Environment engineering solid waste treatment equipment

A solid waste and processing equipment technology, applied in grain processing, clay preparation equipment, chemical instruments and methods, etc., can solve the problems of high manufacturing cost and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

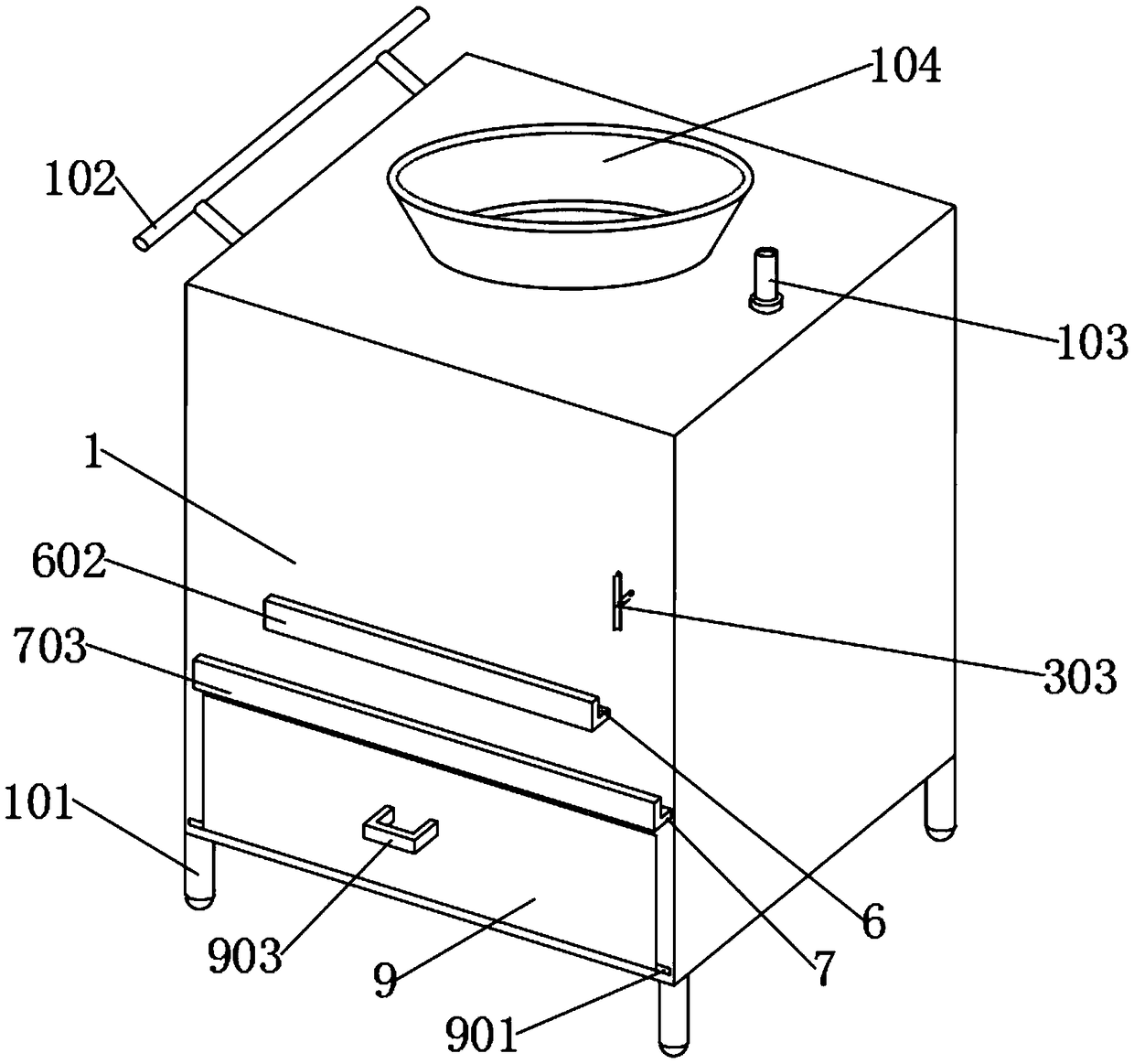

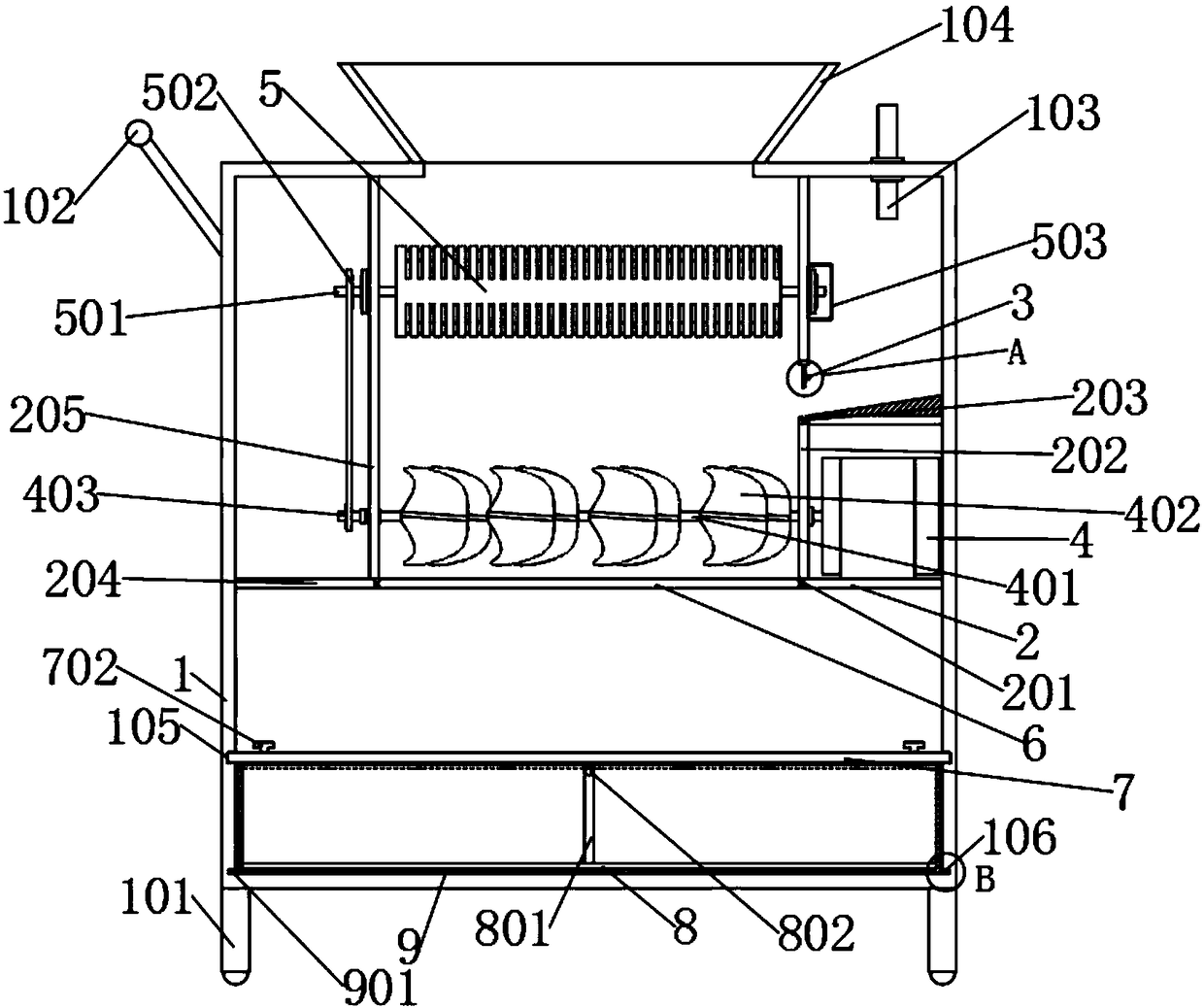

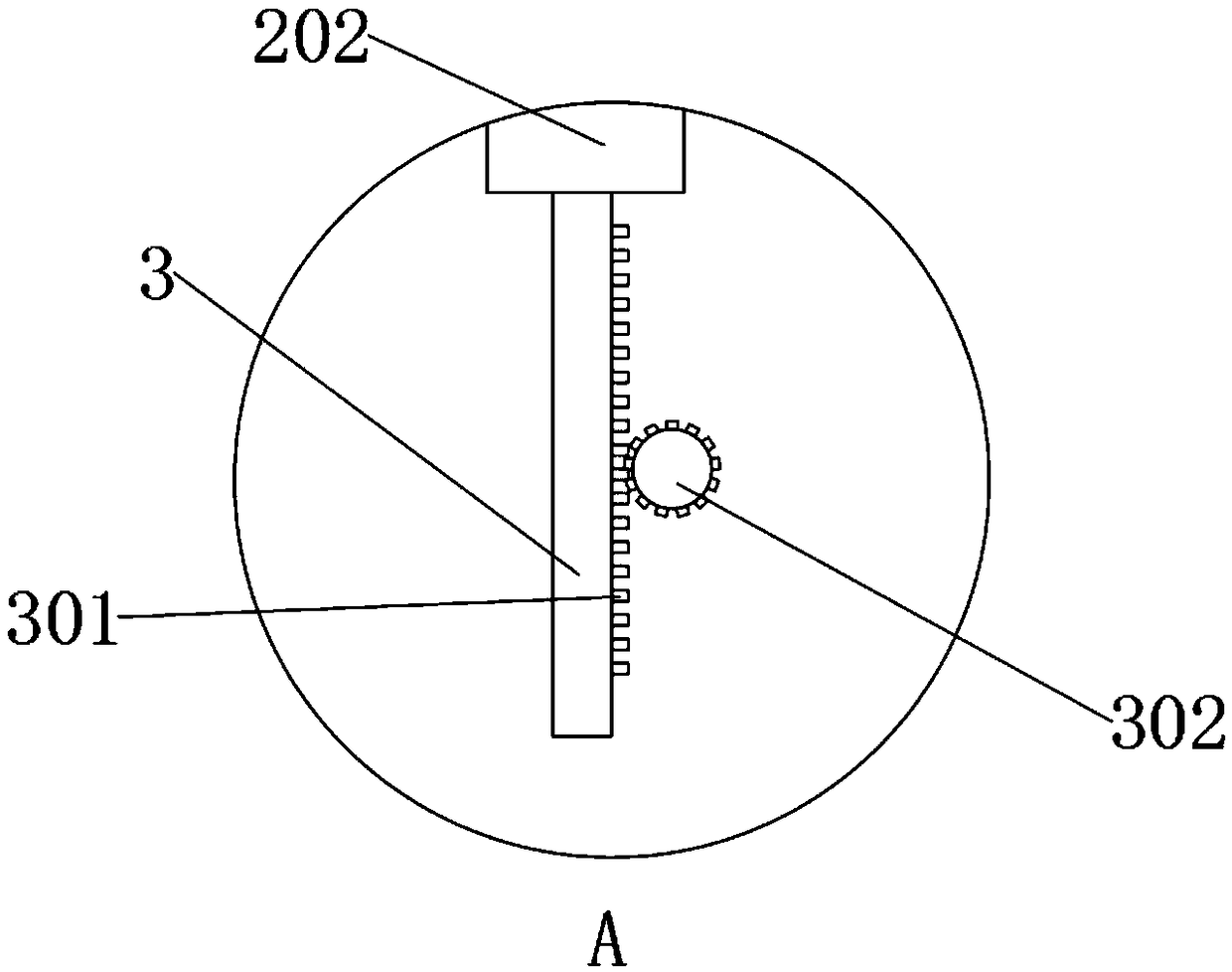

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032]The invention provides a solid waste treatment equipment for environmental engineering, which includes: a main body 1, a universal wheel 101, a push rod 102, a water inlet 103, a feeding port 104, an insertion groove 105, a sliding groove 106, a right layer plate 2, a sliding Groove 201, right vertical plate 202, sealing groove 203, left layer plate 204, left vertical plate 205, sealing plate 3, moving latch 301, moving gear 302, rotating handle 303, motor 4, transmission shaft 401, stirring blade 402 , connecting gear 403, crushing piece 5, crushing shaft 501, crushing gear 502, protective cover 503, baffle plate 6, sliding piece 601, pulling plate 602, moving plate 7, groove 701, blocking piece 702, pulling piece 703, to undertake Plate 8, vertical rod 801, insertion hole 802, pull rod 803, collection bin 9, guide plate 901 and pull piece 902; main body 1 has a rectangular internal hollow structure, and the bot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap