Design method of wind-resistant system with pipeline suspended cable crossing structure

A technology that spans structures and design methods, and is used in suspension bridges, design optimization/simulation, computer-aided design, etc. It can solve the problems of limitations, inability to provide lateral and vertical stiffness, and high engineering costs, and achieve improved lateral and vertical. The effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

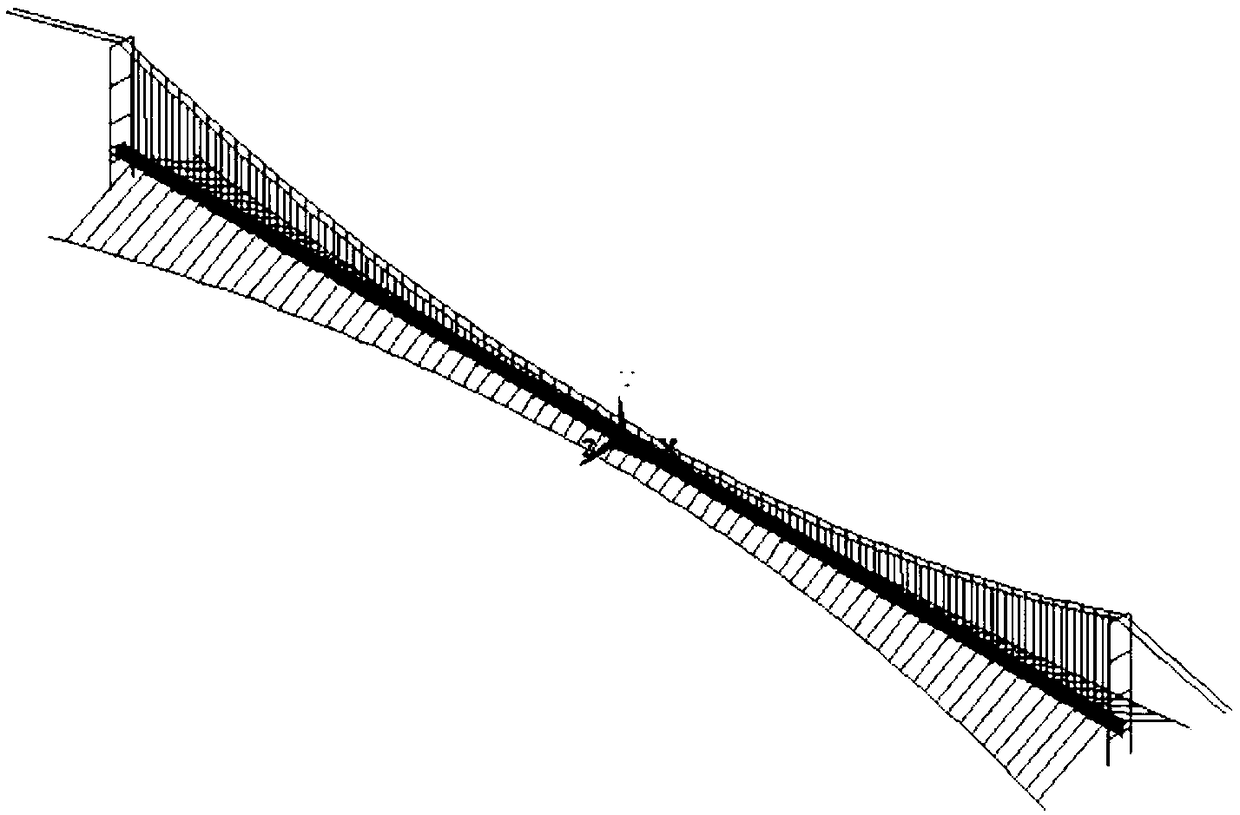

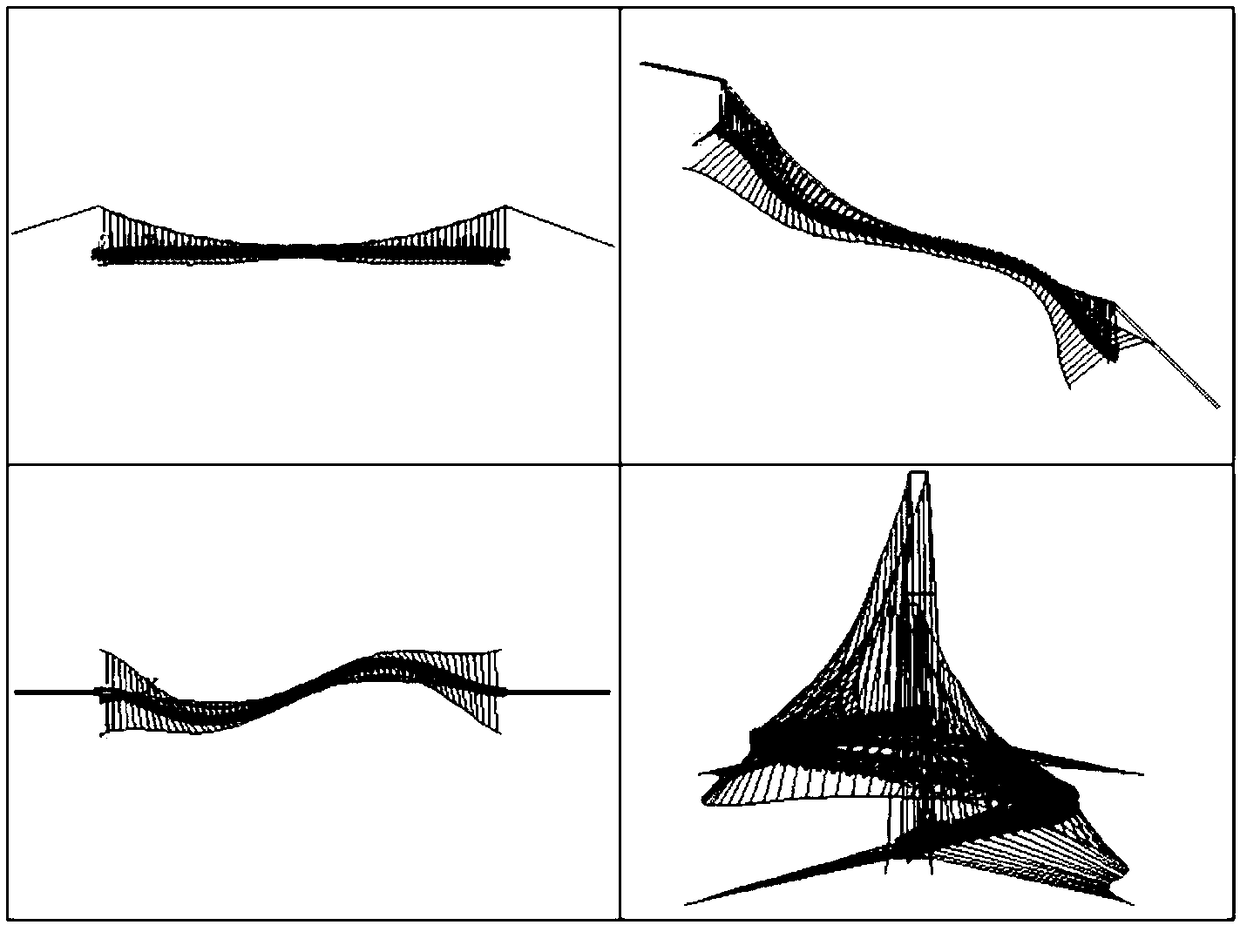

[0053] A pipeline suspension cable spanning structure wind resistance system, such as Figure 5 , 6 As shown, there are two pipeline suspension cables spanning the bridge tower 12, and the pipeline suspension cables span the bridge tower 12 and are fixed on the pier 13, and a cap 14 is provided below the pier 13. The two main cables 11 respectively pass through two pipelines and are suspended across the top of the bridge tower 12 and are arranged in a parabolic shape in the vertical direction. The cable hanger has a pipeline suspension cable to span the bridge deck 15 . The two ends of the pipel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap