Positioning device for automobile mold

A positioning device and automobile mold technology, applied in the field of mold processing, can solve problems such as low positioning accuracy, product error, and small application range, and achieve the effects of high positioning accuracy, reduced production costs, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

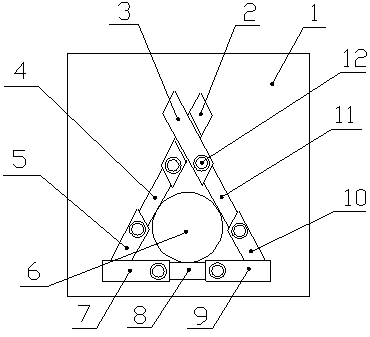

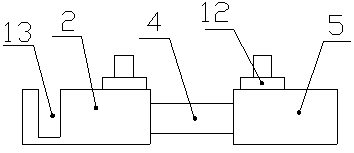

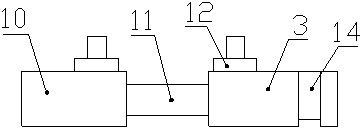

[0016] Such as Figure 1-3 Shown, a kind of automobile mold locating device, it comprises workbench 1, and described workbench 1 is provided with locating plate A, locating plate B and locating plate C, and described locating plate A is composed of outer baffle plate A2, inner The baffle plate A4 and the outer baffle plate B5 are composed, the positioning plate B is composed of the outer baffle plate C7, the inner baffle plate B8 and the outer baffle plate D9, and the described positioning plate C is composed of the outer baffle plate E10, the inner baffle plate C11 and the The outer baffle F3 is composed of one end of the outer baffle B5 and the left side of the rear end surface of the outer baffle C7, and the other end of the outer baffle B5 is plugged with the inner baffle A4. The other end of the plate A4 is plugged into the outer baffle A2, and the side of the outer baffle A2 away from the inner baffle A4 is provided with a card slot 13, and a card block 14 is carded in t...

Embodiment 2

[0019] Such as Figure 1-3 as shown,

[0020] A kind of automobile mold positioning device, it comprises workbench 1, and described workbench 1 is provided with positioning plate A, positioning plate B and positioning plate C, and described positioning plate A is composed of outer baffle plate A2, inner baffle plate A4 and the outer baffle B5, the positioning plate B is composed of the outer baffle C7, the inner baffle B8 and the outer baffle D9, and the described positioning plate C is composed of the outer baffle E10, the inner baffle C11 and the outer baffle Composed of F3, one end of the outer baffle B5 is fixedly connected to the left side of the rear end surface of the outer baffle C7, the other end of the outer baffle B5 is plugged with an inner baffle A4, and the inner baffle A4 is The other end is plugged into the outer baffle A2, and the side of the outer baffle A2 away from the inner baffle A4 is provided with a card slot 13, and a card block 14 is snapped into the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap