A control method for compound braking transition process

A compound braking and transition process technology, applied in electric braking systems, electric vehicles, vehicle components, etc., can solve the problems of increased hydraulic braking force, heat generation, low motor power generation efficiency, etc., to improve braking impact, good control effect, the effect of improving braking consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

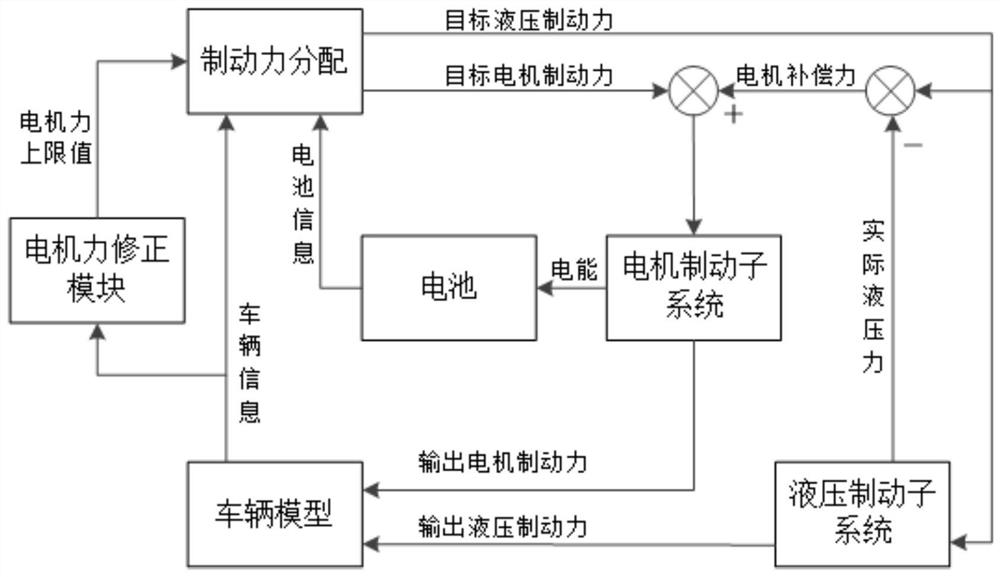

[0032] The invention relates to a method for controlling a composite braking transition process, which comprises the following steps:

[0033] Step 1. Based on the researched vehicle model and compound braking system, analyze vehicle parameters and motor parameters, and determine that the braking deceleration corresponding to the upper limit of motor force is 0.1g.

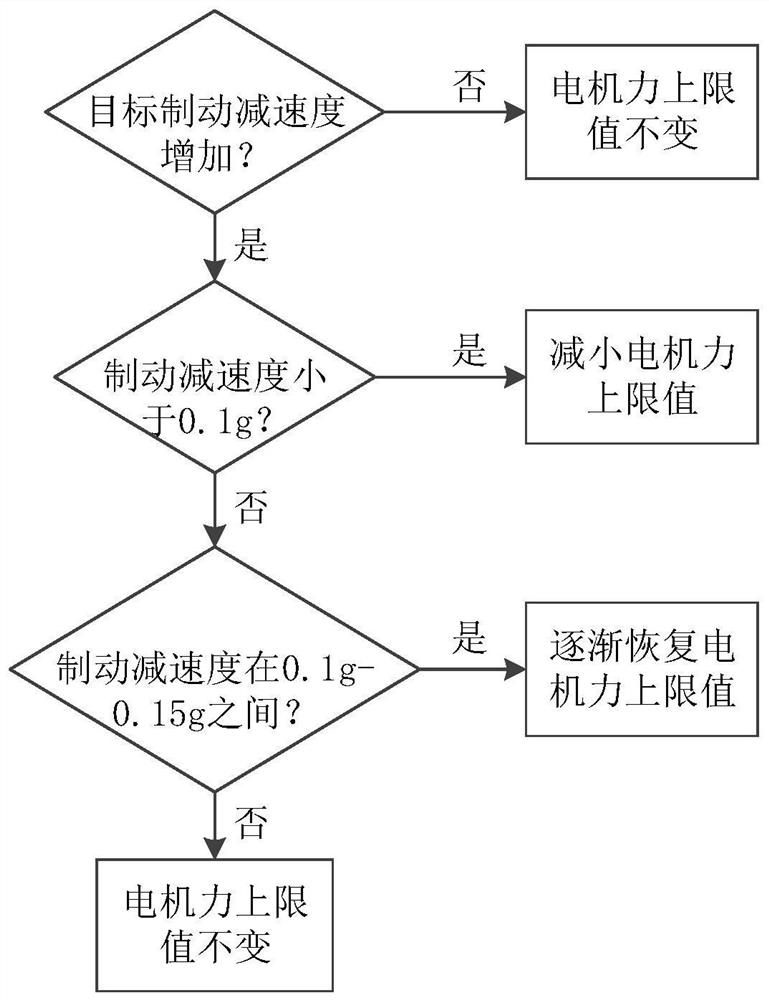

[0034] Step 2. Determine the logic algorithm of the motor force correction module based on the vehicle information and the data obtained in step 1:

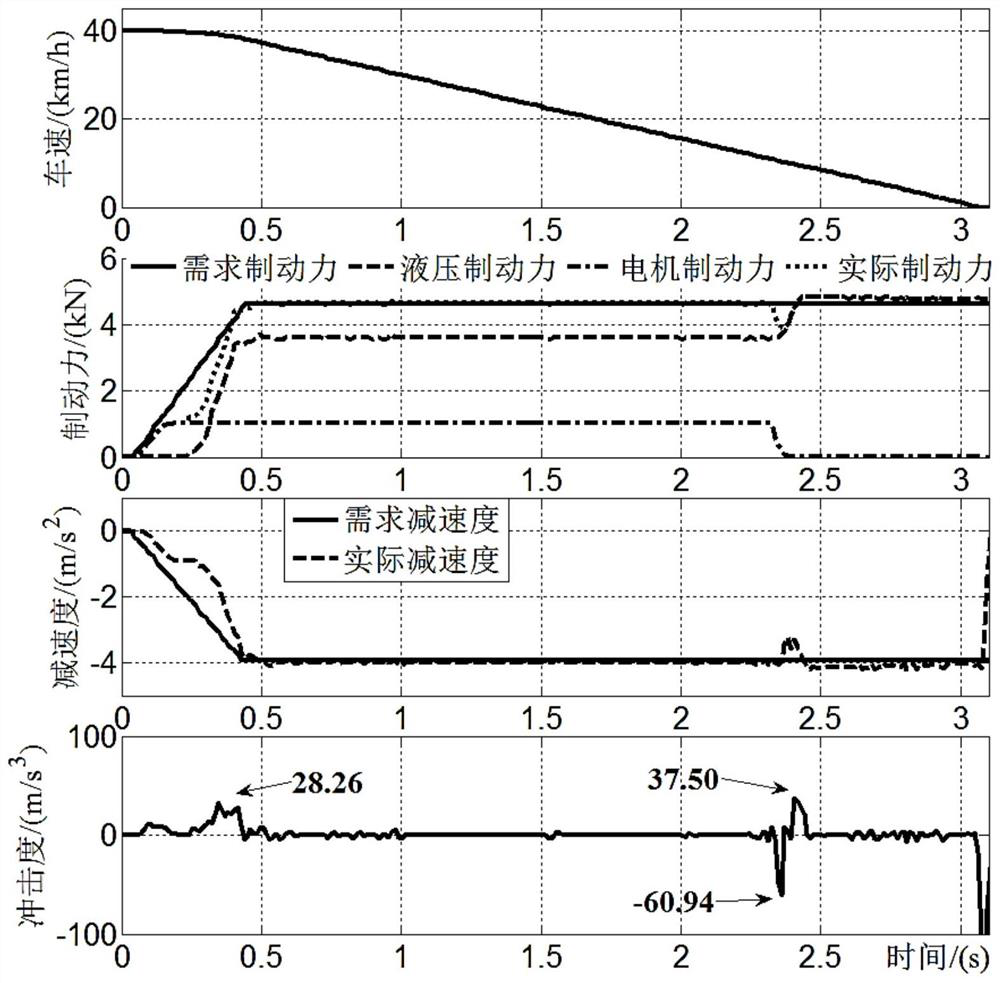

[0035] Motor power correction logic such as figure 2 As shown, according to the state of the vehicle, if the braking demand is increasing and the braking deceleration is less than 0.1g, the hydraulic braking force is about to intervene at this time, so that the upper limit of the electric force of the braking force distribution is lower than the maximum value, so that the hydraulic braking Insufficient braking force due to lag during power intervention can be compe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com