Manual hydraulic press with adjustable height

A manual, adjustable technology, used in punching machines, presses, manufacturing tools, etc., to solve problems such as high flexibility requirements, inconvenient movement, and rigid hydraulic presses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

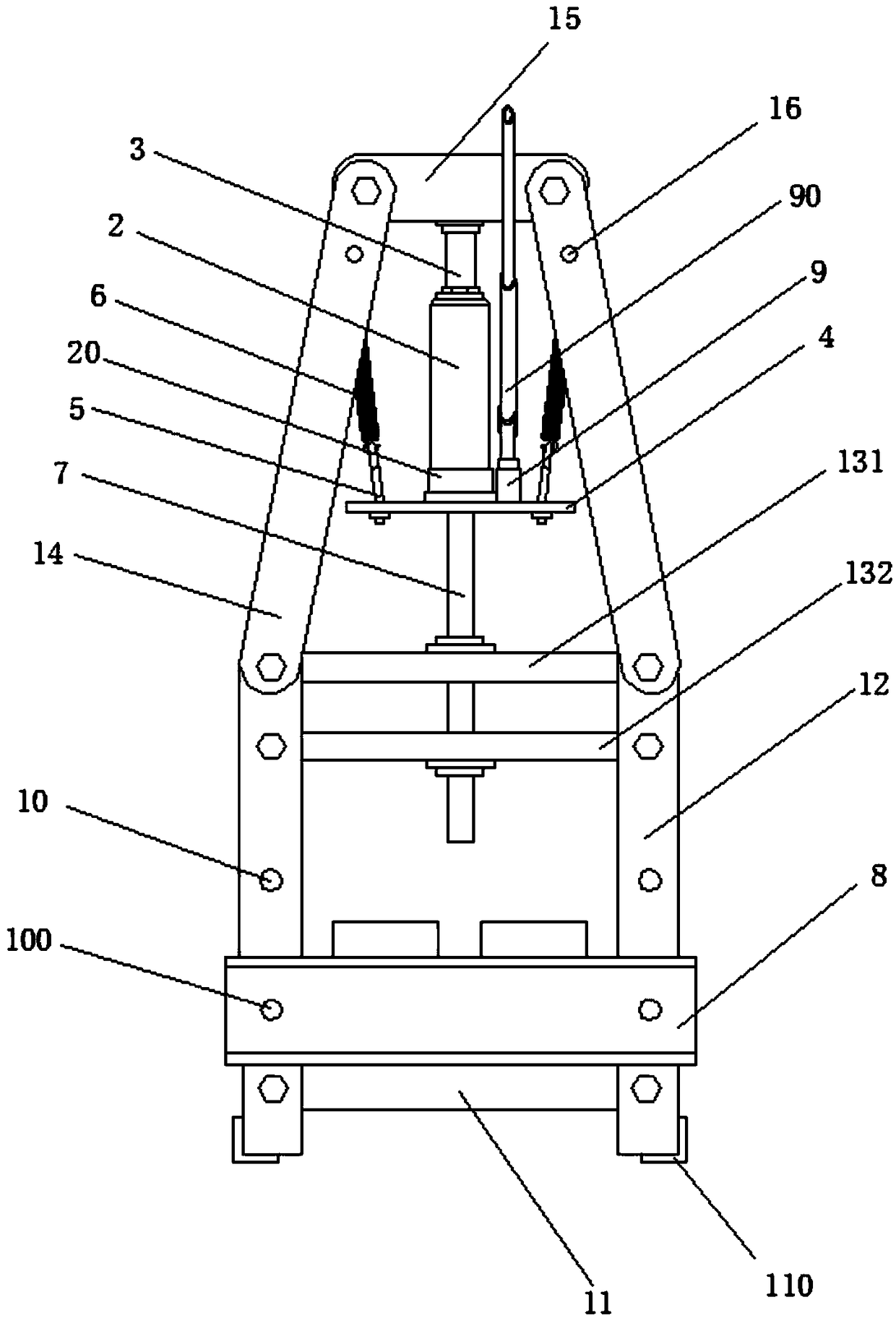

[0016] refer to figure 1 with figure 2 , a height-adjustable manual hydraulic press in the present invention includes a frame 1, a hydraulic cylinder 2, a piston rod 3, a lifting platform 4, a pull ring 5, a pull spring 6, a pressure rod 7 and a workbench 8, and the frame 1 consists of The base 11, the vertical bar 12, the cross bar 13, the oblique bar 14 and the cross beam 15 are composed, the two sides of the base 11 are provided with the vertical bar 12, the tops of the two vertical bars 12 are connected with the horizontal bar 13, the front and rear sides of the vertical bar 12 The tops of the slanting rods 14 are provided with a slanting rod 14, the top of the slanting rod 14 is sandwiched with a beam 15, the middle of the bottom of the beam 15 is fixed with a piston rod 3, the bottom of the piston rod 3 is set with a hydraulic cylinder 2, and the bottom of the hydraulic cylinder 2 A lifting platform 4 is provided, and a bearing seat 20 is arranged on the lifting platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com