A hollow cup motor rotor polishing device

A technology of motor rotor and polishing device, which is applied in the direction of grinding/polishing equipment, parts of grinding machine tools, grinding feed movement, etc., which can solve the operation risks and constraints of occupying the operator's operating time and increasing the mechanical injury of the operator Coreless motor manufacturing cost and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

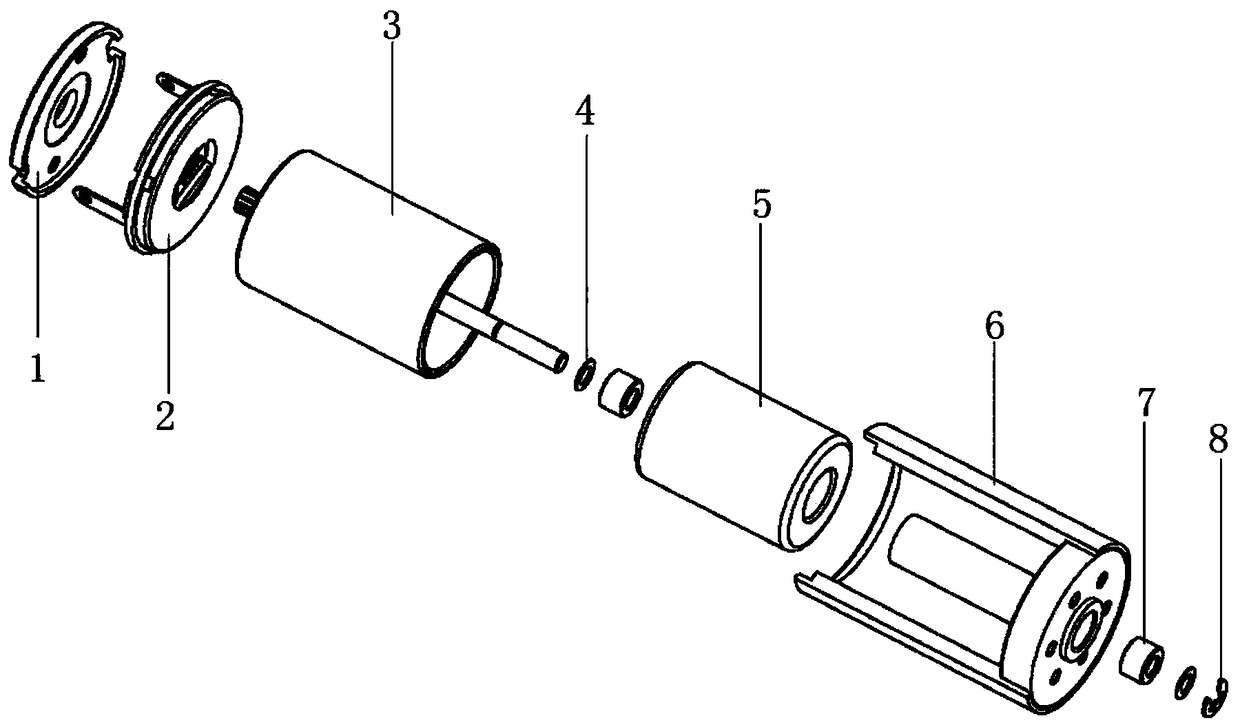

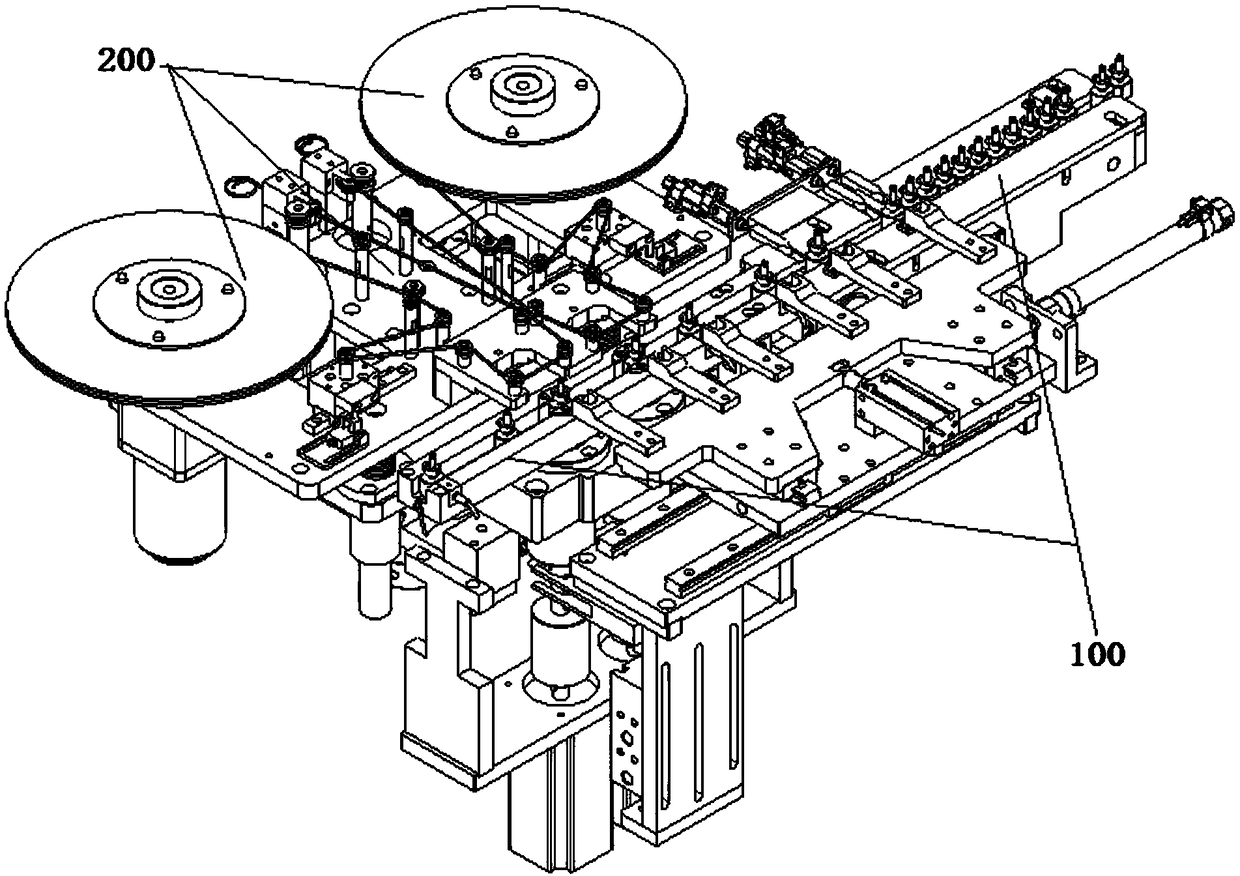

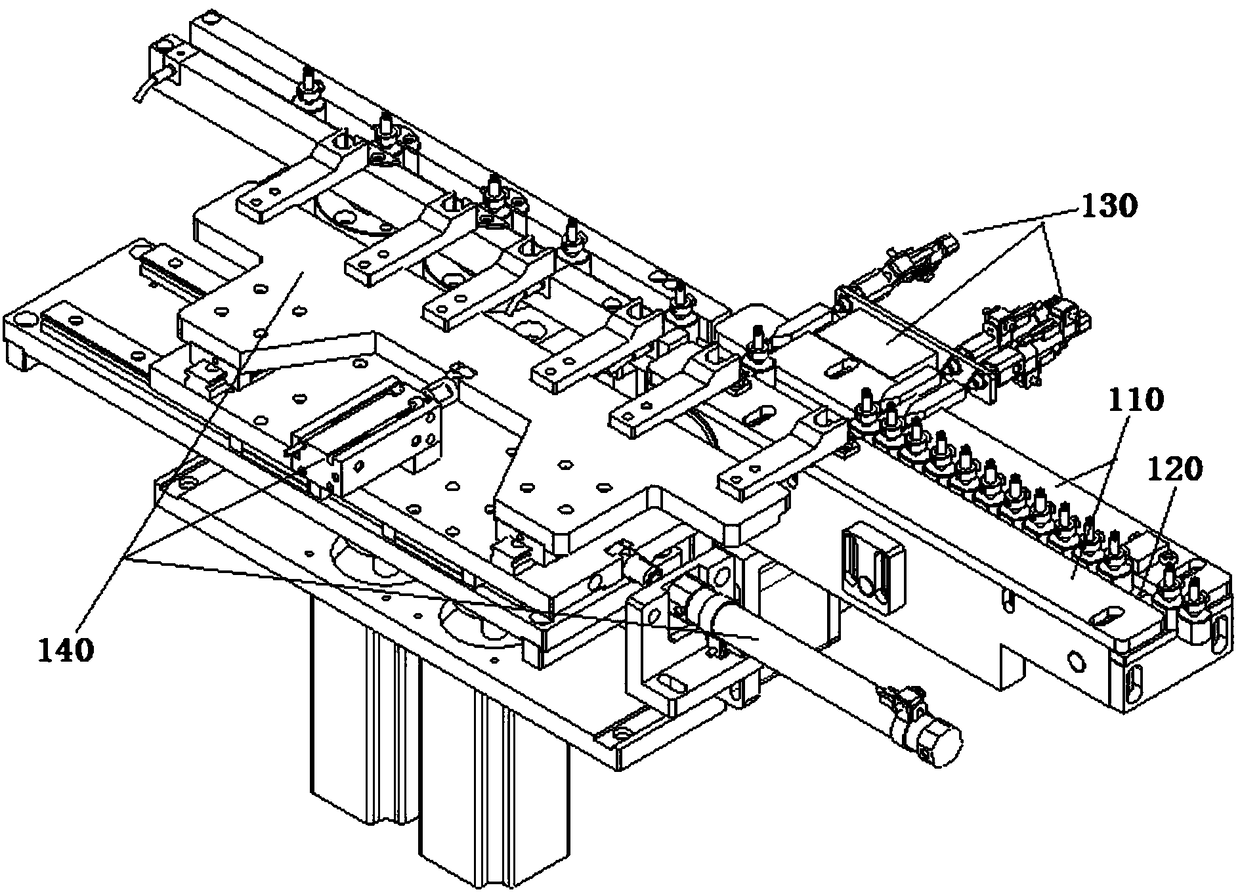

[0039] Such as figure 2 As shown, the present invention provides a hollow cup motor rotor polishing device, including: an automatic feeding device 100 and an automatic polishing device 200; image 3 and Figure 4 As shown, the automatic feeding device 100 includes: a track groove 110, a conveyor belt 120, a material level positioning device 130 and a material shifting device 140; the track groove 110 is composed of two parallel guide plates, and the conveyor belt 120 is arranged directly below the track groove 110; the material level positioning device 130 includes several actuator cylinders 131 fixed on one side of the track groove, and the action end is fixed with a blocking block 132; the blocking block 132 has a degree of freedom of movement for blocking the material running in the track groove; the material shifting device 140 includes: a shifting disc 141 provided with several shift forks 142, and driving the shifting disc 141 in contact with the The tray driving devi...

Embodiment 2

[0045] Figure 10 As shown, in this embodiment, on the basis of Embodiment 1, the base plate 221 is provided with a polishing tape automatic feeding device 240; the polishing tape automatic feeding device includes: a polishing tape feeding tray 241, a polishing tape guide wheel 242 and a polishing tape Belt receiving device 243; the base plate is fixed with a rotary shaft 244, the rotary shaft 244 is provided with the polishing tape material tray 241; the polishing tape receiving device 243 is provided with a polishing tape receiving gear 245 and The polishing belt receiving gear stepping motor 246 that drives the polishing belt receiving gear 245 to rotate; the polishing belt 223 is guided by the polishing belt guide wheel 242 after being drawn out from the polishing belt material tray 241 to the Polishing belt receiving device 243; the output end of the polishing belt receiving gear stepping motor 246 is fixedly provided with a driving gear 247 meshing with the polishing bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com