A floor tile suitable for laying floor heating and its manufacturing method

A manufacturing method and a floor tile technology, applied in the field of building ceramic materials, can solve the problems of poor sealing of wooden floors, affecting physical health, and dust on wooden floors, so as to be beneficial to human health, promote sustainable development, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

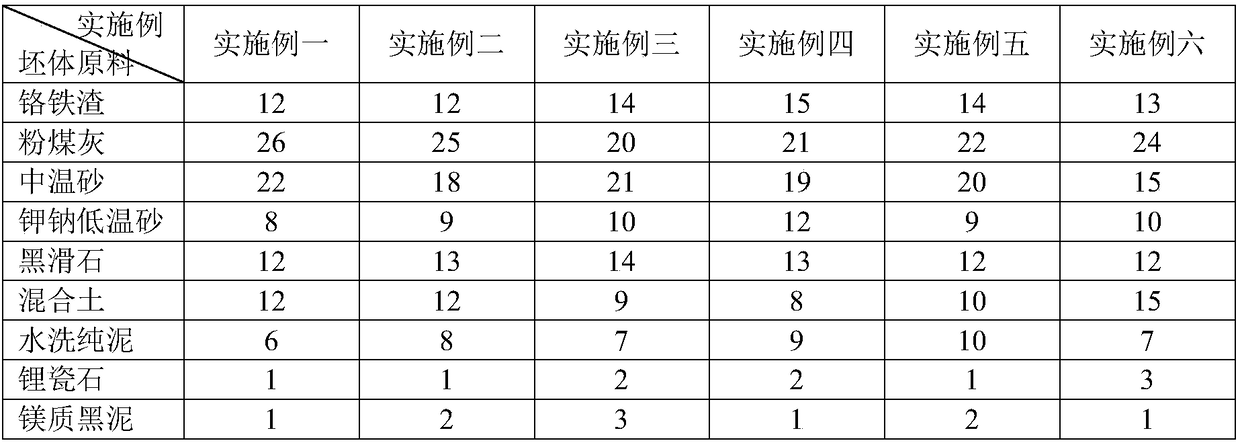

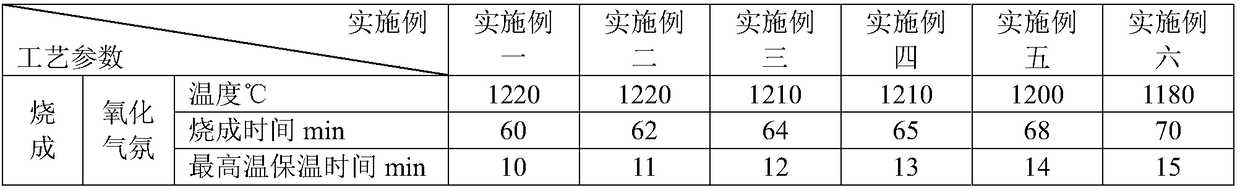

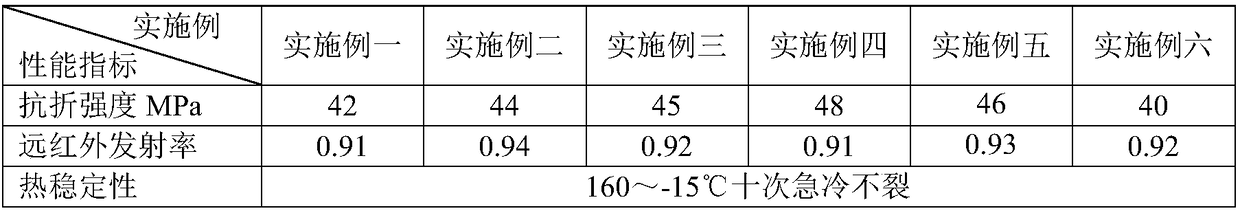

[0025] An embodiment of the present invention is a floor tile suitable for floor heating. The raw material composition of the green body and the chemical composition of the green body raw materials are shown in Table 1 and Table 2 respectively.

[0026] Table 1 The raw material composition of a floor tile suitable for laying floor heating according to the embodiment of the present invention

[0027]

[0028] Table 2 The chemical composition of the body raw materials of a floor tile suitable for floor heating in an embodiment of the present invention

[0029] raw material name

Cr 2 o 3

LiO 2

SiO 2

al 2 o 3

MgO

Fe 2 o 3

CaO

K 2 o

Na 2 o

IL

4.82

/

34.60

24.10

30.54

3.89

2.05

/

/

/

/

/

56.22

28.64

2.68

3.81

3.46

1.39

2.18

1.62

Medium temperature sand

/

/

72.09

19.96

0.23

0.21

0.85

2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com