A double-sided mesh terry cloth

A terry cloth, double-sided technology, applied in textiles and papermaking, knitting, weft knitting, etc., can solve the problems of single fancy fabrics and poor hand feeling, and achieve the effect of increasing fancy varieties and improving the use feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

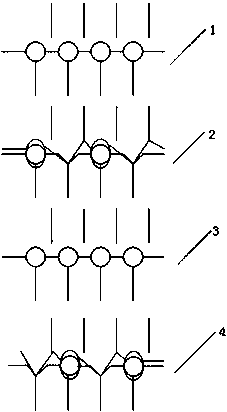

[0022] In this embodiment, the double-sided mesh terry cloth includes a mesh structure main body made of ground yarn and several weaving loop structures arranged on the surface of the mesh structure main body, such as figure 1 As shown, each knitting cycle structure forms a four-way knitting structure through loop yarn knitting. The lower needles in knitting structure 2 form loops and tucks in sequence, and the even-numbered needles in the upper needles raise the corresponding tucks in turn, all the lower needles in the third knitting structure 3 form loops, and the fourth knitting The lower needles in structure 4 are tucked and looped at intervals in turn, and the odd-numbered needles in the upper needles raise the corresponding tucks in turn, and the upper needles in each knitting cycle structure form a pile structure.

[0023] The double-sided mesh terry cloth of the present embodiment is prepared through the following steps:

[0024] (1) Choose double-sided circular knitt...

Embodiment 2

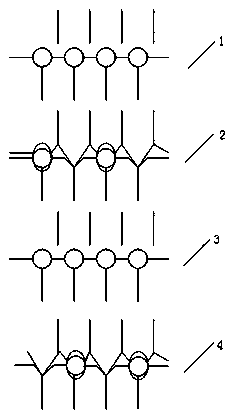

[0028] In this embodiment, the double-sided mesh terry cloth includes a mesh structure main body made of ground yarn and several weaving loop structures arranged on the surface of the mesh structure main body, such as figure 2 As shown, each knitting cycle structure forms a four-way knitting structure through loop yarn knitting. The lower needles in knitting structure 2 form loops and tucks in sequence, and the upper needles lift up the corresponding tucks, all the lower needles in the third knitting structure 3 form loops, and the lower needles in the fourth knitting structure 4 The tucks and loops are sequentially spaced, the upper needles lift up the corresponding tucks, and the upper needles in each knitting cycle structure form a pile structure.

[0029] The double-sided mesh terry cloth of the present embodiment is prepared through the following steps:

[0030] (1) Choose double-sided circular knitting machine with headless needles as the upper needle and conventional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com