Waist rope end face sewing mechanism of waist rope bar tacking machine

A tacking machine and waist rope technology, which is applied to sewing units, sewing machine components, cloth feeding mechanisms, etc., can solve the problems of low waist rope efficiency, inability to complete the length detection, cutting and sewing process at one time, so as to avoid knotting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

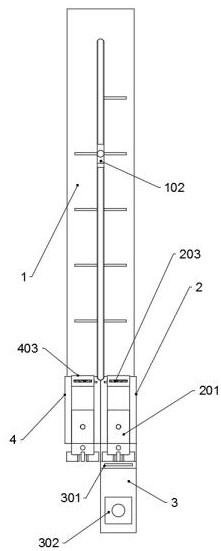

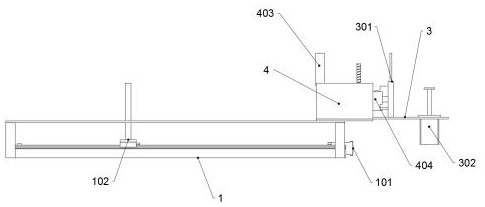

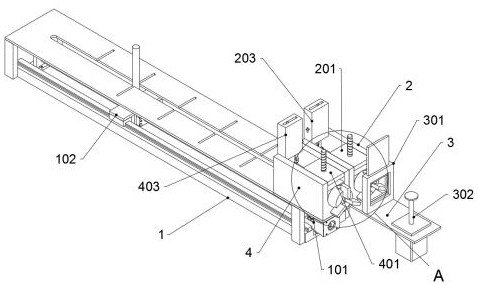

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035]The invention provides a waist rope end face sewing mechanism of a waist rope nosing machine, which includes: a limiting part 1; a limiting groove is provided at the middle position of the top surface of the limiting part 1, and the right side of the top front end of the limiting part 1 is fixedly connected with an adjustment Feeding part 2; the adjusting feeding part 2 is in the shape of a square, a fan-shaped groove is opened at the rear end of the left side of the adjusting feeding part 2, and the inner front position of the adjusting feeding part 2 is fixedly connected with a connecting plate A201, and a threaded hole is opened in the middle of the connecting plate A201 ;Adjust feeding part 2 includes: pressing plate A202, pressing plate A202 has a rectangular shape, and the top middle position of pressing plate A202 is rotatably connected with a screw, and the upper end screw of pressing plate A202 is rotatab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com