A kind of polyester staple fiber and preparation method thereof

A polyester staple fiber and melt technology, which is applied in fiber processing, rayon manufacturing, fiber chemical characteristics, etc., can solve the problem that the thermal insulation performance of polyester staple fiber cannot well meet the thermal insulation requirements, and achieve good thermal insulation performance and improve thermal insulation. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A preparation method of polyester staple fiber, comprising the following steps:

[0022] (1) Mix 300 parts by weight of terephthalic acid and 50 parts by weight of ethylene glycol at 50-60°C; then heat up to 150-160°C for esterification, and the reaction time is 10-15min;

[0023] (2) Add 8-10 parts by weight of dimethylpropanediol, 5-10 parts by weight of 2,5-dimethyl-2,5-hexynediol, 5-15 parts by weight of the product after the esterification reaction Parts of 2-butene-1,4-di-n-butyl ester, 5-10 parts by weight of two (hexane-1,6-diol) titanium, 5-10 parts by weight of composite functional additives, 100 parts by weight of Terephthalic acid and 50 parts by weight of ethylene glycol ester, then heated up to 200-250°C, reacted for 10-15min under 200-300Pa vacuum conditions, and carried out the first polymerization reaction; then at 230-260°C and 250- React under 350Pa vacuum condition for 5-10min, carry out the second polymerization reaction, obtain copolyester melt; T...

Embodiment 1

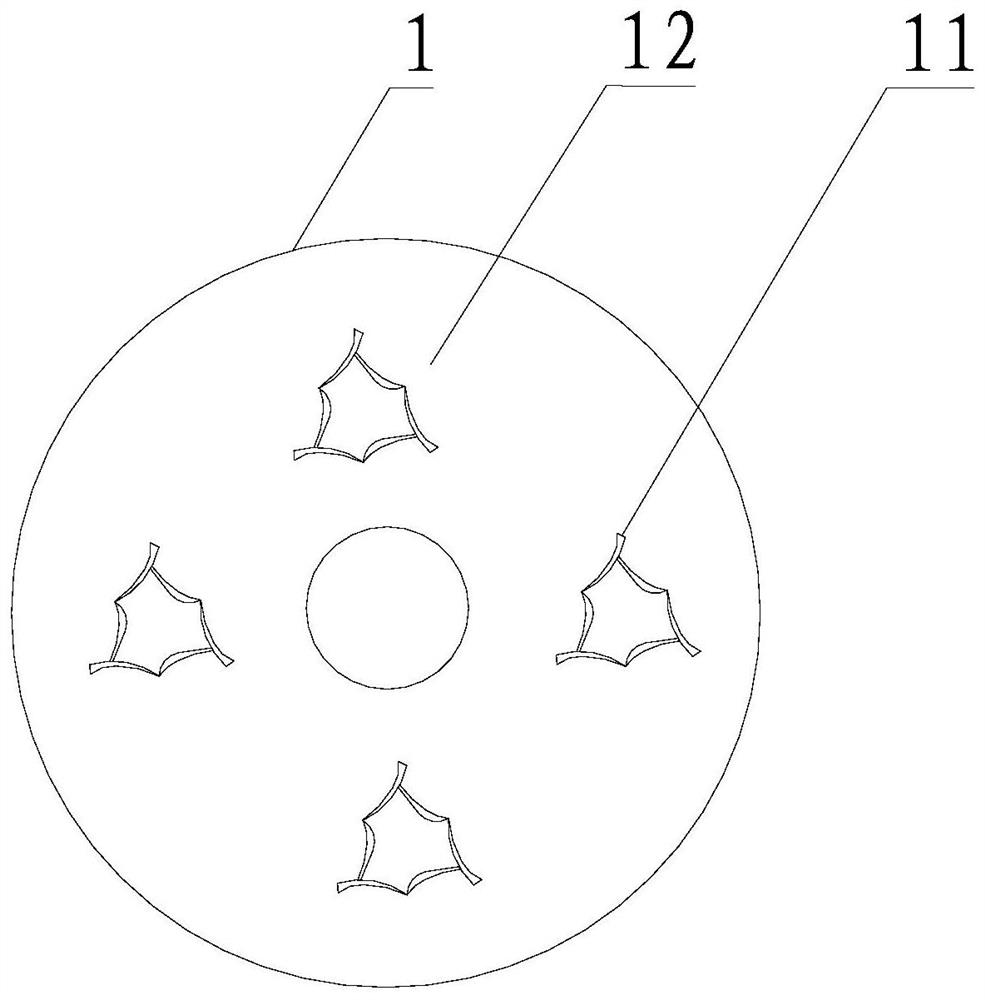

[0038] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0039] The preparation method of the polyester staple fiber of the present embodiment may further comprise the steps:

[0040] (1) Mix 300 parts by weight of terephthalic acid and 50 parts by weight of ethylene glycol at 55°C; then heat up to 155°C for esterification, and the reaction time is 12 minutes;

[0041] (2) Add 9 parts by weight of dimethylpropanediol, 8 parts by weight of 2,5-dimethyl-2,5-hexynediol, 10 parts by weight of 2-butene to the product after the esterification reaction -1,4-di-n-butyl ester, 8 parts by weight of two (hexane-1,6-diol) titanium, 8 parts by weight of composite functional additives, 100 parts by weight of terephthalic acid and 50 parts by weight of ethyl Glycol ester, then heated up to 230°C, reacted under 250Pa vacuum condition for 12min, and carried out the first polymerization reaction; then reacted at 240°C and 300Pa vacuum condition for 8min, carried out the s...

Embodiment 2

[0045] Please refer to figure 1 , the second embodiment of the present invention is:

[0046] The preparation method of the polyester staple fiber of the present embodiment may further comprise the steps:

[0047] (1) Mix 300 parts by weight of terephthalic acid and 50 parts by weight of ethylene glycol at 50°C; then heat up to 150°C for esterification, and the reaction time is 10 minutes;

[0048] (2) Add 8 parts by weight of dimethylpropanediol, 5 parts by weight of 2,5-dimethyl-2,5-hexynediol, 5 parts by weight of 2-butene to the product after the esterification reaction -1,4-di-n-butyl ester, 5 parts by weight of two (hexane-1,6-diol) titanium, 5 parts by weight of composite functional additives, 100 parts by weight of terephthalic acid and 50 parts by weight of ethyl Glycol ester, then heated up to 200°C, reacted under 200Pa vacuum condition for 10min, and carried out the first polymerization reaction; then reacted at 230°C and 250Pa vacuum condition for 5min, carried o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com