Reheat-crack resistant W-containing high-strength low-alloy heat-resistant steel

A high-strength, low-alloy, reheat cracking technology, applied in the field of heat-resistant steel, can solve the problems of increasing the process, unsatisfactory effect of preventing reheat cracks, and increasing labor intensity, so as to suppress reheat cracks and solve reheat cracks. Sensitive to thermal cracking issues, results with reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is described further in detail:

[0063] The purpose of the present invention is to provide a novel low-alloy heat-resistant steel which resists reheating cracks, which greatly improves the resistance Ability to reheat cracks. The steel can be safely and reliably used in super (super) critical thermal power plants.

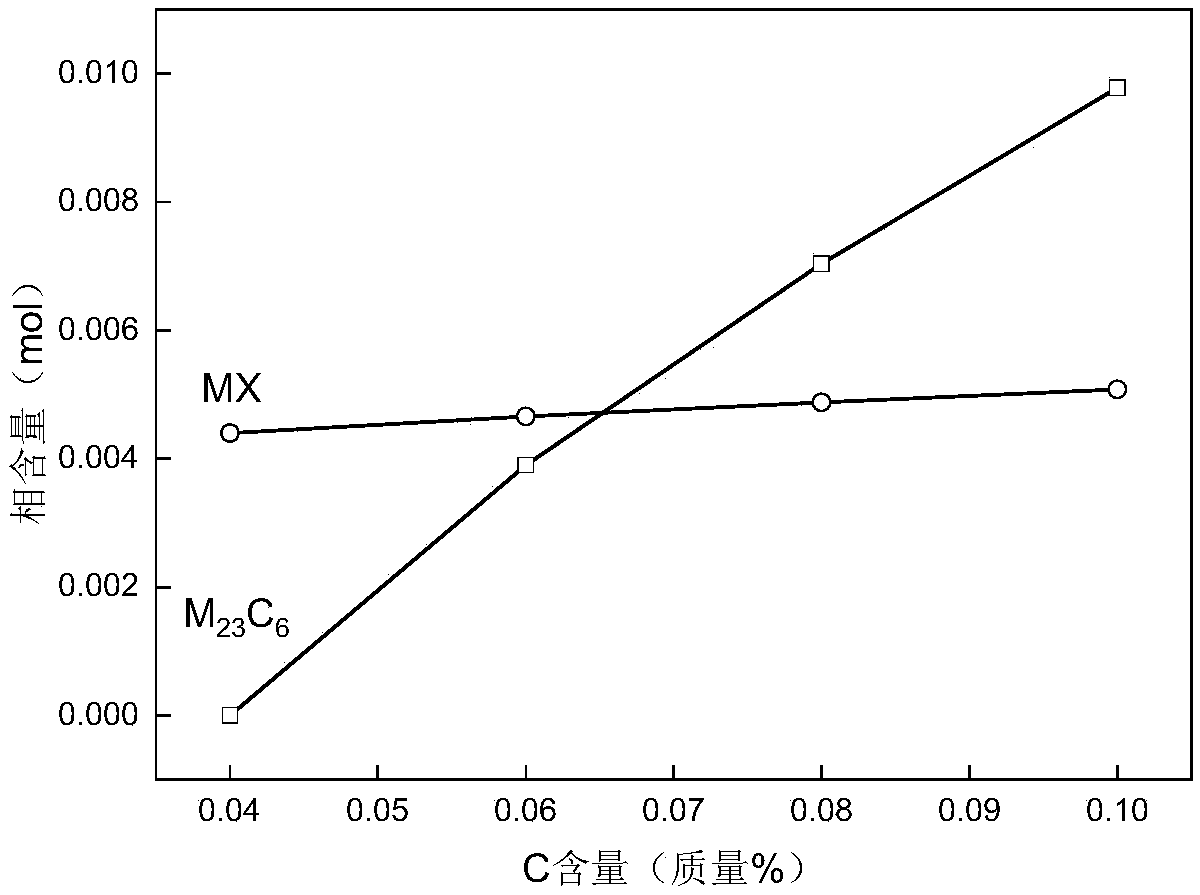

[0064] The chemical composition has the greatest influence on the reheat crack susceptibility of low-alloy heat-resistant steel. C, W, Mo, V, Nb, Ti and other alloying elements will increase the tendency of reheating cracks, but for heat-resistant steel, W and Mo are dissolved in the matrix to provide solid solution strengthening, and V, Nb, Ti, etc. form fine dispersed carbon nitrogen Compounds provide precipitation strengthening, so they are key elements to improve the high temperature creep strength of materials. In order to obtain sufficient high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com