Pipeline suspension cable spanning wind resistant system

A pipeline and system technology, applied in suspension bridges, bridge applications, buildings, etc., can solve problems such as the limitation of wind resistance cables, the inability to provide lateral and vertical stiffness, and the difficulty of wind resistance cable layout, so as to improve the lateral stability of the structure. The effect of vertical stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

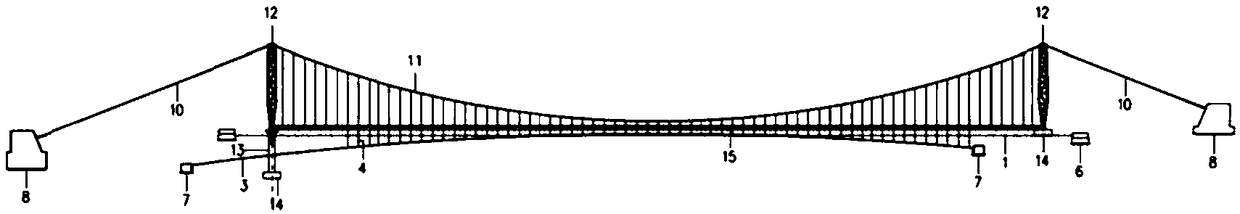

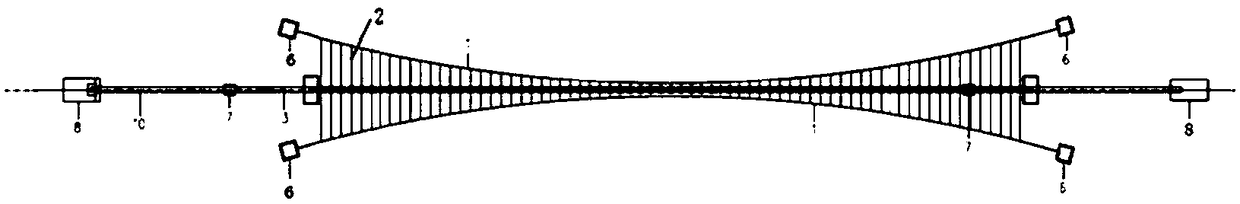

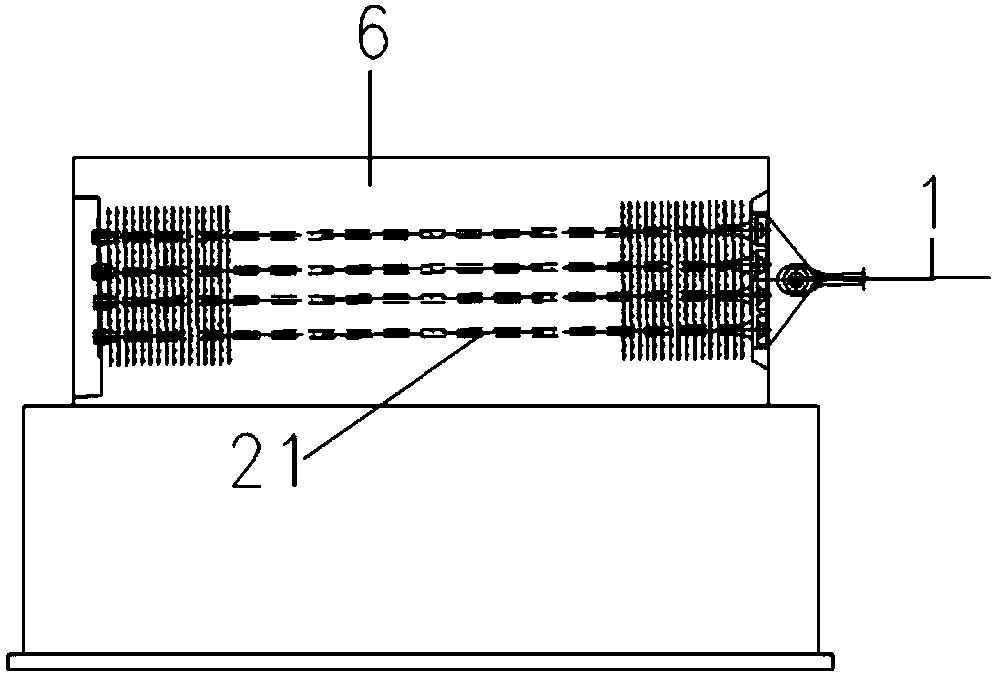

[0032] The designed main span of the pipeline suspension cable spanning project is 360m, the anchor span on the south bank is 109.9m, the anchor span on the north bank is 75.7m, and the total length is 545.6m. The rise-span ratio of the main cable is 1 / 10, the elevation projection span of the horizontal wind-resistant cables is 360m, the total width of the plane projection is 54.6m, and the rise-span ratio of the horizontal wind-resistant cables is 1 / 15. A main cable anchoring pier and two horizontal wind-resistant cable anchoring piers are respectively set across the south and north sides. Two conjugate cables are set under the bridge deck structure, the suspension range of the conjugate cables is 290m, the rise-span ratio is 1 / 42, and a conjugate cable anchorage pier is set on the south bank and the north bank respectively.

[0033] A total of 8 anchor piers are set up in the pipeline suspension cable spanning project, including 2 anchor piers for main cables, 4 anchor piers...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap