A floating grinding device for the surface of anodic steel claws

A technology of anode steel claw and grinding plate, applied in the field of electrolytic aluminum, can solve the problems of low grinding efficiency, low efficiency and unsatisfactory effect, and achieve the effect of compact and orderly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are described below by specific embodiments, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0017] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

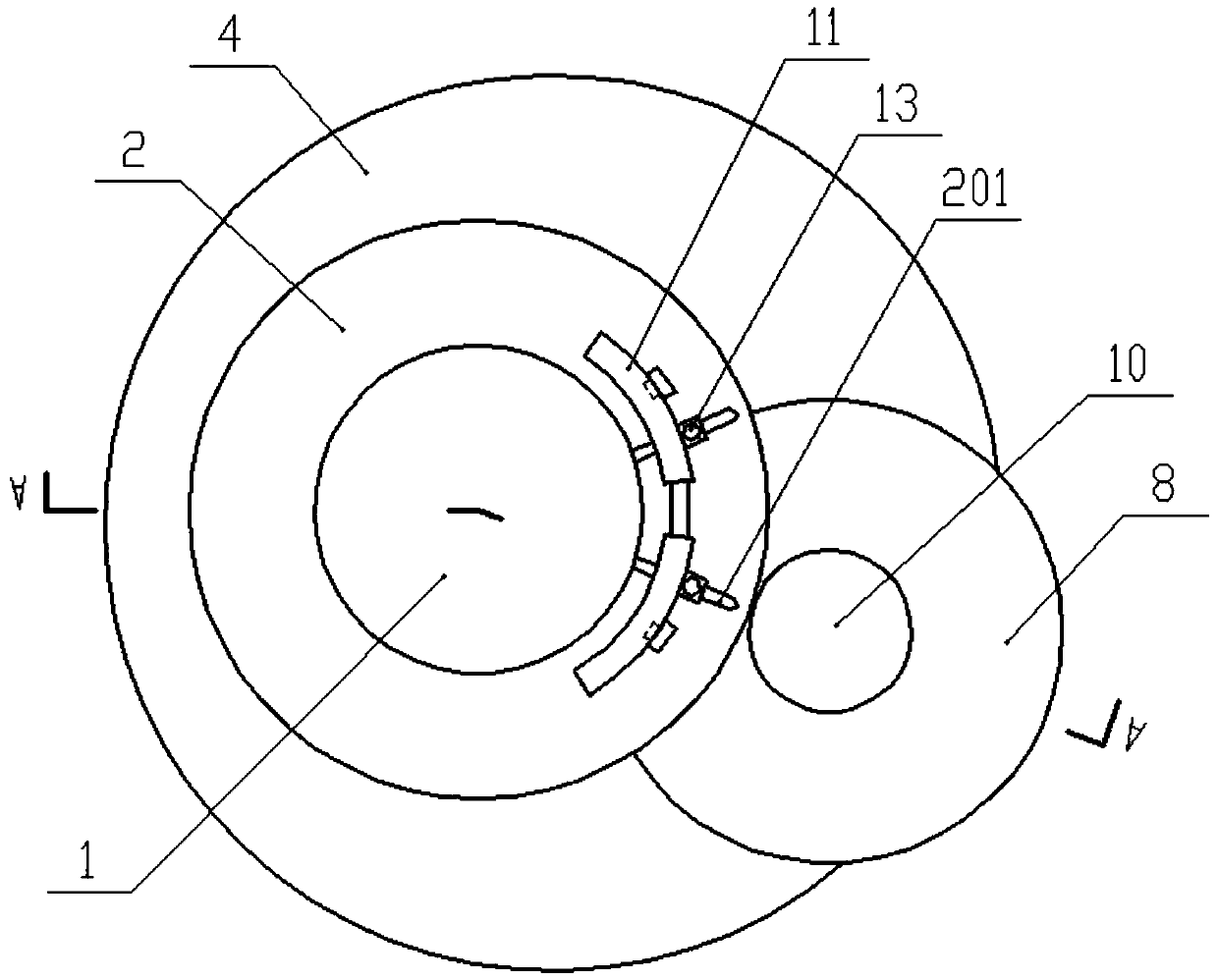

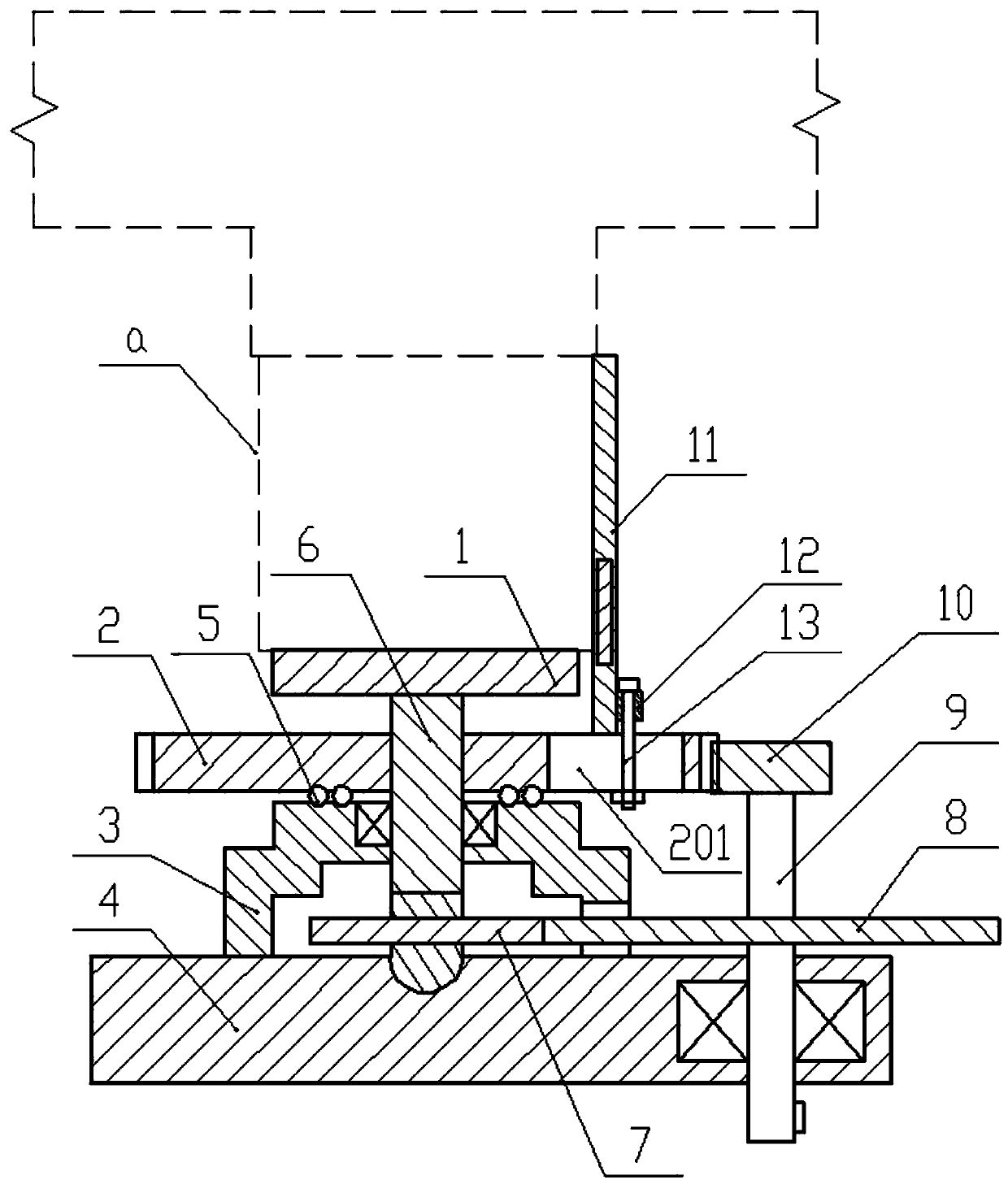

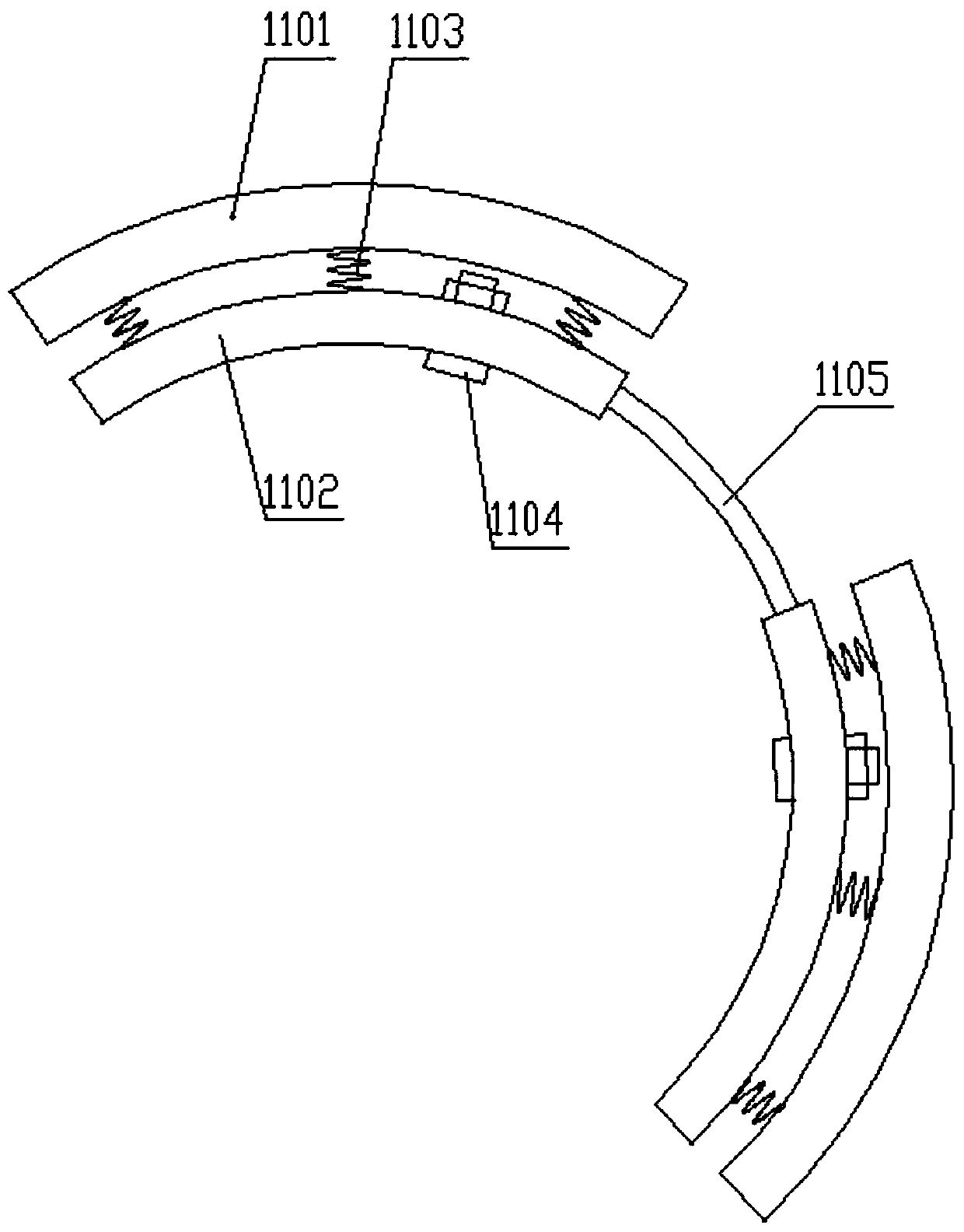

[0018] like figure 1 As shown in -3, a floating grinding device for the surface of anode steel claw, from top to bottom, includes an end surface grinding plate 1, a gear plate 2, a support 3 and a base 4; wherein, the bottom surface of the support 3 is provided with a gear cavity, The bottom surface of the support 3 is fixed and close to the upper surface of the base 4 and closes the cavity of the gear cavity. The gear plate 2 is placed on the top of the support 3, and between the gear plate 2 and the support 3. The two opposite end faces are provided with a plurality of annular grooves with arc-shaped cross-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com