Automated folding-type corner protecting ring producing line

A corner protector and production line technology, applied in the field of machinery, can solve problems such as low efficiency, and achieve the effect of avoiding uneven forming and angle deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

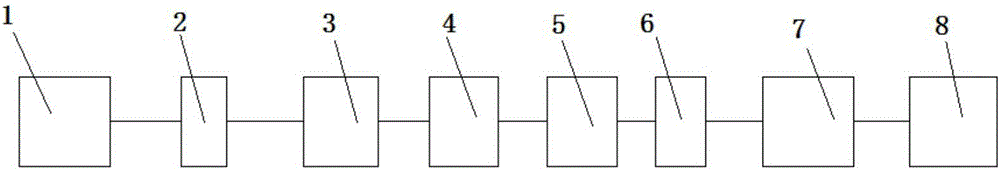

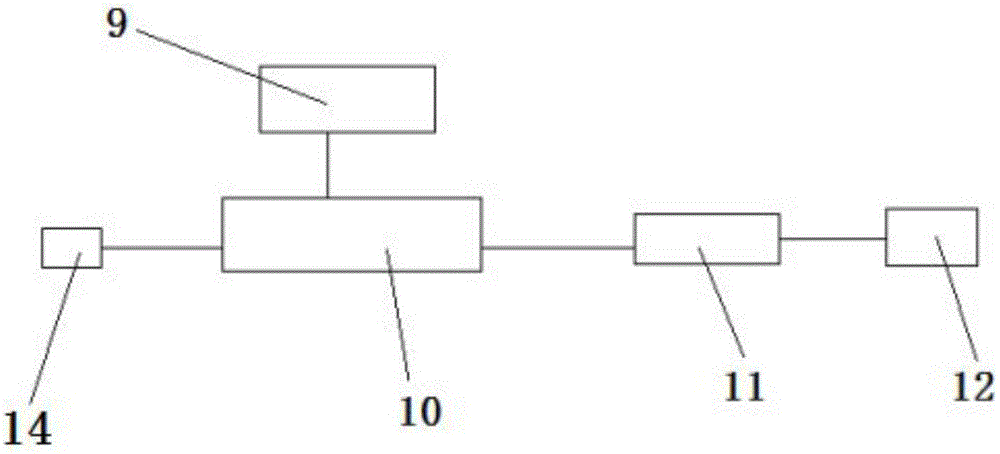

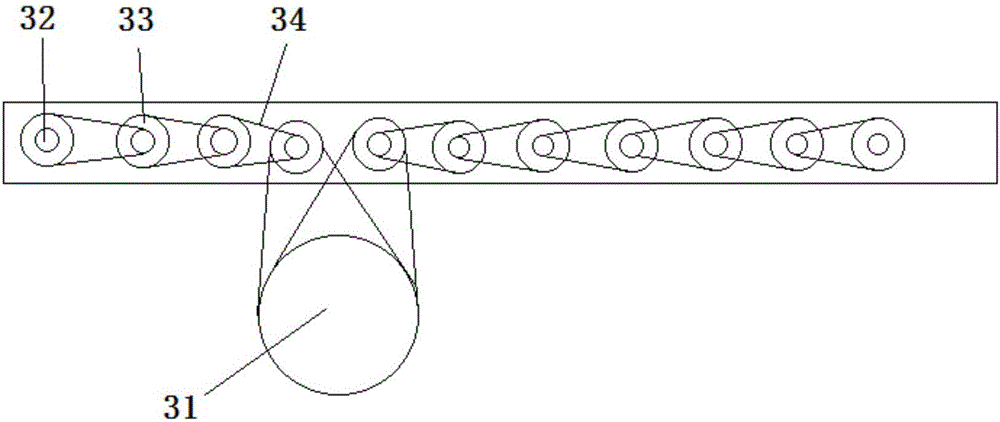

[0021] The present invention is described in detail below in conjunction with accompanying drawing, as shown in the figure, the present invention comprises unwinding machine 1, joint spot welding machine 2, folding rolling mill 3, punching machine 4, right-angle rolling mill 5, servo spot welding machine 6, Servo shearing machine 7 and forming machine 8; Also comprise control device, described control device comprises PLC10, motor controller 11, encoder 14, induction contact 19 and display device 9; Described unwinding machine comprises motor 12 drives Pulley, the steel belt is wound on the belt pulley; the motor is connected with the motor controller 11, the motor controller 11 is connected with the PLC10, the induction contact 19 is arranged on the bottom of the steel belt 13, and whether the induction contact 19 is connected with the The contact signal of steel belt 13 is transmitted to PLC10, and PLC10 controls whether the motor rotates through the motor controller accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com