Pay-off retainer and use method thereof

A technology of retainer and pay-off reel, applied in the field of electric power, can solve the problems of too fast speed, too loose winding of the reel, affecting use, etc., and achieve the effect of maintaining balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

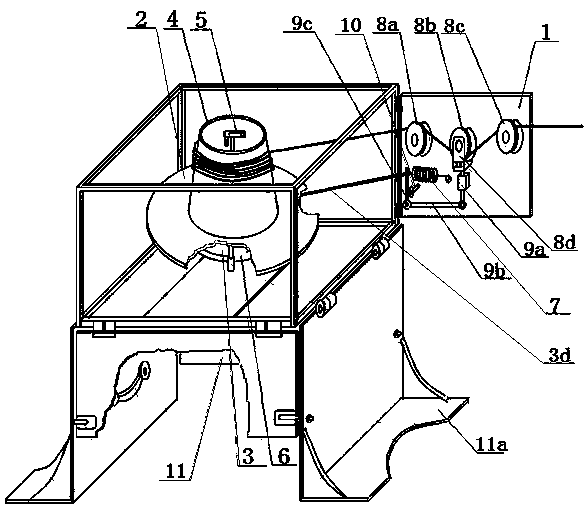

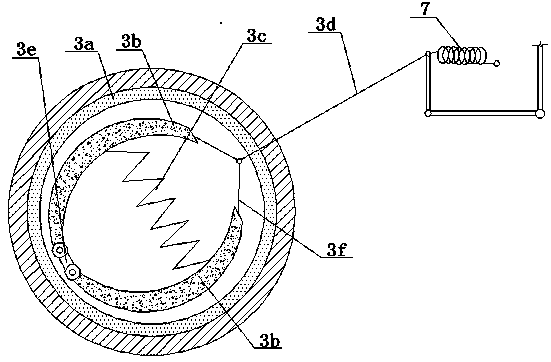

[0034] Such as figure 1 As shown, a pay-off holder includes an operating box, a pay-off part, and a tension control part. One side of the operating box is provided with an openable and closeable operating door 1, and the pay-off part is arranged in the operating box. The pay-off part includes pay-off reel 2 and brake mechanism 3. The top of the pay-off reel is provided with a spool 4, the bottom of the pay-off reel 2 is fixed on the bottom surface of the operating box by a rotating shaft 6, and the upper end of the rotating shaft is connected with the rotating handle 5 is connected, the rotating handle 5 is arranged in the wire support 4, the rotating handle in this embodiment is a folding rotating handle with a folding joint, the braking mechanism 3 is arranged on the shaft, the braking mechanism 3 includes a brake drum 3a, a brake pad 3b, a return spring 3c and a brake rib 3d. The brake drum 3a is installed on the inner wall of the shaft 6 to rotate with the shaft. Two brake p...

Embodiment 2

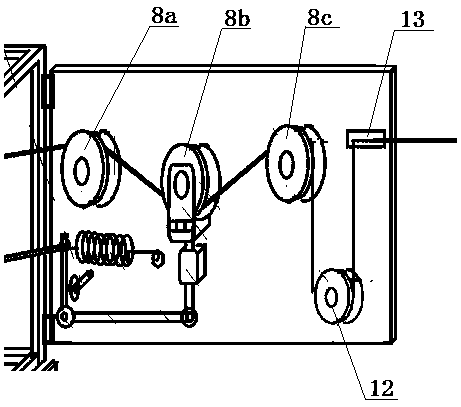

[0042] The difference between this embodiment 2 and embodiment 1 lies in: on the basis of embodiment 1, a wire take-up pulley 12 and a wire clamp 13 are added, and the wire take-up pulley 12 is fixed on the operating door and is located on the second bearing On the lower side of the force pulley 8c, the second force-bearing pulley 8c and the wire take-up pulley 12 are matched up and down; the wire clamp 13 is fixed at the outer end of the operating door, and the position of the wire clamp 13 and the wire take-up pulley 12 is up and down In cooperation, a semi-open C-shaped wire clamping groove is provided on the wire clamping device 13, and the opening degree of the wire clamping groove is adjustable; the sensing pulley 8b is connected to the pulley frame via the axle, and one end of the axle is blocked by the sliding block, The other end of the axle is blocked by an adjusting plug.

[0043] The use method of this embodiment 2 includes the following steps:

[0044] 1) Preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com