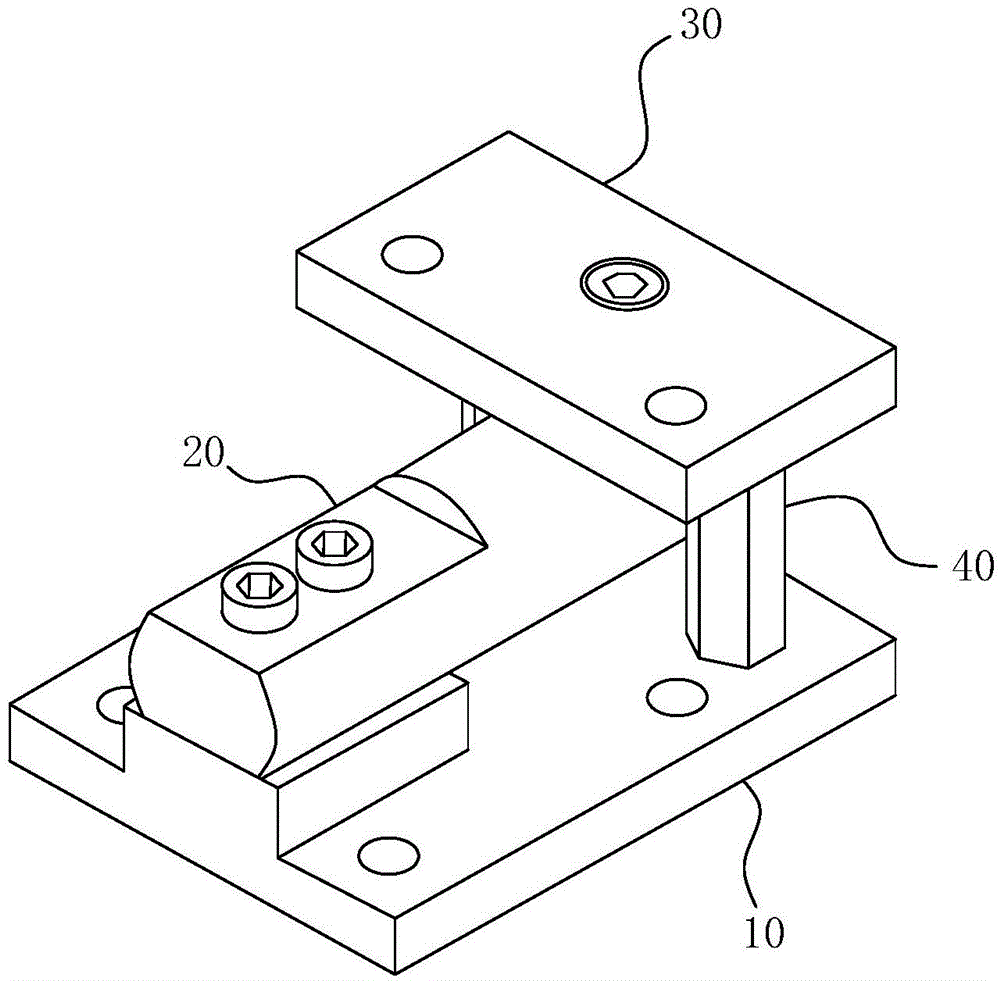

Mainboard expanding device

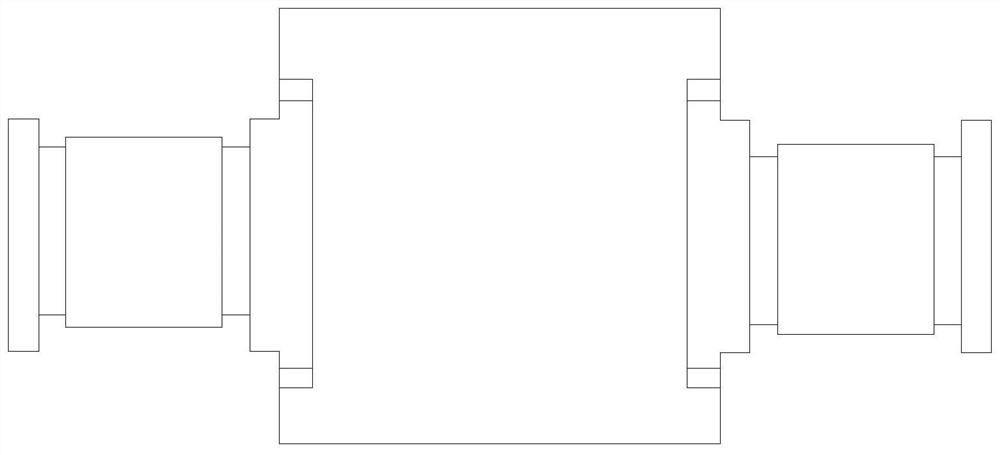

InactiveCN102193582AAvoid positional interferenceCoupling device connectionsDigital processing power distributionExpansion cardEngineering

The invention discloses a mainboard expanding device. The mainboard expanding device comprises a mainboard, an expansion slot, a mainboard element, an expansion card, an adapter card and a conversion chip, wherein the expansion slot is reserved in the mainboard and meets a first standard; the mainboard element is connected on the mainboard; the expansion card meets a second standard; the adapter card is connected between the expansion slot and the expansion cared; and the conversion chip is used for mutually converting signals meeting the first standard and the signals meeting the second standard. The expansion card is supported by the adapter card and is vertically arranged above the mainboard; an avoidance part is reserved between the adapter card and the mainboard; and the avoidance part can at least partially accommodate the mainboard element. The mainboard expanding device can avoid the position interference between the expansion card and the mainboard element; and the expansion card with large volume can be adopted.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

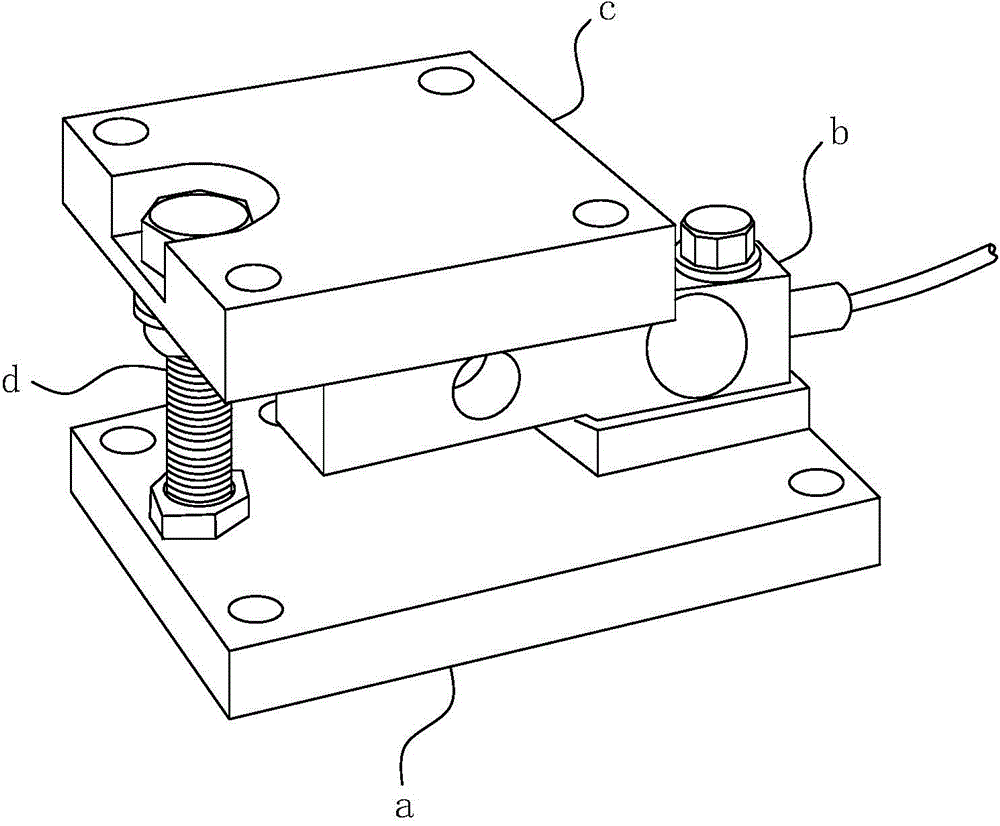

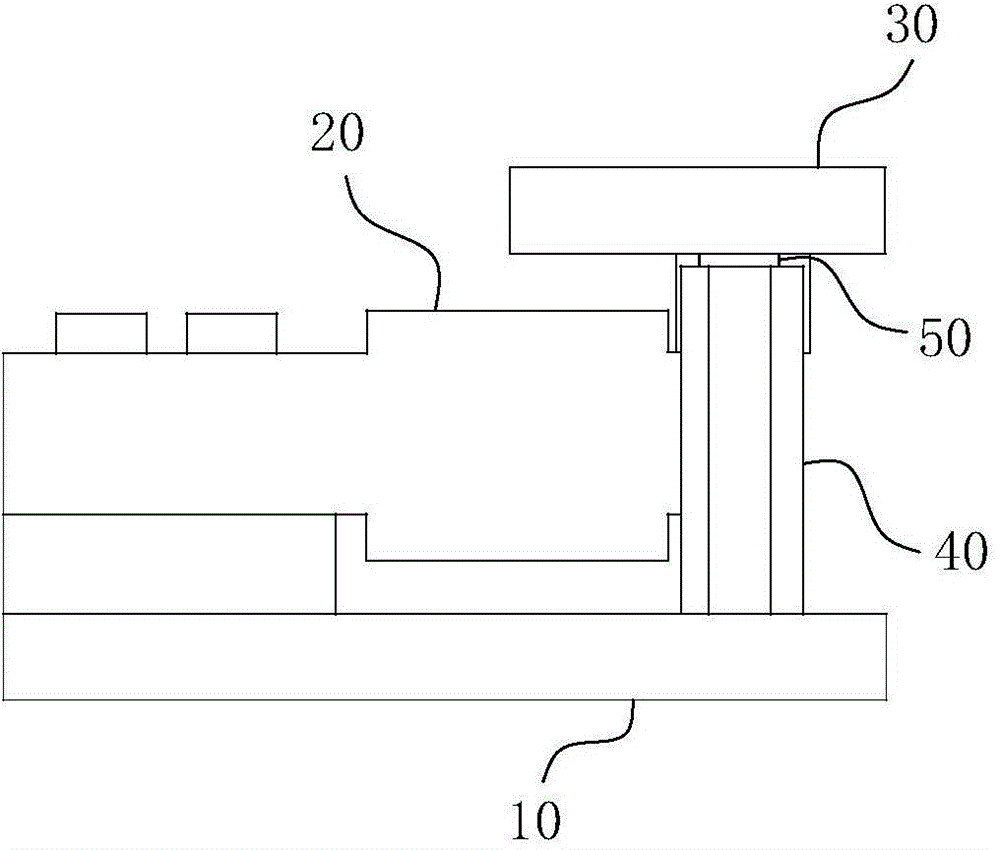

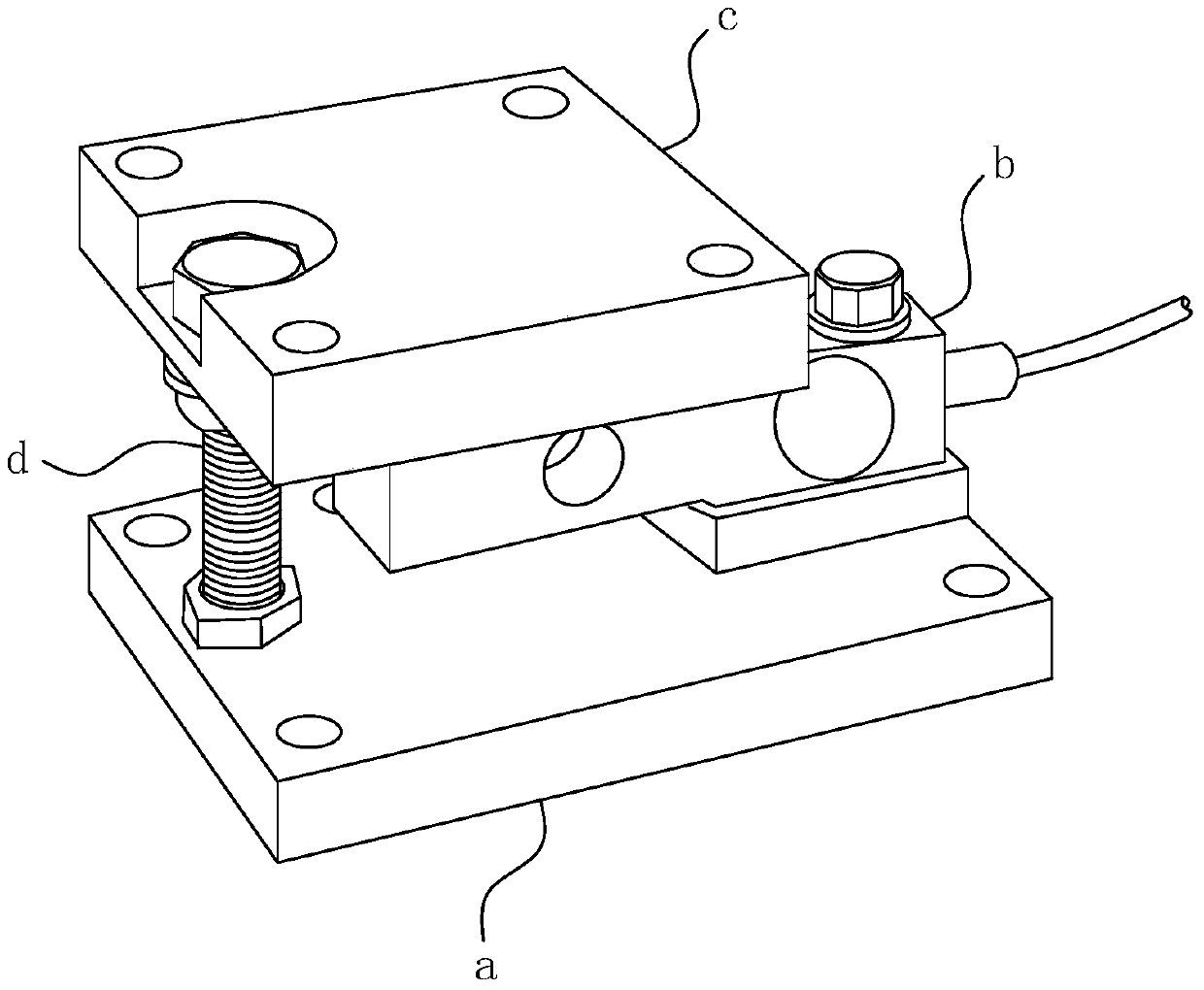

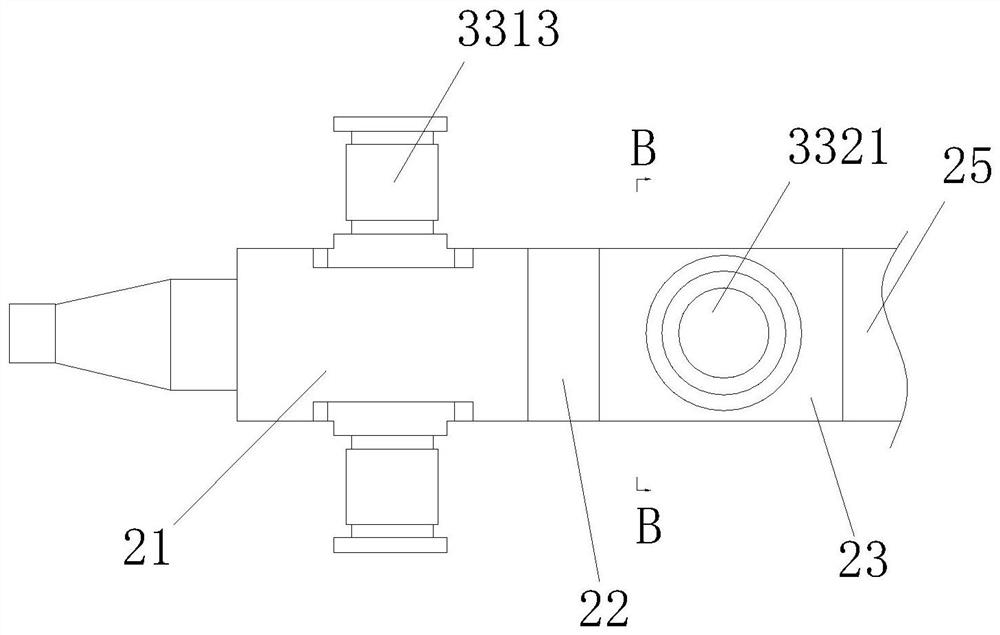

Sensor weighing module

ActiveCN104931121AAvoid horizontal movementAvoid over-settling problemsSpecial purpose weighing apparatusFault toleranceEngineering

The invention belongs to the weighing and packing technical field and relates to a sensor weighing module for an automated production line. The sensor weighing module of the invention comprises a base, a beam type sensor and a bearing plate; the module also comprises supporting columns for supporting the bearing plate, wherein at least two supporting columns which are symmetrically distributed at two ends of the bearing plate along the central line of the bearing plate exist; one of opposite surfaces of each supporting column and the bearing plate is provided with a spherical matching part, and the other surface of the opposite surfaces is provided with a hemisphere-shaped spherical groove which is shaped to match a position which is matched with the hemisphere-shaped spherical groove; and along a vertical direction, a distance left between the spherical groove and the spherical matching part is equal to the set pressed sinking height of the bearing plate. The sensor weighing module of the invention can satisfy weighing accuracy requirements. The sensor weighing module has the advantages of work flexibility, high fault tolerance rate, low installation precision requirement, reliable operation and further prolonged service life.

Owner:HEFEI GENERAL MACHINERY RES INST

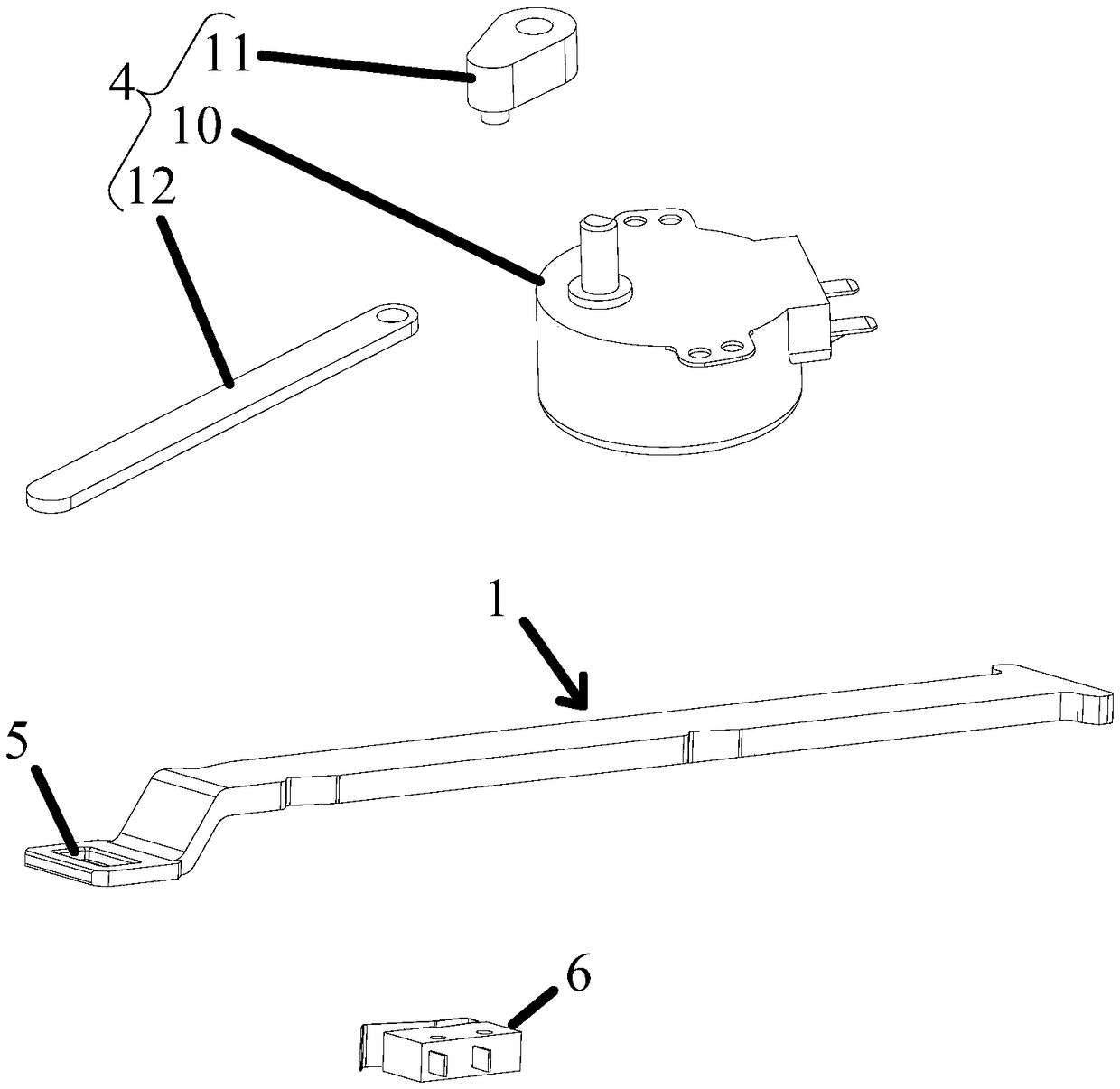

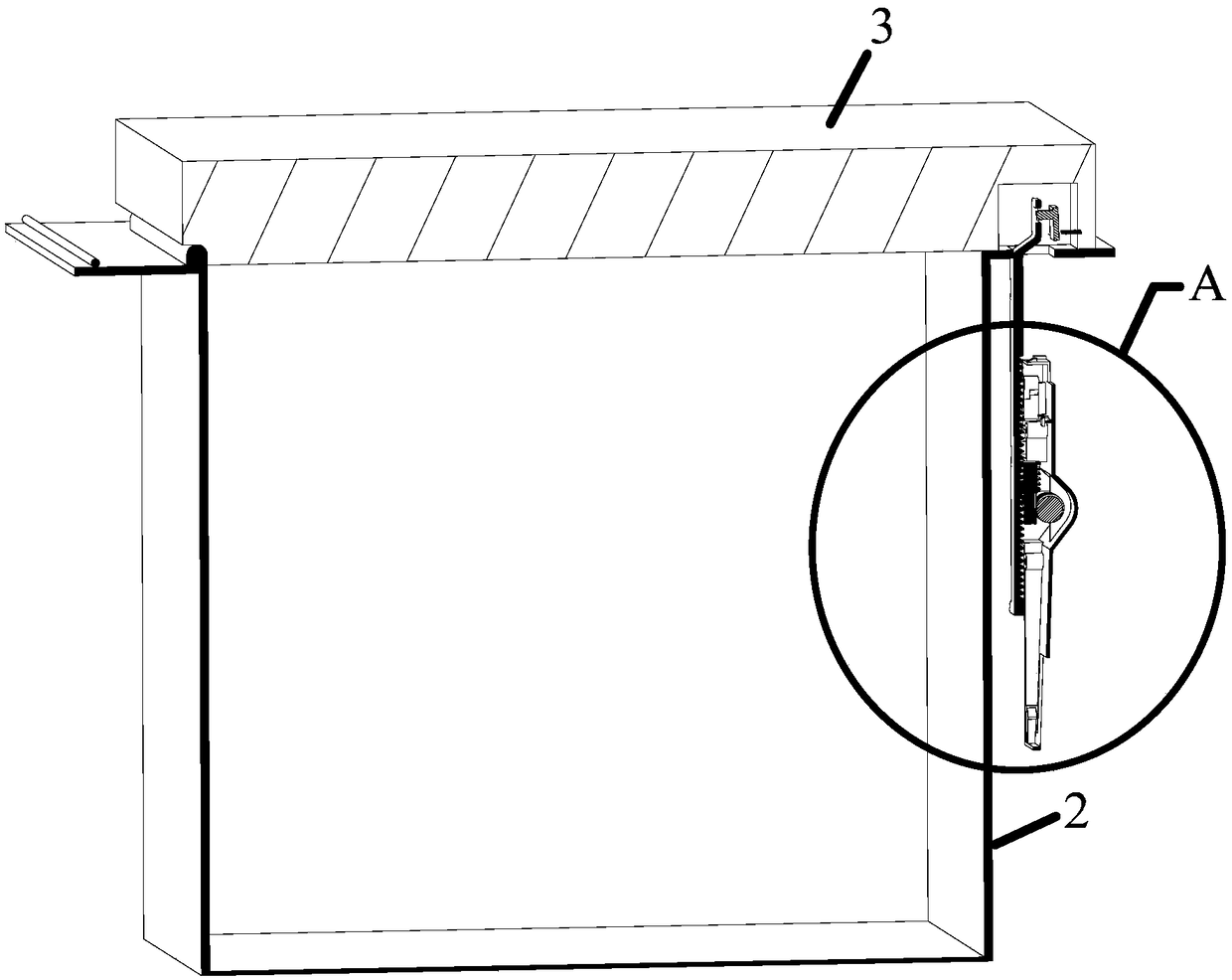

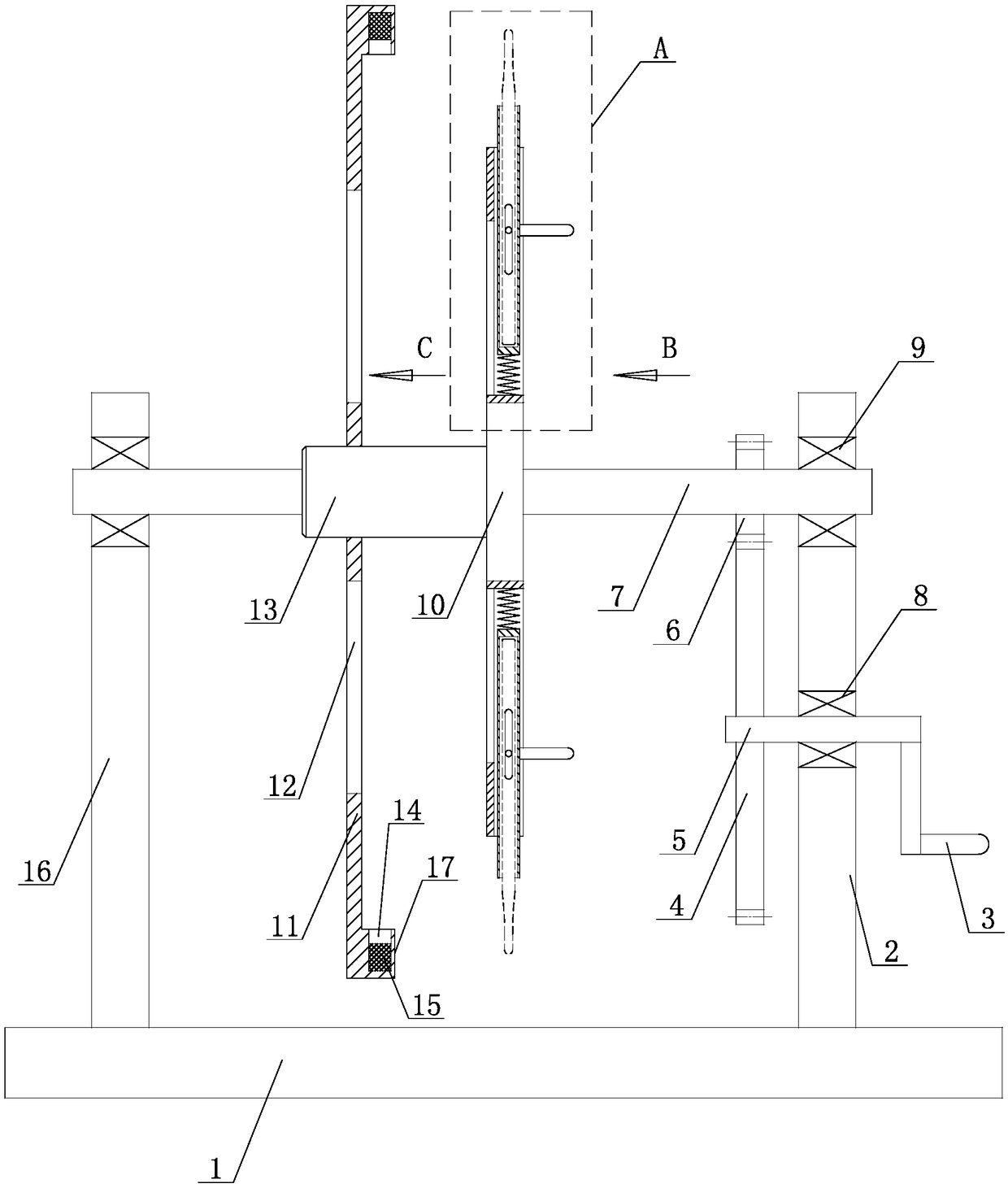

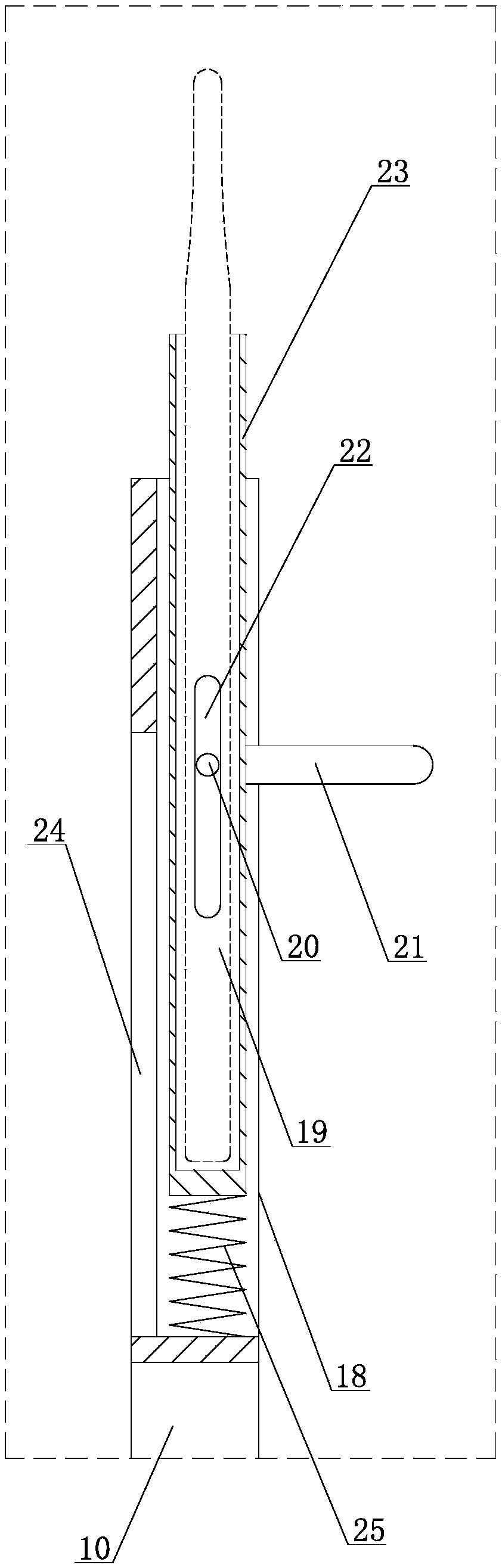

Automatic door opening device and dish washing machine provided with same

PendingCN109209131AEasy to drive and storeSimple structureTableware washing/rinsing machine detailsPower-operated mechanismMechanical engineeringEngineering

The invention discloses an automatic door opening device and a dish washing machine provided with the same. The automatic door opening device comprises a pushing rod, a crank connecting rod drive assembly and a first induction element, wherein the pushing rod is arranged on a machine body provided with a machine door, the end, facing the machine door, of the pushing rod is connected with the machine door through a connecting structure, the pushing rod is provided with a stretching-out position for driving the machine door to be opened to a certain degree, and a resetting position for the machine door to retract into the machine body, the crank connecting drive assembly drives the pushing rod to be switched between the stretching-out position and the resetting position, the first inductionelement detects the connecting state of the machine door and the pushing rod, when the connecting structures separates the pushing rod from the machine door, the first induction element sends a detection signal to the crank connecting rod drive assembly to control the crank connecting rod drive assembly to drive the pushing to retract to the resetting position, and by means of the structure, the problems that domestic appliance equipment like the dish washing machine in the prior art needs to be opened through a handle on the machine door of the equipment, the science and technology sense is low, and use experience of users is poor are solved.

Owner:GREE ELECTRIC APPLIANCES INC

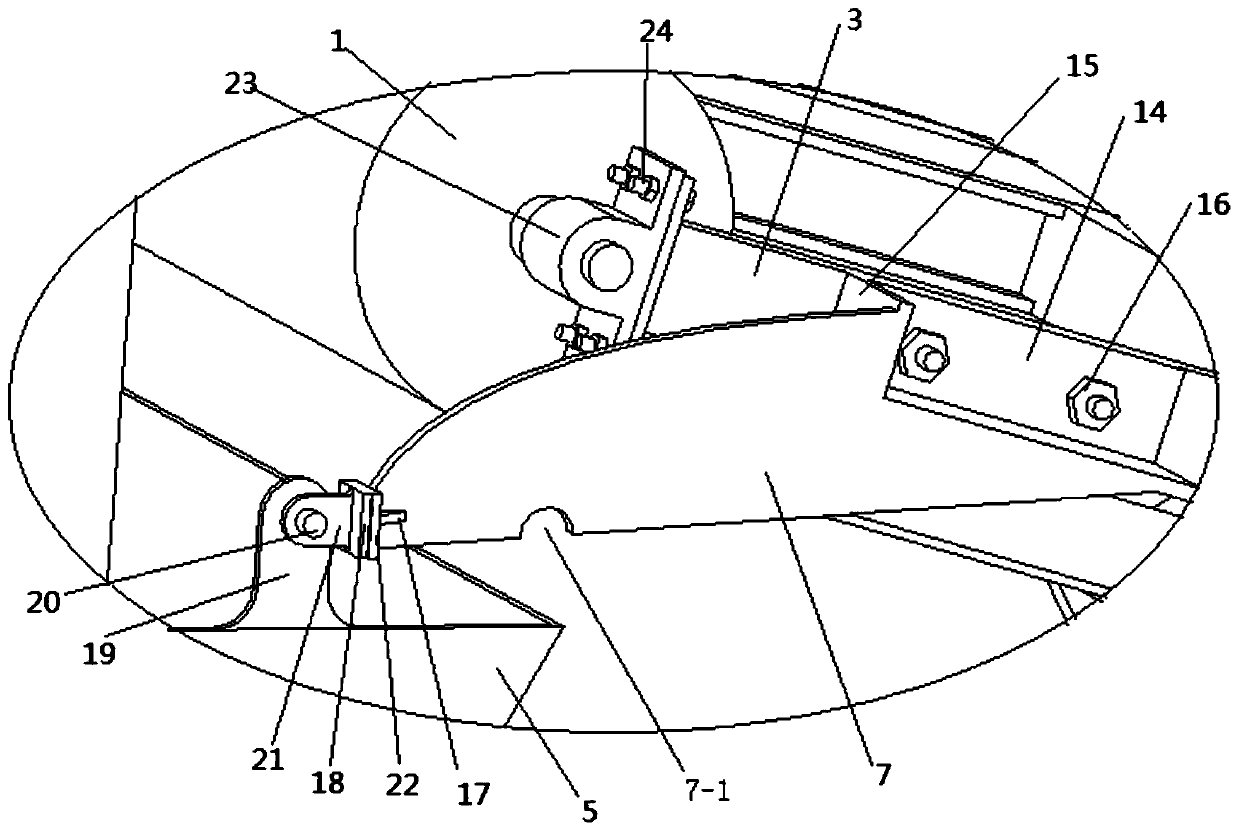

Continuous type mixing station stock bin with online sampling device and sampling method

PendingCN110834967AAvoid unevennessRealize quantitative samplingConveyorsWithdrawing sample devicesGas cylinderControl theory

The invention discloses a continuous type mixing station stock bin with an online sampling device and a sampling method. The continuous type mixing station stock bin comprises a conveyor belt rack, ahanging beam, a guide hopper, a guide tube and a finished product bin, wherein the conveyor belt rack is placed in an inclined mode; the hanging beam is in bolt connection to the conveyor belt rack; the guide hopper is hinged with the hanging beam; a blocking plate is welded on the guide hopper; the lower part of the guide hopper is equipped with the finished product bin; one side of the finishedproduct bin is hinged with the guide tube; and the discharge end of the guide tube is connected to the conveyor belt rack through a weighing scale. The sampling method comprises the following steps: I, clearing zero for a weighing sensor; II, inputting a sampling weight value, namely a preset value; III, automatically sampling by pressing down an enter key, and controlling a pulling hopper gas cylinder to push back the guide hopper while accumulated flow achieves the preset value, thereby accomplishing sampling. The continuous type mixing station stock bin is simple in structure, is convenientand quick in sampling, and can realize online automatic sampling.

Owner:CHANGAN UNIV

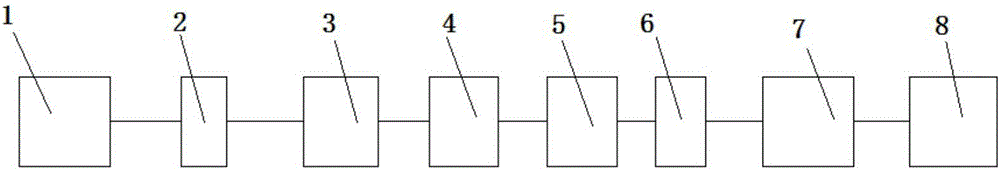

Automated folding-type corner protecting ring producing line

PendingCN107433456AGuaranteed movement speedAvoid uniformityOther manufacturing equipments/toolsProduction linePunching

The invention discloses an automated folding-type corner protecting ring producing line. The automated folding-type corner protecting ring producing line comprises a belt placing machine, a joint point welding machine, a folding rolling mill, a punching machine, a right angle rolling mill, a servo point welding machine, a servo shearing machine and a forming machine which are arranged in sequence and further comprises a controlling device. The controlling device comprises a PLC, a motor controller, an encoder, an induction contact head and a display. A motor is connected with the motor controller. The motor controller is connected with the PLC. The PLC controls whether the motor rotates or not through the motor controller according to received signals. The automated folding-type corner protecting ring producing line has the advantages that 1, uneven forming and angular deviation caused by the unstable speed of a steel belt during traditional single-machine operation are avoided; 2, the punching machine and the servo shearing machine are arranged on a servo base, it is ensured that shapes of punched holes and shearing sizes which are fit for the standard can be still formed during the steel belt moving; and 3, position interference between the first-formed end surface of a corner protecting ring and a bending wheel is avoided through a spiral placing table.

Owner:SHENYANG FENGHE PACKING

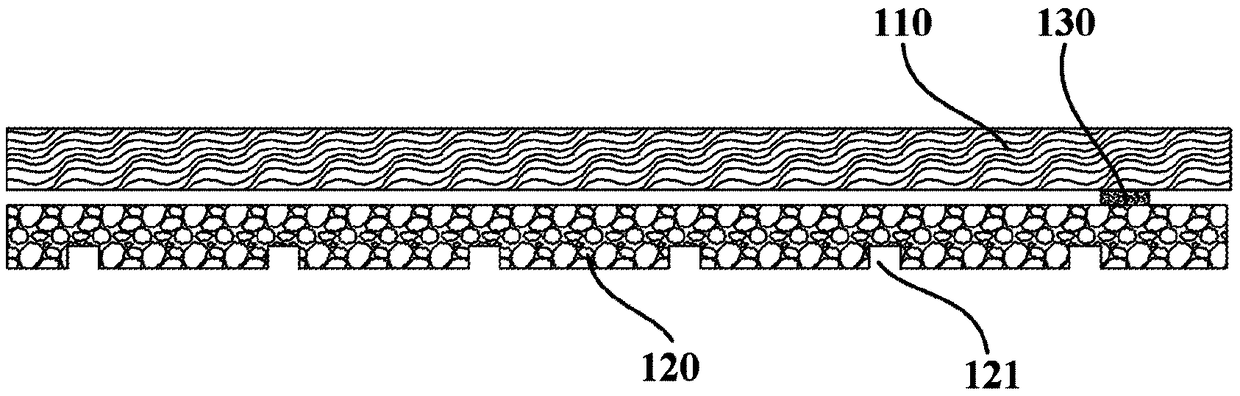

Vacuum insulated panel and refrigerator

InactiveCN108870851ALow thermal conductivityReduce contact areaLighting and heating apparatusInsulation for cooling apparatusGlass fiberOptoelectronics

The invention provides a vacuum insulated panel. The vacuum insulated panel comprises a core material and a clad material. The core material includes a glass fiber layer and a perforated foam layer, and the glass fiber layer and the perforated foam layer are arranged layer by layer in an overlaying mode, and groove structures are formed in the surface, deviating from the perforated foam layer, ofthe glass fiber layer. The clad material wraps the core material, vacuum is formed between the clad material and the core material, and containing parts for arranging external heat exchange pipelinesare arranged at the corresponding positions of the groove structures. The structure can avoid more glass fiber fragments in the glass fiber layer of the core material, prevent the clad material of thevacuum insulated panel from being destroyed, prevent the failure of the vacuum insulated panel, and reduce the thermal conductivity of the vacuum insulated panel.

Owner:HAIER SMART HOME CO LTD +1

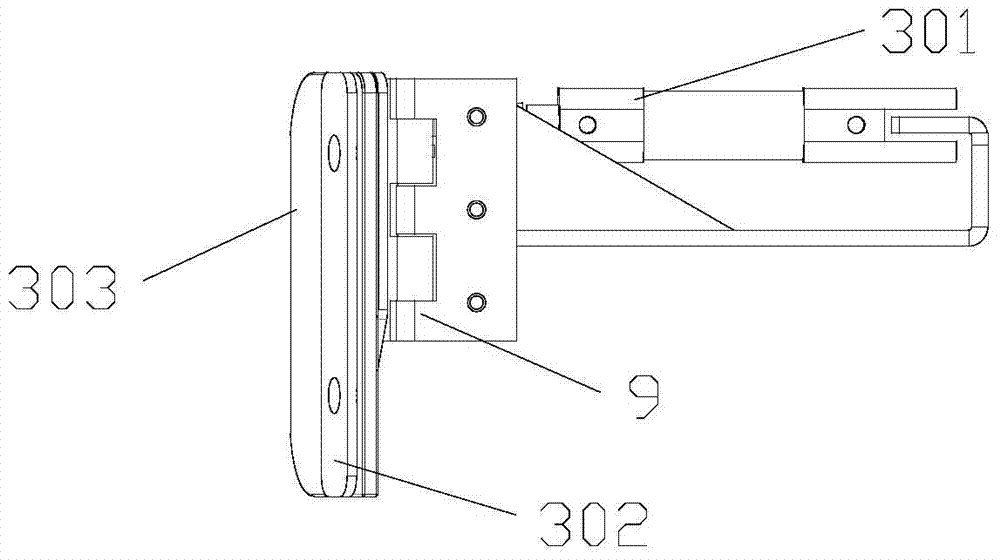

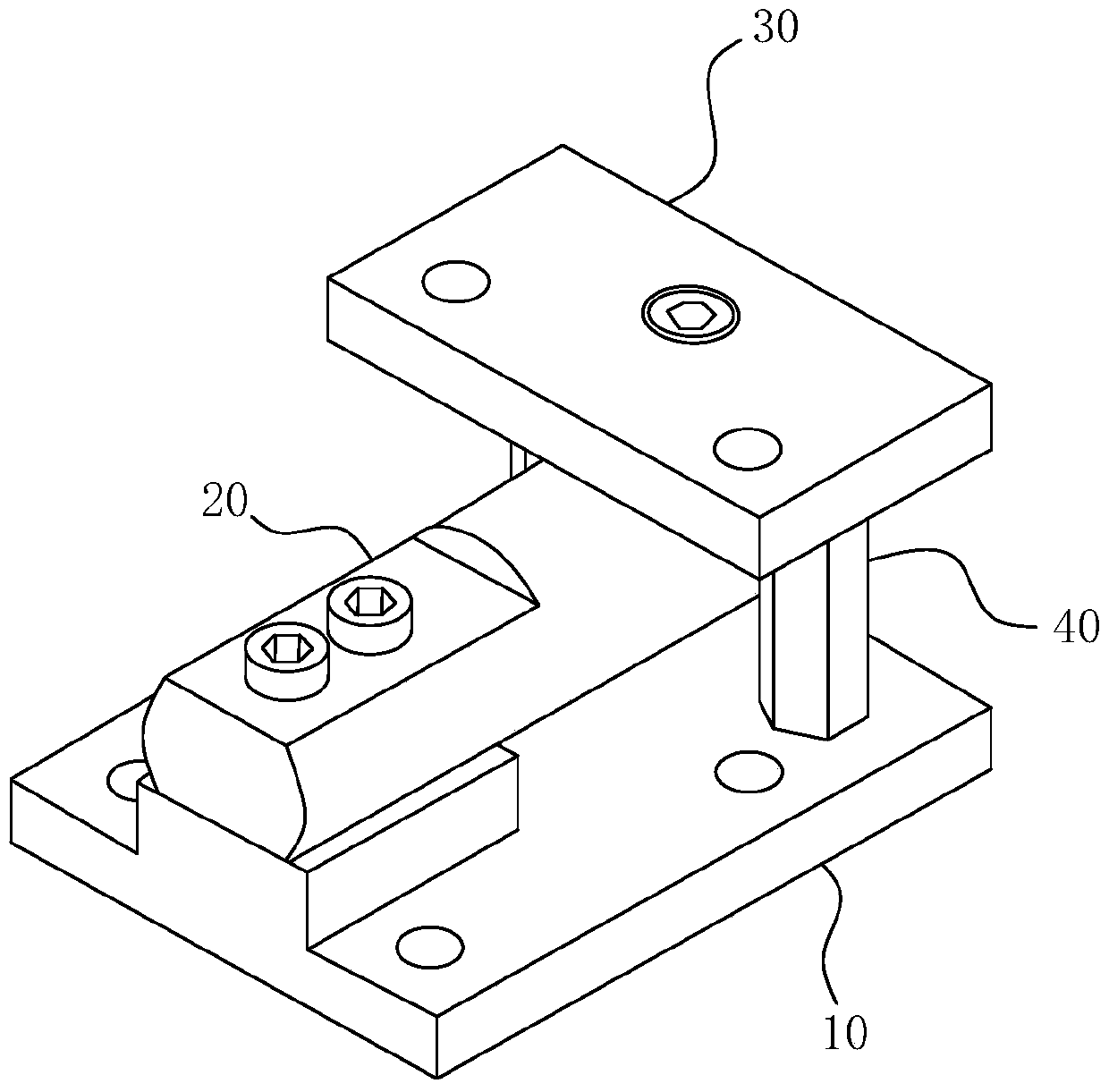

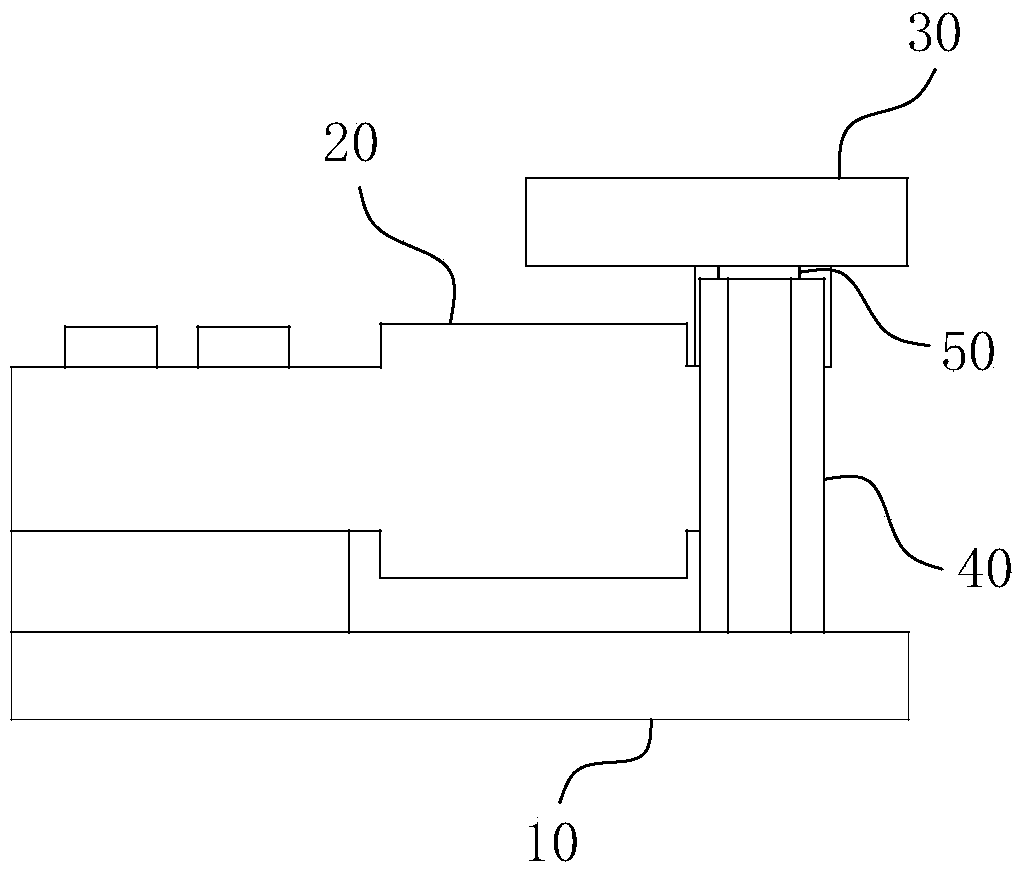

Linkage tool clamp

PendingCN109909772AAvoid the hassle of clampingAvoid the problem of clamping errorMetal working apparatusPositioning apparatusNumerical controlLocking mechanism

The invention discloses a linkage tool clamp. The linkage tool clamp includes a clamping mechanism used for fixing a workpiece, a linkage mechanism connected with the clamping mechanism and driving the clamping mechanism to rotate in the vertical direction, a locking mechanism for limiting and fixing the clamping mechanism and blocking rotation of the clamping mechanism in the vertical direction.The linkage mechanism drives the clamping mechanism to rotate in the vertical direction, thus the workpiece can be machined in a four-axial linkage mode through machine equipment such as a digital control machine tool, the trouble that in the prior art, a component is needed to be clamped repeatedly when the complex component is machined is avoided, meanwhile the problem that clamping errors are generated in the clamping process is avoided, and the production machining efficiency and the product quality of products are effectively improved.

Owner:黑龙江北鸥卫浴用品有限公司

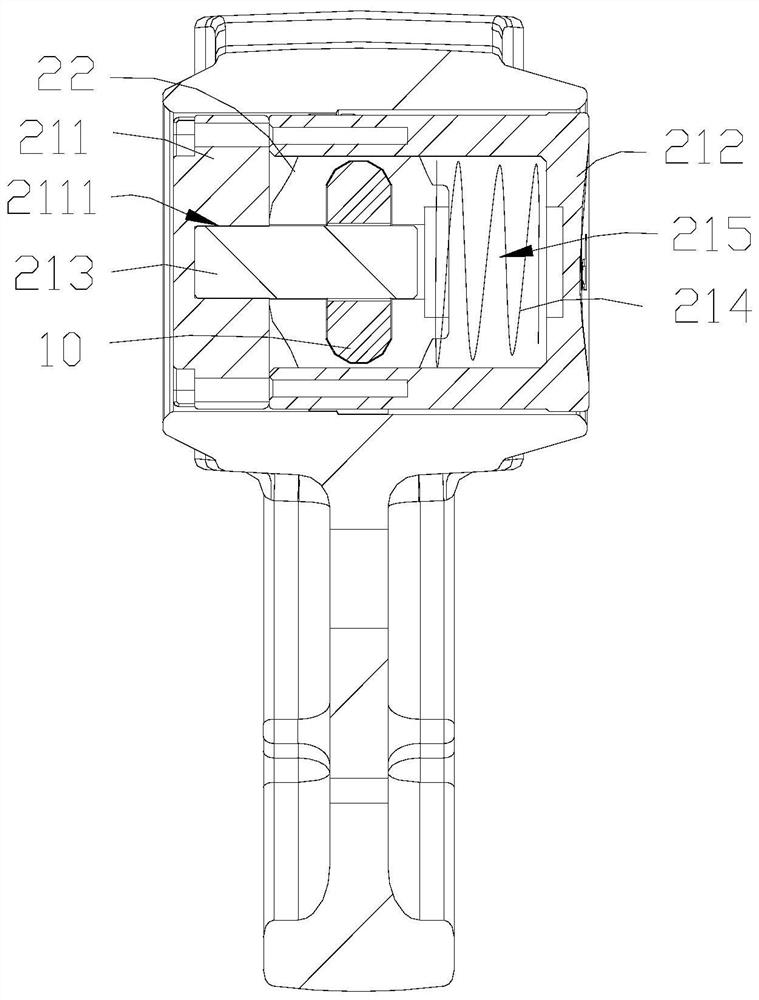

Heavy-type inverted studded thread bolt mounting tooling and use method of same

ActiveCN108217454AAvoid positional interferenceEnsure balanceSpannersWrenchesStructural engineeringMiddle line

A heavy-type inverted studded thread bolt mounting tooling and a use method of same. The tooling includes: a sling frame, which is provided with a main beam, a sub-beam at one side of the main beam, ajoint which is arranged on the middle of the other side of the main beam and is extended, and a clamping plate arranged on the outer end of the joint. Sling holes, which are arranged in an isoscelestriangle shape, are formed in two ends of the main beam and the sub-beam. The top ends of the sling holes arranged in the isosceles triangle shape are located on the outer end of the sub-beam and arelocated at the extension line of the central line of the joint. A clamping thread hole, which is matched with the structure of a to-be-mounted inverted studded thread bolt, is formed on the outer endof the clamping plate. When the sling frame is under an idle or loaded status, the gravity of one side of the is larger than that of one side of the joint with the sling frame as the central line, sothat the sling gravity is located between the sling holes, which are arranged in an isosceles triangle shape, between the main beam and the sub-beam. The structure effectively overcomes position interference of a sling hoisting rope and corresponding equipment parts, and ensures that the inverted studded thread bolt can be maintained to be balanced, stable and safe during the slinging and moving processes.

Owner:DONGFANG TURBINE CO LTD

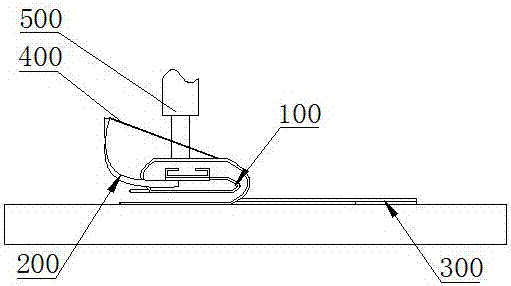

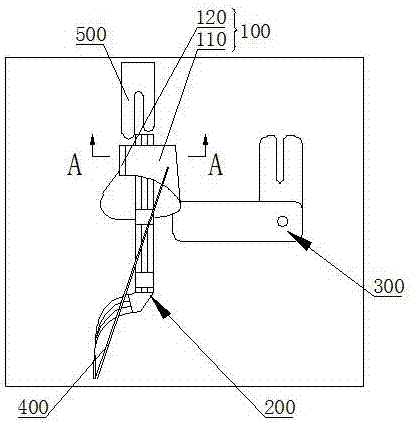

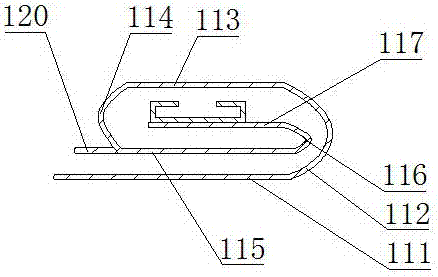

Device for adding adhesive interlining strips to costume edges

The invention provides a device for adding adhesive interlining strips to costume edges, and relates to the technical field of sewing machines. The device is arranged on the table top of a sewing machine, is located at the front end of a presser foot, and comprises a cloth drum for winding cloth, an interlining feeding strip and a fixed frame, wherein the interlining feeding strip penetrates through the cloth drum and is used for feeding the adhesive interlining strips, and the fixed frame is connected with the outer side of the cloth drum. The device is simple in structure and low in cost, and an operator can wind and form the cloth through the device at a time; meanwhile, the adhesive interlining strips are synchronously fed, and the flatness of the cloth and the consistency of the width of the costume edges are guaranteed; due to synchronous feeding and one-time sewing forming of the cloth and the adhesive interlining strips, the operation difficulty is greatly lowered, processing efficiency is improved, and the good using effect and extensive popularization value are achieved.

Owner:JIHUA 3534 CLOTHING

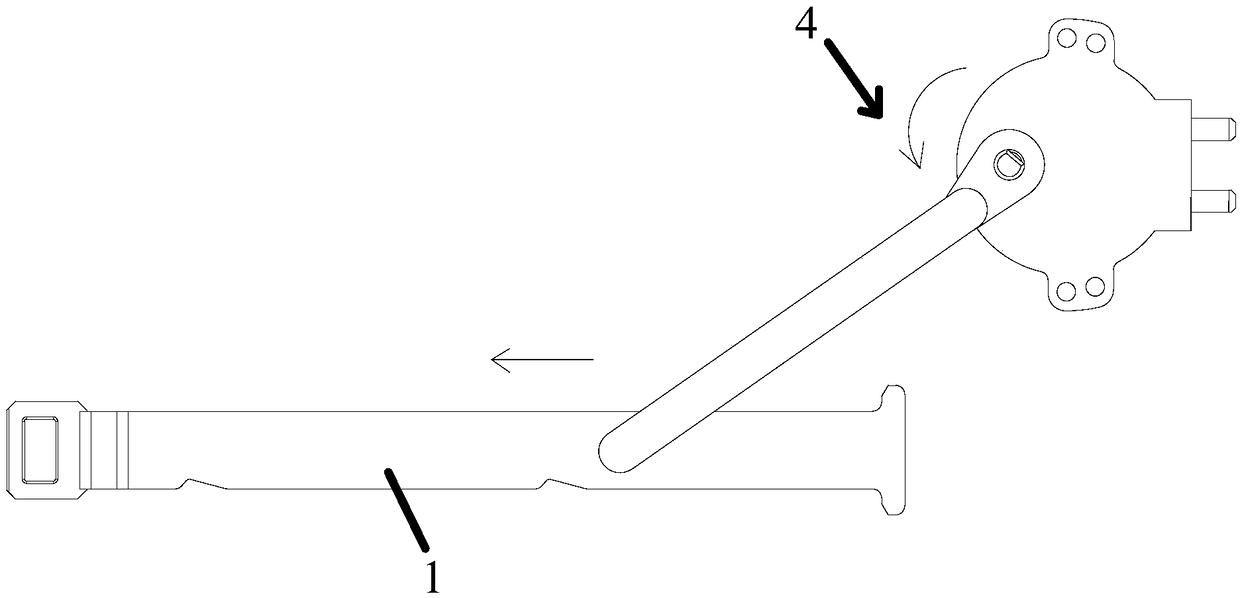

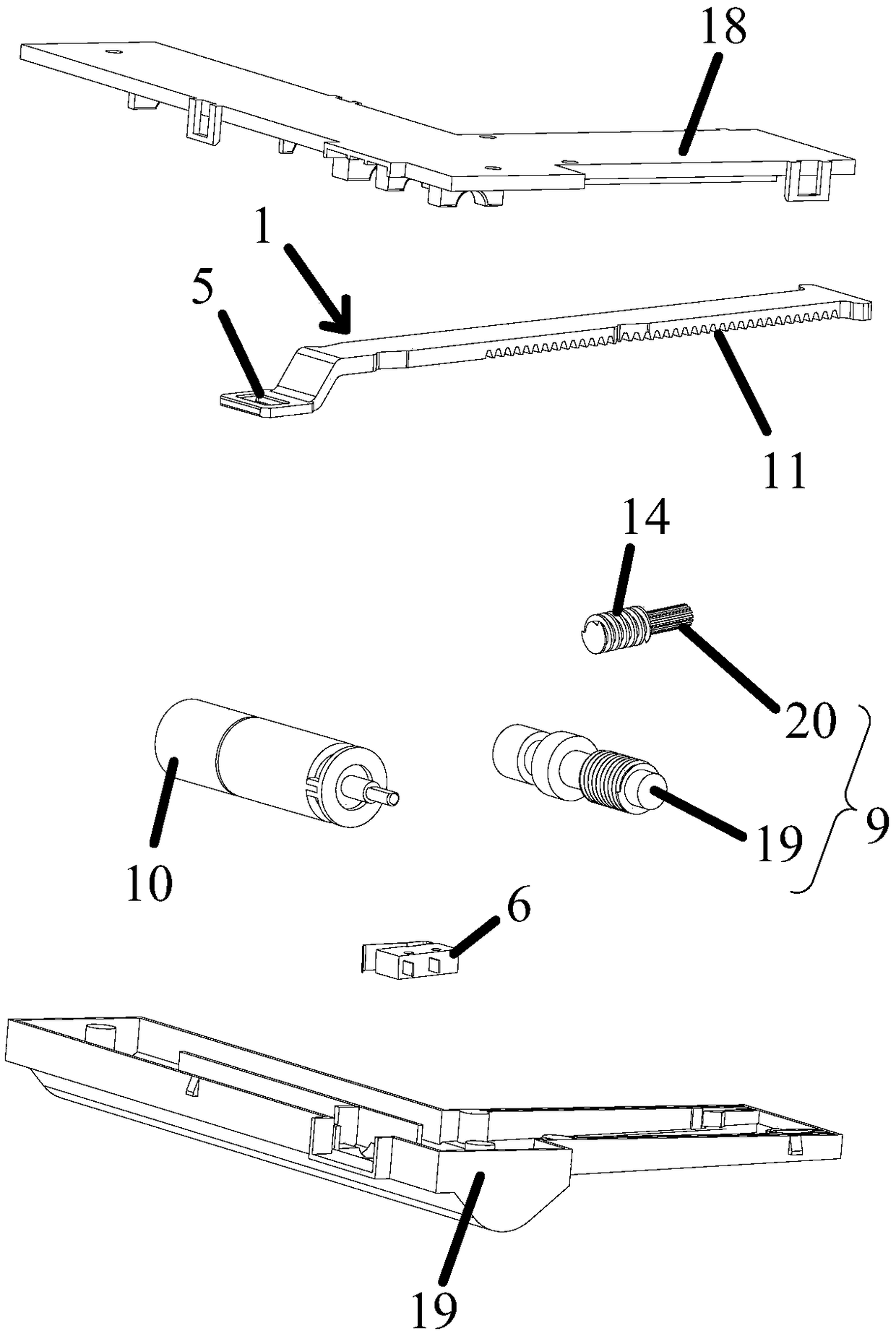

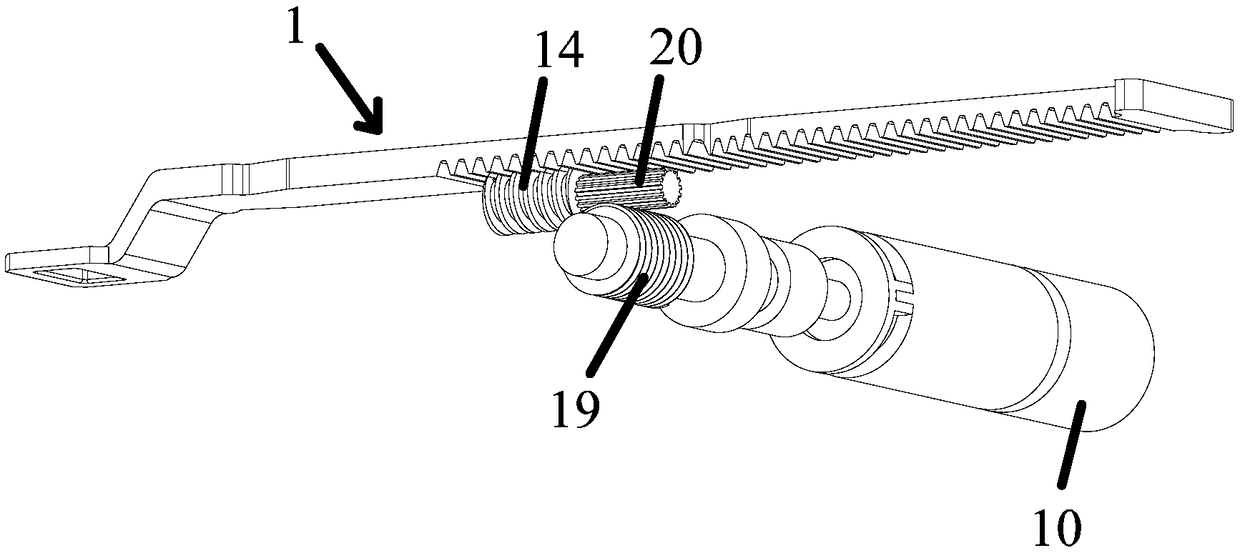

Automatic door opening device and dish washing machine provided with automatic door opening device

PendingCN109209132AEasy to drive and storeLow sense of technologyTableware washing/rinsing machine detailsPower-operated mechanismEngineeringElectrical and Electronics engineering

The invention discloses an automatic door opening device and a dish washing machine provided with the automatic door opening device. The automatic door opening device comprises a push rod, a driving assembly and a first sensing element, wherein the push rod is arranged on a machine body with a machine door, the end, facing the machine door, of the push rod is connected with the machine door through a connecting structure, and the push rod is provided with an extension position for driving the machine door to open a certain opening and a reset position for retracting the machine body; the driving assembly drives the push rod to be switched in the extension position or the reset position through a worm and worm gear mechanism; and the first sensing element detects the connection state of themachine door and the push rod, when the connecting structure is disconnected and the push rod is separated from the machine door, the first sensing element controls the driving assembly to drive thepush rod to retract to the reset position by sending a detection signal to the driving assembly, so that the problems of low scientific and technological sense and poor user experience due to the factthat the dish washing machine and other household electrical appliances need to be opened through a handle on the machine door in the prior art are solved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Rotary thermometer placing rack for pediatric department

InactiveCN108613747AImprove work efficiencyNo sorenessThermometer detailsThermometers using material expansion/contactionDrive shaftPrism

The invention discloses a rotary thermometer placing rack for the pediatric department. The rotary thermometer placing rack comprises a base. A left support and a right support are fixed on the base.A first rotating shaft is arranged between the left support and the right support. The first rotating shaft is provided with a transmission gear. A driving shaft is inserted in the right support belowthe first rotating shaft. A crank is fixed on the external end surface of the driving shaft. A driving gear is arranged on the driving shaft. The driving gear is engaged with the transmission gear. Ahexagonal prism is fixed on the first rotating shaft. The central axis of the hexagonal prism and the central axis of the first rotating shaft are arranged on the same straight line. Multiple placingcavities are evenly distributed on the circumferential direction of a placing plate. Each placing cavity is internally provided with a placing cylinder of which the top end is provided with an opening. Each placing cylinder is internally provided with a thermometer. The beneficial effects of the rotary thermometer placing rack for the pediatric department are that (1) the structure is simple; and(2) operation is quite convenient.

Owner:杨峰堡

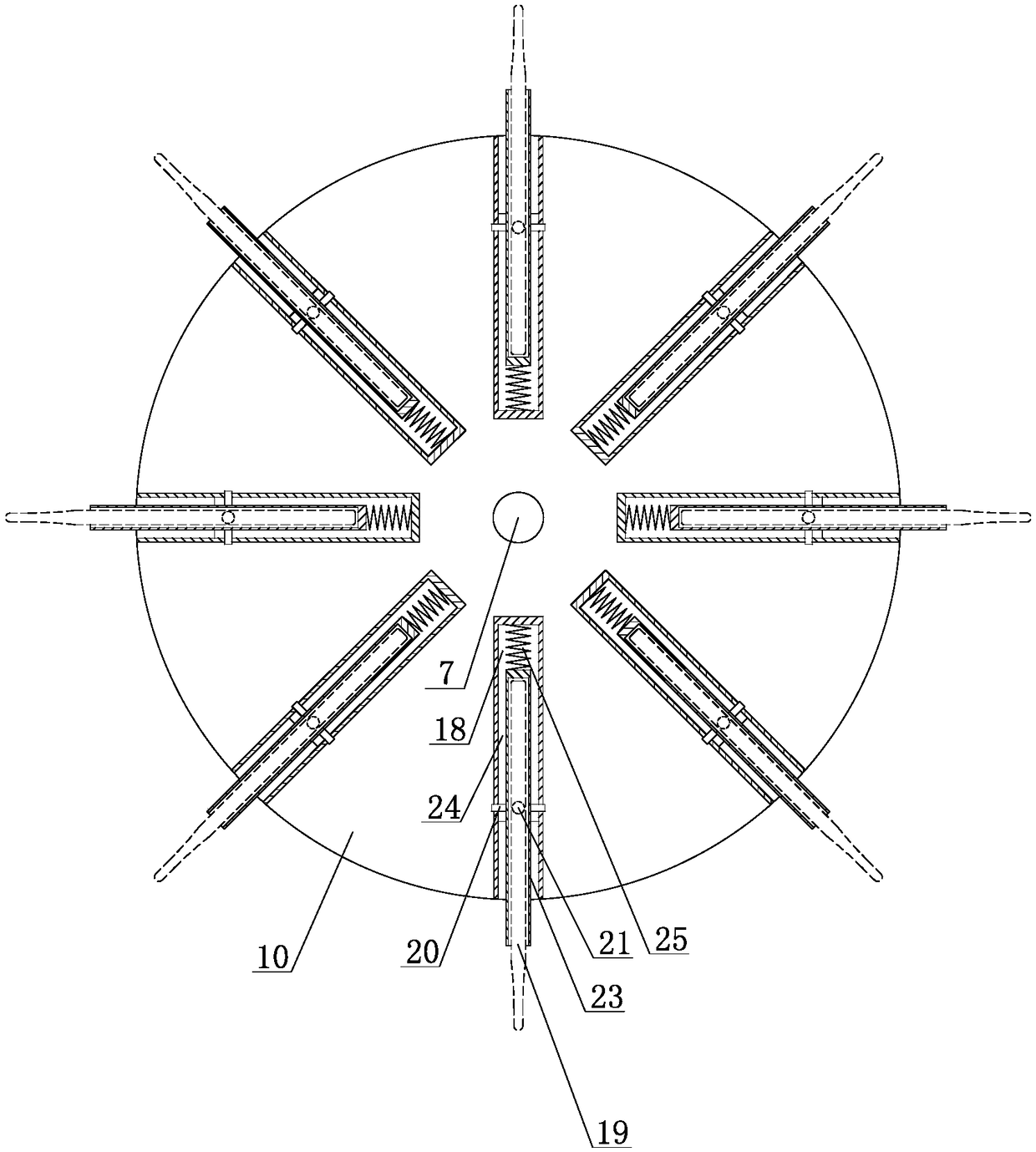

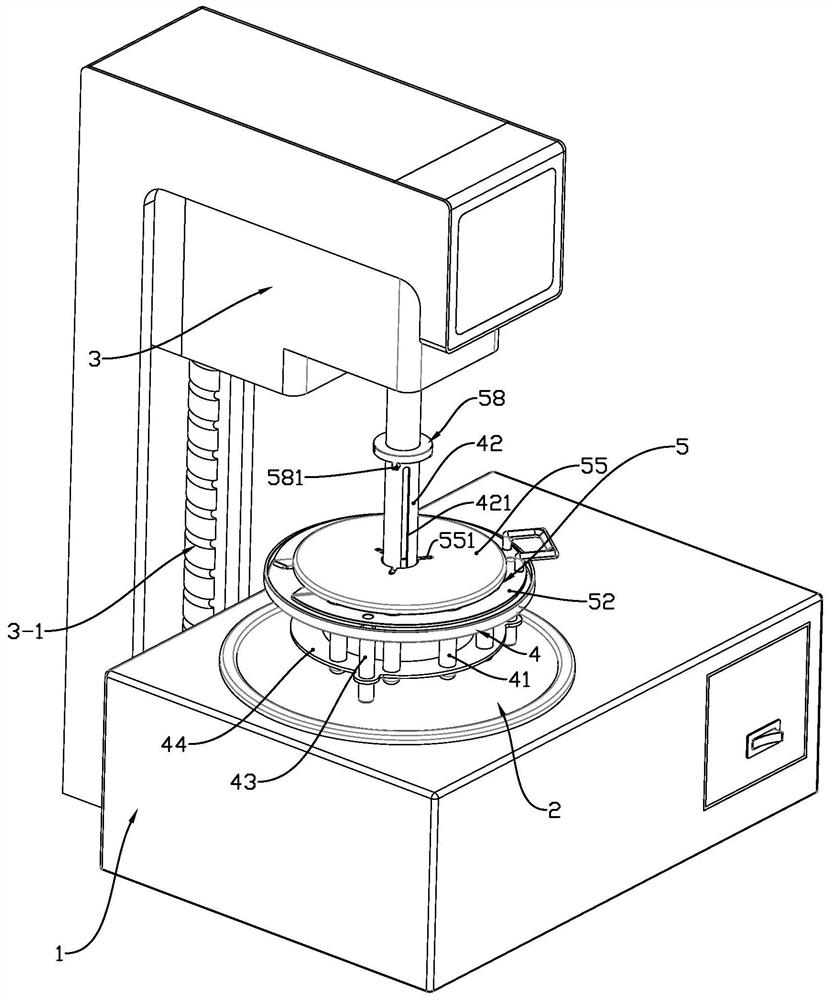

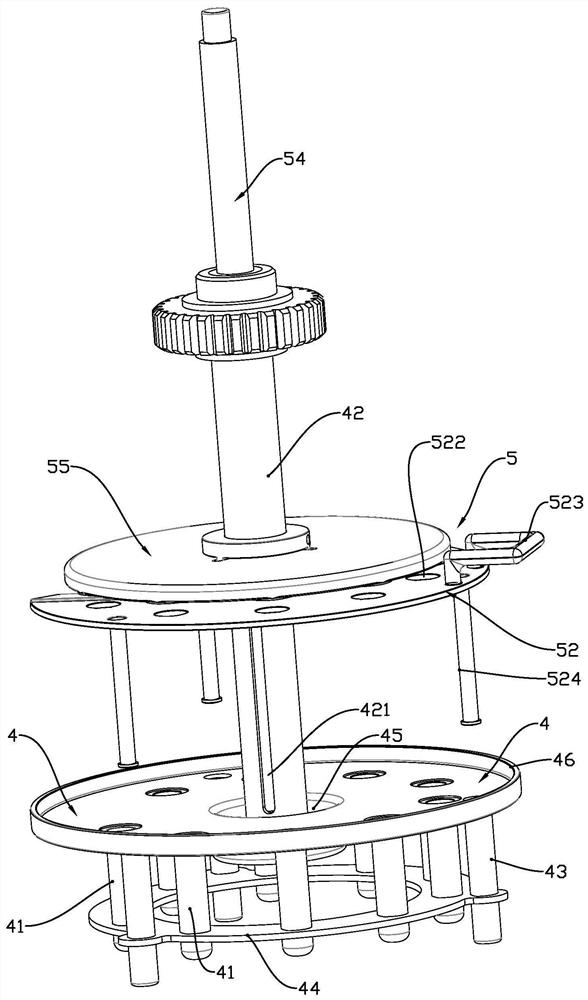

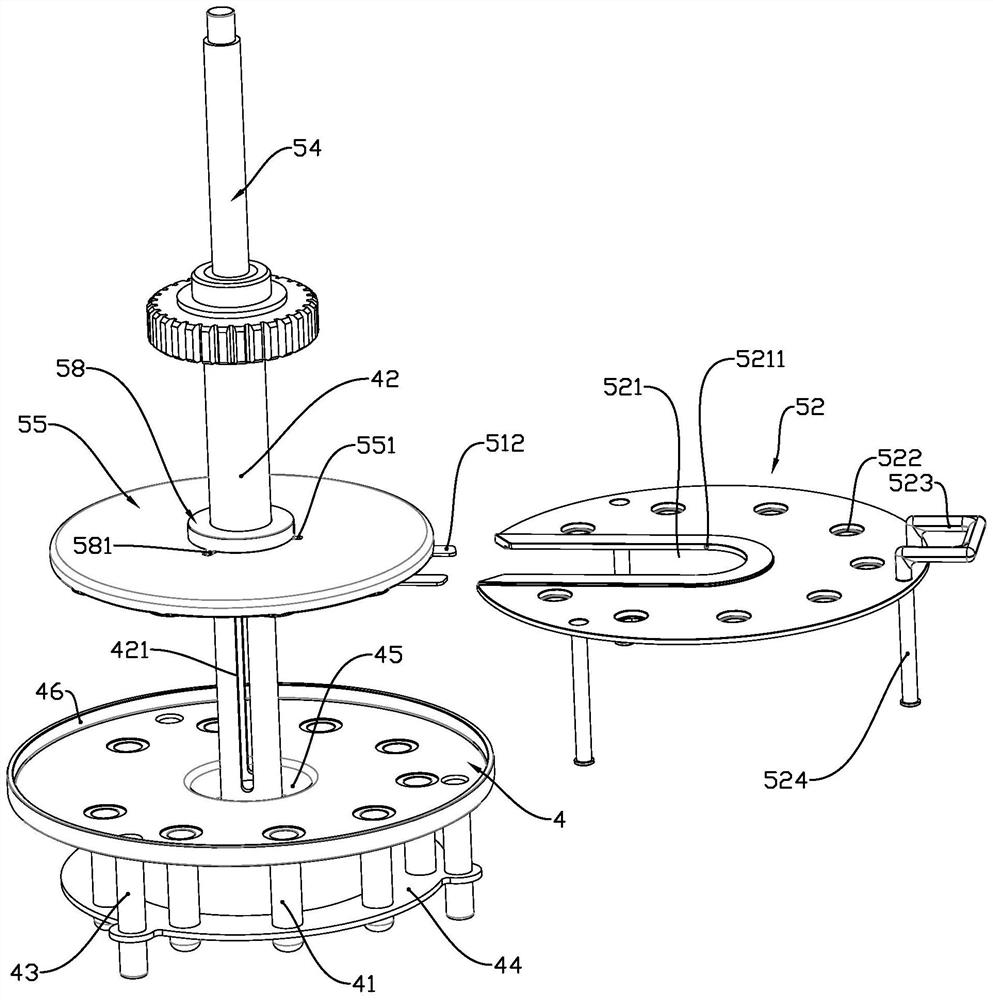

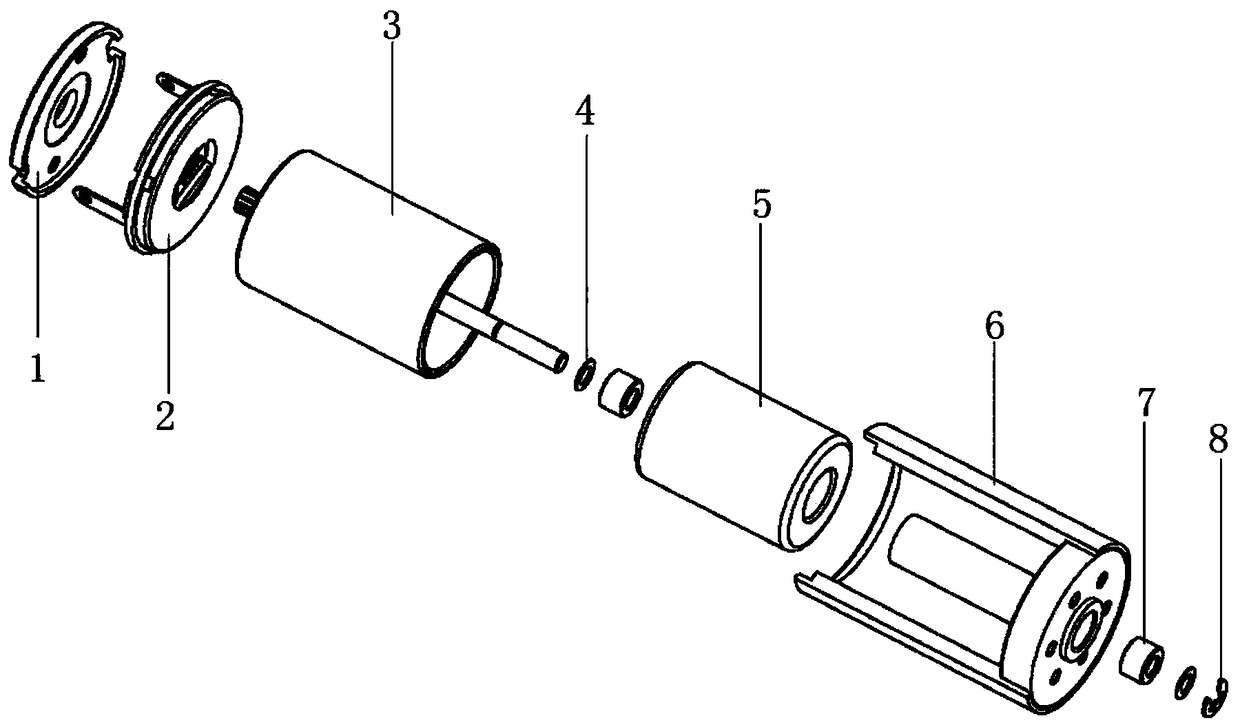

Rotary cell resuscitation instrument

PendingCN113337393AAvoid warm-up timeImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBiomedical engineeringCryopreservation

The invention relates to a rotary cell resuscitation instrument. The rotary cell resuscitation instrument comprises a machine body, a water bath kettle and a water bath execution device, wherein the water bath execution device comprises a lifting machine head and a cryopreservation tube bearing device on the lifting machine head; the cryopreservation tube bearing device comprises an immersion bath tray with spacer bushes, a cryopreservation tube fixing mechanism and a rotating mechanism; the immersion bath tray is mounted on a hollow rotating shaft of the rotating mechanism; a tray seat on a disc-shaped cryopreservation tube shelf of the cryopreservation tube fixing mechanism can axially slide outside the hollow rotating shaft; a driving head which axially slides and is in circumferential linkage is arranged in the hollow rotating shaft; a connecting pin on the driving head penetrates through an avoiding slotted hole in the hollow rotating shaft and then is connected with the tray seat; the driving head is connected with a driving mandrel; a cryopreservation tube positioning disc of the disc-shaped cryopreservation tube shelf is detachably assembled on the tray seat in a pushing and inserting manner along a U-shaped opening; cryopreservation tube shelf seat holes in the cryopreservation tube positioning disc are in one-to-one correspondence to the spacer bushes and are in sealing fit with the spacer bushes; and a disc-shaped cover plate which is used for opening and closing upper ports of the cryopreservation tube shelf seat holes and elastically pressing cryopreservation tubes is arranged on the tray seat. The rotary cell resuscitation instrument has the advantages of high cell resuscitation efficiency, low pollution and convenience in operation.

Owner:THE FIRST AFFILIATED HOSPITAL OF WENZHOU MEDICAL UNIV

Waist rope end face sewing mechanism of waist rope bar tacking machine

ActiveCN113684616AAvoid positional interferencePrevent kinkingWorkpiece carriersWork-feeding meansIndustrial engineeringSewing machine

The invention provides a waist rope end face sewing mechanism of a waist rope bar tacking machine, relates to the technical field of sewing instruments, and solves the problems that in the manufacturing process of sewn two ends of a waist rope, the waist rope needs to be integrally cut according to a proper length and then can be sewn through an additional sewing device, and the step of replacing the waist rope needs to be completed manually, so that the waist rope sewing efficiency is relatively low, and the length detection cutting and sewing processes cannot be completed at a time. The waist rope end face sewing mechanism of the waist rope bar tacking machine comprises a limiting part; a limiting groove is formed in the middle of the top end face of the limiting part; an adjusting feeding part is fixedly connected to the right side of the front end of the top of the limiting part; the front end and the rear end of the limiting groove are semicircular; and scale values are arranged on the two sides of the limiting groove correspondingly. The waist rope can be cut at a proper position, so that the size of the waist rope conforms to the actual cutting size, and the overlarge error is avoided; and meanwhile, sewing treatment is carried out, so that manual participation is avoided while the production efficiency is improved.

Owner:南通恒仟花边织带有限公司

Buffer device for preventing yarn breakage, doffer and working method thereof

The invention discloses a damping device for preventing yarn breakage. The damping device comprises a power device, a fixing piece and en elastic piece, wherein an output shaft of the power device is fixedly connected with the fixing piece, the power device drives the fixing piece to swing, and one end of the fixing piece is fixedly connected with the elastic piece. According to the damping device for preventing the yarn breakage, a yarn left on a spindle blade can be effectively prevented from being inserted to be broken by using the damping device when an empty bobbin is inserted, and therefore the yarn end remaining rate is improved; meanwhile, the invention further provides a doffing machine, the damping machine is arranged on the doffing machine, the empty bobbins discharged from a tube discharging cylinder of the doffing machine is not prone to break the yarns, the yarn end remaining rate is improved, and the workload of yarn connecting workers is reduced. The invention further provides a working method for the doffing machine, the yarn end remaining rate can be improved, balloon separators are not needed to be overturned, and therefore the working efficiency is improved.

Owner:TONGLING SOBONE INTELLIGENT EQUIP

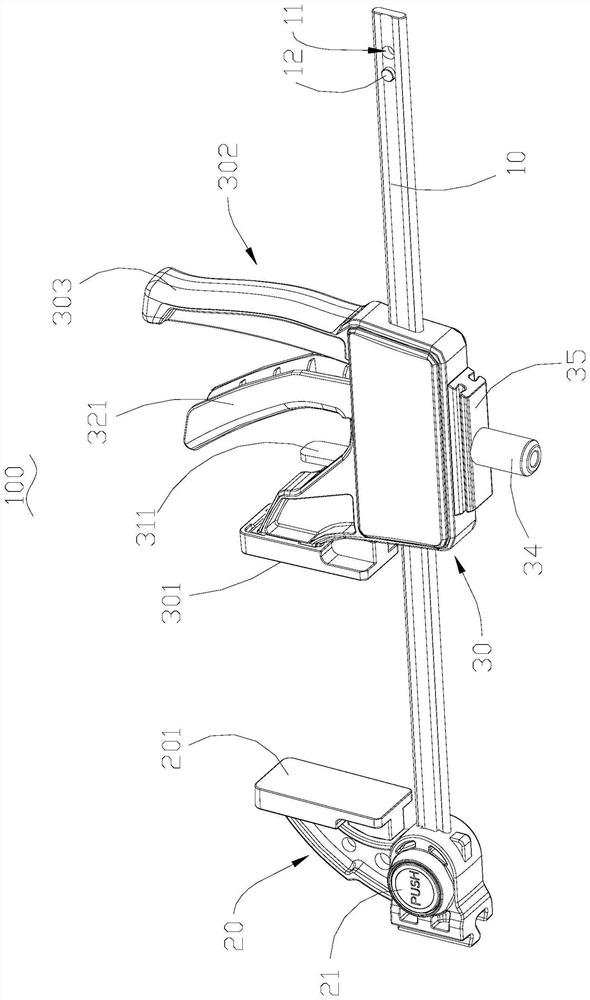

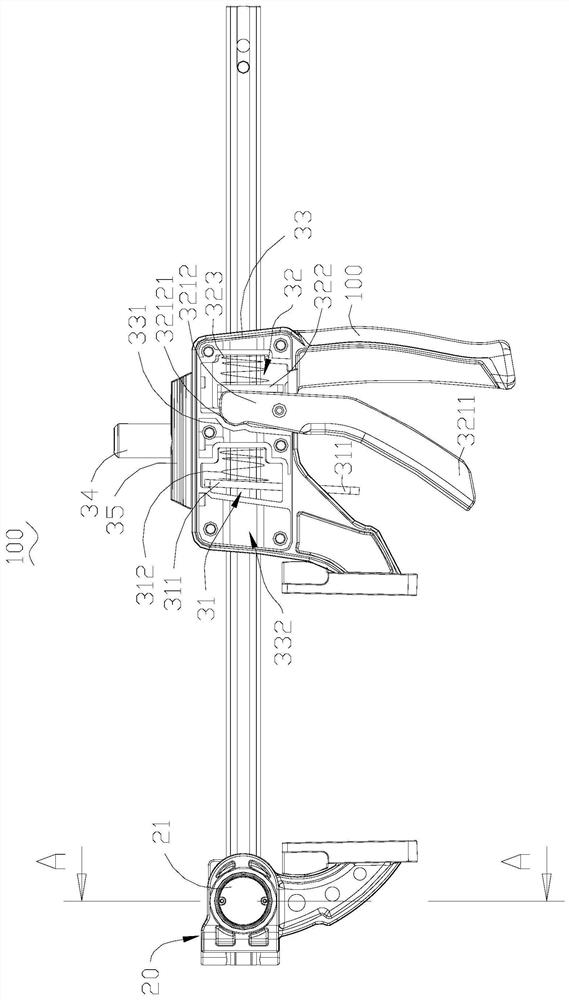

Clamp and workbench assembly

Owner:HANGZHOU UNITED ELECTRIC MFG CO LTD

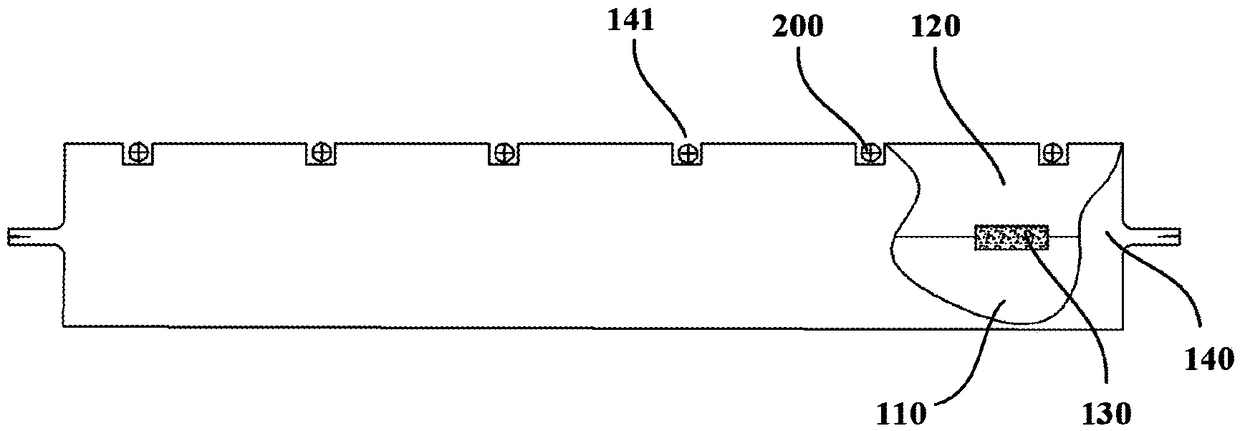

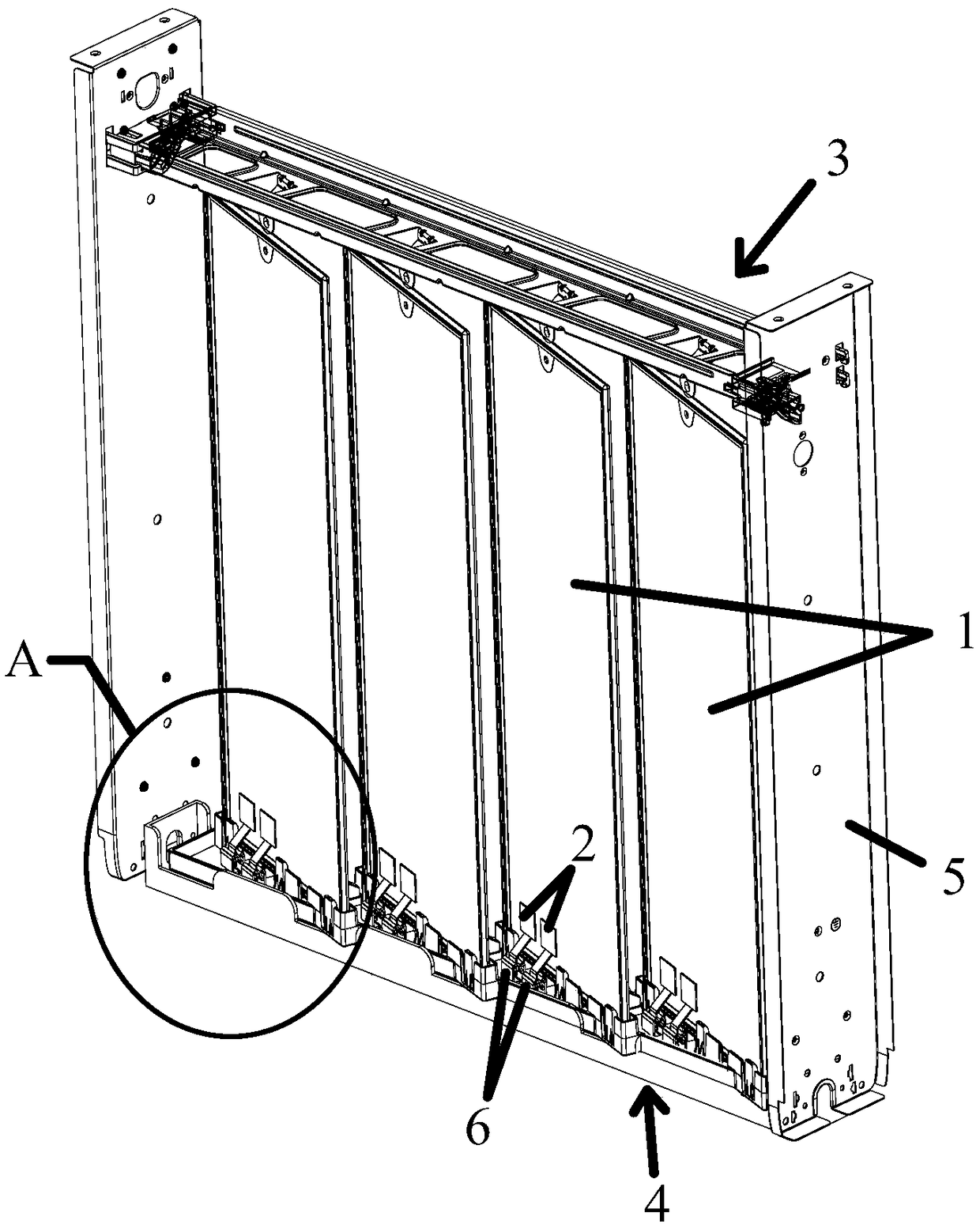

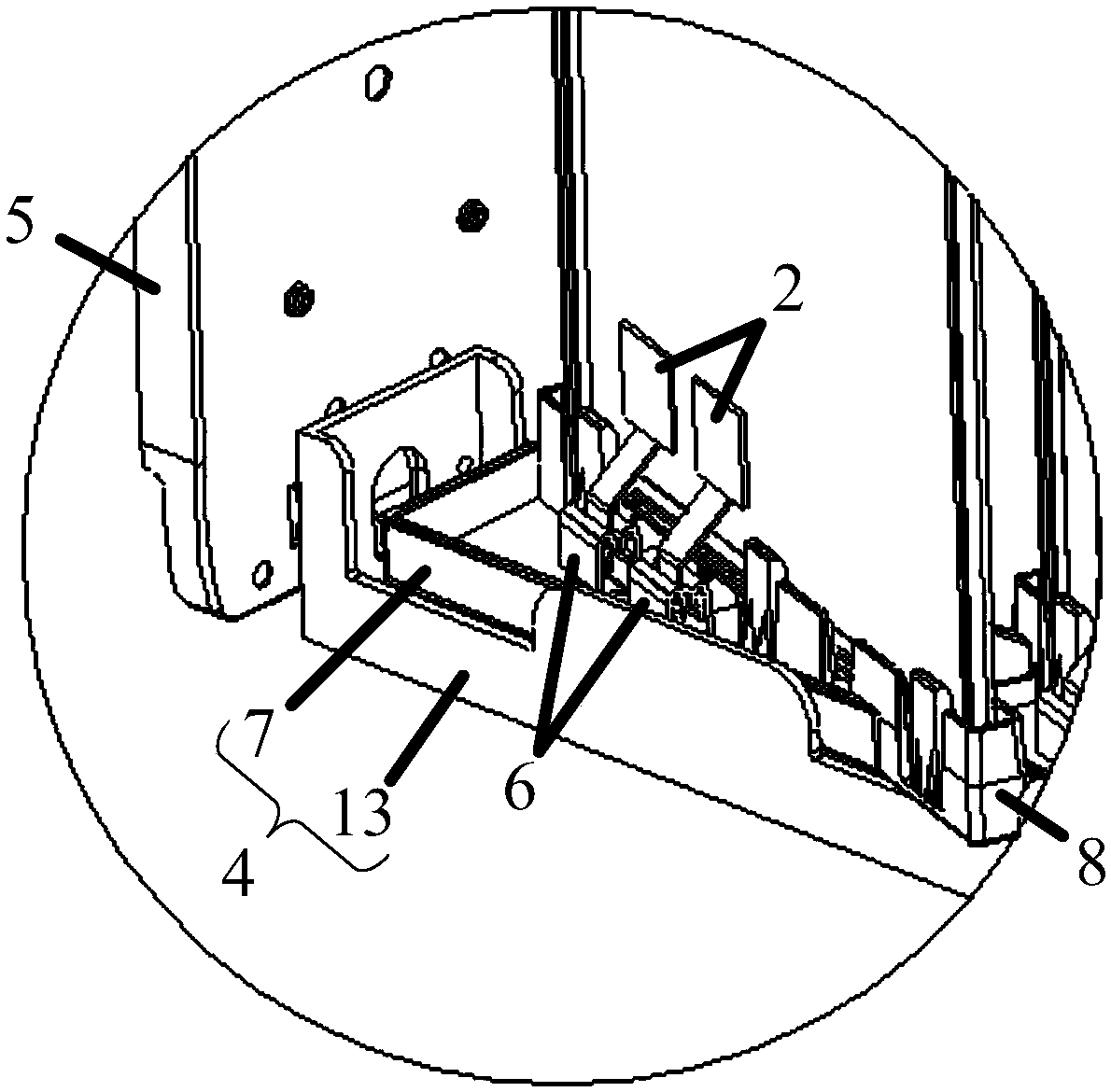

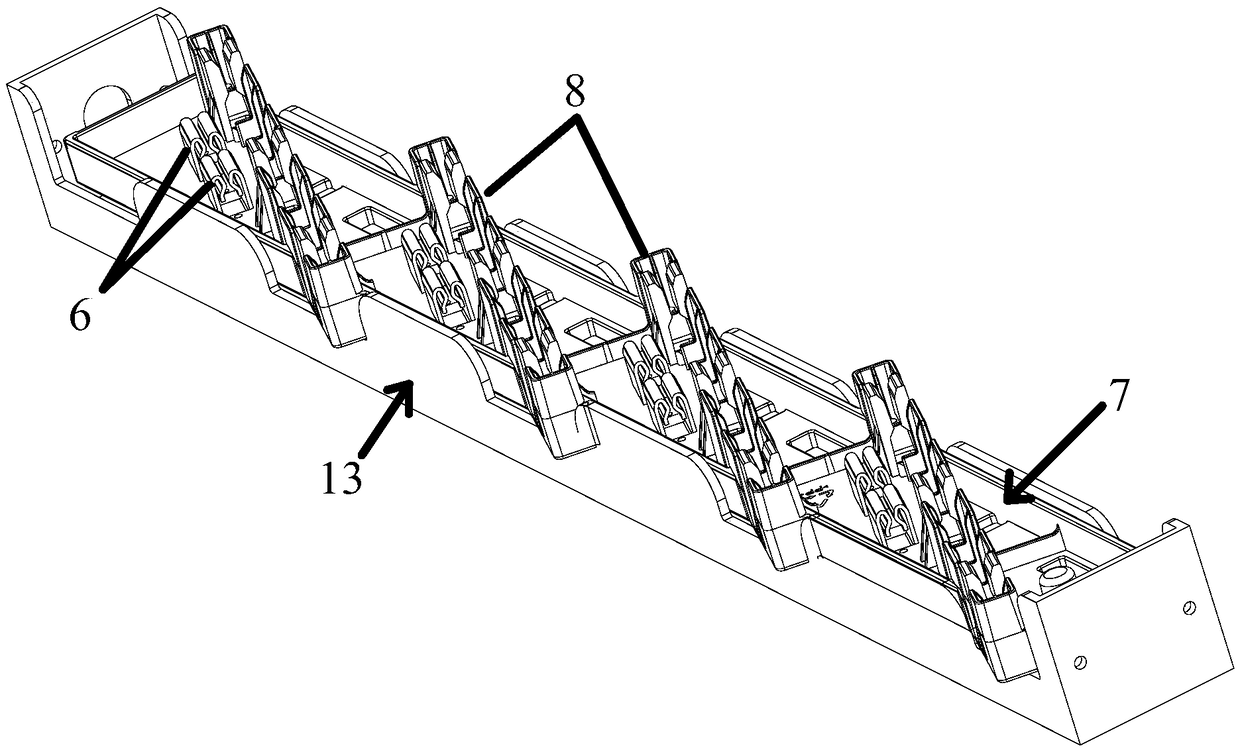

Electrothermal film heater and assembly method thereof

ActiveCN109210605AImprove installation efficiencyAvoid mistakesLighting and heating apparatusElectric heating systemFixed frameElectrical and Electronics engineering

The invention discloses an electrothermal film heater and an assembly method thereof. The electrothermal film heater comprises electrothermal film sheets, a fixing frame and terminal connecting pieces. The electrothermal film sheets are provided with connection terminals; the fixing frame comprises a fixing beam and supporting members, wherein the fixing beam is connected with the electrothermal film sheets, and the supporting members are used for supporting the fixing beam; and the terminal connecting pieces are arranged on the fixing beam which is insulated from the terminal connecting pieces, and communicates with a power supply circuit, and when the electrothermal film sheets are installed on the fixing beam, the connection terminals are in contact connection with each other so as to communicate with the power supply circuit. The connection terminals on the electrothermal film sheets are connected with the terminal connecting pieces which are connected to the power supply circuit in advance so as to supply power to the electrothermal film sheets, and the problem of low assembly efficiency of electrothermal film sheets caused by high connection difficulty and complex operation procedures of the electrothermal film sheets of an electrothermal film heater in the prior art is solved.

Owner:GREE ELECTRIC APPLIANCES INC

An auxiliary device for dismantling and assembling electric poles

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +3

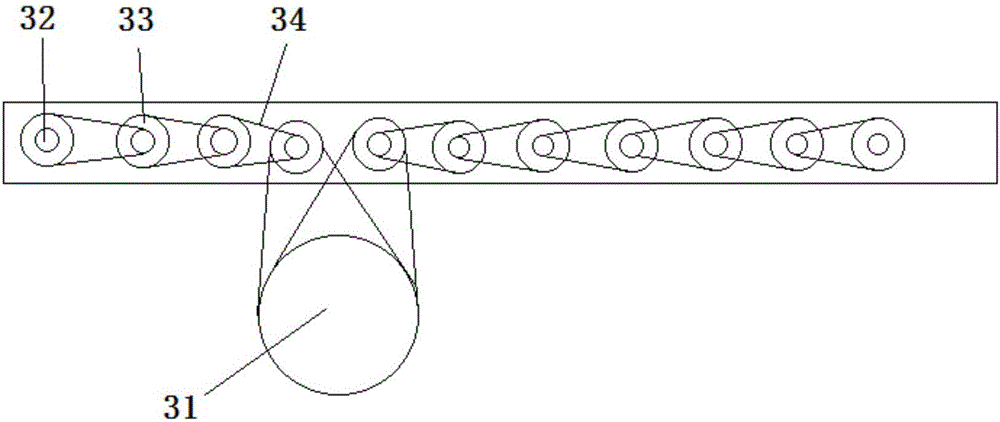

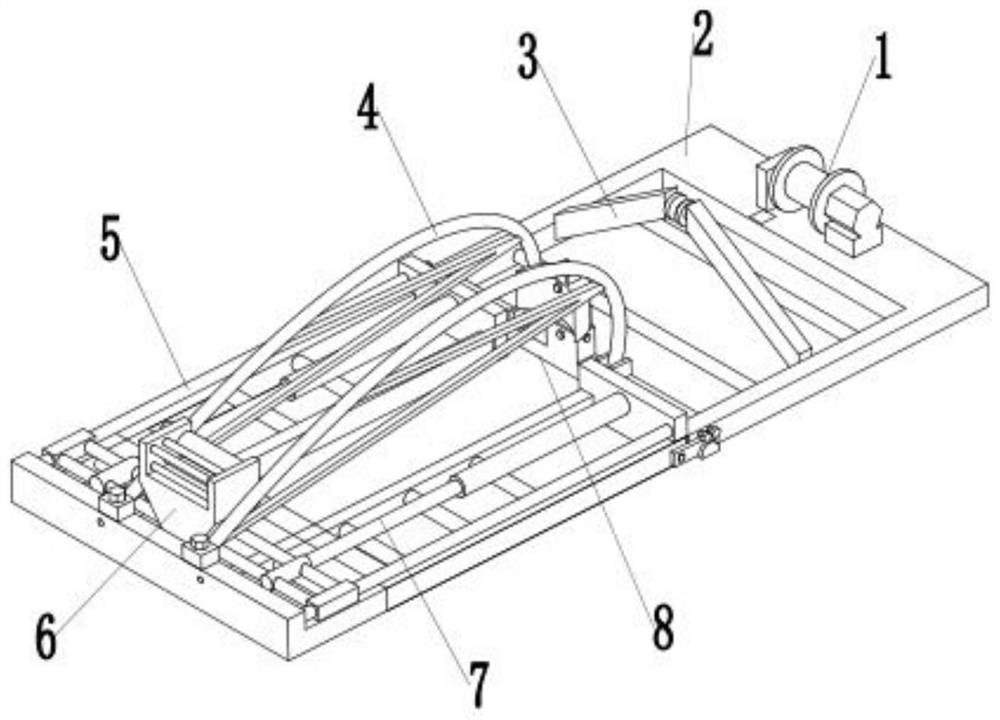

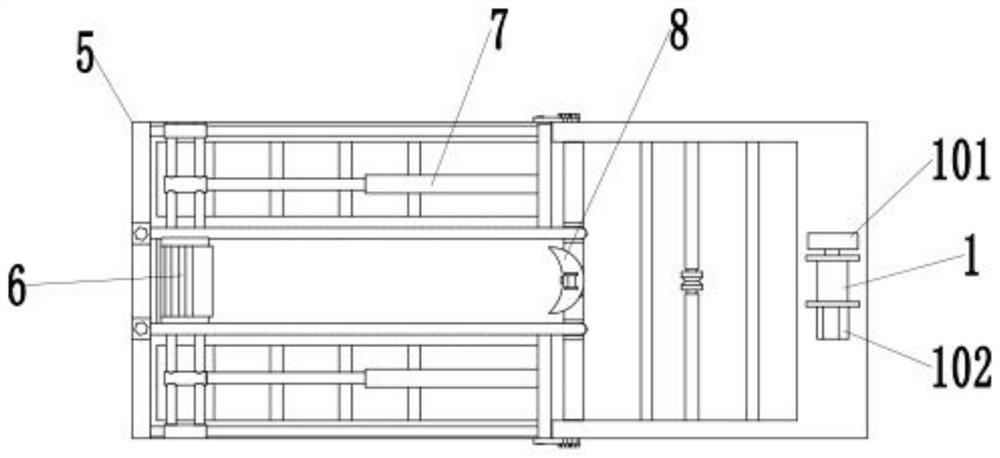

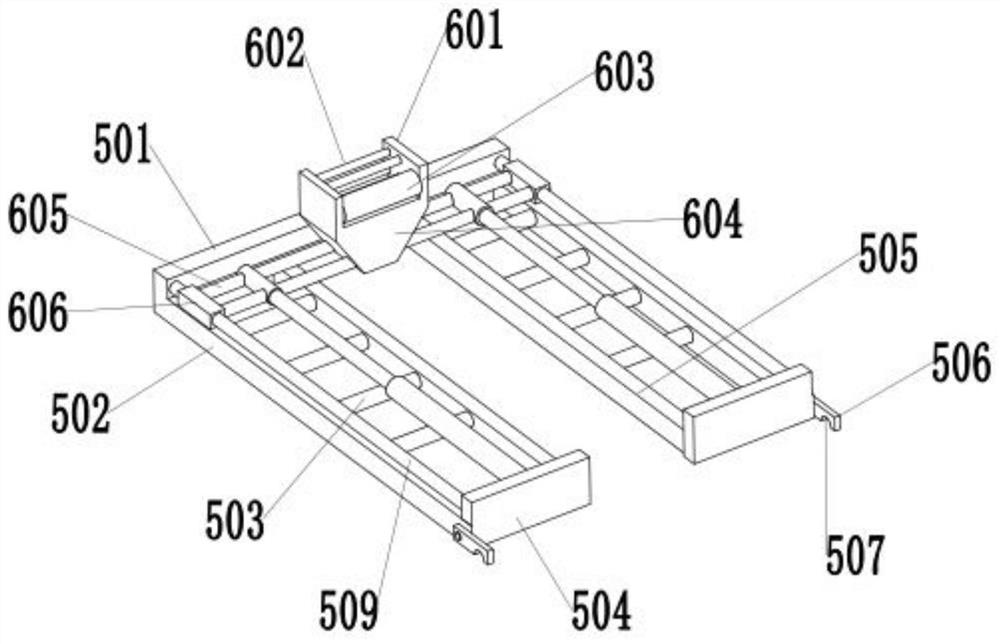

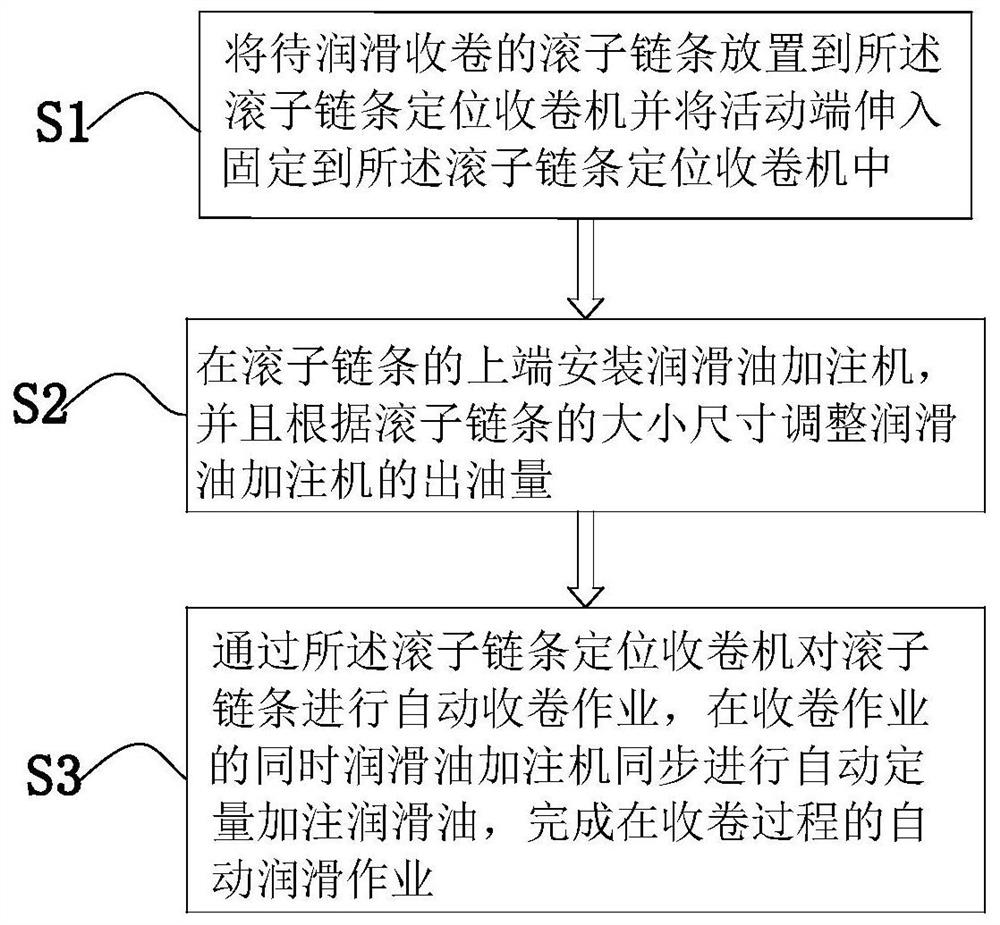

Roller chain lubrication method

InactiveCN112058942AEasy to installEasy to disassembleLiquid surface applicatorsShearing machinesWinding machineElectric machinery

The invention relates to a roller chain lubrication method which is mainly completed by a roller chain positioning and winding machine in a matched mode; the roller chain positioning and winding machine comprises a winding hollow roller, an inner hollow pipe, a telescopic clamping part, a first motor and a protruding rod; the winding hollow roller is connected with the inner hollow pipe through the telescopic clamping part, so that mounting and dismounting of the winding hollow roller are facilitated; the first motor works to drive the inner hollow pipe, the winding hollow roller and the protruding rod to rotate; when the protruding rod makes contact with the roller chain, the protruding rod moves in a direction away from the roller chain; when the protruding rod rotates to the position corresponding to a hole in the roller chain, the protruding rod extends into the hole of the roller chain under the action of the telescopic clamping part; and according to the winding mode of the roller chain, the movable end of the roller chain does not need to be manually fixed to the end of the winding hollow roller, so the working time is shortened, the procedures needing to be operated by personnel are reduced, and the work efficiency is improved.

Owner:溧阳市超强链条制造有限公司

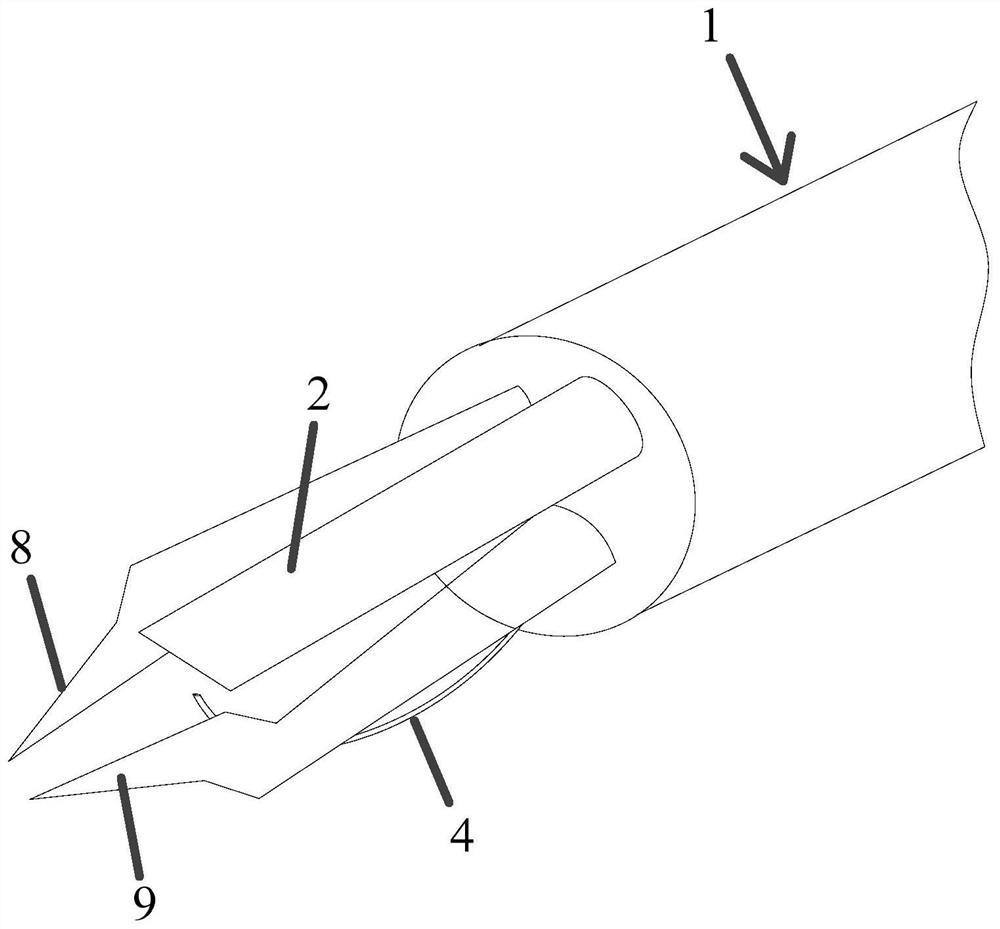

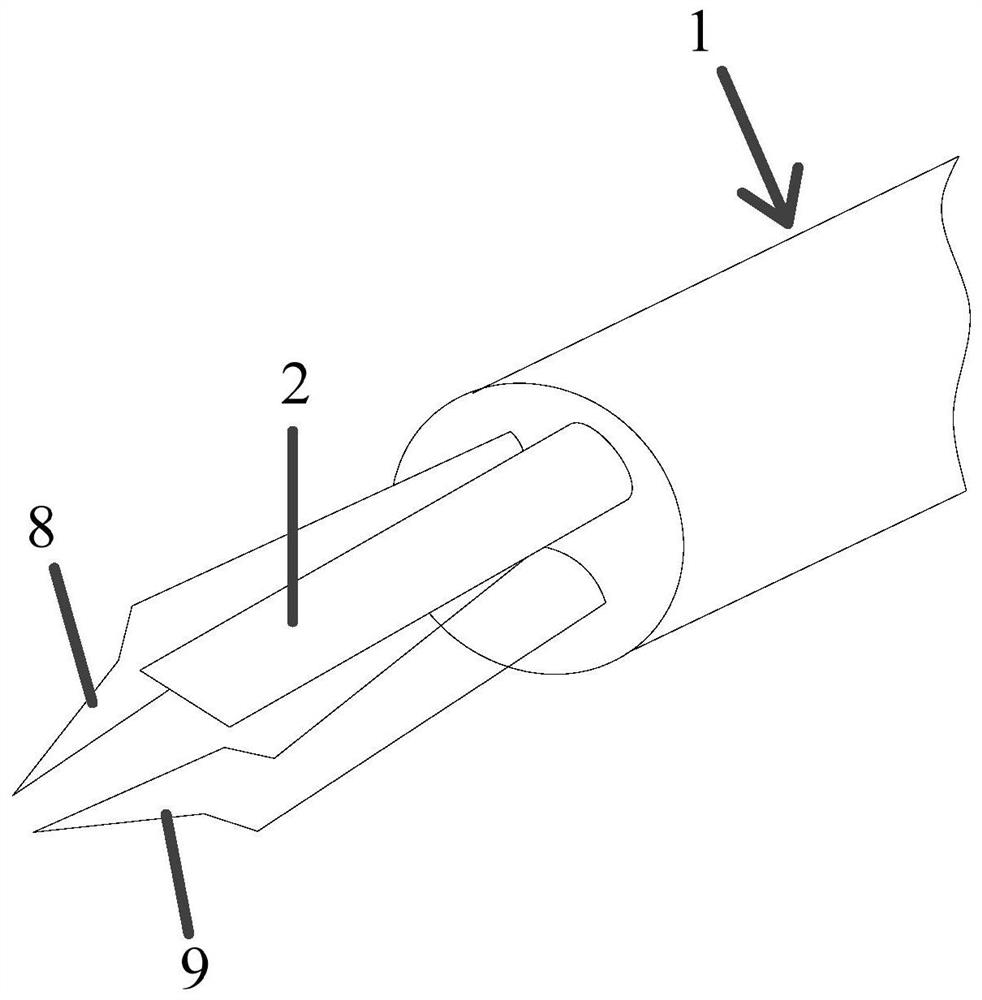

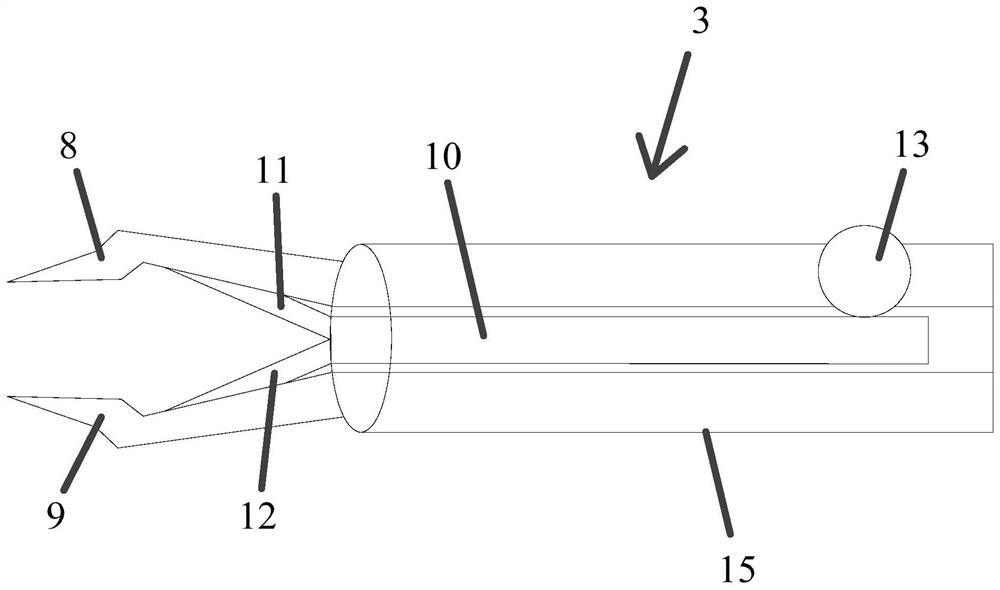

A kind of instrument for thoracoabdominal surgery with laparoscopic rigid mirror

ActiveCN112957107BEasy to cleanWill not affect normal workCannulasSurgical needlesHuman bodyAbdominal cavity

A thoracoabdominal surgical instrument with a rigid laparoscope, comprising: a positioning sleeve; a rigid laparoscope is driven and telescopically arranged in the positioning sleeve, and the rigid laparoscope has an extended position extending out of the positioning sleeve and retracted into the positioning sleeve The retracted position of the tube; the surgical actuator is arranged in the positioning sleeve, and the operating end of the surgical actuator extends out of the positioning sleeve; the hard mirror cleaner includes: a medium conduit arranged in the positioning sleeve, and a medium conduit end The nozzle at the end; the medium conduit is a curved flexible tube whose end is bent towards the lens of the laparoscopic rigid mirror. The above-mentioned structure solves the problem in the prior art that the rigid laparoscope and the thoracoabdominal surgical instrument cannot be combined to enter the abdomen of the human body through a through hole in the abdomen of the human body.

Owner:南昌华安众辉健康科技股份有限公司

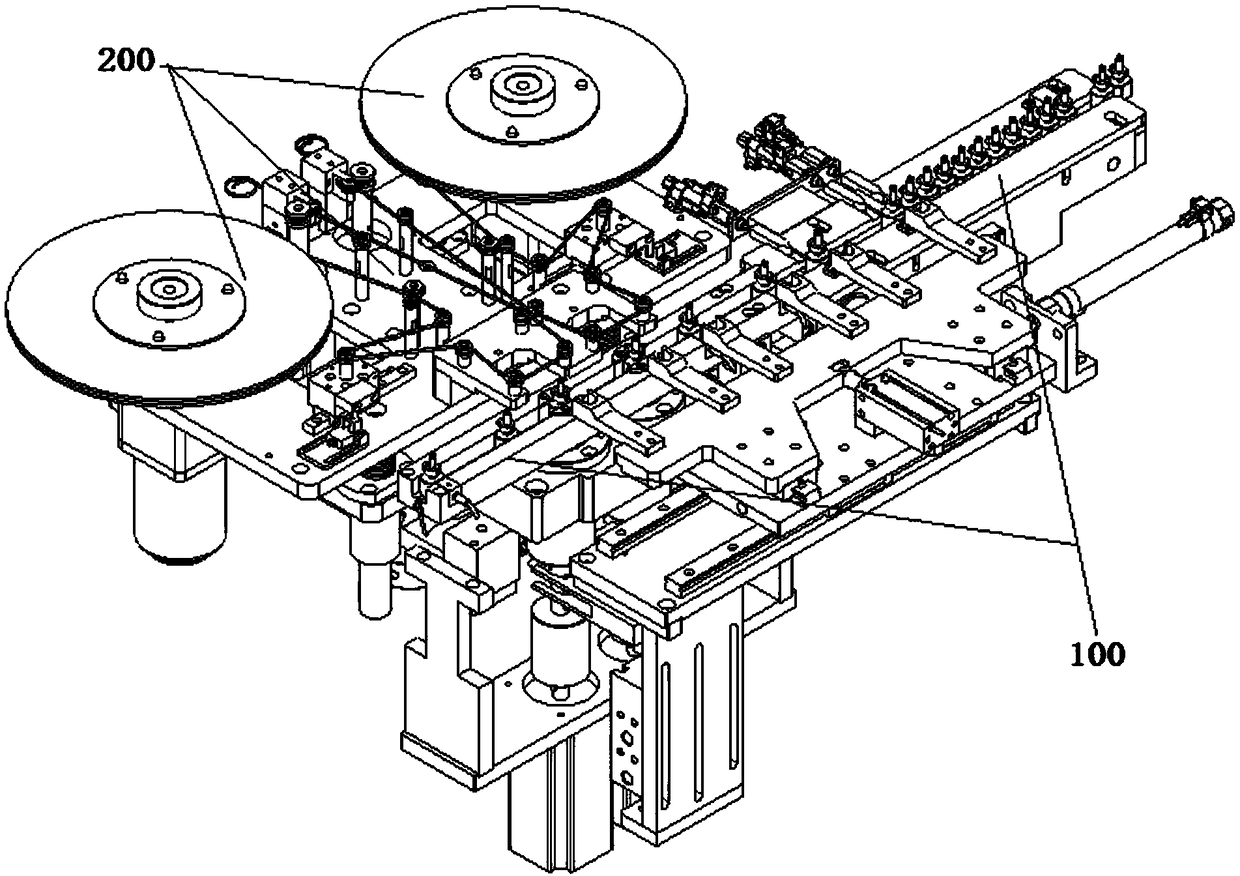

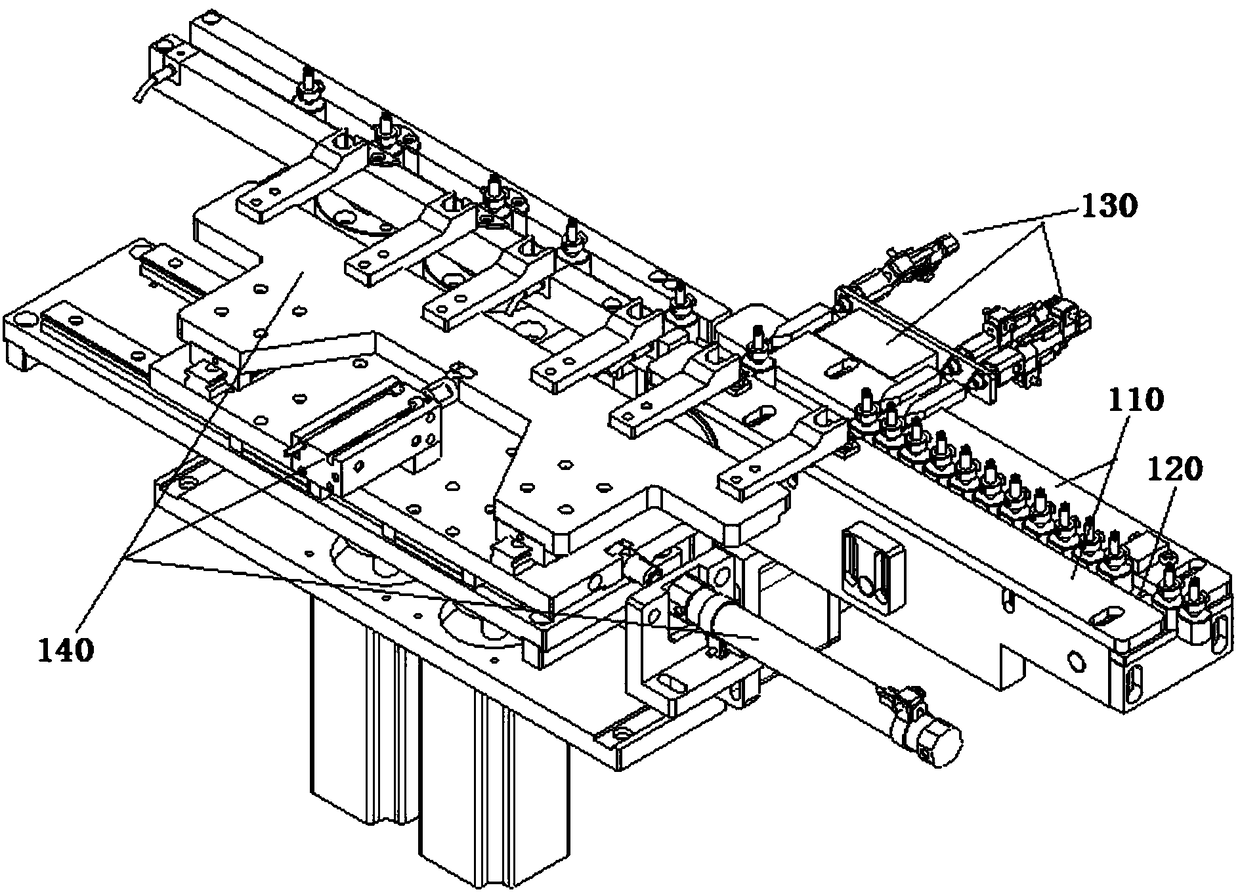

A hollow cup motor rotor polishing device

ActiveCN106425769BStrong structural supportAvoid positional interferenceBelt grinding machinesGrinding feedersElectric machineryEngineering

The invention discloses a polishing device for a hollow cup motor rotor. The polishing device has the technical advantages of simple structure, convenience in maintenance and high operation efficiency. The structure of the polishing device comprises an automatic feeding device and an automatic polishing device, wherein the automatic feeding device comprises a rail slot, a conveyer belt, a material level positioning device and a material stirring device; the material stirring device comprises a material stirring plate and a material plate driving device; the material stirring plate is equipped with a plurality of stirring forks; the material plate driving device is used for driving the material stirring plate to traverse on a plane as high as the plane of the rail slot; the automatic polishing device comprises a material rotation driving device, a polishing belt feeding device and a polishing executing device for driving the polishing belt feeding device to advance and retreat; the polishing belt feeding device comprises a base plate and a polishing belt; the base plate is equipped with a station slot; the polishing belt is arranged above the station slot. The polishing device provided by the invention can automatically polish the hollow cup motor rotor located in an automatic production line of the hollow cup motor rotor.

Owner:ONCE TOP MOTOR MFG

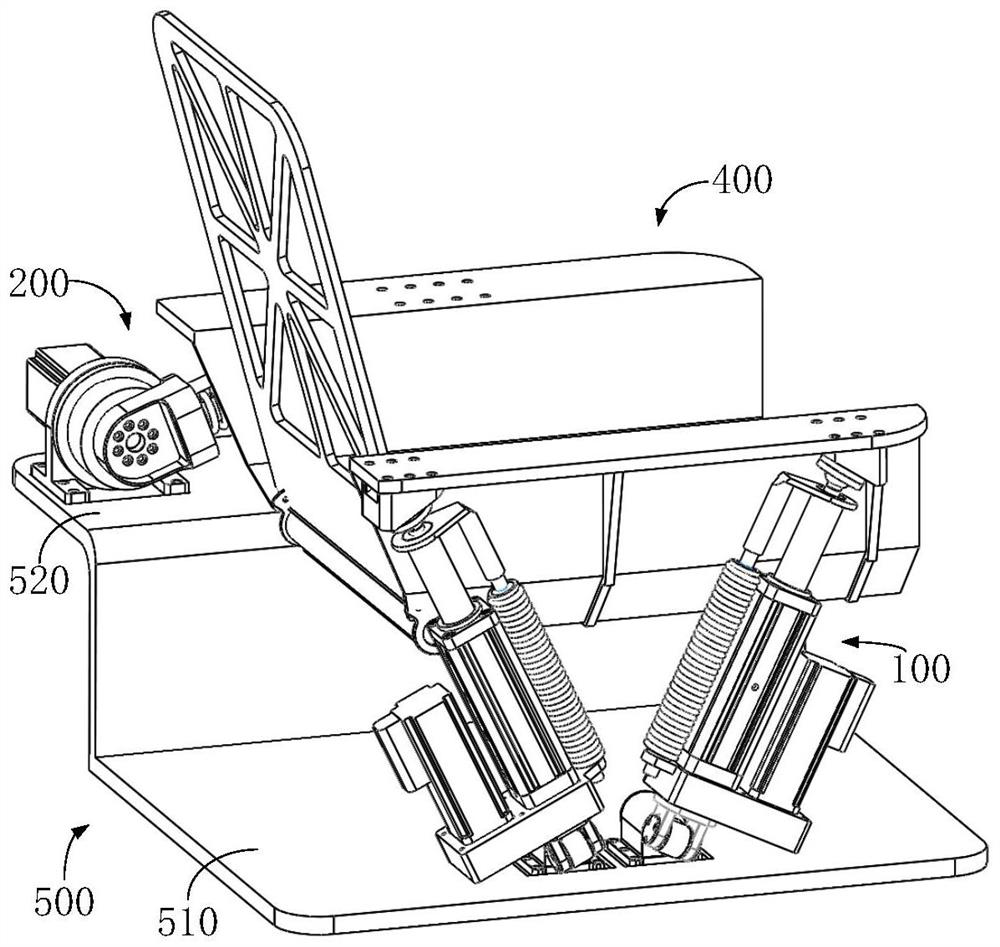

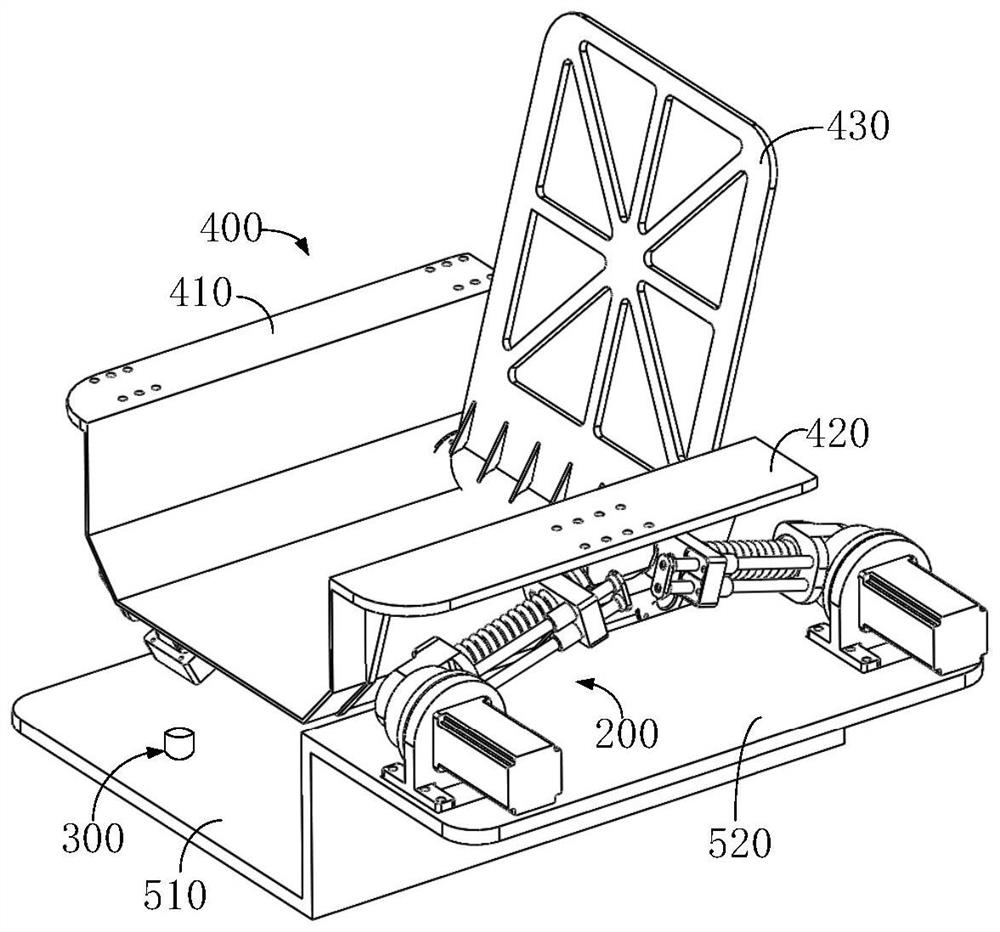

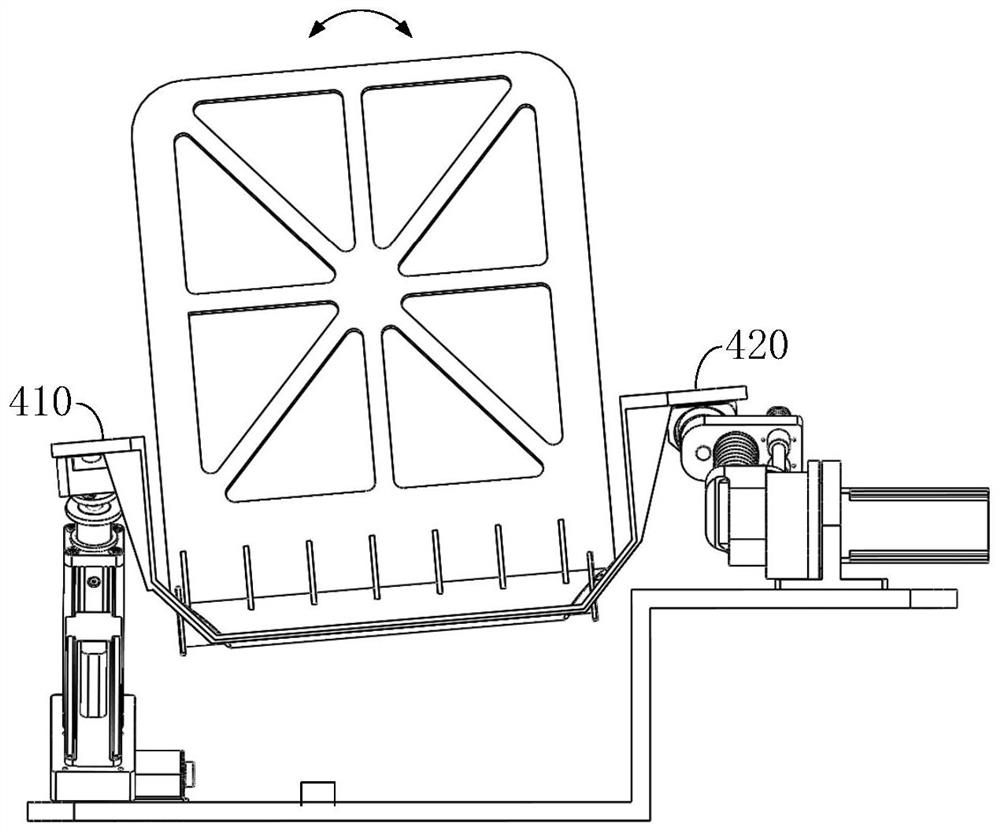

Self-balancing damping seat mounted on traffic equipment

ActiveCN114475378ADoes not affect size layoutFreedom of movement controlSeat suspension devicesControl theoryBalancing vibrations

The invention discloses a self-balancing vibration reduction seat installed on traffic equipment. The self-balancing vibration reduction seat comprises a seat body, a first vibration reduction device, a second vibration reduction device, a sensing device and a control device. The sensing device is used for acquiring motion information of the traffic equipment. The first damping device and the second damping device are used for being connected with the seat body, so that the seat body is parallel to a chassis of the traffic equipment in the initial state. The control device controls the first damping device and the second damping device to operate according to the motion information so as to drive the seat body to move up and down, pitch and roll, so that the seat body recovers balance. The first damping device and the second damping device are arranged at different height positions in the accommodating space, so that position interference between the seat body and the interior of the accommodating space can be effectively avoided; the first damping device and the second damping device can control the motion freedom degrees of the seat body in all directions under the condition that the size of the seat body is not affected, and the seat body is kept stable.

Owner:上海新纪元机器人有限公司

A sensor weighing module

ActiveCN104931121BAvoid horizontal movementAvoid over-settling problemsSpecial purpose weighing apparatusFault tolerancePlate column

The invention relates to the technical field of weighing and packaging, in particular to a sensor weighing module used in an automatic production line. The present invention includes a base, a beam sensor and a load-bearing plate. This module also includes support columns for supporting the load-bearing plate. The support columns are at least two symmetrically located at both ends of the load-bearing plate along the center line; One of the opposing surfaces of the supporting pillar and the load-bearing plate is provided with a spherical matching part, and the matching part of the other surface of the above-mentioned opposing surface is arranged with a hemispherical spherical groove that matches each other; in the vertical direction , the distance between the spherical groove and the spherical matching part is equal to the set pressure subsidence height of the bearing plate. The present invention can not only meet the requirement of weighing accuracy, but also reflect its better working flexibility and flexibility. At the same time, the fault tolerance rate is higher, the installation accuracy requirement is lower, and the working reliability and even the service life can be further improved. .

Owner:HEFEI GENERAL MACHINERY RES INST

An impact extrusion repair device for geological exploration components

ActiveCN111204696BIncrease the mixing entropyImprove the mixing effectShaking/oscillating/vibrating mixersLiquid transferring devicesElevation angleEngineering

The invention discloses an impact-type extrusion repairing device for geological exploration components, which includes a traction base, a conveying device, an adjusting table body and an adjusting frame, and the conveying device is sequentially provided with an upper and lower azimuth excitation vibration area from left to right . Adjust the fixed area and the side azimuth excitation vibration area, the conveying device also includes an output device, fan-shaped protrusions are installed on the underside of the adjustment table body, and an inverted U-shaped support frame is provided on the upper side of the adjustment table body, The lower end of the adjustment frame is provided with a guide sleeve and a cantilever rod, and the middle part of the adjustment frame is equipped with a support control device and a pitch angle control device, and the support control device is located inside the pitch angle control device. The present invention adopts different azimuth excitation methods to vibrate and mix the mixed medium, the mixing entropy value is high, and the mixing effect is good, and various methods can be used to adjust the elevation angle of the whole device in different azimuths, which is suitable for repairing work in different positions of geological exploration .

Owner:ANHUI UNIV OF SCI & TECH

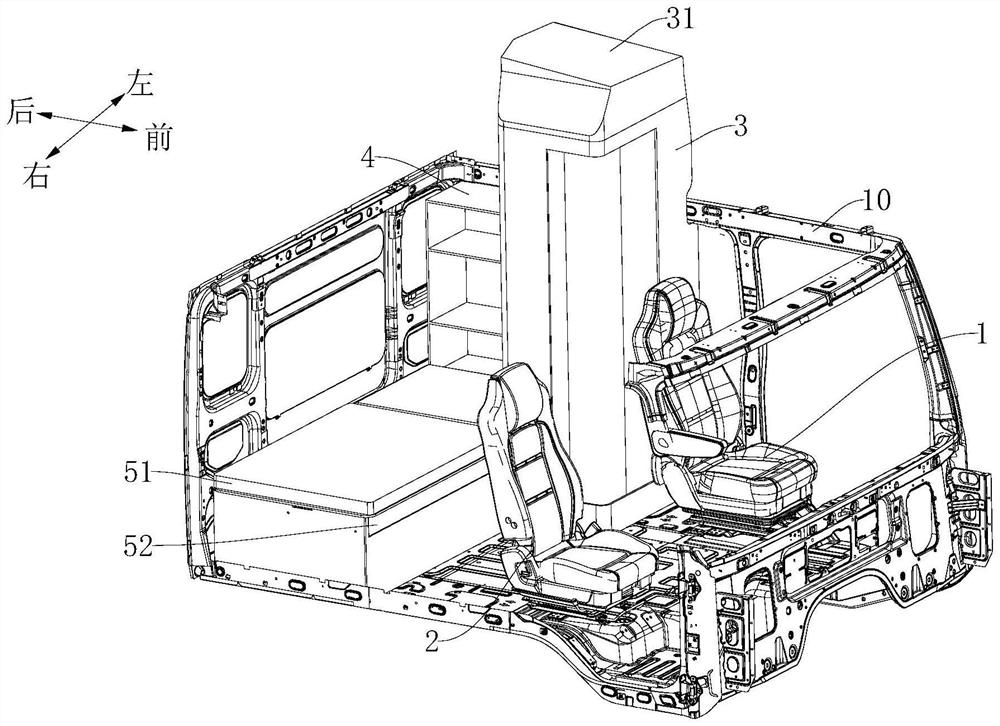

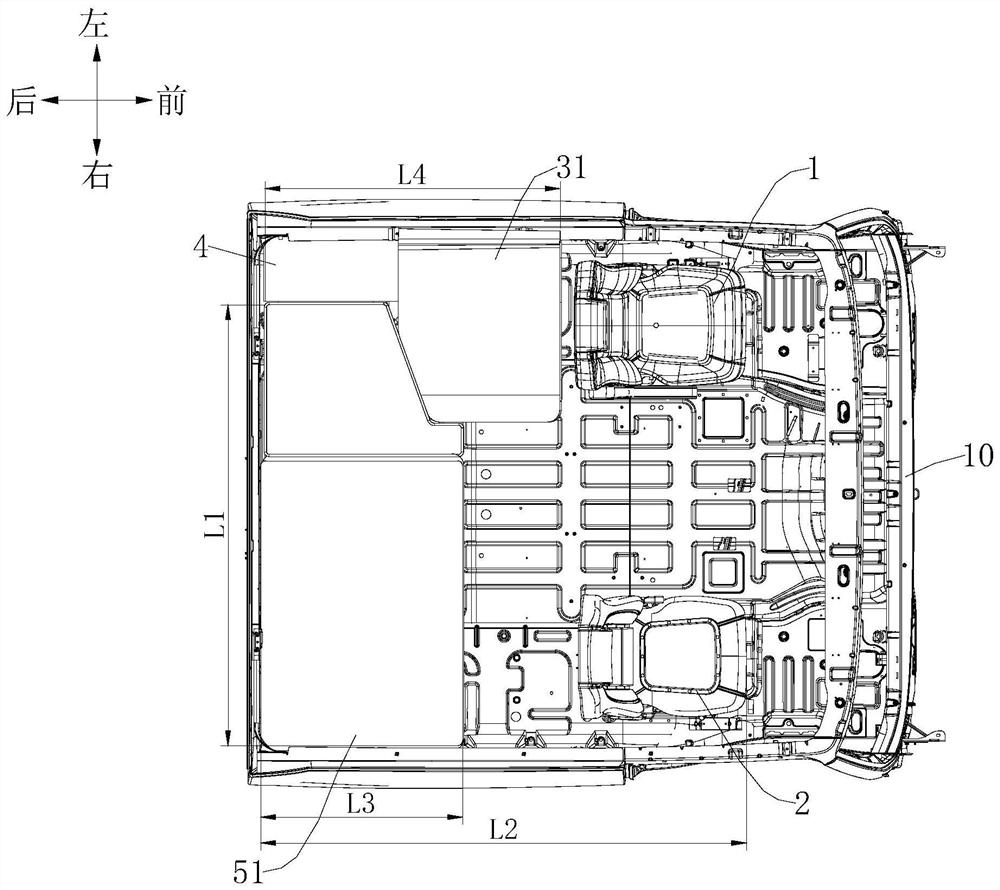

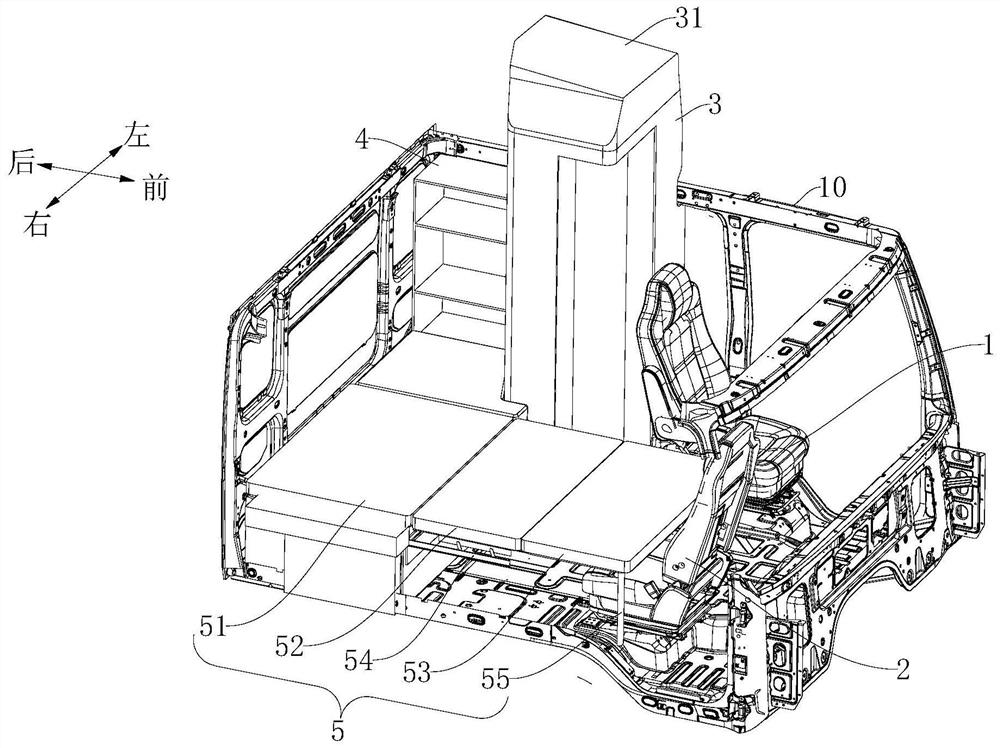

Truck head

PendingCN114030531AMeet basic needsReduce volumeLoading-carrying vehicle superstructuresControl theoryTruck

The invention relates to the technical field of automobiles, and particularly discloses a truck head which comprises a shell, and a driver seat, a co-driver seat, a shower compartment, a first storage cabinet and a folding bed assembly are arranged in the shell. The driver seat and the co-driver seat are arranged at the front end of the shell and are sequentially arranged in the left-right direction, and the bottom of the co-driver seat and the bottom of the shell rotate relative to each other. The shower compartment and the first storage cabinet are arranged on the rear side of the driver seat and are sequentially arranged in the front-back direction. The folding bed assembly is arranged on the rear side of the co-driver seat and comprises a seat body, a first plate body and a second plate body hinged to the front side of the first plate body, the seat body and the co-driver seat are oppositely arranged in a spaced mode, a containing cavity is formed in the front side of the seat body, and sliding rails are arranged on the left side and the right side of the containing cavity in a sliding mode respectively. The left side and the right side of the first plate body are hinged to the two sliding rails respectively, and at least two supporting legs which are arranged at intervals are hinged to the second plate body.

Owner:DONGFENG LIUZHOU MOTOR

Waist rope end face sewing mechanism of a waist rope tacking machine

ActiveCN113684616BAvoid positional interferencePrevent kinkingWorkpiece carriersWork-feeding meansStructural engineeringIndustrial engineering

The invention provides a waist rope end face sewing mechanism of a waist rope nosing machine, relates to the technical field of sewing equipment, and solves the problem that the waist rope must be cut to a proper length before it can pass through an additional sewing device in the process of making both ends of the waist rope sewing. For the sewing process, the steps of replacing the waist rope need to be completed manually, which makes the sewing efficiency of the waist rope low, and the length detection, cutting and sewing process cannot be completed at one time. The waist rope end face of a waist rope tacking machine The sewing mechanism includes a limiting part; a limiting groove is set in the middle of the top surface of the limiting part, and an adjusting feeding part is fixedly connected to the right side of the top front end of the limiting part. The front and rear ends of the limiting groove are semicircular, and the limiting Scale values are set on both sides of the groove, which can cut the waist rope at a suitable position to ensure that the size of the waist rope conforms to the actual cutting size and avoid excessive errors. At the same time, it is sewed to improve production efficiency and avoid manual participation.

Owner:南通恒仟花边织带有限公司

Double clutch automatic speed transmission

ActiveCN101424328BSave spaceEasy to useToothed gearingsGearing detailsAutomatic transmissionGear wheel

The invention relates to a double-clutch automatic speed changer, which comprises an input shaft (31), an input shaft gear (1), a first auxiliary shaft (6), a second auxiliary shaft (8), an intermediate shaft (7), a power output device, at least one odd-shift gear pair, at least one even-shift gear pair, a first clutch (2) fixed on the first auxiliary shaft (6) and a second clutch (3) fixed on the second auxiliary shaft (8). The speed changer is characterized in that the power output device comprises a differential (29) and a planetary mechanism fixedly connected with the differential (29). The speed changer has the advantages that the speed changer is small in gear quantity, small in axial length, light in weight and easier to arrange and use in small-size front-wheel driven cars.

Owner:CHONGQING TSINGSHAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com