Rotating assembly and support

A technology for rotating components and connectors, applied in the direction of machine/support, connecting member, supporting machine, etc., can solve problems such as cable exposure, cable damage, and excessive twisting of cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

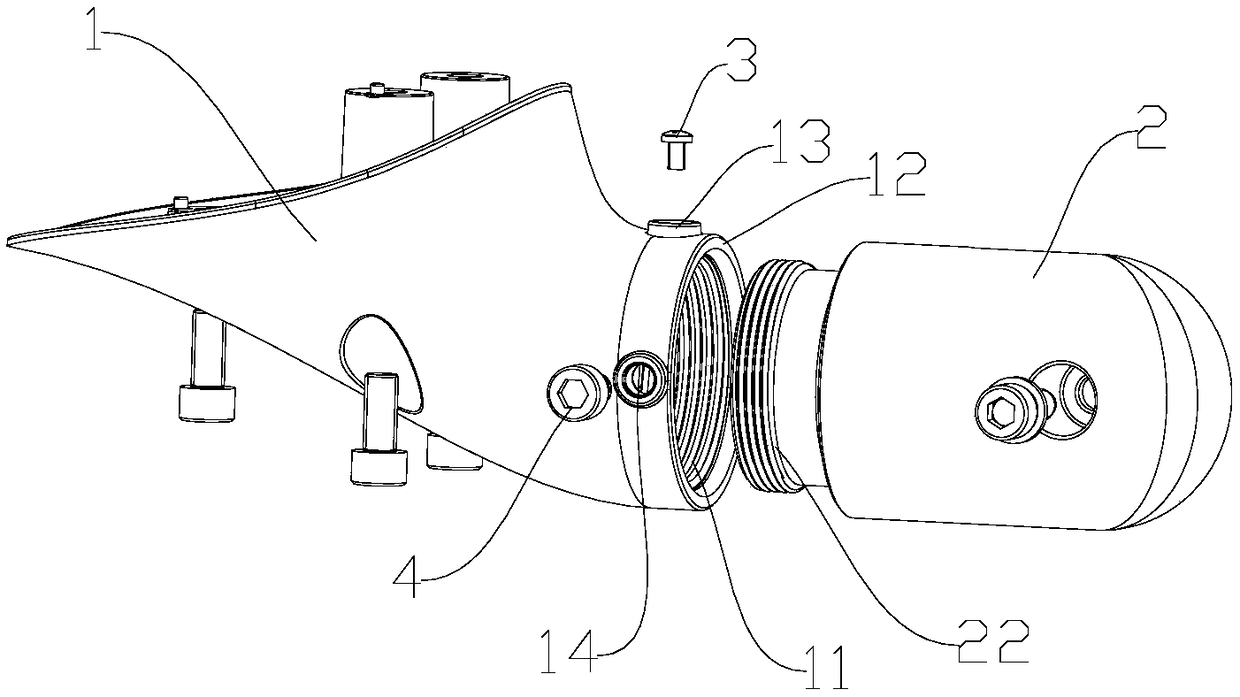

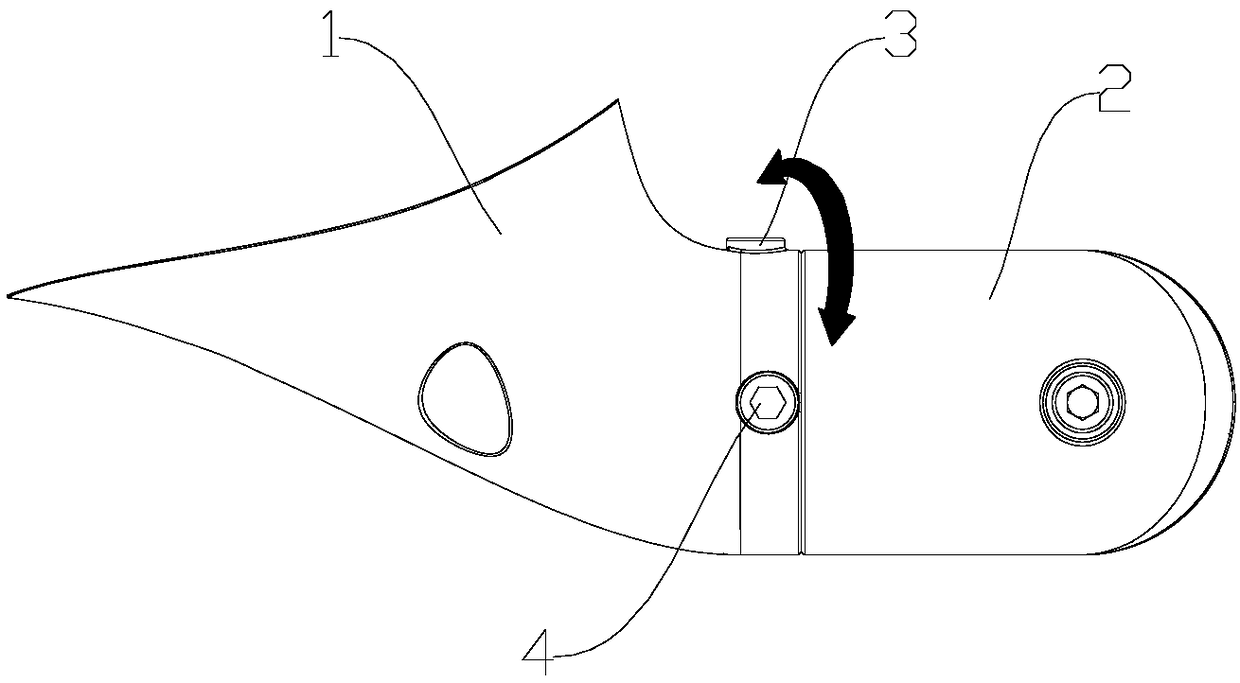

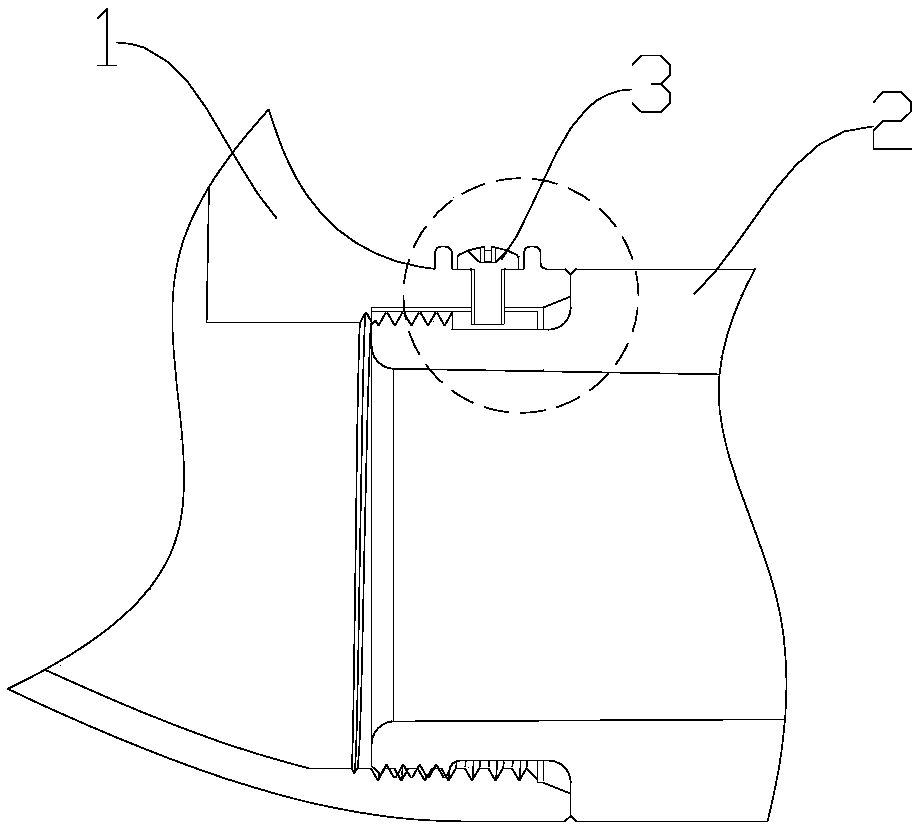

[0052] On the one hand, the embodiment of the present invention provides a rotating assembly, the rotating assembly includes a first connecting piece, a second connecting piece and a limiting structure;

[0053] Wherein, the end surface of the first end of the first connecting piece has a connecting hole, and the inner wall of the connecting hole has an internal thread; the outer circumference of the first end of the second connecting piece has an external thread for cooperating with the connecting hole; the limiting structure It is arranged on the first connecting piece and the second connecting piece, and is used for limiting the maximum rotation angle between the first connecting piece and the second connecting piece to 360° when the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap