Double clutch automatic speed transmission

A technology of automatic transmission and double clutch, which is applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problems of increasing the size, weight and price of the transmission mechanism, the number of transmission gears, and the difficulty of installing small cars, etc., to achieve saving Effects of layout space, compact structure, and reduction in the number of gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

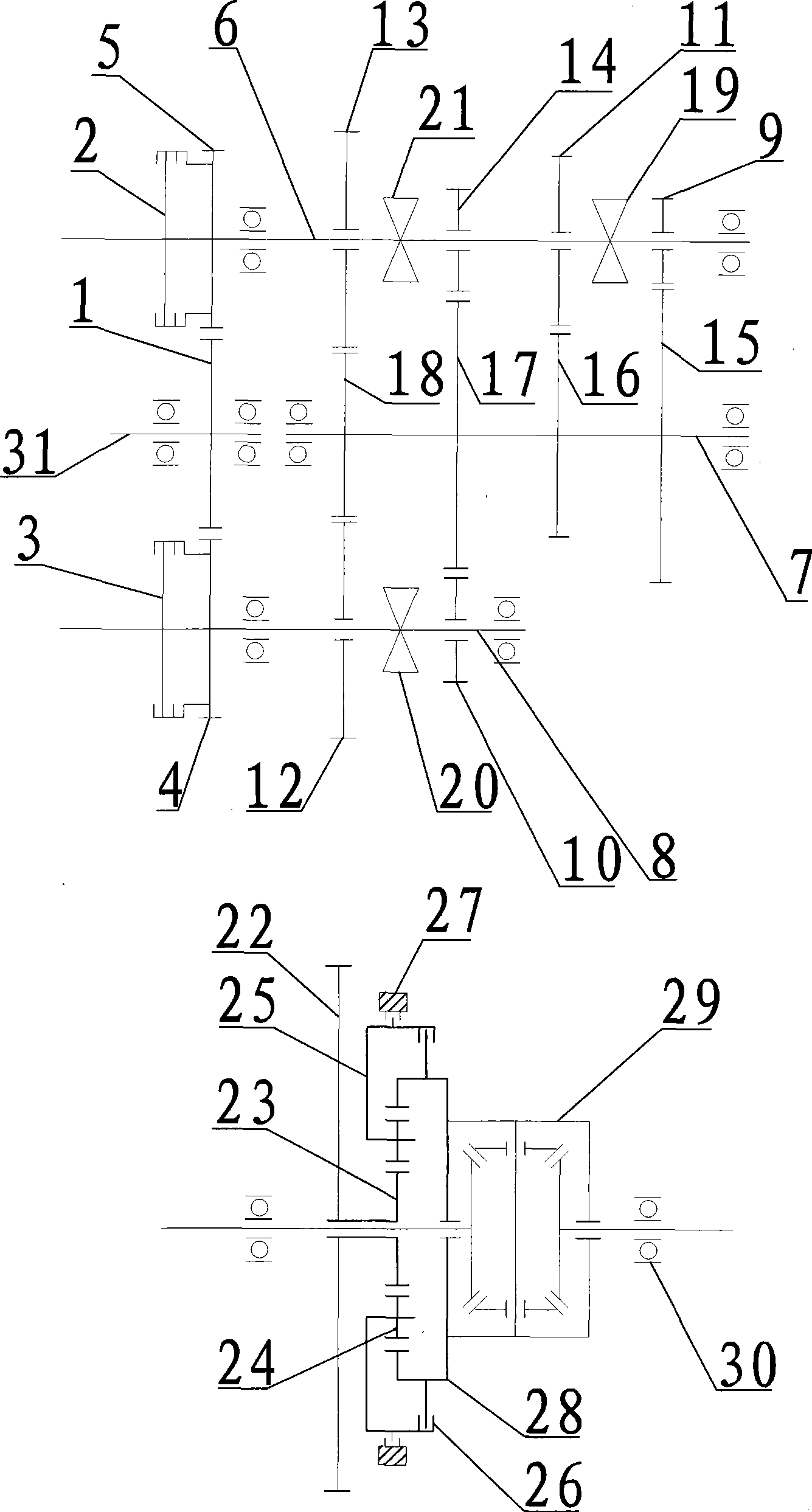

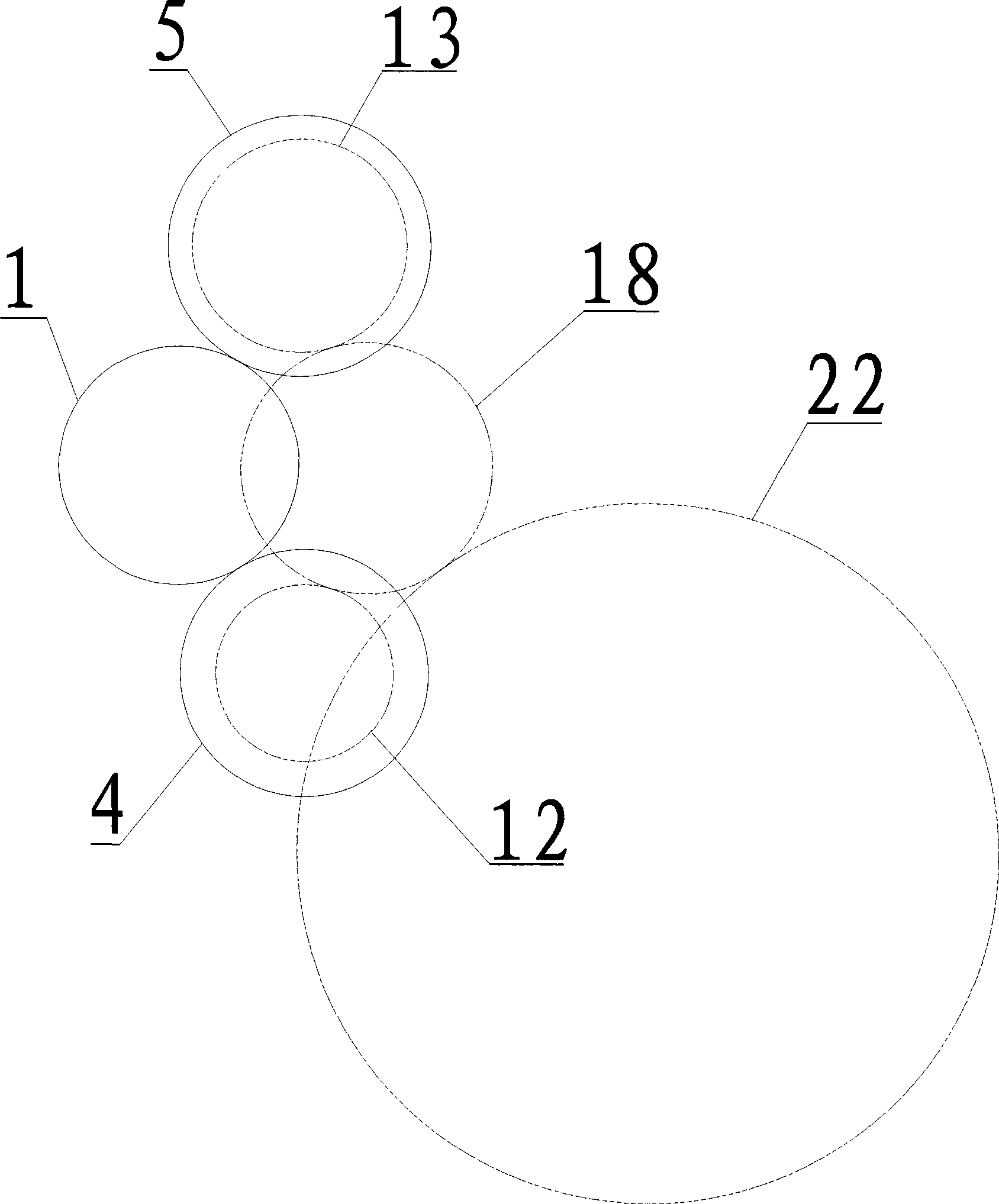

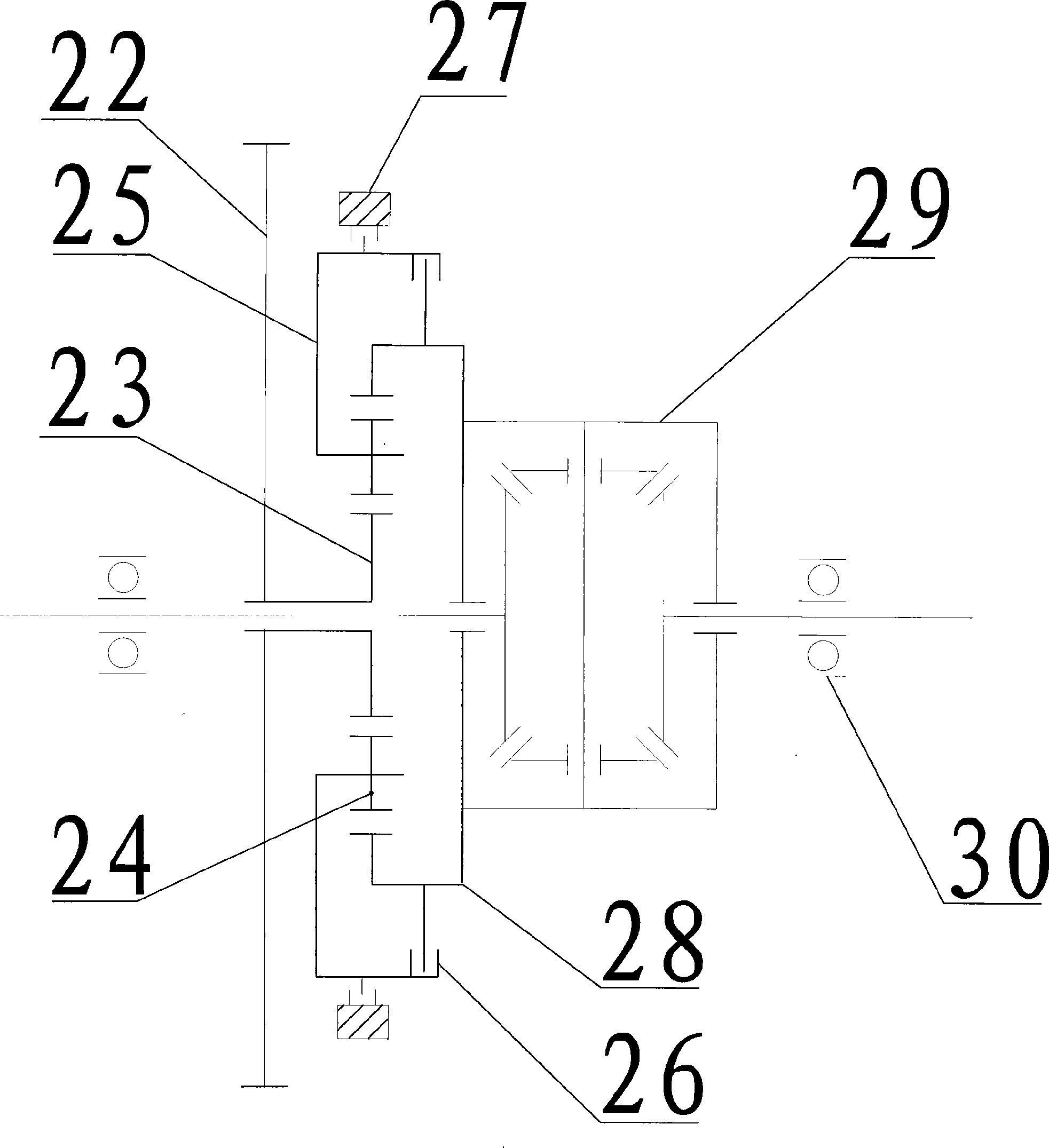

[0023] Embodiment 1: as figure 1 and figure 2 As shown, a dual-clutch automatic transmission includes an input shaft 31, an input shaft gear 1, a first countershaft 6, a second countershaft 8, an intermediate shaft 7, and a power output device, which are fixed on the first countershaft 6 The first clutch 2, the second clutch 3 fixed on the second secondary shaft 8, the power output device includes a differential 29, a planetary mechanism fixedly connected with the differential 29, the planetary mechanism Including sun gear 23, planetary gear 24, planetary input gear 22, ring gear 28 and planet carrier 25, a planet carrier brake 27 is connected between the planet carrier 25 and the housing of the transmission, and between the ring gear 28 The planet carrier clutch 26 is also connected between them; the planetary input gear 22 meshes with the driven gear on the intermediate shaft 7 and is fixed with the sun gear 23, and the ring gear 28 is fixed with the differential 29; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com