Soft ventilating type bus window

A bus and window technology, applied in the field of bus windows, can solve the problems of increasing the spread of lung diseases, lack of circulation, and lack of oxygen for passengers, so as to relieve crowdedness, expand the air intake range, and reduce odors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

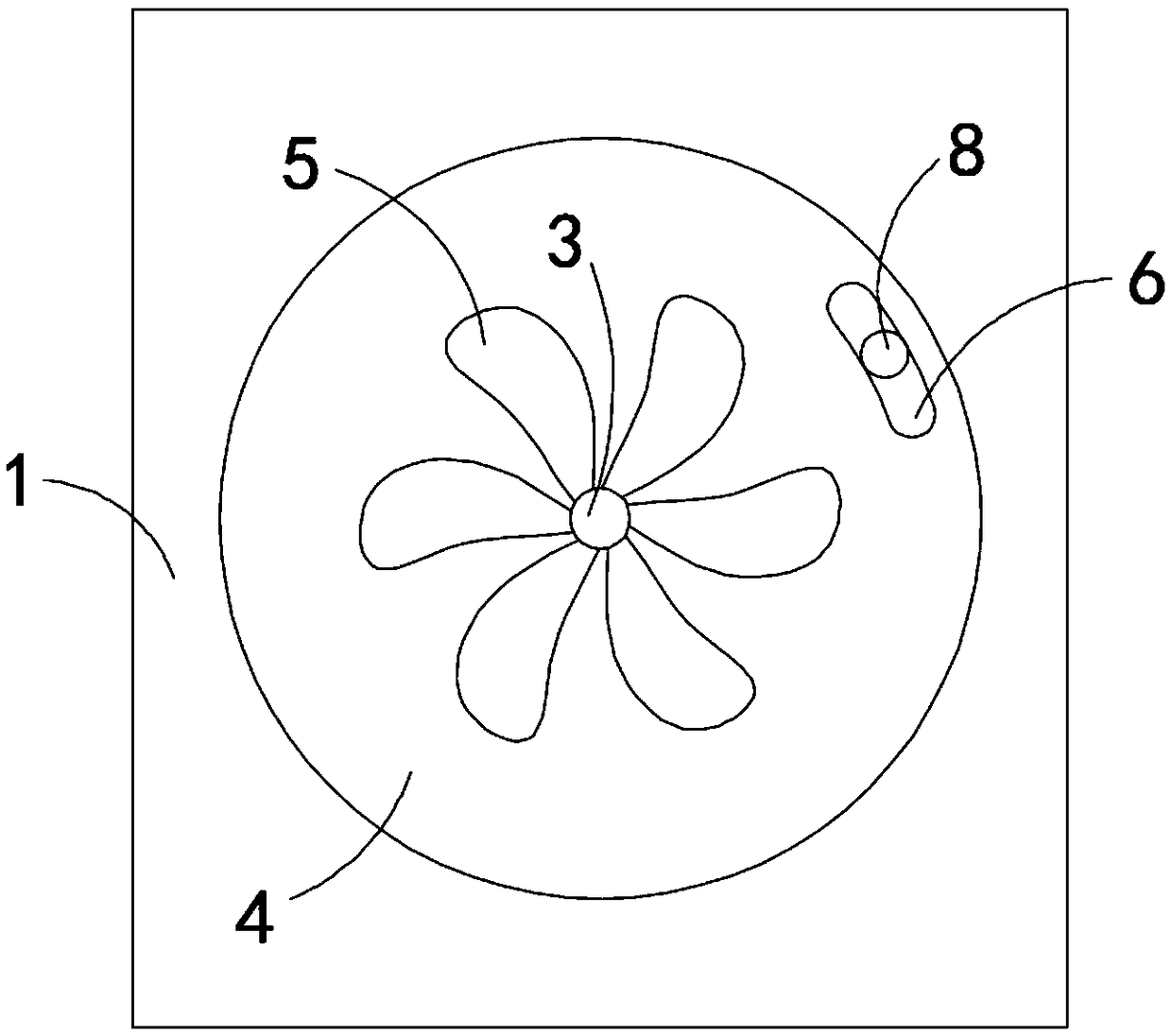

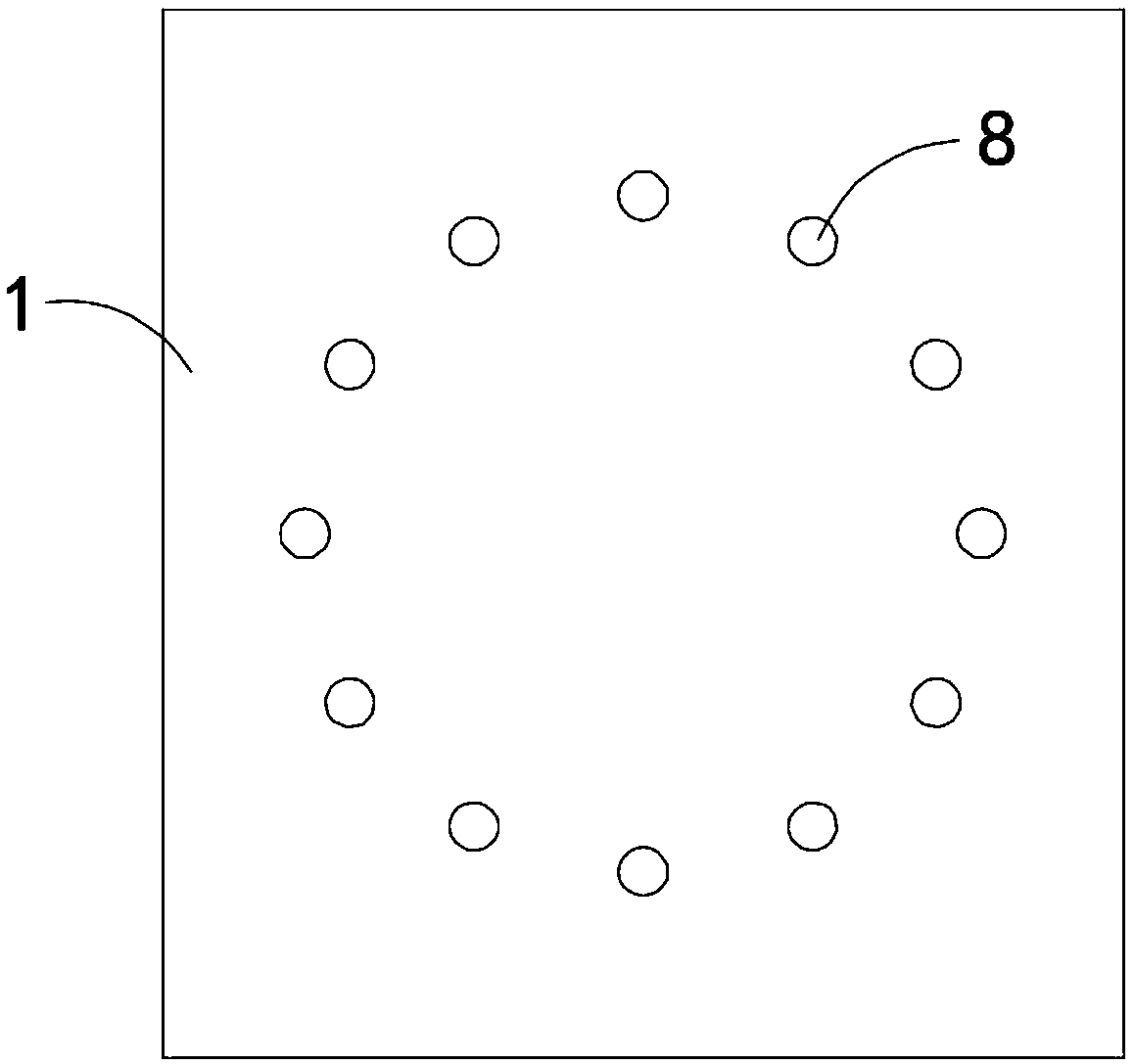

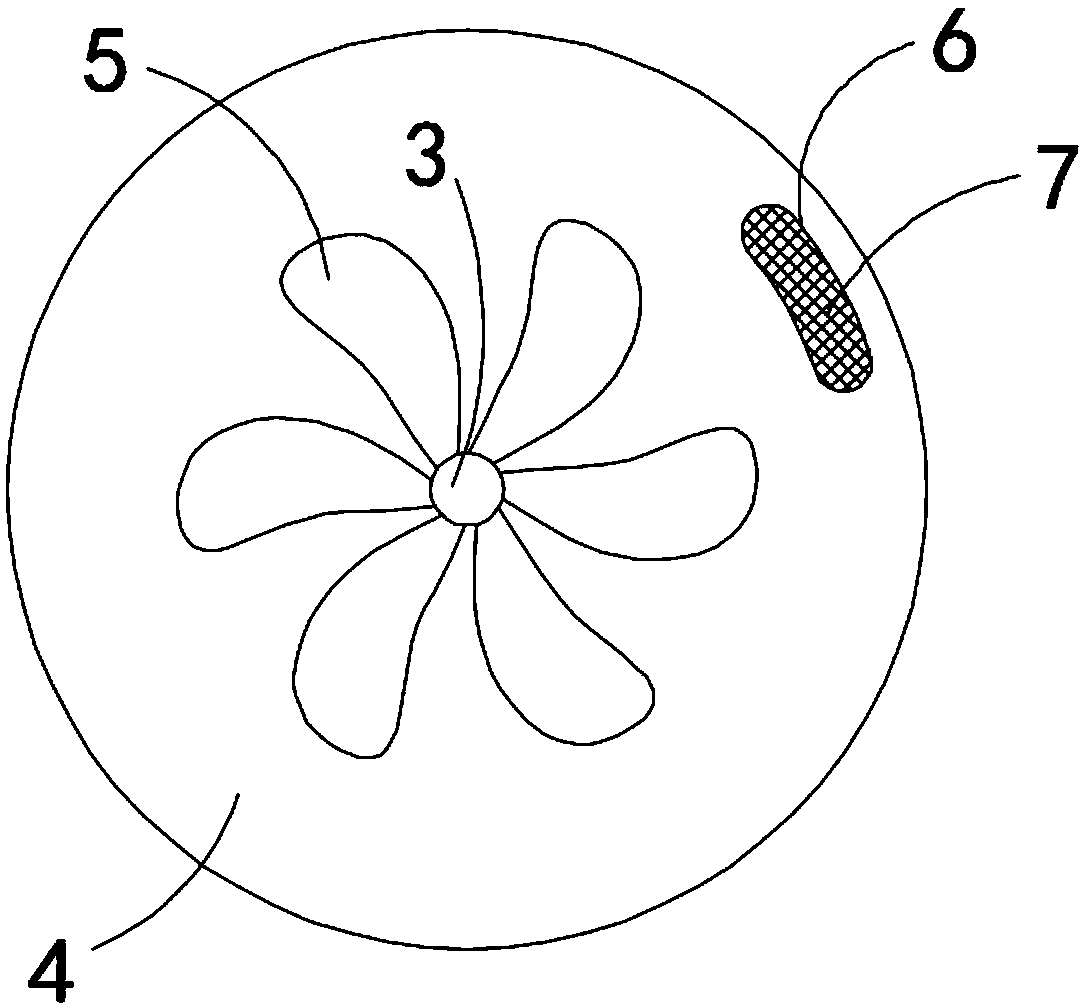

[0022] Such as Figure 1-4 As shown, a soft ventilation bus window includes a window body 1, a groove 2 is arranged on the outer wall of the window body 1, and a rotating shaft 3 is connected to the groove bottom wall of the groove 2, and the rotating shaft 3 The upper coaxial is fixedly connected with the rotating disk 4 and the wind wheel 5, the wind wheel 5 is located on the outside of the rotating disk 4, the rotating disk 4 is provided with an arc-shaped air inlet 6, and the inside of the arc-shaped air inlet 6 is fixedly connected with a filter screen 7, The window body 1 is provided with a plurality of ventilation holes 8 matched with the arc air inlet 6, and the length of the arc air inlet 6 is greater than or equal to the distance between two adjacent ventilation holes 8, so that the arc There is always gas entering in the shaped air inlet 6, and a plurality of ventilation holes 8 are evenly distributed around the center of the rotating disk 4. The line is arranged o...

Embodiment 2

[0025] Such as Figure 5-6 As shown, the difference between this embodiment and Embodiment 1 is that: the window body 1 is provided with a cavity 9, and the cavity 9 is provided with a heat conduction plate 10, and the heat conduction plate 10 can be made of a material with better thermal conductivity, such as Metal material, the heat conduction plate 10 is in contact with the side wall of the cavity 9 near the inner side of the window body 1, the rotating shaft 3 extends into the cavity 9 and is coaxially fixedly connected with the heat conduction plate 10, the heat conduction plate 10 and the inner side wall of the cavity 9 Rotating and sealed connection, the heat conduction plate 10 is provided with an arc-shaped exhaust port 11 that matches the ventilation hole 8, and the arc-shaped exhaust port 11 and the arc-shaped air inlet 6 are symmetrically distributed about the axis line of the rotating shaft 3, so that the gas During the process of entering the cavity 9 from the ar...

Embodiment 3

[0028] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 2 is that an installation groove 12 is provided on the outer end surface of the rotating shaft 3, and the installation groove 12 communicates with the interior of the cavity 9 through a plurality of purification holes 13, and the installation groove 12 can be The filter element 14 is disassembled and connected. Specifically, an internal thread can be set on the side wall of the installation groove 12, and the outer surface of the filter element 14 can be made as an external thread matching the internal thread, so that the filter element 14 can be replaced conveniently.

[0029] In this embodiment, when the external air passes through the cavity 9, the filter element 14 can purify the air and keep the air fresh. It is worth mentioning that the filter element 14 can also be a solid air freshener, which is used to reduce the Odors inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com