A method for measuring rheological parameter range of wall surface putty construction

A technology for rheological parameters and measurement methods, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as poor data comparability and misleading formula adjustment, and achieve the effect of overcoming large data errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

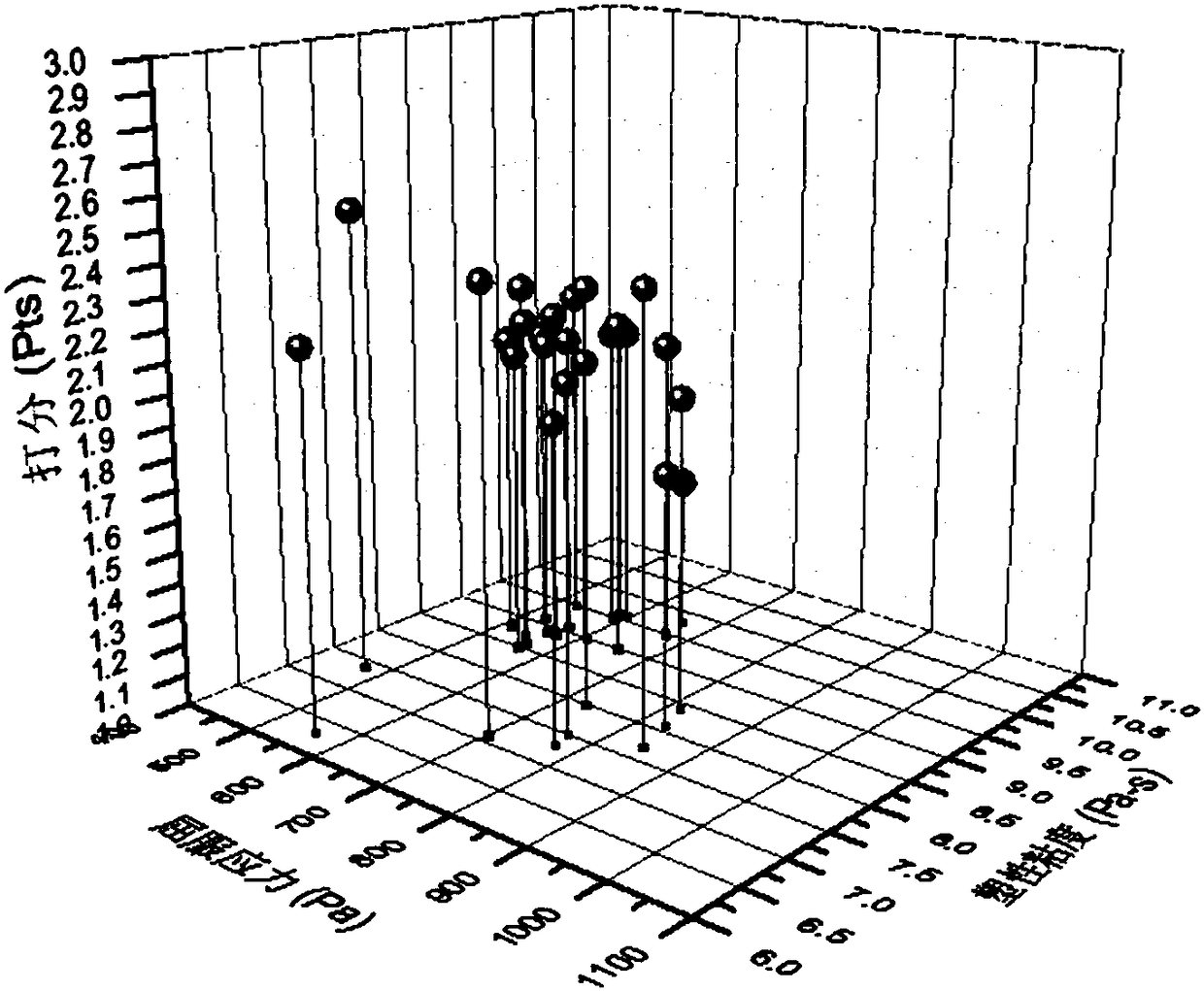

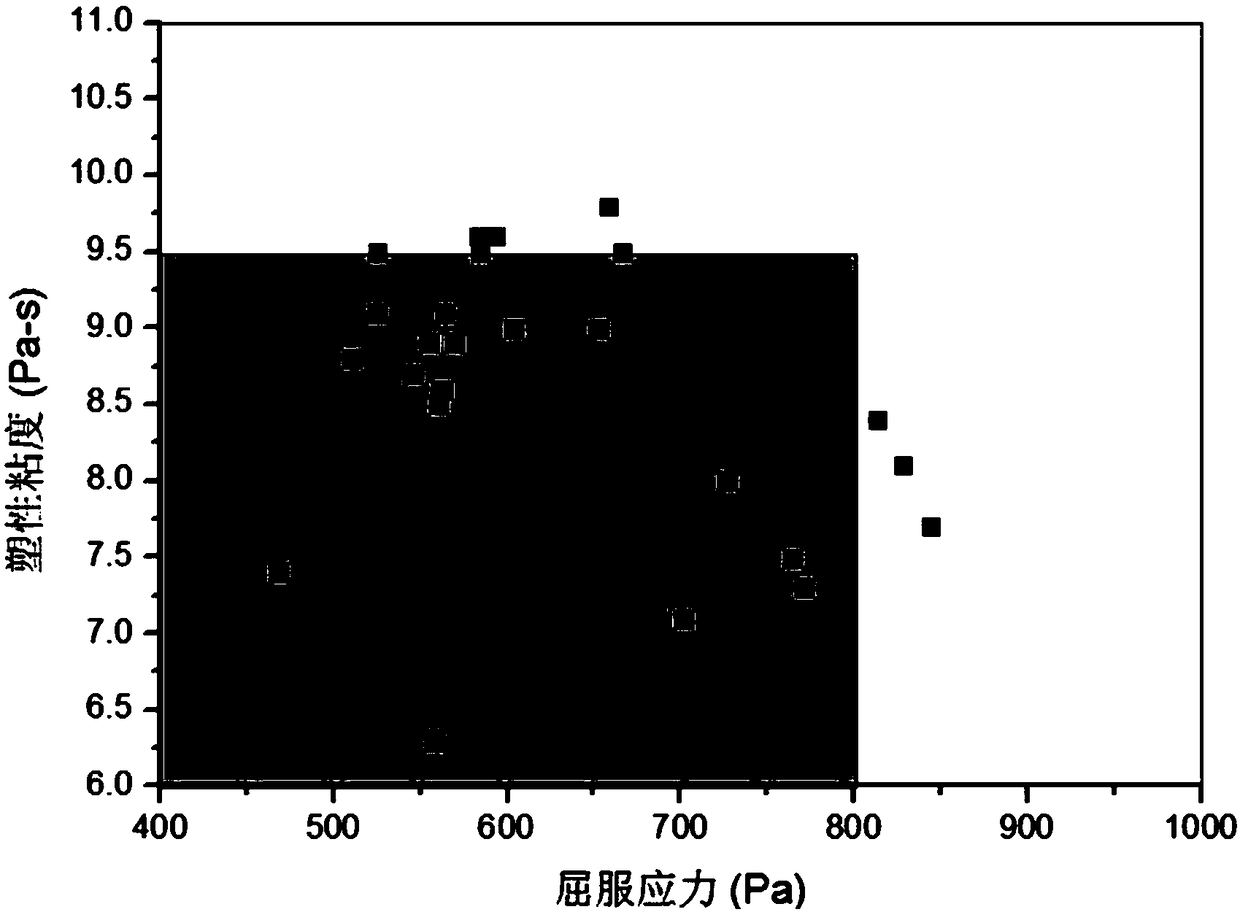

[0043] This embodiment provides a method for measuring the range of rheological parameters of wall putty construction, including: measuring the rheological parameters of several putty samples, and manually scoring the construction performance of each putty sample, and determining according to the scoring value of each putty sample The range of rheological parameters of putty samples with satisfactory construction performance.

[0044] In the above scheme, the acquisition of the rheological parameter range of the putty construction performance is based on manual scoring, and the accuracy of the rheological parameter range of the putty construction performance can be improved by scoring the putty samples by senior construction personnel, although this method is based on manual scoring. Scoring, but more objectively provides a method of identifying the construction performance of putty, and identifies the construction performance of putty in the form of data (rheological parameter...

Embodiment 2

[0081] In embodiment two, specific rheological parameter range determination methods are provided according to specific examples:

[0082] Step 1. Prepare putty paste samples according to the formula in Table 1.

[0083] The sample preparation method is as follows: first add an appropriate amount of water to the production kettle, slowly add the adhesive while stirring at a constant speed with a dispersing plate, at this time, a large amount of foam appears, and then add other additives such as defoamers in turn, after 15 minutes A homogeneously dispersed liquid is obtained. Slowly add heavy calcium powder, reduce the rotating speed of the dispersing disc and disperse for 15 minutes to obtain a paste-like finished product.

[0084] Table 1 Basic formula composition of surface layer putty samples

[0085]

[0086]

[0087] Step 2, collect samples at the lower part of the kettle, and fill the reserved samples into a 5L tank. Sample tools for batch scraping application, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com