Universal fixing crankshaft tool

A crankshaft and tool technology, applied in the field of universal fixed crankshaft tools, can solve problems such as low production efficiency, complicated operation, and difficulty in meeting production needs, and achieve the effects of preventing tool falling off, simple and fast operation, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

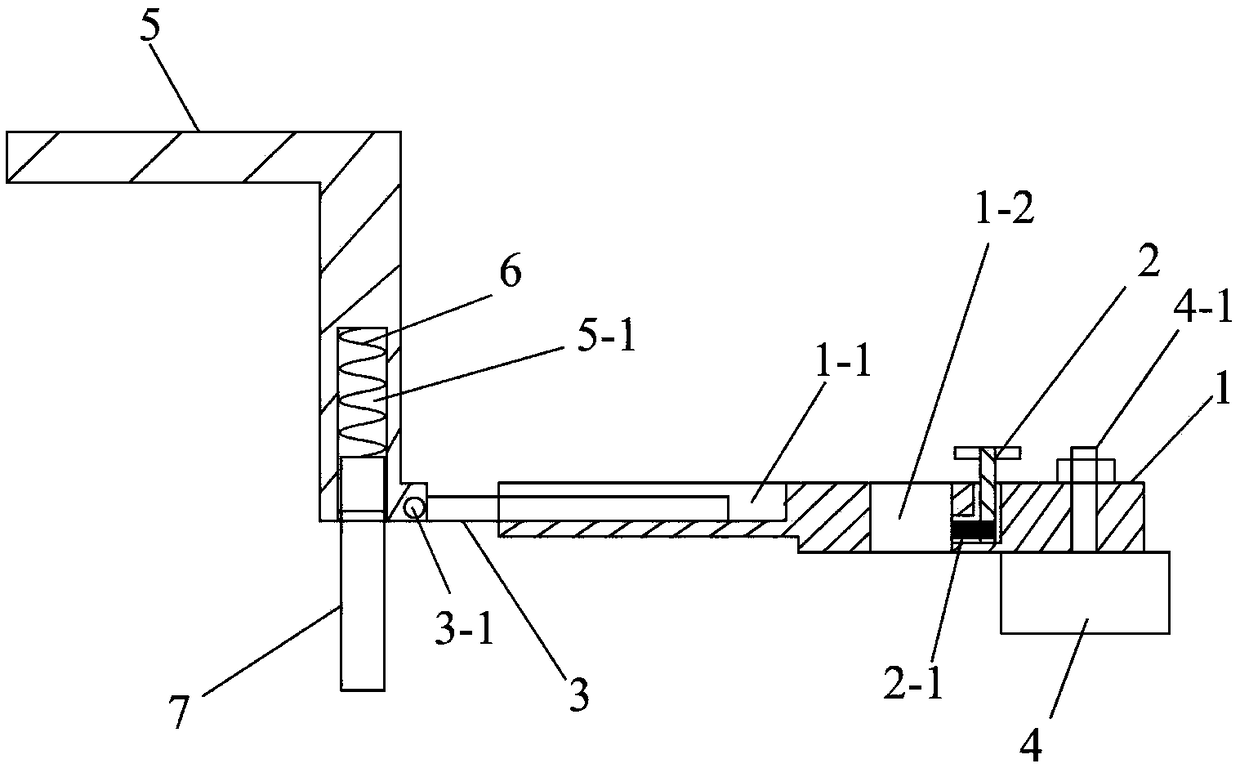

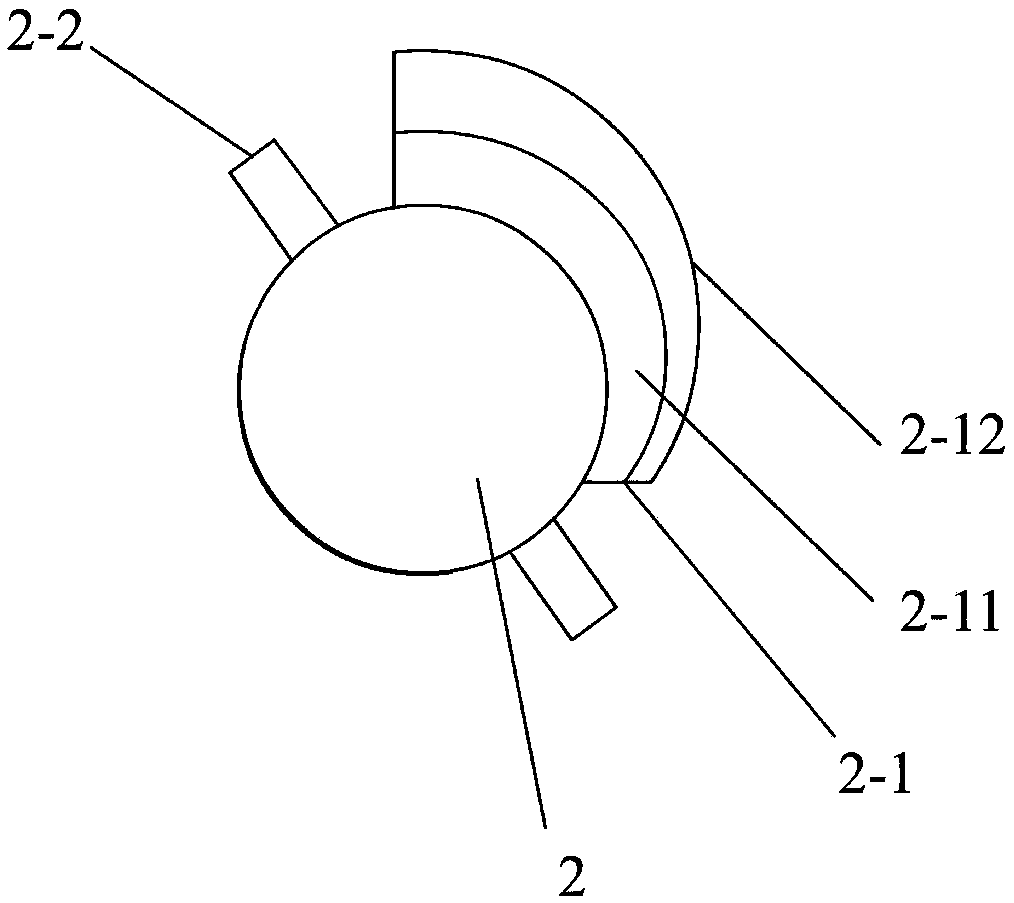

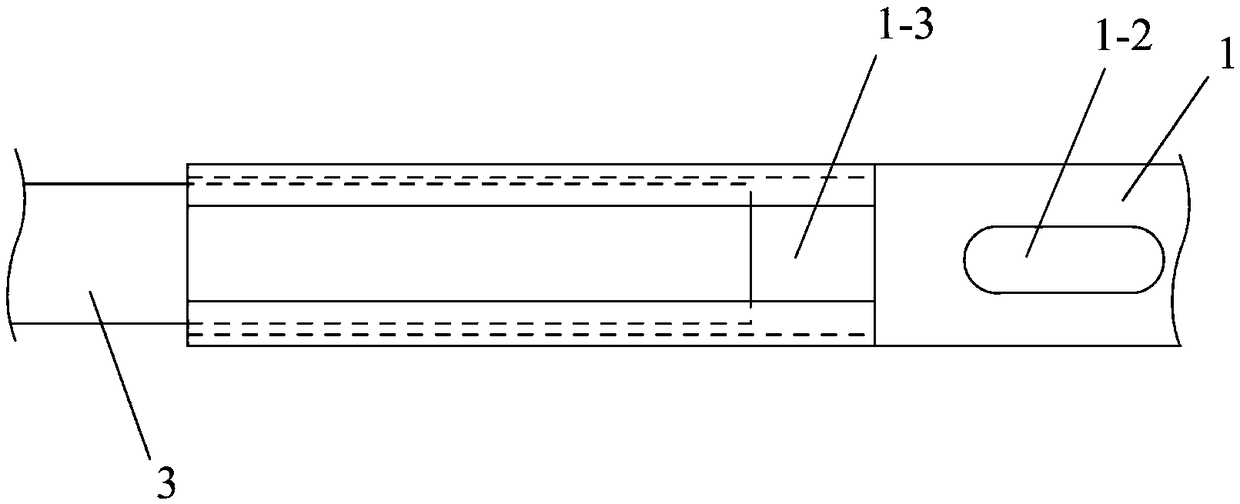

[0018] Such as Figure 1~3 As shown, a universal fixed crankshaft tool includes a connecting plate 1 and a handle 5. In this embodiment, the handle 5 is approximately in the shape of a "7". One end of the connecting plate 1 is detachably fixed with a crankshaft positioning block 4. In this embodiment, a fixing hole is provided on the right part of the connecting plate 1, and then the lower end of the screw rod 4-1 is combined with the crankshaft for positioning. Block 4, and detachably fixed by nuts. The crankshaft positioning block 4 matches the end hole of the crankshaft, and the crankshaft positioning block 4 can be replaced for crankshafts of different types; There is also a flywheel positioning pin hole 1-2 between 4 and the expansion plate chute 1-1; it also includes an expansion plate 3 and a flywheel shell pin 7; the expansion plate 3 is inserted into the expansion plate chute 1-1 The other end is rotatably connected to the lower part of the handle 5 through the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com