Brushing device

A brushing and coating technology, which is applied in the direction of construction and building construction, etc., can solve the problems of inconvenient brushing on the inner and outer walls of pipes, etc., and achieve the effects of convenient and easy disassembly, wide application range, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

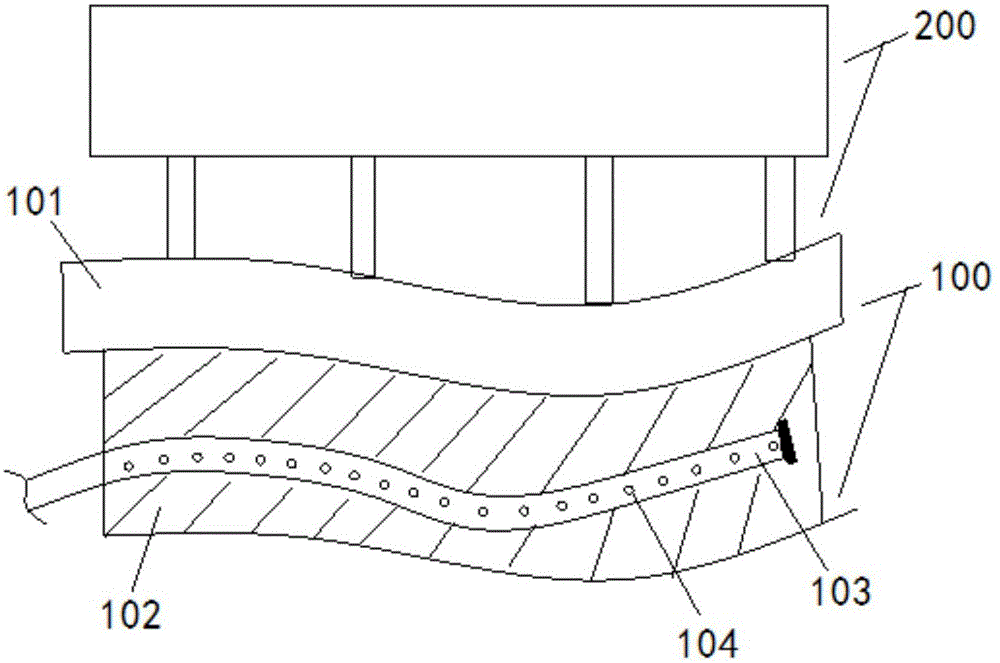

[0030] Without loss of generality, as figure 1 As shown, the present invention provides a brushing device, including: a flexible brush body 100 and a brushing surface shape adjustment mechanism 200; wherein,

[0031] The flexible brush body 100 includes: a flexible elastic piece 101 and a cleaning block 102 fastened on the flexible elastic piece; a paint delivery pipe 103 is arranged in the form of a package in the cleaning piece; The wall is distributed with several fine pores 104 connected with the pipes, the diameter of which matches the particle size of the paint;

[0032] The brushing surface profile adjustment mechanism 200 is firmly connected with the flexible brush body 100; there is at least one surface on the cleaning block as a cleaning surface; At least one of end extrusion force, middle push force and middle pull force is used to change the surface shape of the cleaning surface.

[0033] During use, only need to connect the paint delivery pipe 103 with the disch...

Embodiment 2

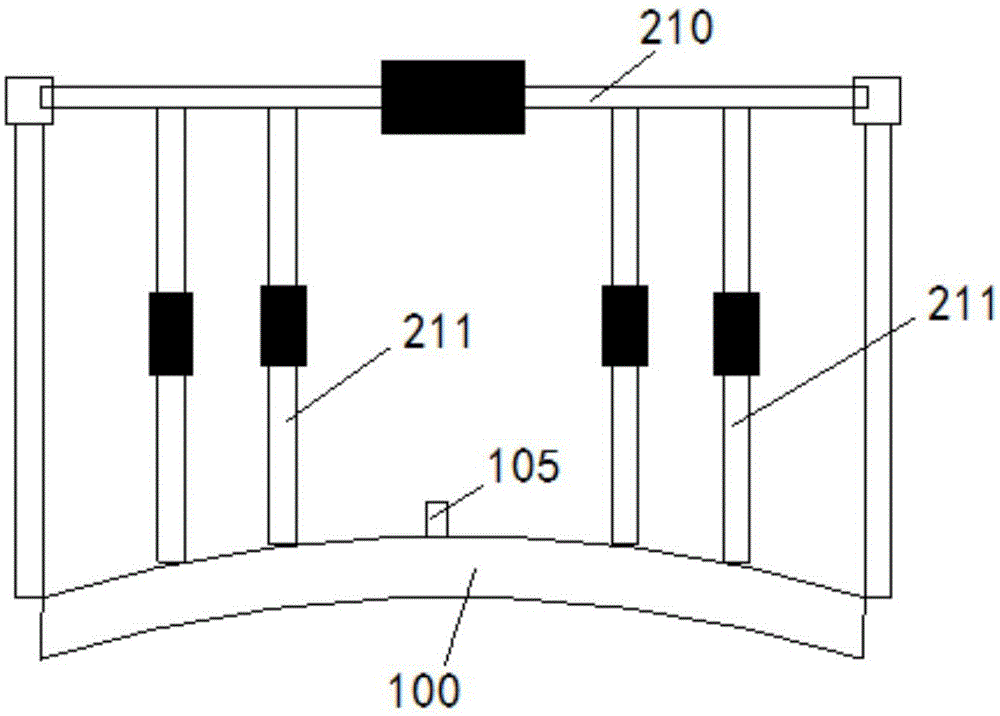

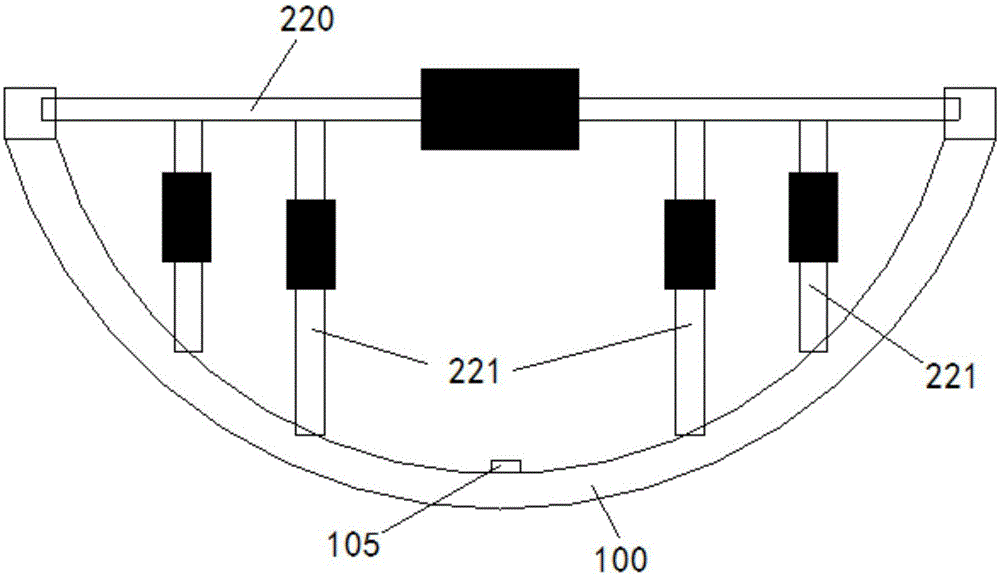

[0038] In the present invention, on the basis of the above-mentioned embodiments, the brushing surface adjustment mechanism is a concave surface adjustment mechanism or a convex surface adjustment mechanism; the concave surface is adapted to the curved surface of the outer wall of the pipeline; compatible with the surface.

[0039] preferred, such as figure 2 As shown, in a preferred technical solution of this embodiment, the concave surface adjustment mechanism includes: a C-shaped truss 210 with adjustable opening spacing at both ends, and is arranged on the C-shaped truss 210, one end of which is connected to the Several push-pull surface adjustment rods 211 fastened to the C-shaped truss; the length of the push-pull surface adjustment rod 211 can be adjusted; the two ends of the C-shaped truss 210 and the push-pull surface adjustment rod 211 The other ends of each are fastened to the flexible brush body 100 respectively.

[0040] It should be noted that, in this embodim...

Embodiment 3

[0048] Further, on the basis of the above embodiments, the present invention further includes an extension rod; the extension rod is firmly connected with the brushing surface profile adjustment mechanism. The setting of the extension rod provides structural technical support for hand-held brushing.

[0049] Preferably, in a preferred technical solution of this embodiment, the structure of the extension rod is a telescopic rod with a length adjustment function, so as to provide further structural support for brushing with different heights or lengths.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com