Heavy-type inverted studded thread bolt mounting tooling and use method of same

A technology for installing tooling and flipping, which is used in manufacturing tools, trucks, transportation and packaging, etc., can solve the technical difficulty of increasing the installation of heavy-duty flip-wire bolts, and it is difficult to meet the installation requirements of heavy-duty flip-wire bolts. It can improve the flexibility and practicability, the structure is simple, and the versatility is enhanced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

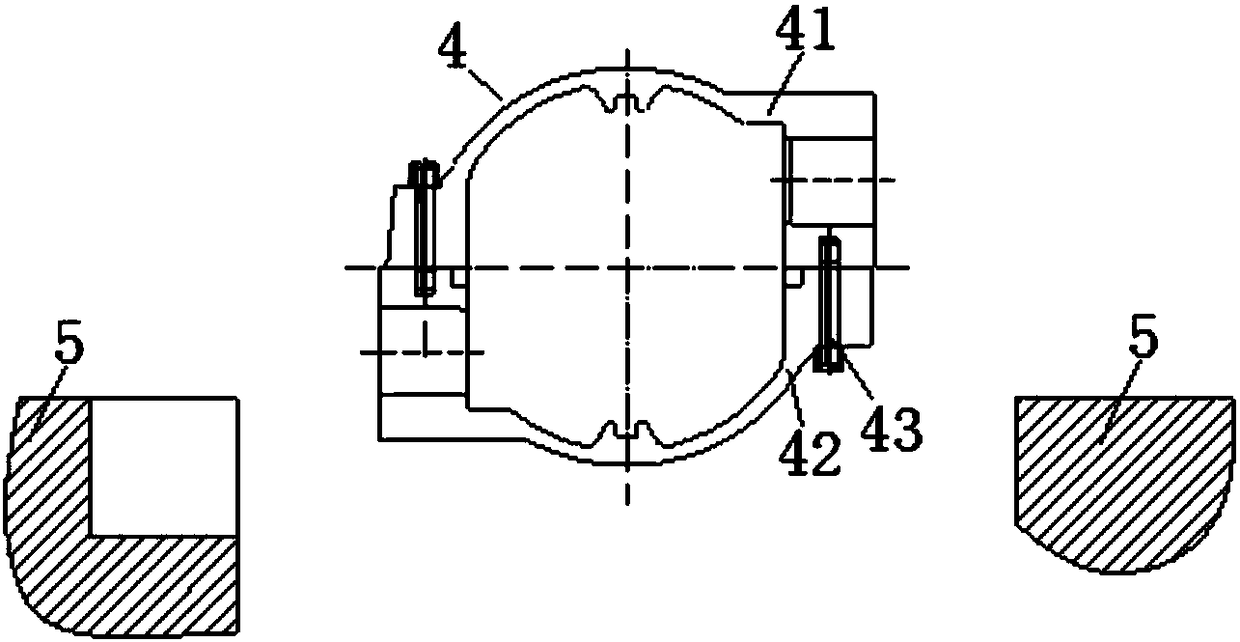

[0034] see figure 1 As shown, in the design structure of the steam turbine cylinder with horizontal tangential steam inlet valves on both sides of the cylinder, the steam turbine is arranged on the installation base 5; the steam inlets of the cylinder 4 on the installation base 5 are generally set to two, and the steam turbine on the cylinder Half 41 and cylinder lower half 42 are each provided with one. For the structure in which the steam inlet is located in the upper half 41 of the cylinder, there is an upside-down screw bolt 43 between the mid-section planes of the upper half 41 and the lower half 42 of the cylinder, based on which the upside-down screw bolt 43 is a typical heavy-duty bolt , its installation on the cylinder 4 requires the help of the following installation tools.

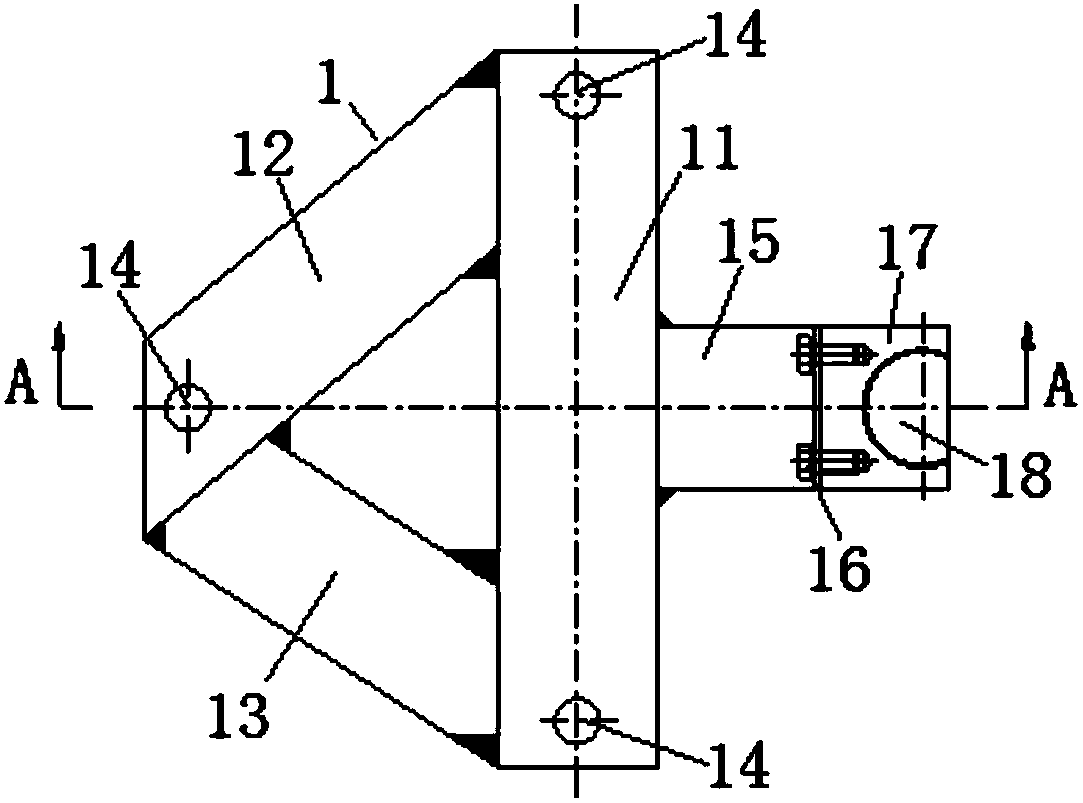

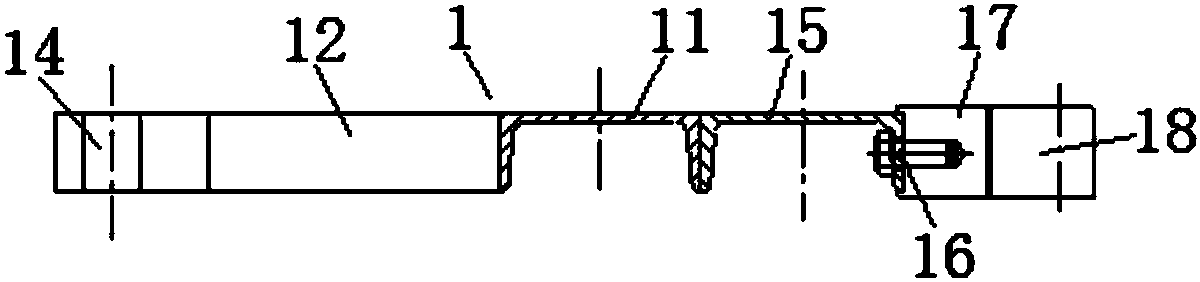

[0035] see figure 2 and image 3 As shown, the installation tools required for the installation of the above-mentioned heavy-duty upside-down bolts 43 on the cylinder 4 include a lifting fra...

Embodiment 2

[0052] In the design structure of the steam turbine cylinder with horizontal tangential steam inlet valves on both sides of the cylinder, the steam turbine is arranged on the installation base; the steam inlet of the cylinder on the installation base is generally set to two, the upper half of the cylinder and the lower half of the cylinder respectively. set one up. For the structure in which the steam inlet is located in the upper half of the cylinder, there is an upside-down screw bolt between the upper half of the cylinder and the mid-section of the lower half of the cylinder. The installation requires the help of the following installation tools.

[0053] The above-mentioned installation tools required for the installation of the above-mentioned heavy-duty upside-down bolts on the cylinder include lifting brackets, auxiliary bolts and wrenches.

[0054] Wherein, the lifting frame has a main girder, an auxiliary girder, a joint and a splint.

[0055] The main girder is a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com