Gluing device of gluing printing machine

A technology of offset printing and rubber rollers, which is applied to the device for coating liquid on the surface, coating, etc., which can solve the problems of uneven pressure at both ends and uneven thickness of squeegee, and achieve the effect of easy operation and improved squeegee effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

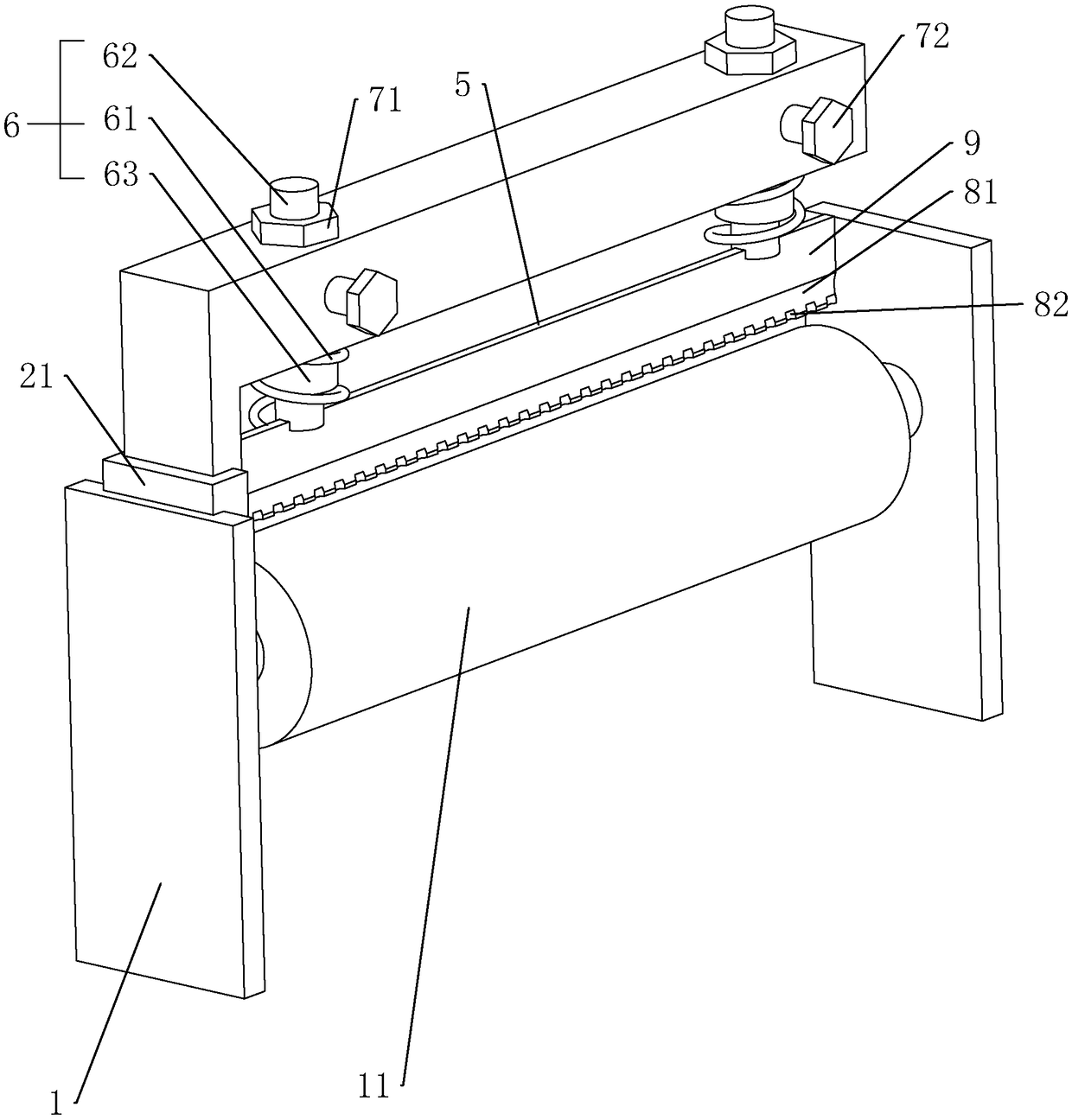

[0022] As shown in the figure, a gluing device of a sizing printing machine includes wallboards 1 and gluing rollers 11 rotatably connected between the wallboards 1 . The upper rubber roller 11 is driven by a motor (not shown in the figure) and placed horizontally.

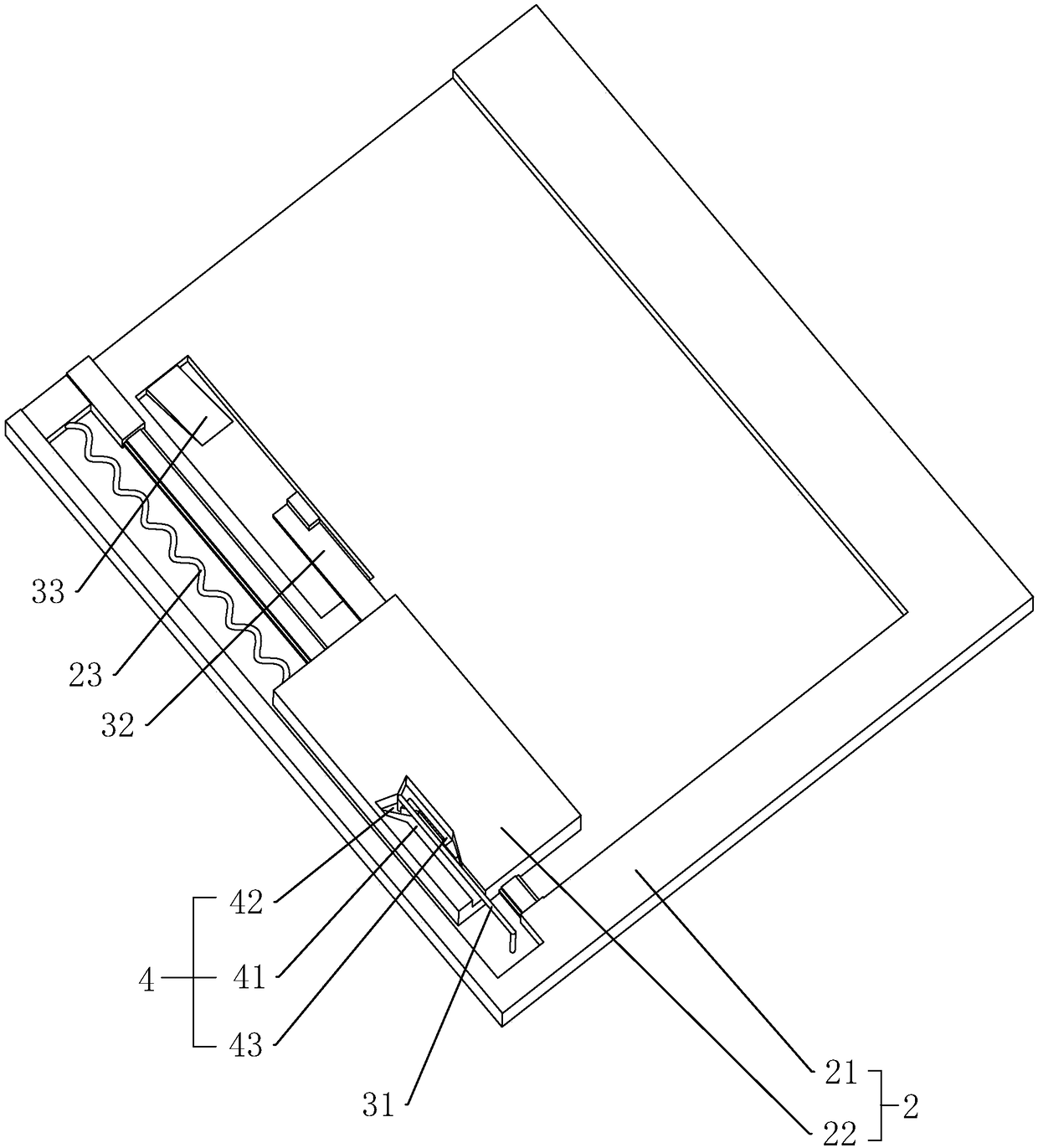

[0023] The scraper mechanism 2 is located above the upper rubber roller 11 and includes a support frame 21 , a sliding seat 22 and a first elastic member 23 . The support frame 21 is vertically fixed on the wallboard 1, and the sliding seat 22 is vertically slidably connected to the support frame 21. The first elastic member 23 is a spring, one end is connected to the support frame 21 , and the other end is fixedly connected to the sliding seat 22 . The first elastic member 23 always exerts an upward pulling force on the sliding seat 22 .

[0024] An L-shaped hook 31 is rotatably connected to the surface of the support frame 21 , and a position-limiting mechanism 4 for embedding the L-shaped hook 31 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com