Pole mounting system having unique base and method of assembly thereof

A technology for installing systems and base plates, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of increasing the cost of column installation structures and the time required for installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

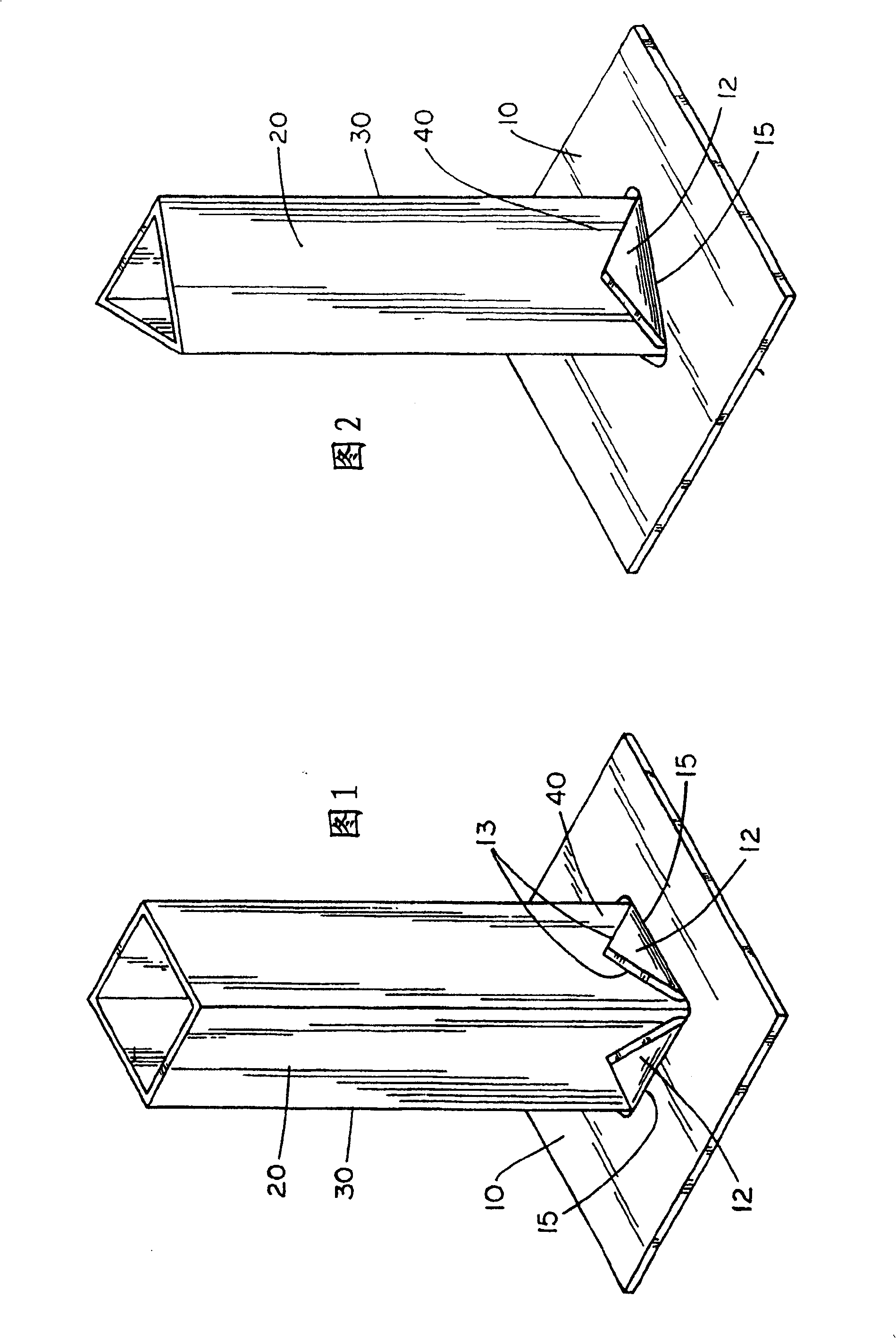

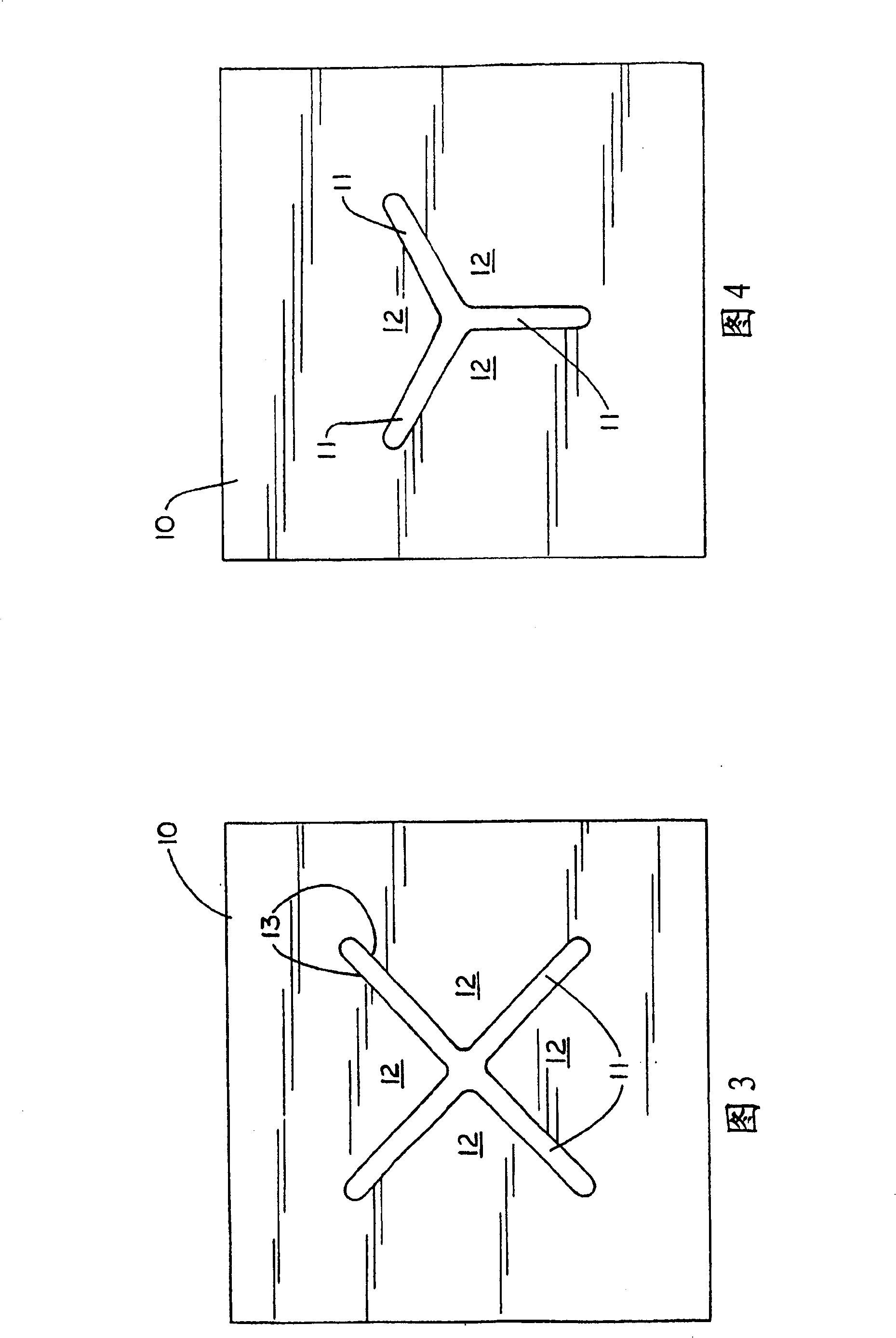

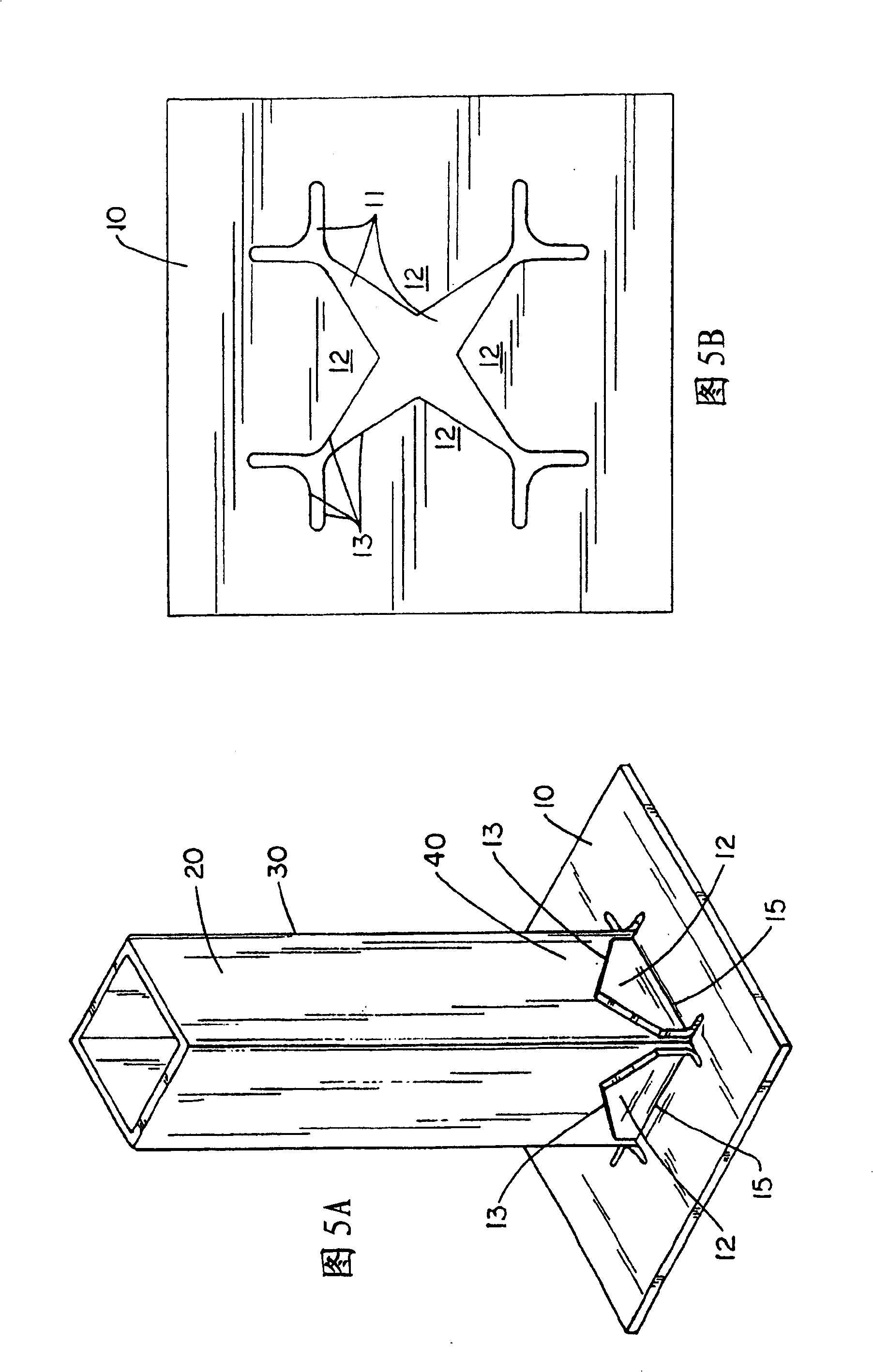

[0049] Referring to FIG. 1 , a post mounting system according to the present invention is generally indicated by the reference numeral 30 . Post mounting system 30 connects lower end 40 of post 20 to base plate 10 to provide improved structural support. The pillars 20 have a quadrilateral cross-section, are preferably metallic, and are preferably hollow. Depending on the use of the vertical member, wiring or conduits may run through the column 20 .

[0050] As shown, substrate 10 is preferably metallic, oriented generally perpendicular to posts 20 . Four lugs 12 (two not shown) are connected to base plate 10 at joints 15 . The lugs 12 are aligned in vertical alignment with the post 20 and are welded to the lower end 40 along at least a portion of the upper edge 13 . The junction 15 defines an opening in the substrate 10 in which the post 20 is disposed. Optionally, the lower end 40 may be further connected to the base plate 10 by welding along at least a portion of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com