Linkage tool clamp

A tooling fixture and clamping mechanism technology, applied in the field of mechanical processing, can solve problems such as repeated clamping, affecting product production efficiency and product quality, so as to avoid clamping errors, improve production and processing efficiency and product quality, and improve product competition force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

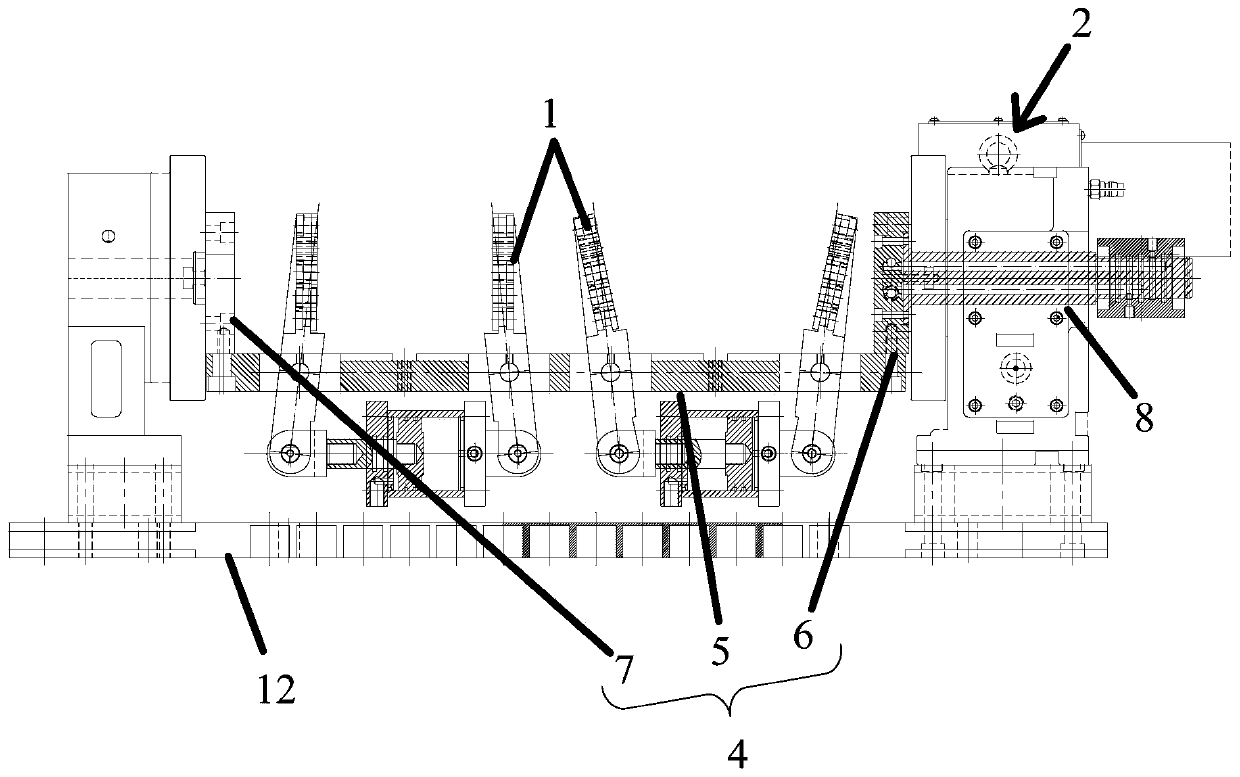

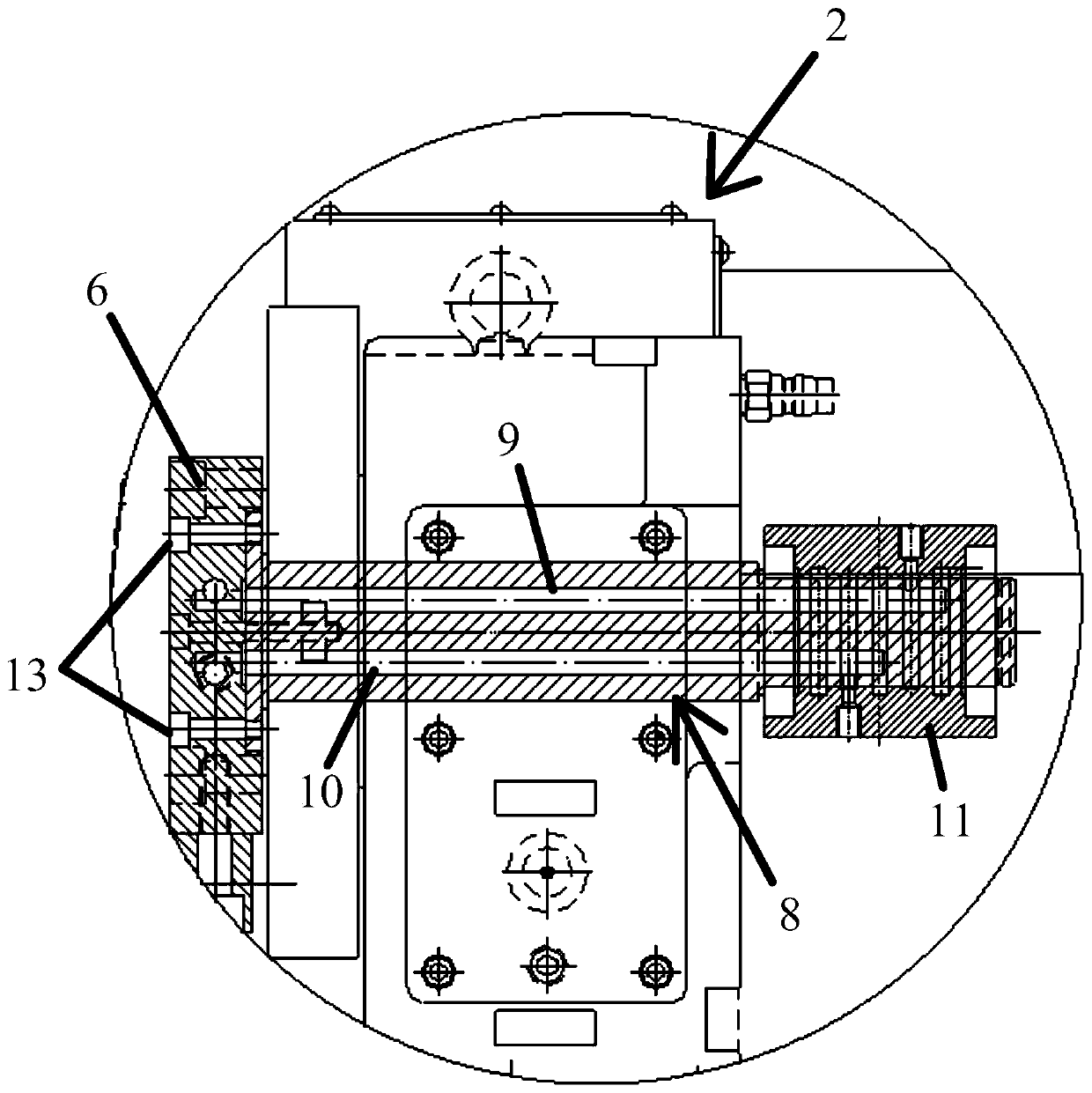

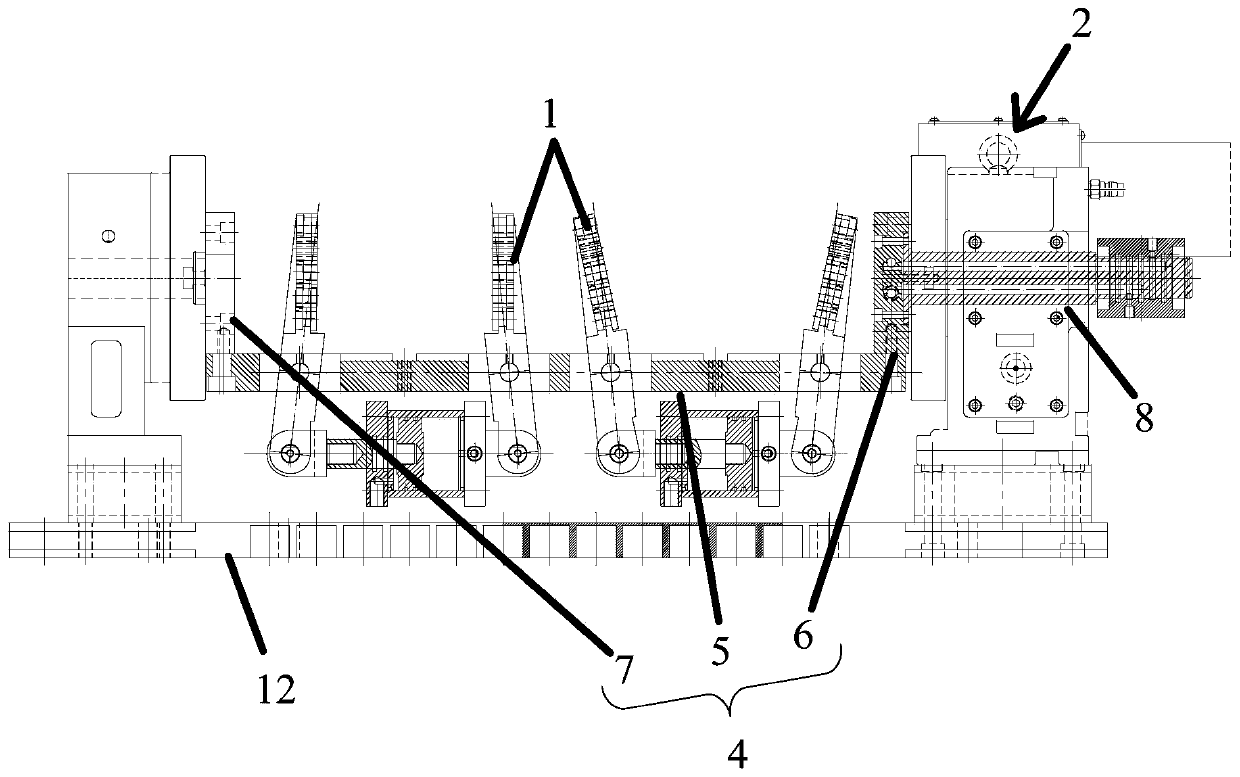

[0042] This embodiment provides a linkage fixture for processing sanitary ware, such as figure 1 shown, which includes:

[0043] The clamping mechanism 1 is a claw structure for clamping and fixing the parts of the sanitary ware. The above-mentioned claw structure is driven by hydraulic oil to clamp the parts of the sanitary ware. The clamping mechanism 1 driven by the hydraulic oil has a clamping mechanism. The advantages of stability and firmness;

[0044] The linkage mechanism 2 is connected with the clamping mechanism 1 and drives the clamping mechanism 1 to rotate in the vertical direction. The dial; the clamping mechanism 1 is installed on the turret 4 and the number is two. When processing parts such as sanitary ware, CNC machine tools and other processing equipment can process the X-axis and Y-axis in the horizontal direction of the parts, and the Z-axis in the vertical direction, and then drive the parts in the vertical direction through the linkage fixture. Rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com