Integrated and optimized automatic assembling and disassembling mechanism for furniture folding door

A technology for automatic disassembly and assembly of folding doors, which is applied to the suspension devices of wing leaves, windows/doors, building components, etc. Improve the effect of sliding opening and closing, meet the disassembly and use, and avoid the effect of easy falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

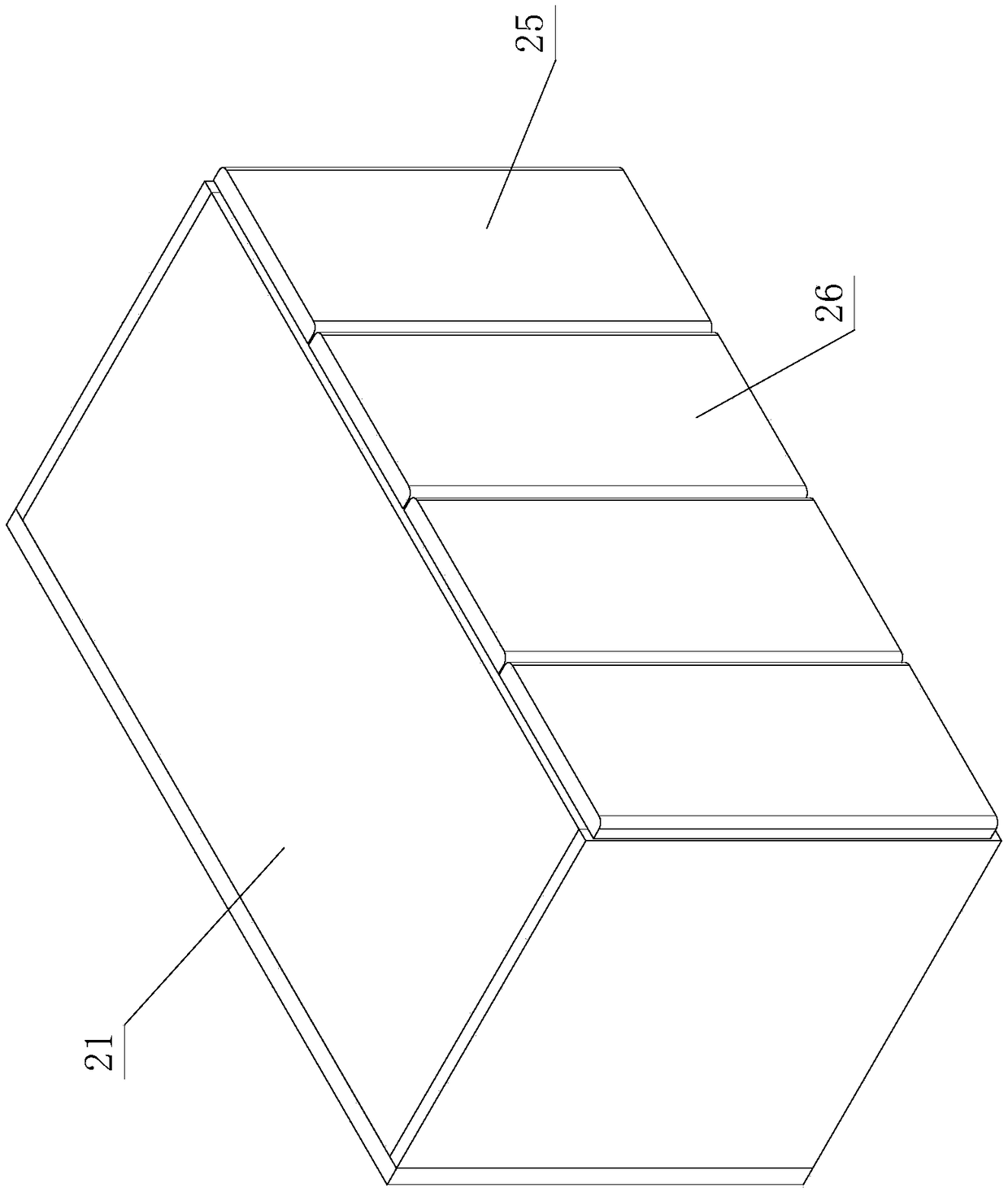

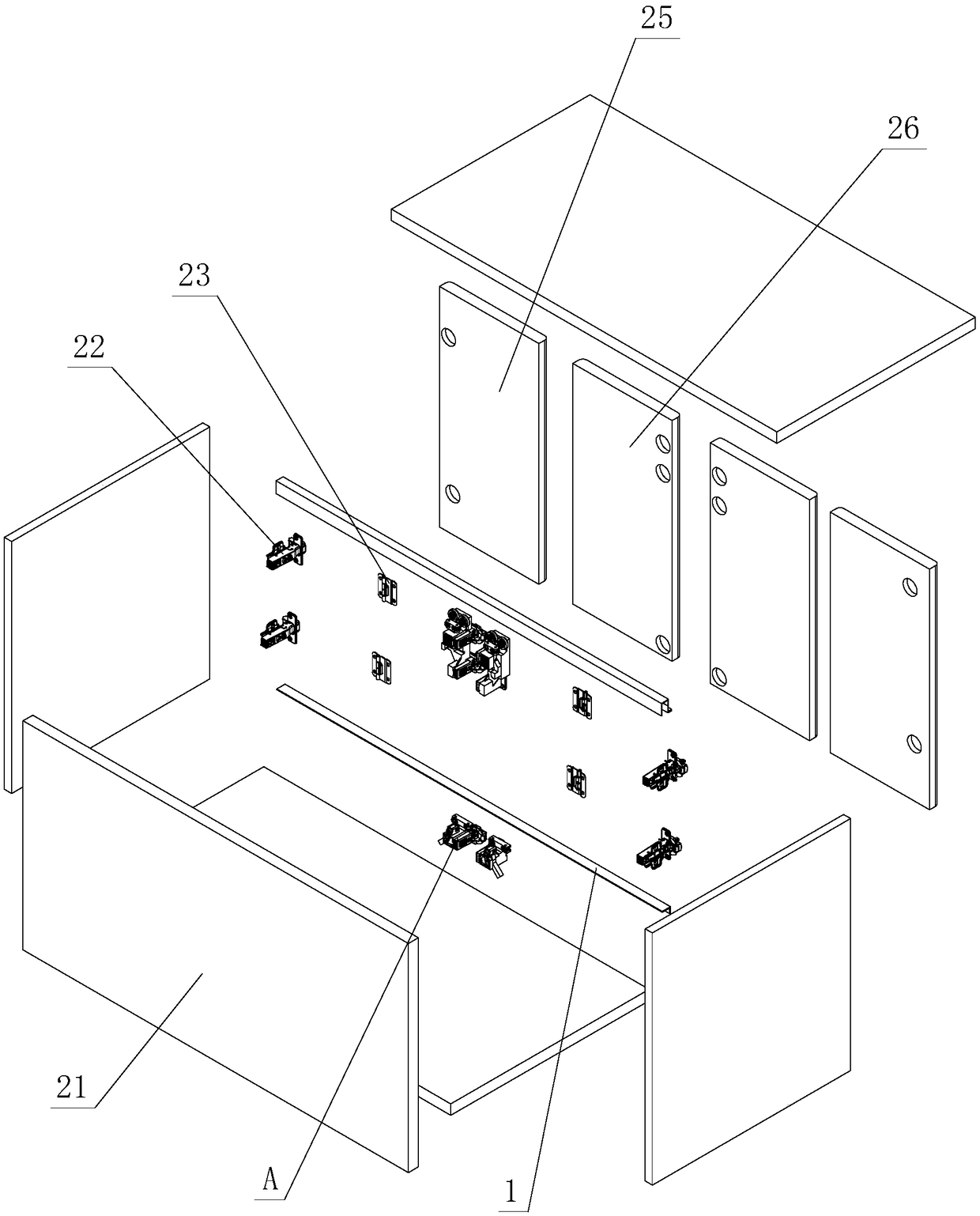

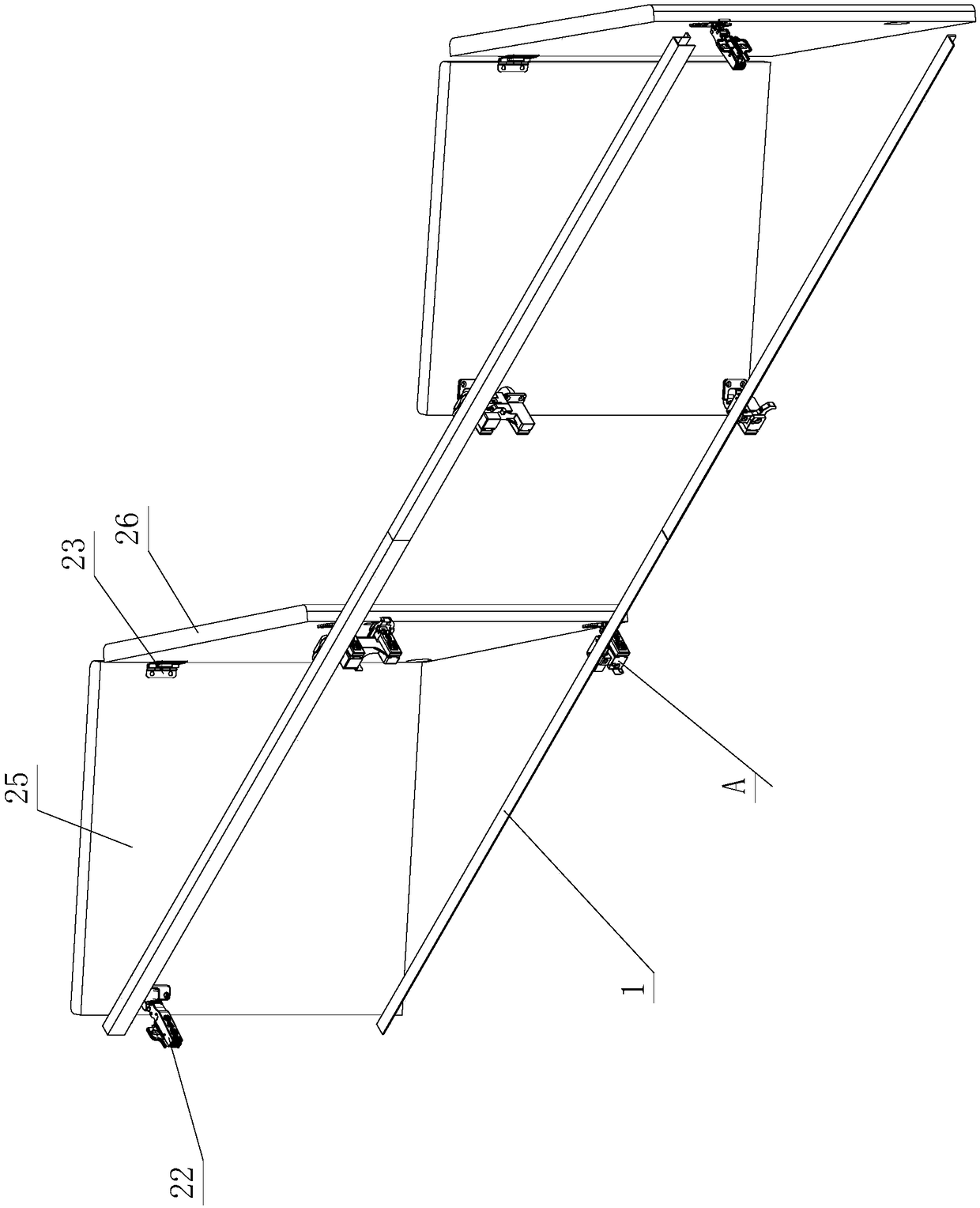

[0029] see Figure 1-Figure 14 , an integrated and optimized automatic disassembly mechanism for furniture folding doors, including an automatic disassembly device A and a slide groove 1, an automatic disassembly device A including a bracket element 2, a movable element 3, a locking element 4, a movable rotating wheel 5 and Positioning the rotating wheel 6; wherein, a movable elastic member 7 is arranged between the movable element 3 and the support element 2, the movable element 3 is elastically rotated or swings on the support element 2 through the movable elastic member 7, and the movable rotating wheel 5 is rotated and arranged on the movable element 3, and through the rotation or swing of the movable element 3 to disengage or rotate on the sliding groove 1, the positioning rotating wheel 6 is positioned and rotated on the support element 2, and rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com