Method for cutting clothes in seven-line three-type mode

A clothing and edge technology, applied in the field of clothing, can solve the problems of cumbersome process, cumbersome plate making, and difficult to learn, etc., and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

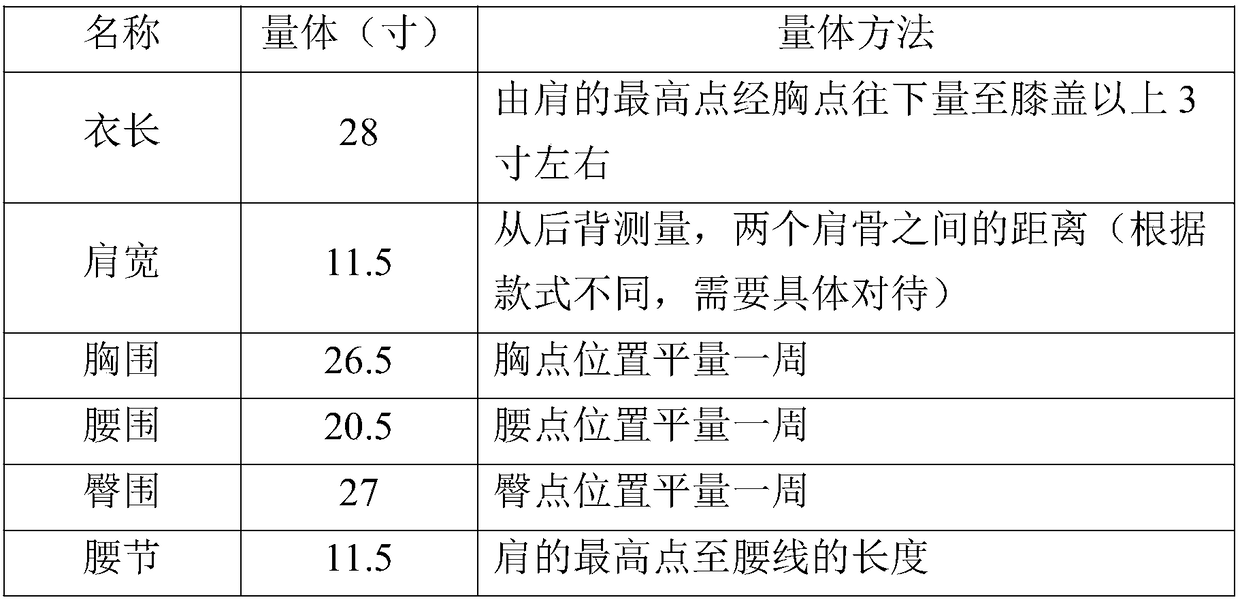

[0044] The method of using seven lines and three styles to cut clothing is years of custom experience. Combined with the comprehensive concept of modern clothing design, it sums up the overall position of the human body where the shoulders, chest, waist, and hips are located, so as to create a perfect body proportion. In the method of cutting clothes with seven lines and three styles, the idea of prototype conversion is carried out from five types of basic pattern making and drawing of skirts, dresses, shirts, pants, and suits. Within seven days, you can learn all the pattern-making and pattern-making. From then on, cutting is very simple, and sewing is a skilled trade.

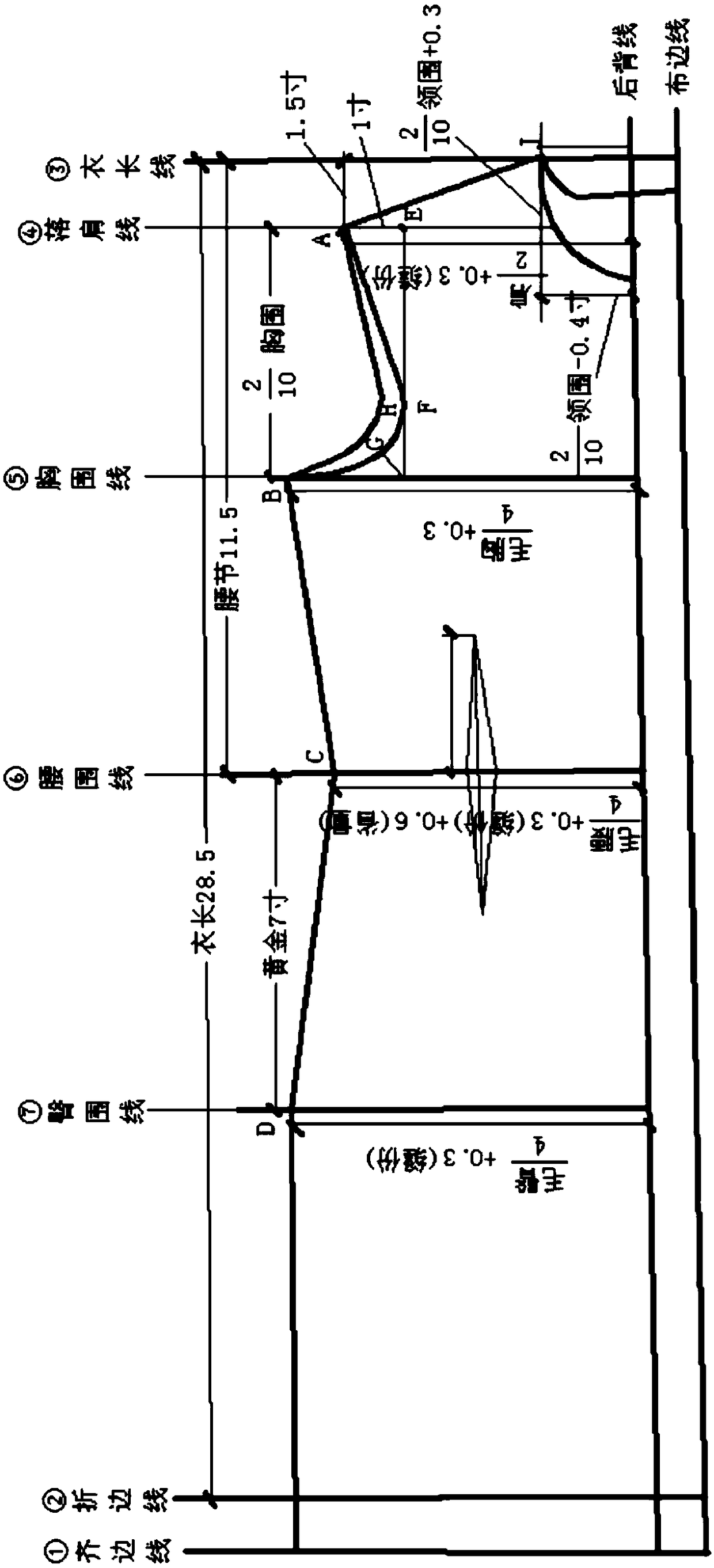

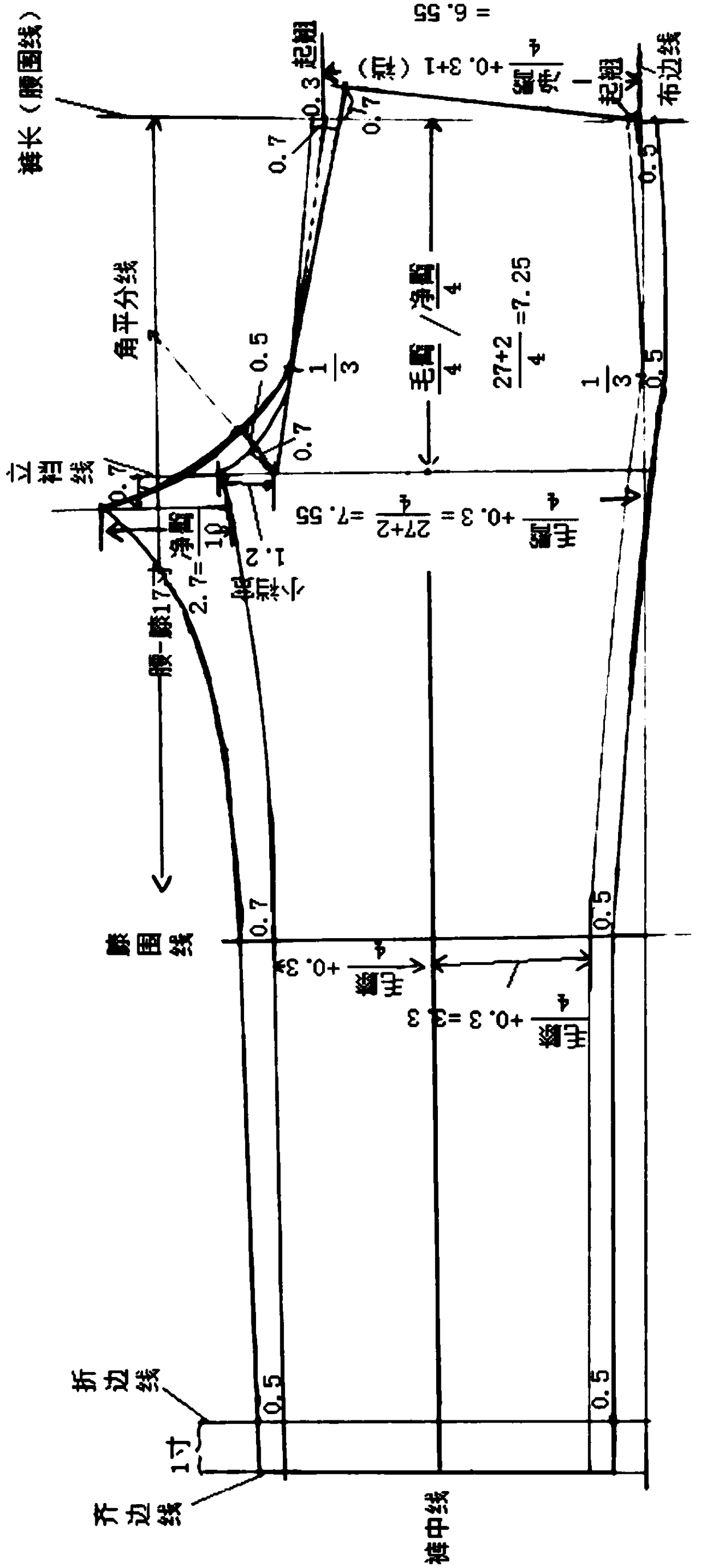

[0045] figure 1 It is a schematic diagram of the process of making a dress layout using the method of cutting clothes with seven lines and three patterns according to an embodiment of the present application. see figure 1 , a method of cutting garments using seven lines and three styles, generally can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com