Cutting bag rolls for supermarkets

A bag-cutting and reeling technology, which is applied in the field of plastic bags, can solve the problems of not being able to fix plastic bags, troubles, and ingredients that cannot be directly put into the shopping basket, and achieve the effect of easy tearing with one hand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

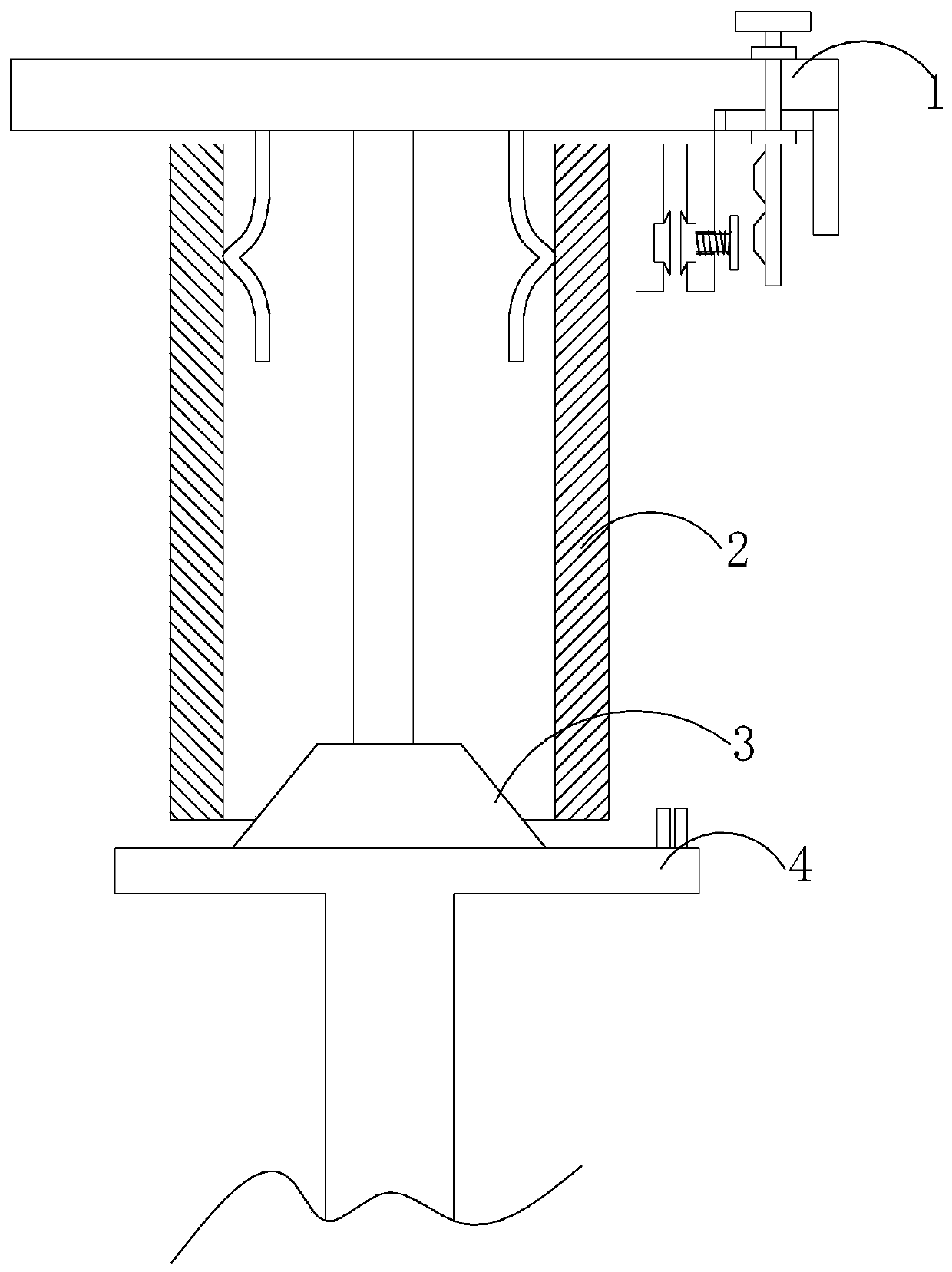

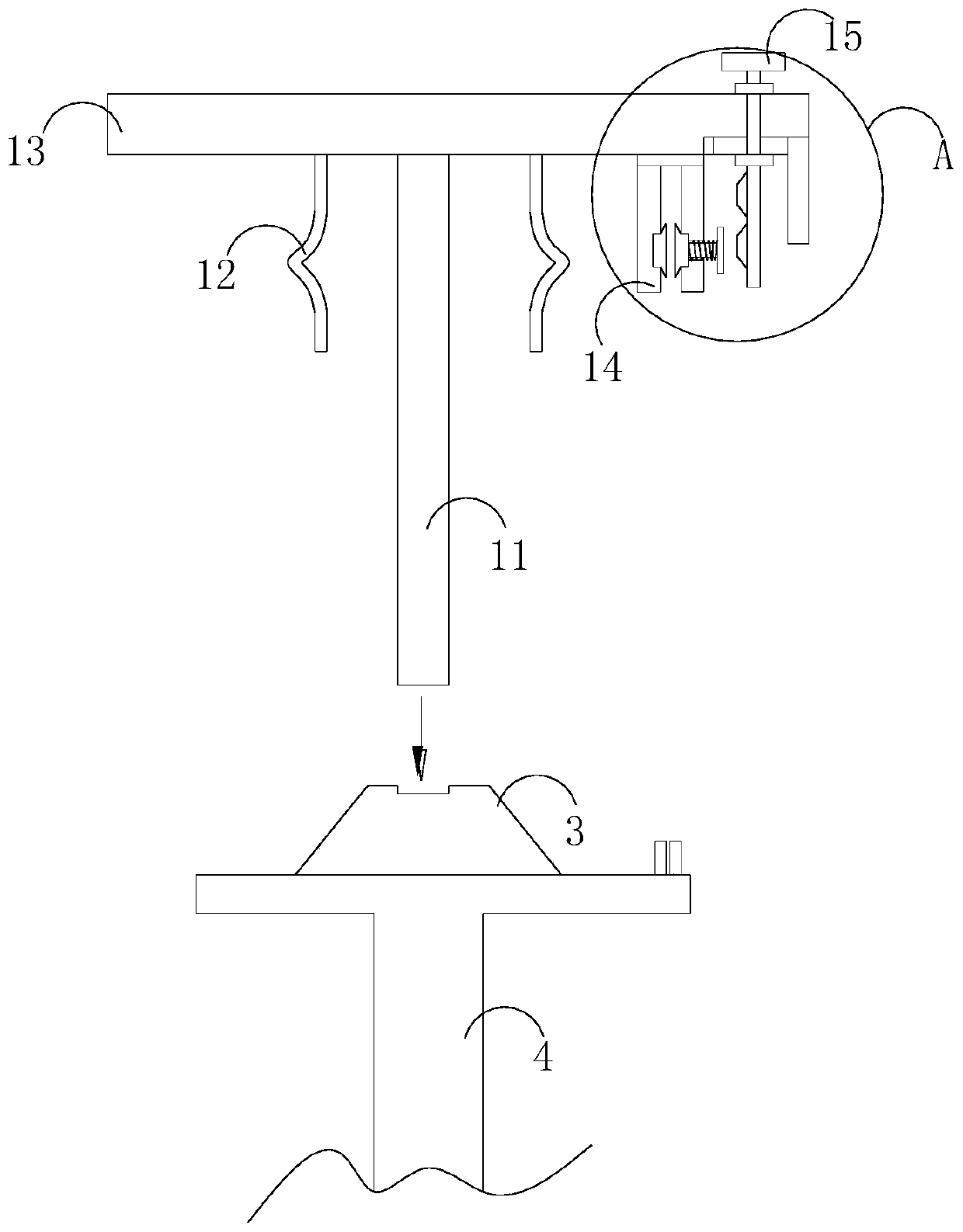

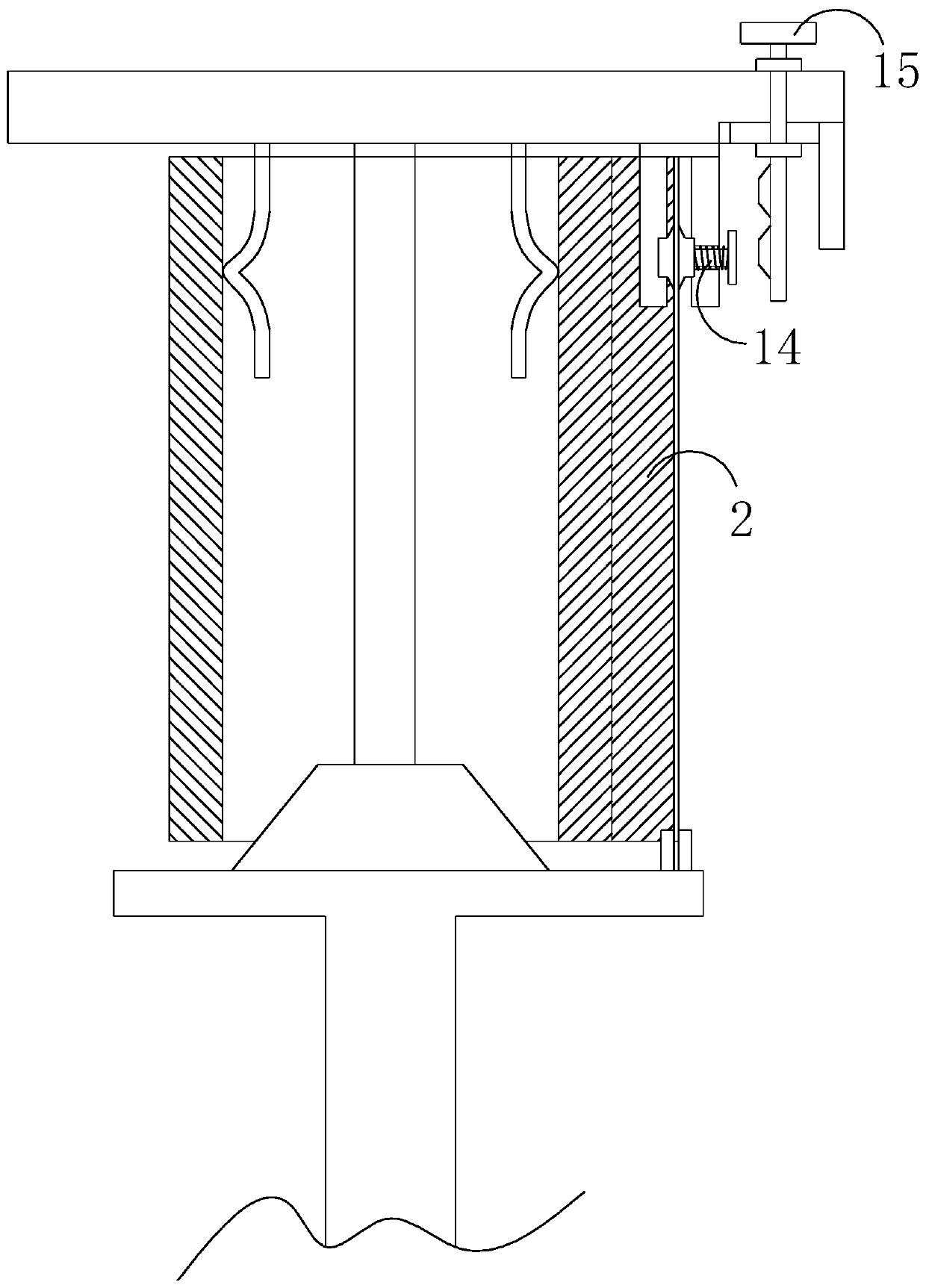

[0030] See Figure 1-Figure 5 , The present invention provides a bag cutting roll used in supermarkets. The structure includes a bag cutting structure 1, a plastic bag roll 2, a round table 3, and a placing table 4. The placing table 4 has a T-shaped structure and the horizontal end is welded vertically in the middle. The round table 3 has a notch in the middle of the round table 3, and this notch is matched with the bag cutting structure 1 located directly above it, and a plastic bag roll 2 is placed on the placing table 4.

[0031] The bag cutting structure 1 is mainly composed of a three-dimensional support 11, a spring sheet 12, a cover plate 13, a clamp 14, and a cutting knife 15. The cover plate 13 is vertically provided with a three-dimensional support 11 in the middle of the bottom surface. And the cover plate 13 are welded by a welding machine, the end of the three-dimensional pillar 11 is matched with the notch on the round table 3, the two sides of the three-dimensiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com