Noise reducing structure for hermetically sealed compressor

A compressor and hermetic technology, applied in rotary piston machines, components of pumping devices for elastic fluids, and rotary piston/oscillating piston pump components, etc., can solve problems such as reducing suction volume efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

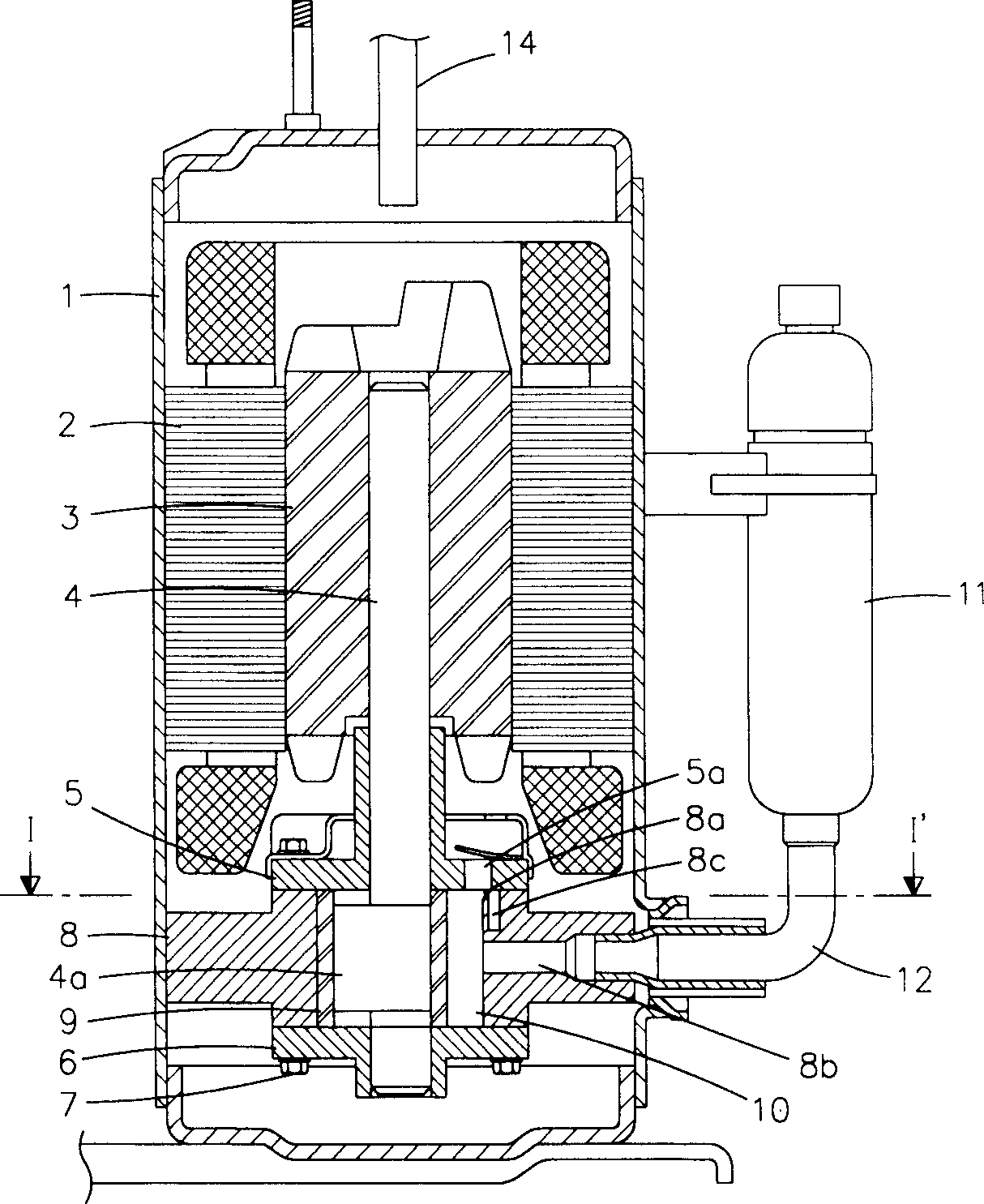

[0033] The noise reduction structure of the hermetic compressor according to the first embodiment of the present invention will be described below with reference to the drawings.

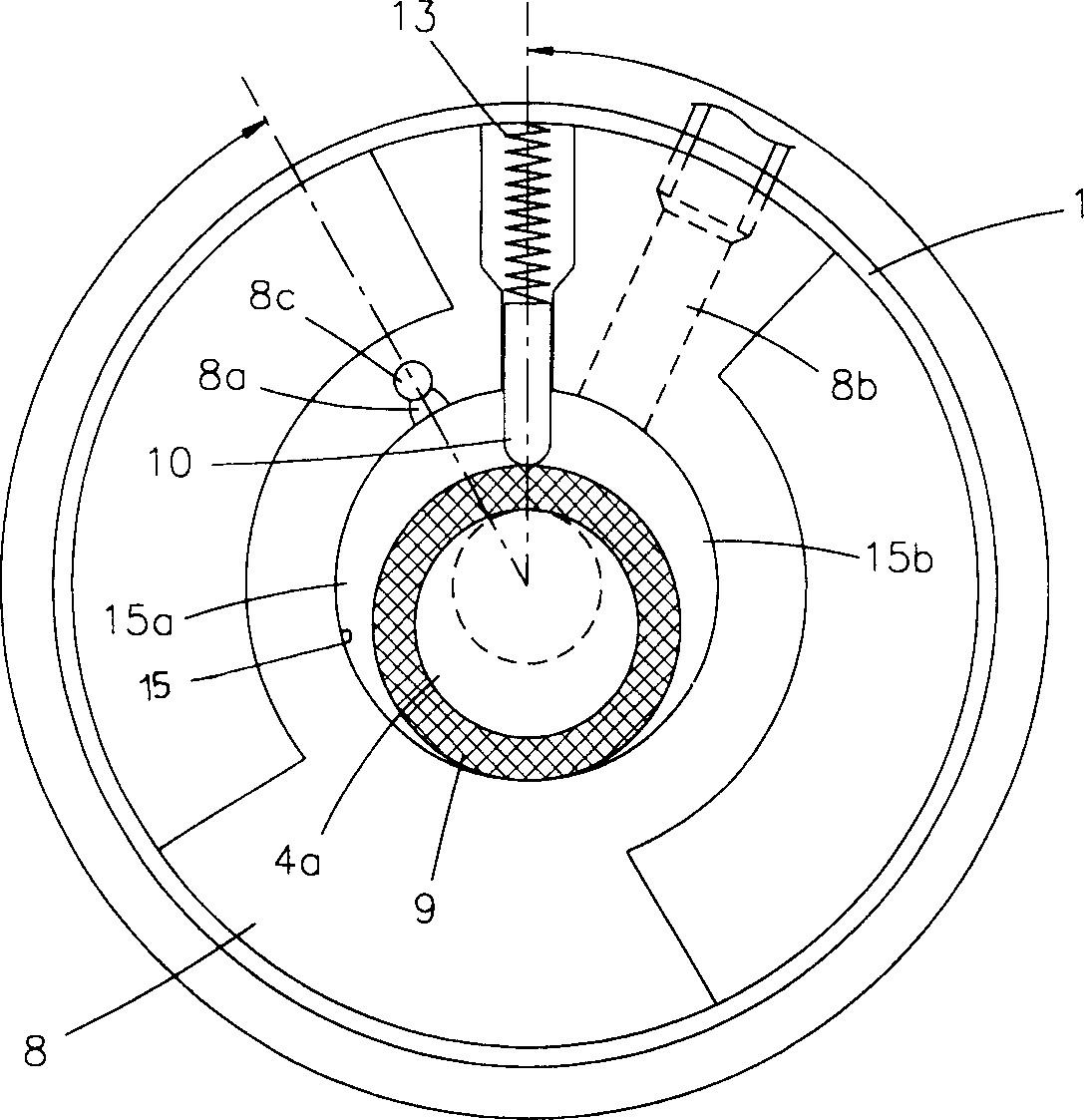

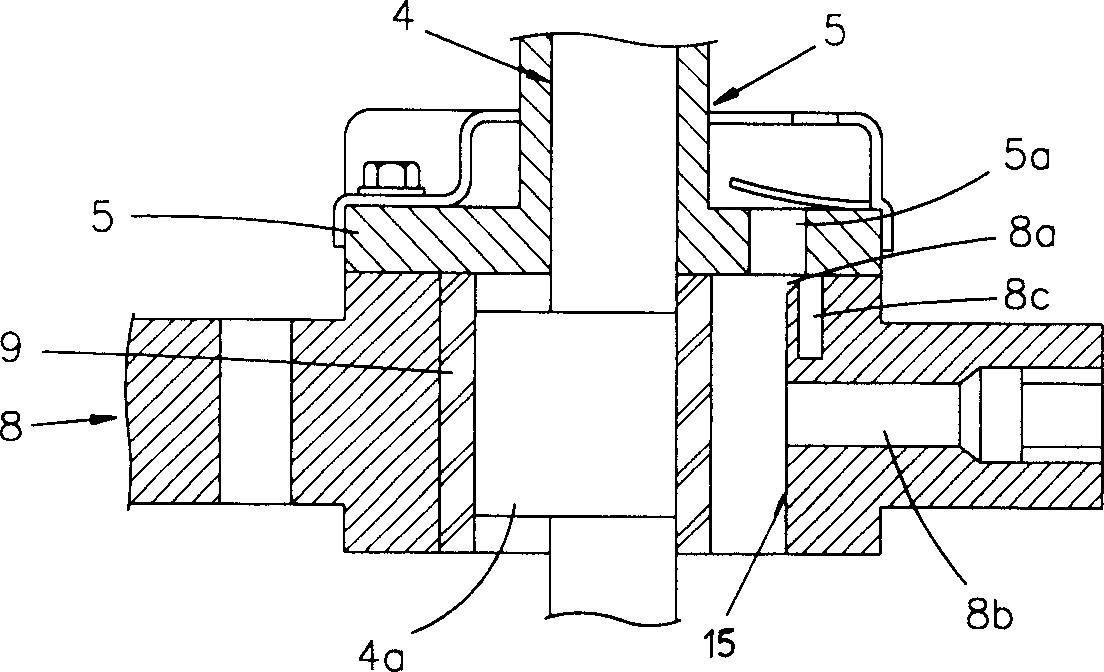

[0034] Such as Figure 4 , 5 Shown in and 6, an upward noise-reducing chamber 108c with a predetermined volume is formed in the cylinder wall of the cylinder 115 at the center of the cylinder block 108 toward the lower bearing 106, and a line communicates with the above-mentioned noise-reducing chamber 108c and The communication passage 108d of the compression chamber of the cylinder 115 .

[0035] The noise-reducing chamber 108c and communication channel 108d formed above are all located at 210°-270° from the position where the radial valve plate 110 divides the interior of the cylinder 115 into a high-pressure chamber 115a and a low-pressure chamber 115b when installed. within the range of angles.

[0036] The upwardly formed noise-reducing chamber 108c has a cylindrical shape, and the ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com