Cable-trench cover plate

A technology of cable trench cover and cover plate, which is applied in the direction of cable installation, ground cable installation, electrical components, etc. It can solve the problems of poor waterproof and anti-skid effect, low installation efficiency, and easy theft of cables, so as to improve the safety of use , The installation efficiency is improved, and the sealing effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

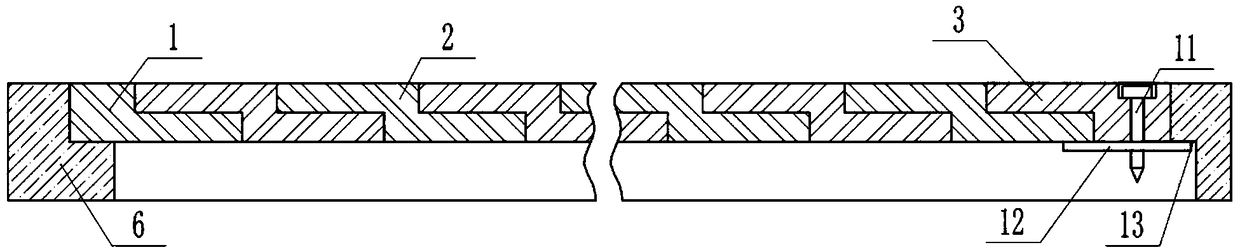

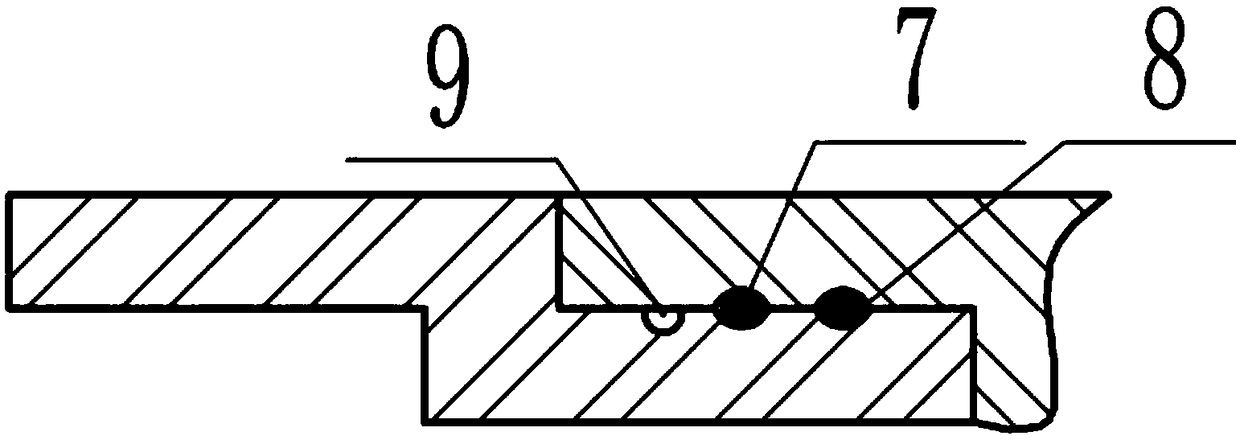

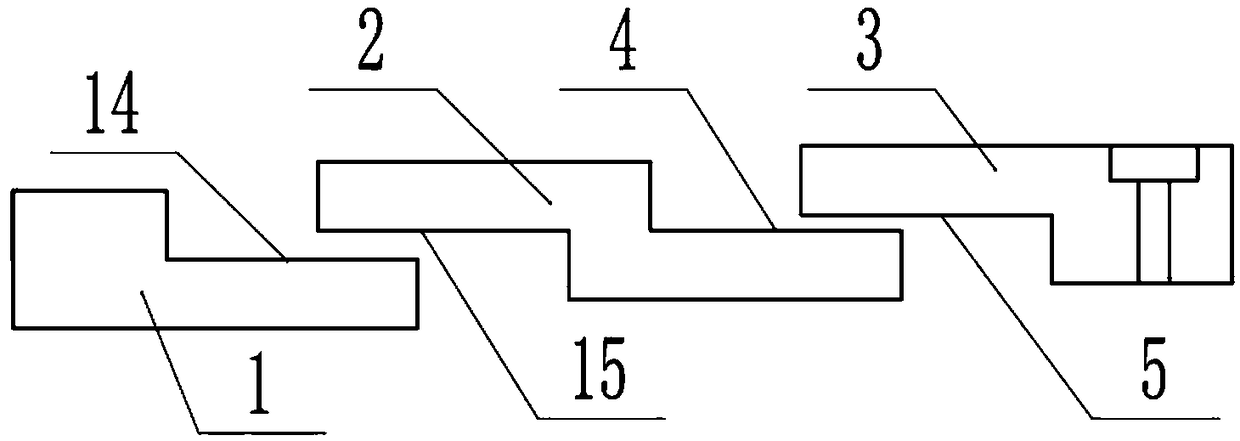

[0023] Example 1: as Figure 1-Figure 4 As shown, a cable trench cover includes a start cover 1, an intermediate cover 2 and a termination cover 3 that are sealed and installed on the placement groove 6. The upper right end of the start cover 1 is provided with a first notch step 14, The middle cover plate 2 has a vertically bent zigzag structure, the bottom of the left end is provided with a second gap step 15, the upper side of the right end is provided with a third gap step 4, the second gap step 15 is crimped on the first gap step 14 and the second gap The left end of the step 15 is closely abutted on the left end face of the first notch step 14, and the middle cover plate 2 is made of multiple pieces, and the adjacent two pieces are crimped on the third notch step 4 through the second notch step 15, terminating the bottom of the left end of the cover plate 3. A fourth notch step 5 is provided, the fourth notch step 5 is crimped on the third notch step 4 at the right end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com