Patents

Literature

39results about How to "Realize positioning connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

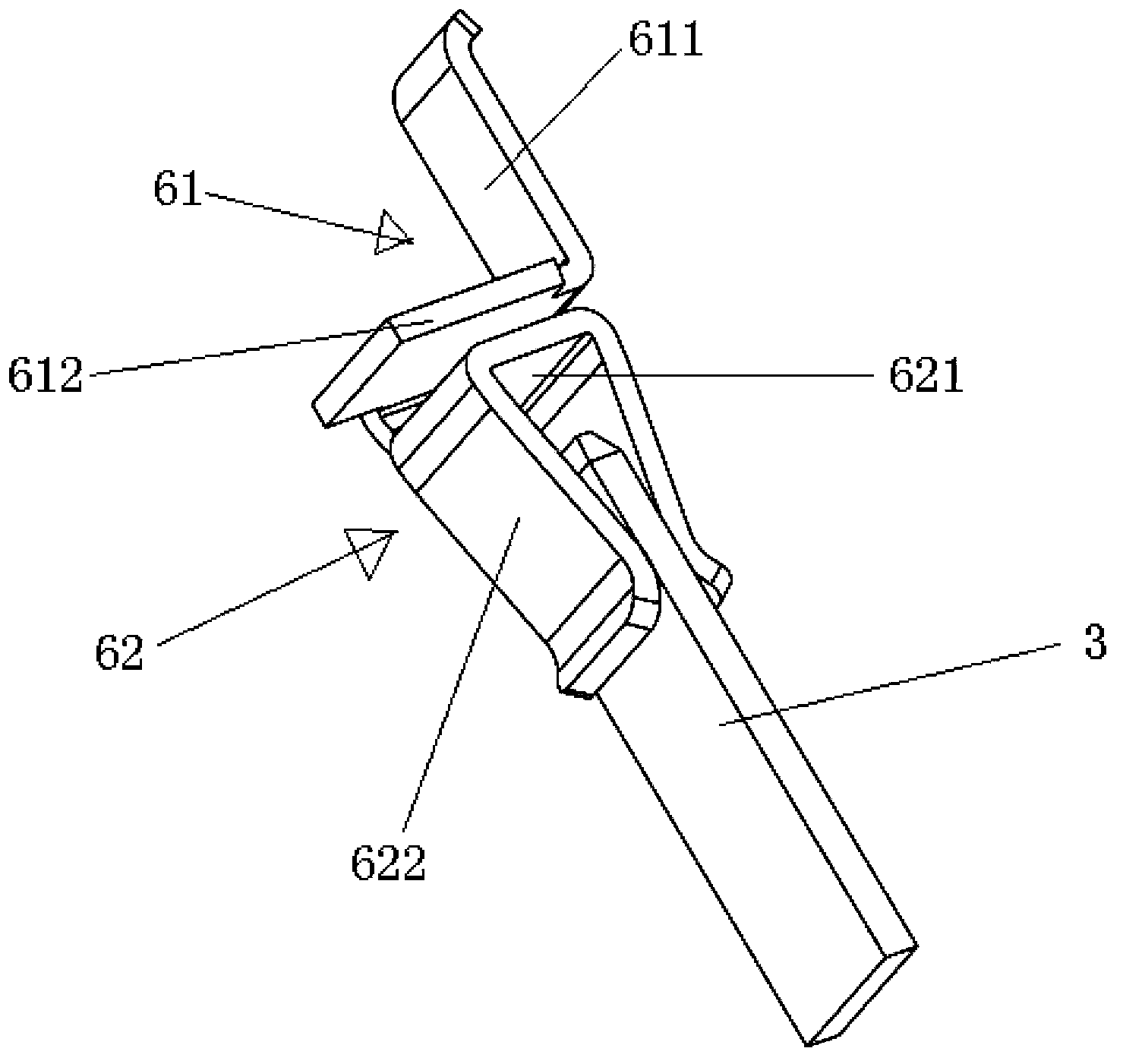

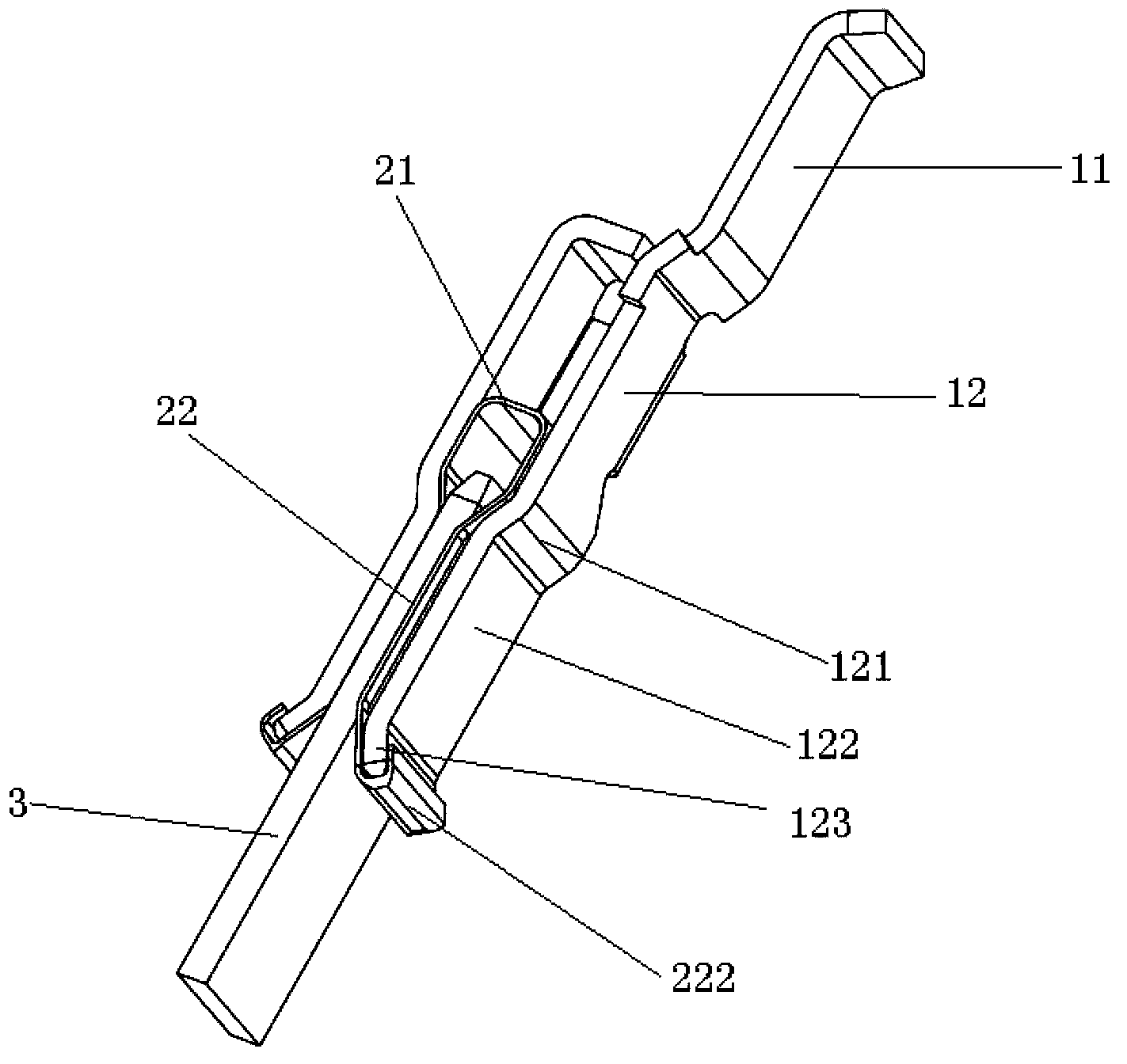

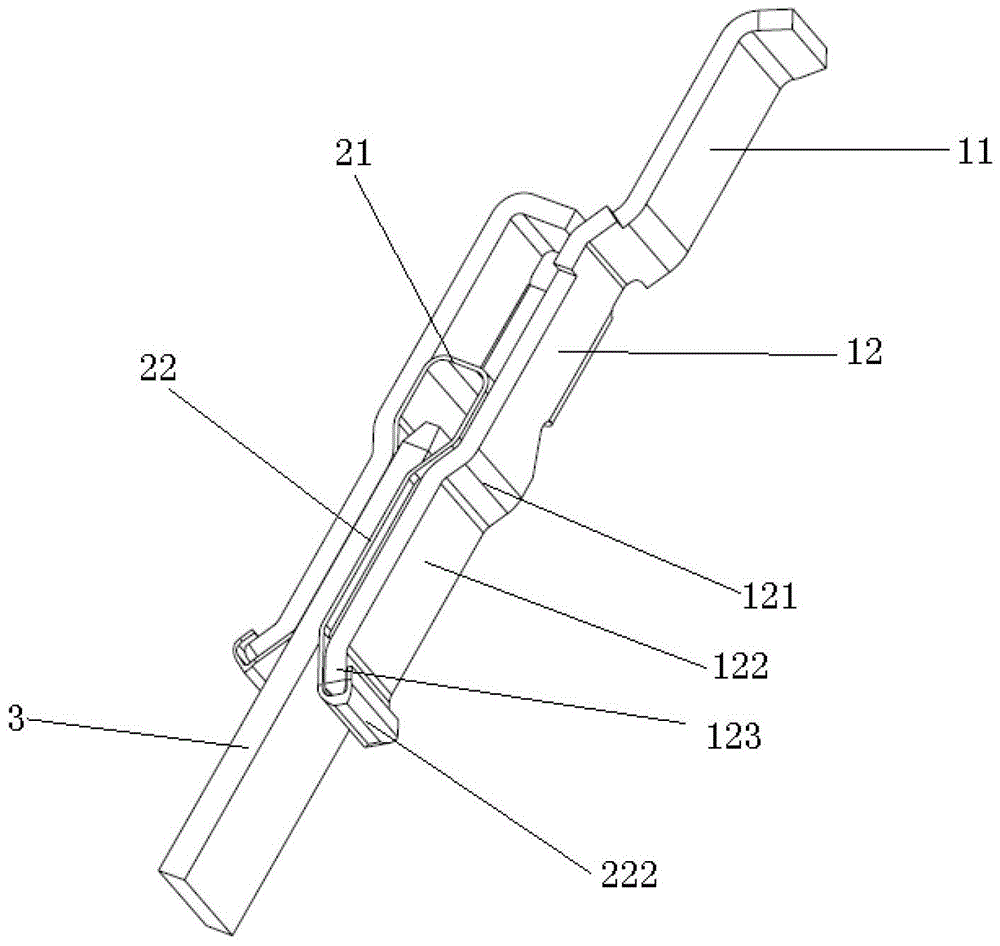

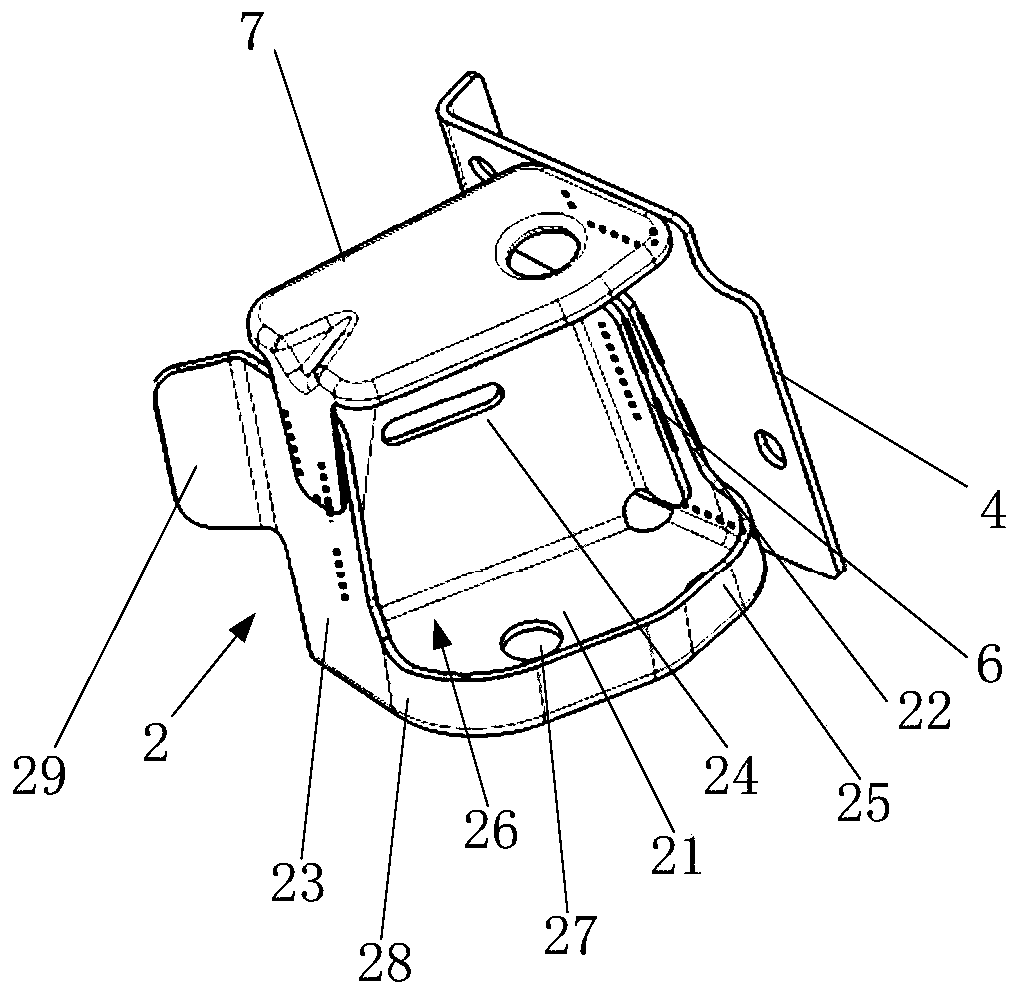

Low-cost large-current clip terminal for electric connector

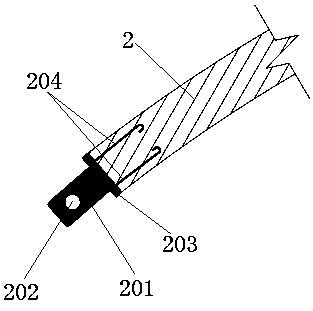

ActiveCN104143718AImprove connection reliabilityImprove conductivityCoupling contact membersElectricityEngineering

The invention discloses a low-cost large-current clip terminal for an electric connector. The low-cost large-current clip terminal comprises a terminal body and an elastic clip. The elastic clip comprises a connecting piece and two clamping pieces, wherein the connecting piece has high conductivity and elasticity and is integrally formed, the two clamping pieces are oppositely arranged, and the common end of the two clamping pieces is integrally connected with the connecting piece. The terminal body comprises a conductive plate and two clip opening pieces, wherein the conductive plate has high conductivity and is integrally formed, the two clip opening pieces are oppositely arranged, and one end of one clip opening piece is integrally connected with the conductive plate. The elastic clip is arranged between the two clip opening pieces in a located and sleeved mode. The connecting piece faces the conductive plate and is attached to the clip opening pieces. The two clamping pieces can elastically clamp metal inserts to be connected. According to the low-cost large-current clip terminal, an integrated structure with only one clamping point is replaced by the clip structure with multiple contacts, the connection reliability of the clip terminal can be effectively improved, the size of the elastic contact part of the clip terminal can be decreased, and therefore the consumption of high-conductivity elastic copper materials and the production cost can be lowered.

Owner:DINKLE M&E CHINA

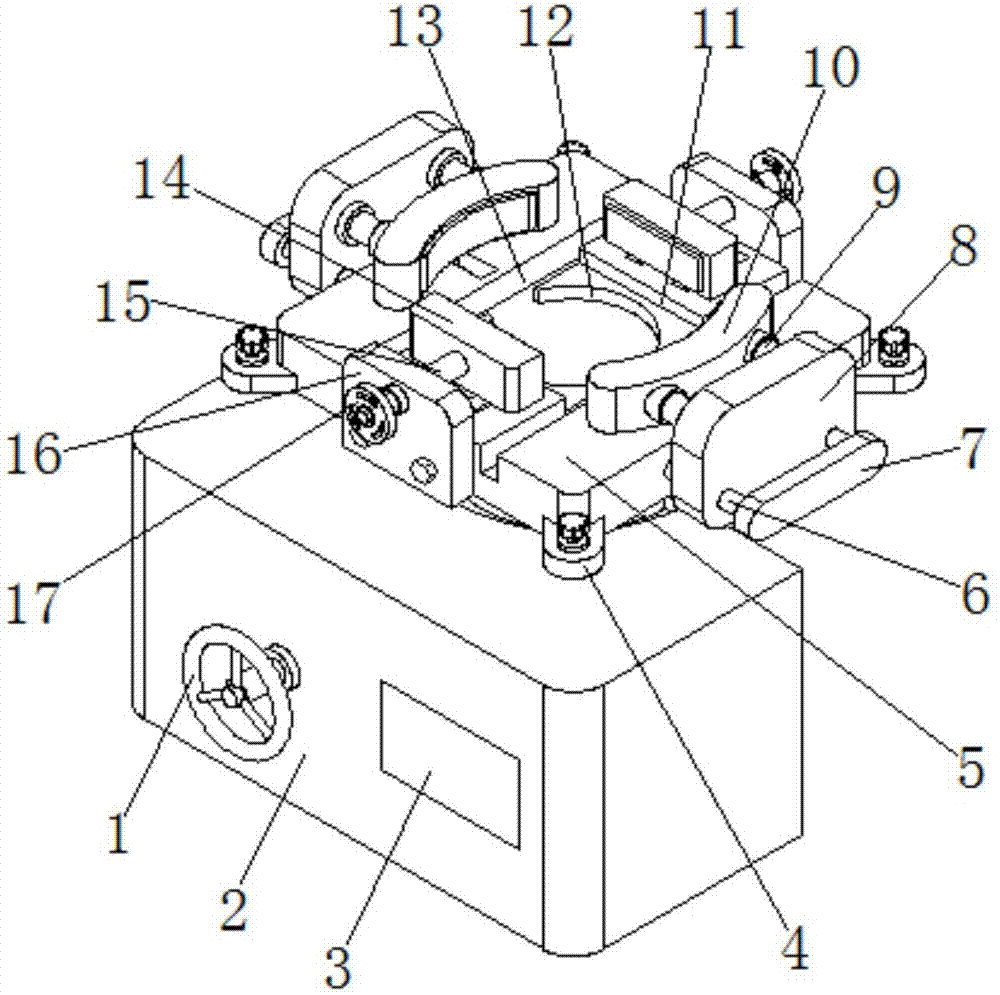

Machining clamp with adjustable direction

InactiveCN107322341ARealize positioning connectionPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a machining clamp with the adjustable direction. The machining clamp comprises a machine tool body. A clamp body is arranged on the upper side of the machine tool body. The side, close to the machine tool body, of the clamp body is connected with one end of a main shaft, and the other end of the main shaft extends into the machine tool body and is connected with the machine tool body through a bearing. A worm wheel is arranged at the middle position of the main shaft. The side, close to the worm wheel, in the machine tool body is connected with a worm through a bearing. The worm and the worm wheel are connected in a matched manner. One end of the worm extends to the outer portion of the machine tool body and is connected with a rotation wheel. Through the rotation wheel, the worm, the main shaft and the worm wheel, the angle and direction of the clamp body can be adjusted, arc fixing plates, rectangular positioning grooves, arc positioning grooves and rectangular fixing plates can be applicable to different situations of a workpiece clamping reference plane, and positioning connection of the clamp body and the machine tool body can be achieved through a fixing anti-skid plate and a positioning ring type boss.

Owner:王佳庆

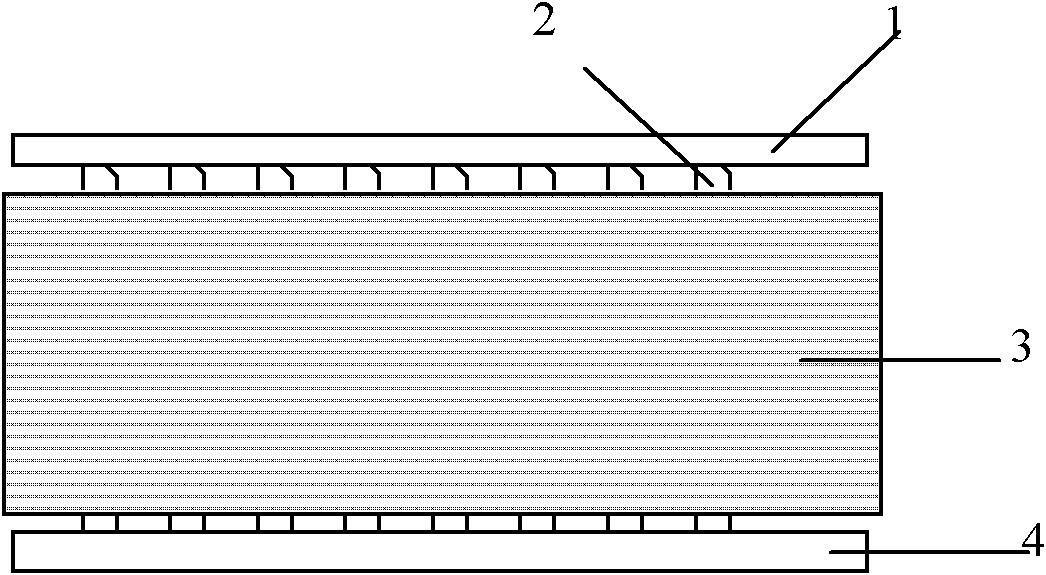

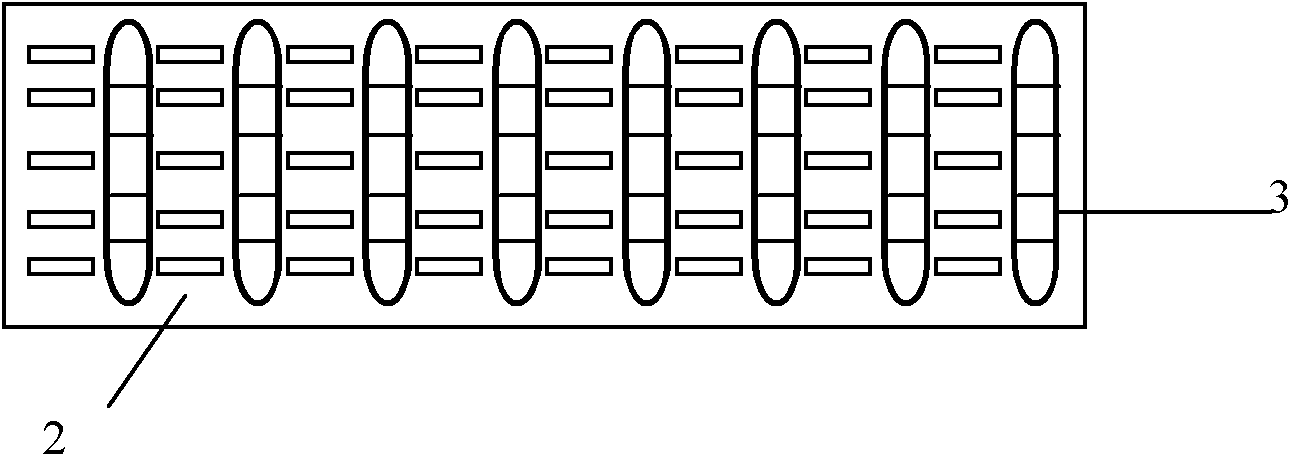

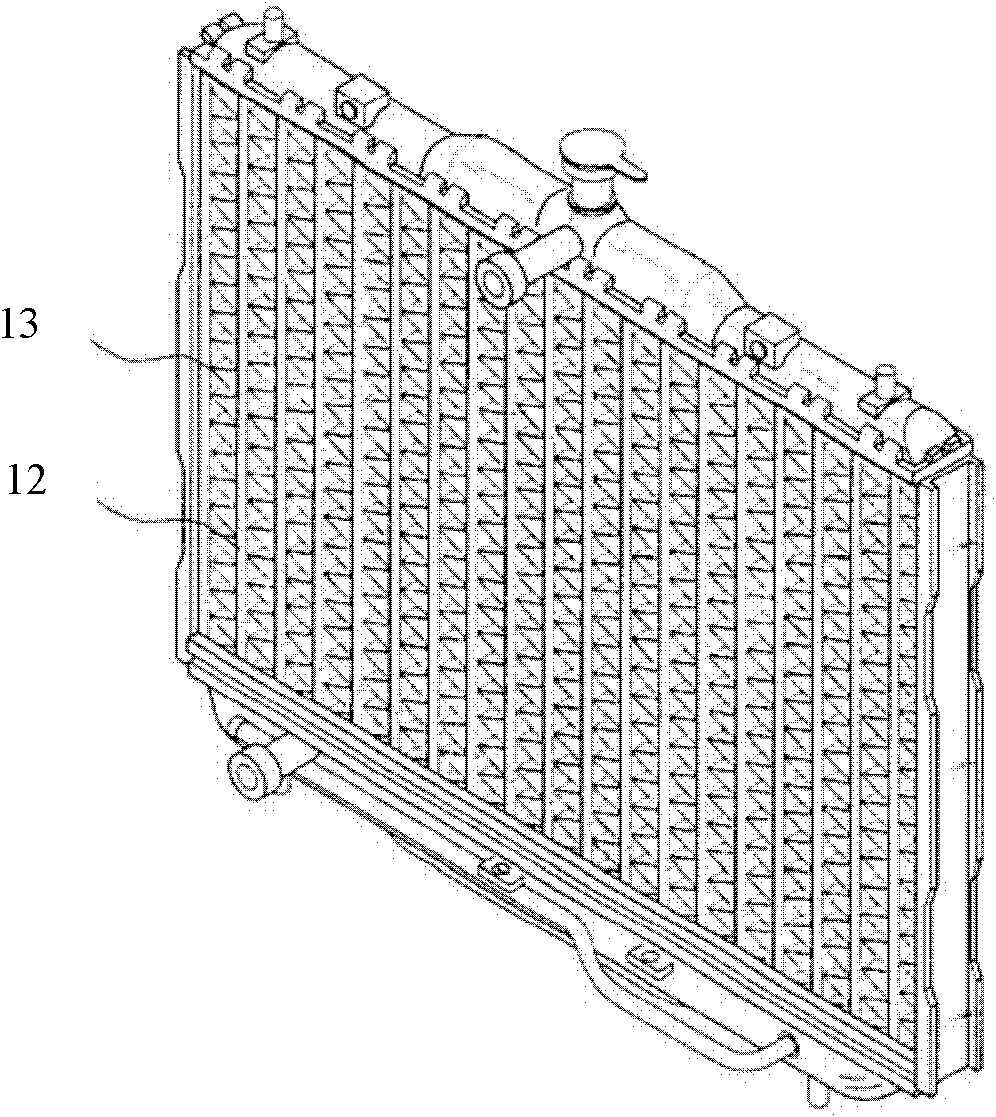

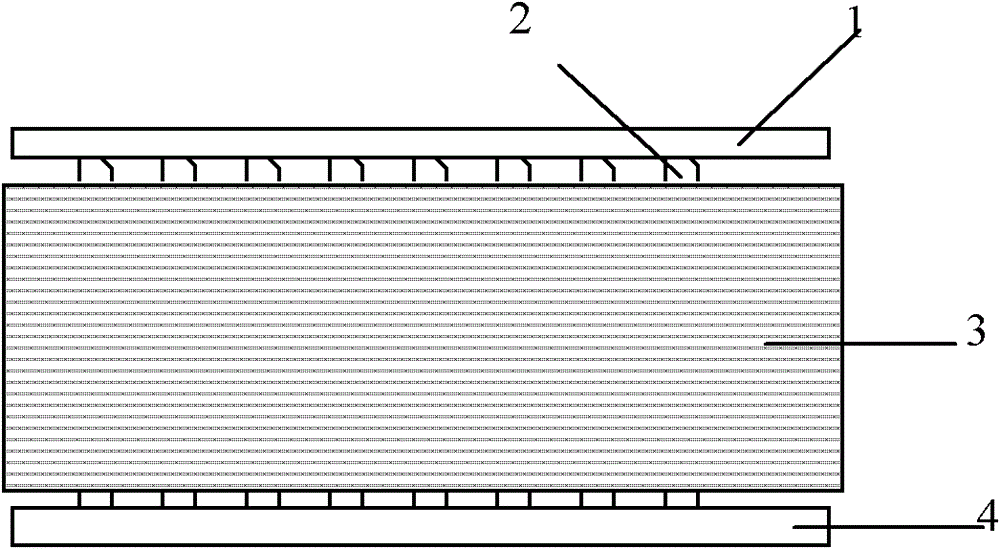

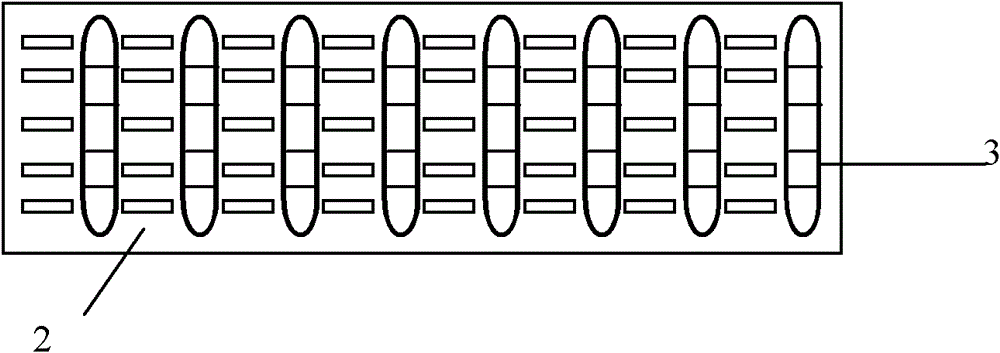

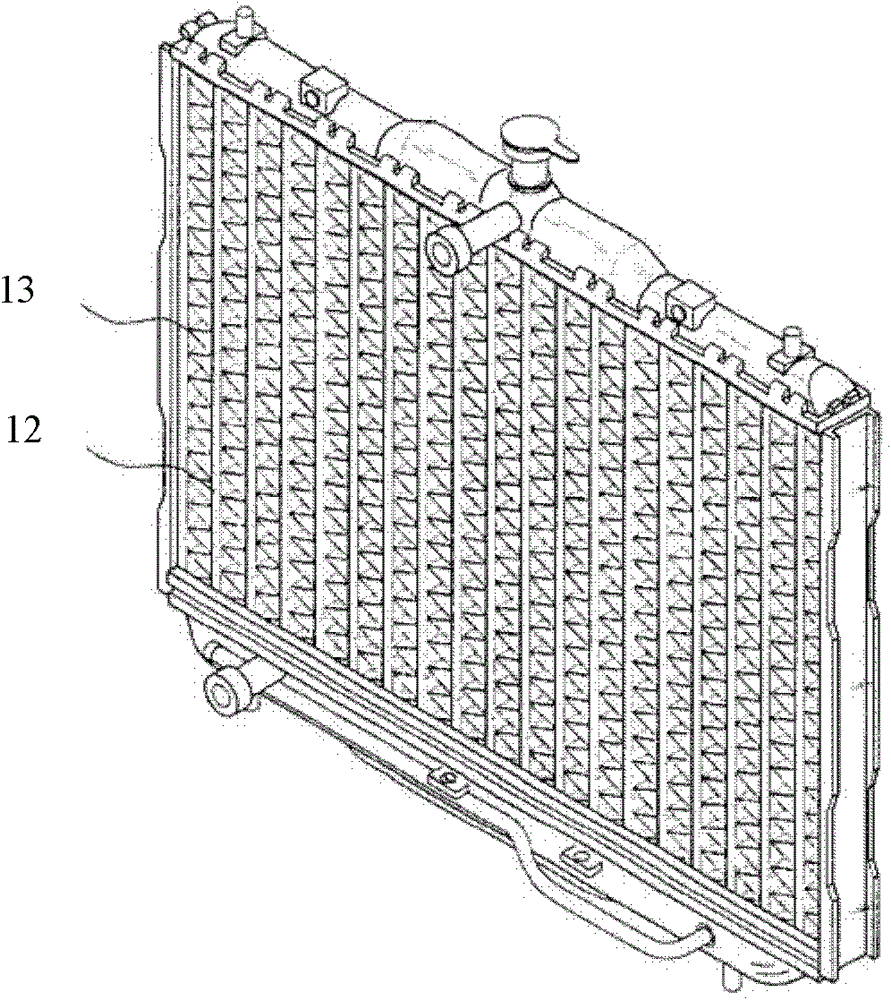

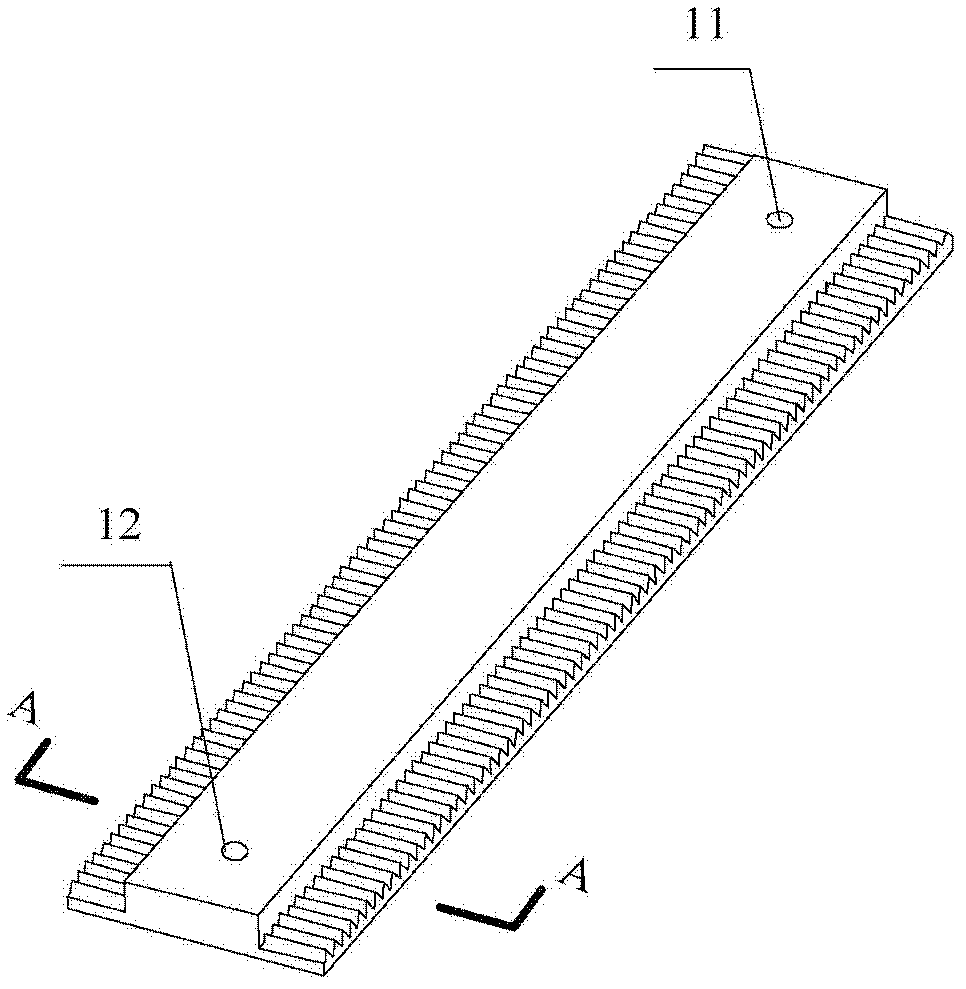

Heat exchanger structure and assembly process thereof

InactiveCN102338587AImprove product qualityImprove welding strengthTubular elementsFlangingEngineering

The invention discloses a heat exchanger structure. The heat exchanger structure comprises fins and a flat pipe connected with the fins in a locating manner, wherein grooves are concavely formed inwards on two side surfaces of the flat pipe and extend along the length direction of the flat pipe. The invention also discloses an assembly process of the heat exchanger structure, comprising the following steps of: (1) sequentially piling and fixing the fins; (2) embedding a lug boss of a welding material sheet into each groove in a matching manner, and connecting the welding material sheet and the flat pipe in the locating manner; (3) locating the flat pipe connected with the welding material sheet in the locating manner and the fins; and (4) placing the flat pipe and the fins in a brazing furnace to weld. By using the heat exchanger structure and the assembly process thereof, the welding material uniformity is improved, a connecting region is beneficially formed by the welding material around a contact point of the fins and the flat pipe, the welding strength is improved, and because the grooves are arranged in the middle of the flat pipe, the density of microchannels in the center of the flat pipe is reduced, the phenomenon, such as freezing and the like caused by too low temperature in the center is improved, the pipeline groove radius can be correspondingly increased while the welding quality is ensured, and a flanging height is beneficially designed.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Heat exchanger structure and its assembly process

InactiveCN102338587BImprove uniformitySimplify the setup processTubular elementsEngineeringWeld strength

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

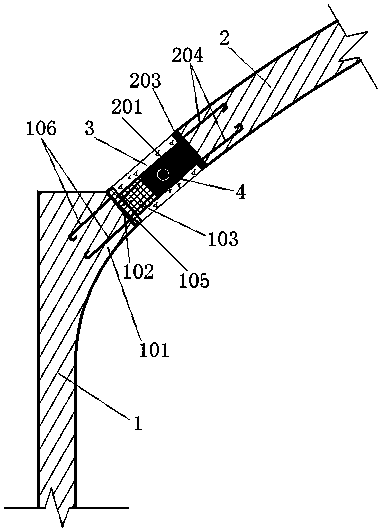

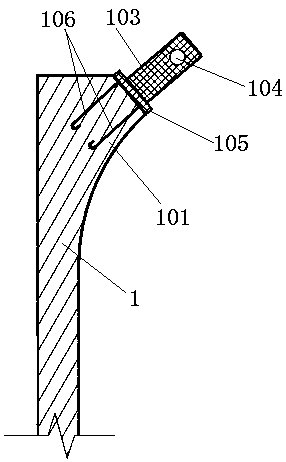

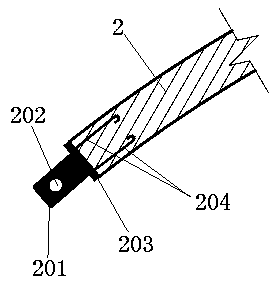

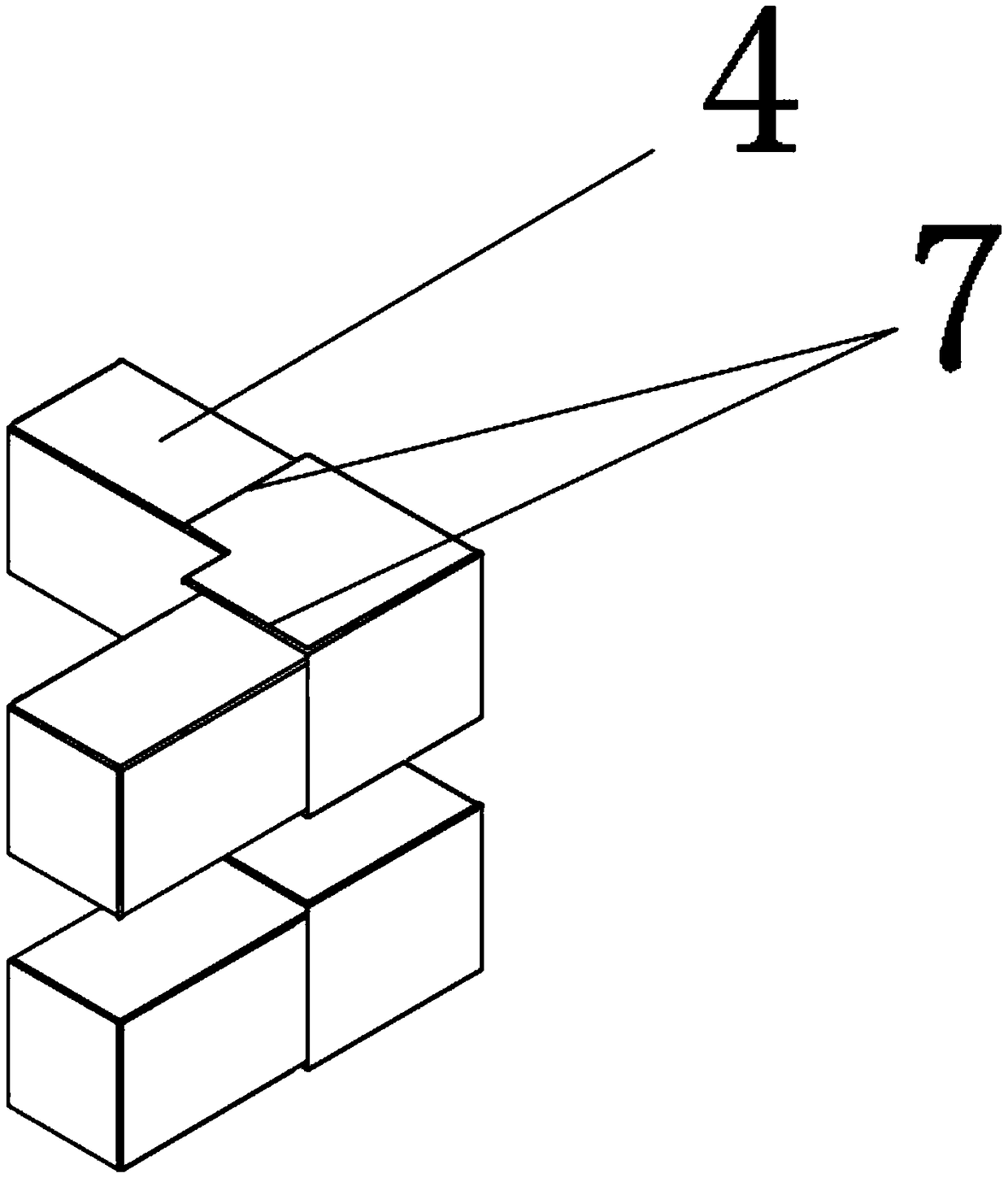

Fabricated structure side wall prefabricated member and connection structure thereof with arched plate

PendingCN110359487AEasy to achieve large space effectGood building visual effectArtificial islandsUnderwater structuresClerestoryBuilding construction

The invention belongs to the underground engineering construction technology field, and particularly relates to a fabricated structure side wall prefabricated member. The fabricated structure side wall prefabricated member comprises a side wall prefabricated member body, wherein a support face is arranged at the top of the side wall prefabricated member body, a first connection piece with at leasta part embedded in the side wall prefabricated member body is arranged on the support face, and the first connection piece comprises first connection plates used for connecting with an arced plate ina positioning mode. The invention further provides a connection structure of the fabricated structure side wall prefabricated member and the arched plate. The connection structure comprises the arched plate and the above side wall prefabricated member, wherein an arc-shaped prefabricated member is supported on the side wall prefabricated member, the arc-shaped prefabricated member and the side wall prefabricated member body are connected through a cast-in-place structure, a second connection piece is arranged at one end of the arc-shaped prefabricated member, and the second connection piece is connected with the first connection plates in the positioning mode. The first connection plates on the fabricated structure side wall prefabricated member and second connection plates on the arc-shaped plate are connected in the positioning mode, and the arc-shaped prefabricated member and the side wall prefabricated member body are connected through the cast-in-place structure, and then a three-hinged arch structure is formed, and furthermore realization of underground column-free vault large space effect is facilitated.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

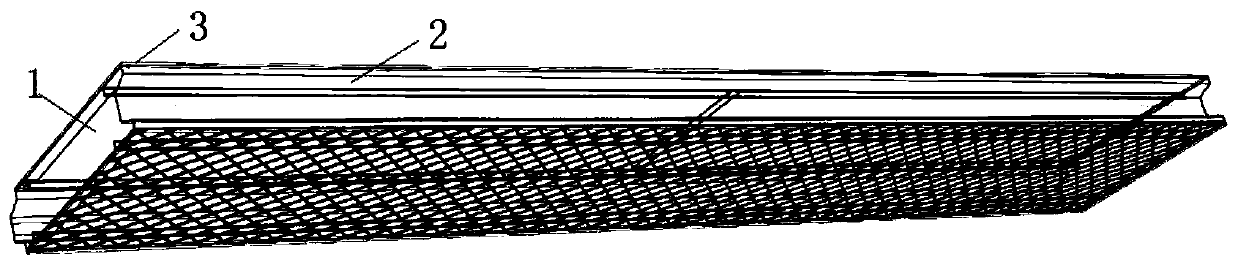

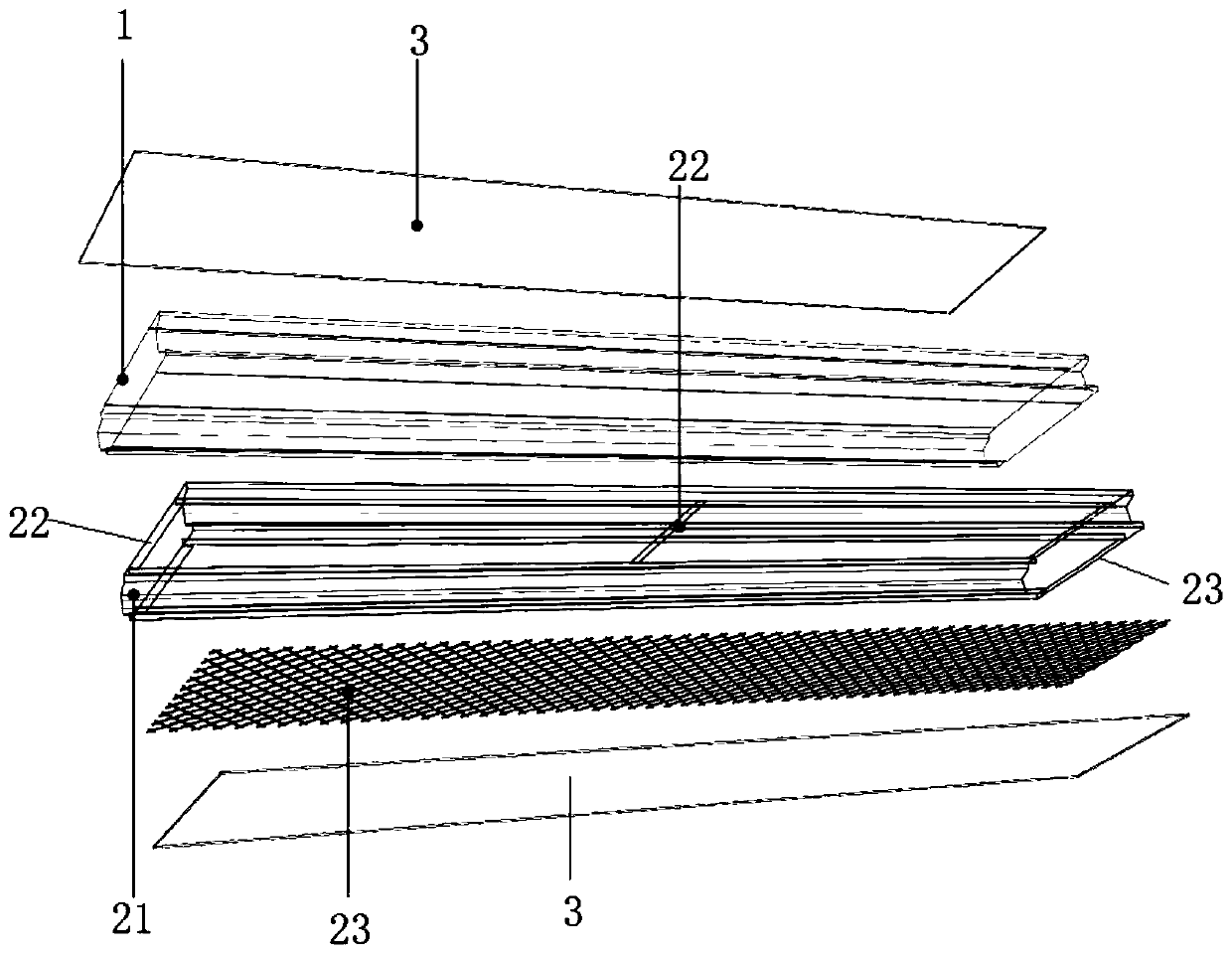

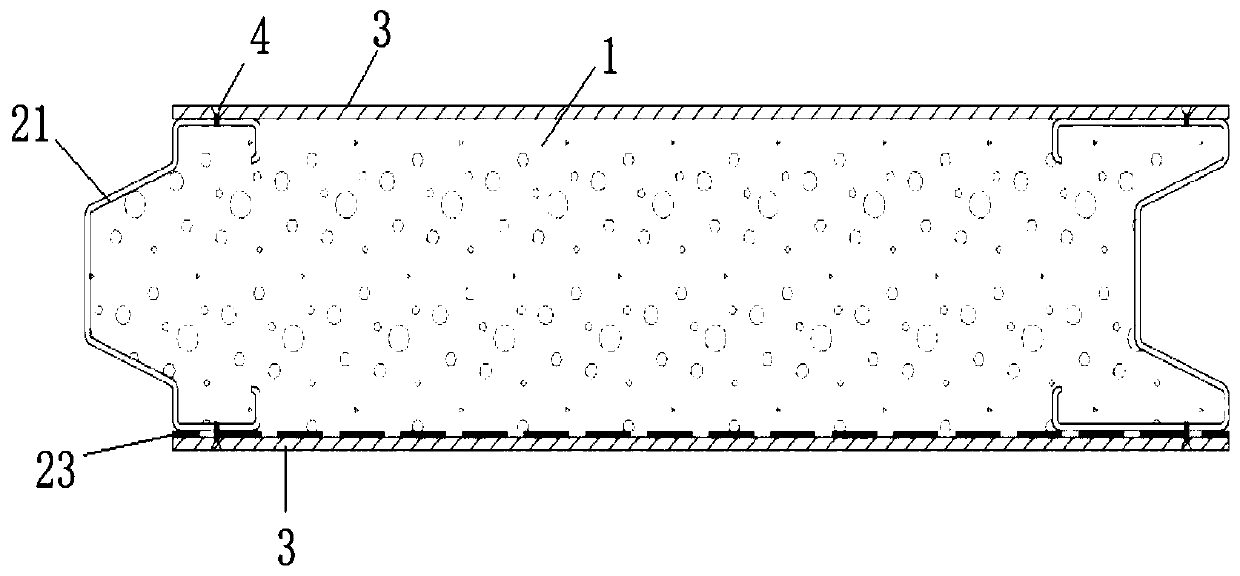

High-strength lightweight composite floor slab and floor system thereof

The invention discloses a high-strength lightweight composite floor slab and a floor system thereof. The high-strength lightweight composite floor slab comprises a polyphenyl particle foam concrete plate, a steel plate tray and face plate bodies, wherein the outer portion of the polyphenyl particle foam concrete plate is wrapped with the steel plate tray; the face plate bodies are fixed to the upper surface and the lower surface of the steel plate tray. The steel plate tray comprises C-shaped steel plates on the two sides, and the upper sides and the lower sides of the end of the C-shaped steel plates on the two sides are connected through transverse tie steel plates to form a quadrangular frame; a steel wire net is fixed to the bottom of the quadrangular frame. The novel steel plate traywith a frame and a bottom is designed, by installed the steel plate tray on the outer side of the polyphenyl particle foam concrete plate, the defect is overcome that polyphenyl particle foam concretehas no bar holding force, the polyphenyl particle foam concrete material can be used for the floor slab, and the floor slab made from the polyphenyl particle foam concrete has the advantages of beinglow in mass and high in strength, the construction process is simple, the technical requirements for on-site installation are low, the construction period is short, the floor slab can be reused afterbeing removed and meets the requirements for environment-friendly and civilized construction.

Owner:上海泛太建筑设计有限公司

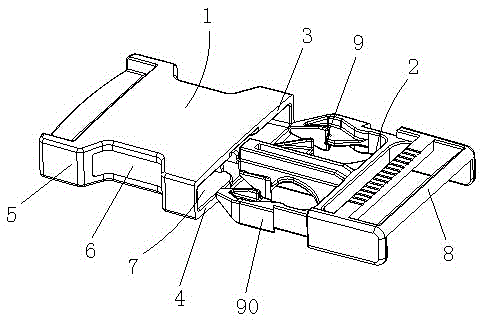

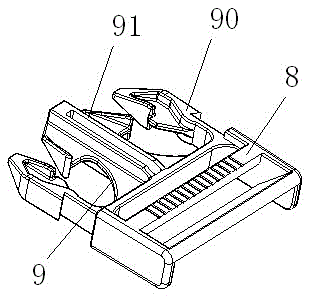

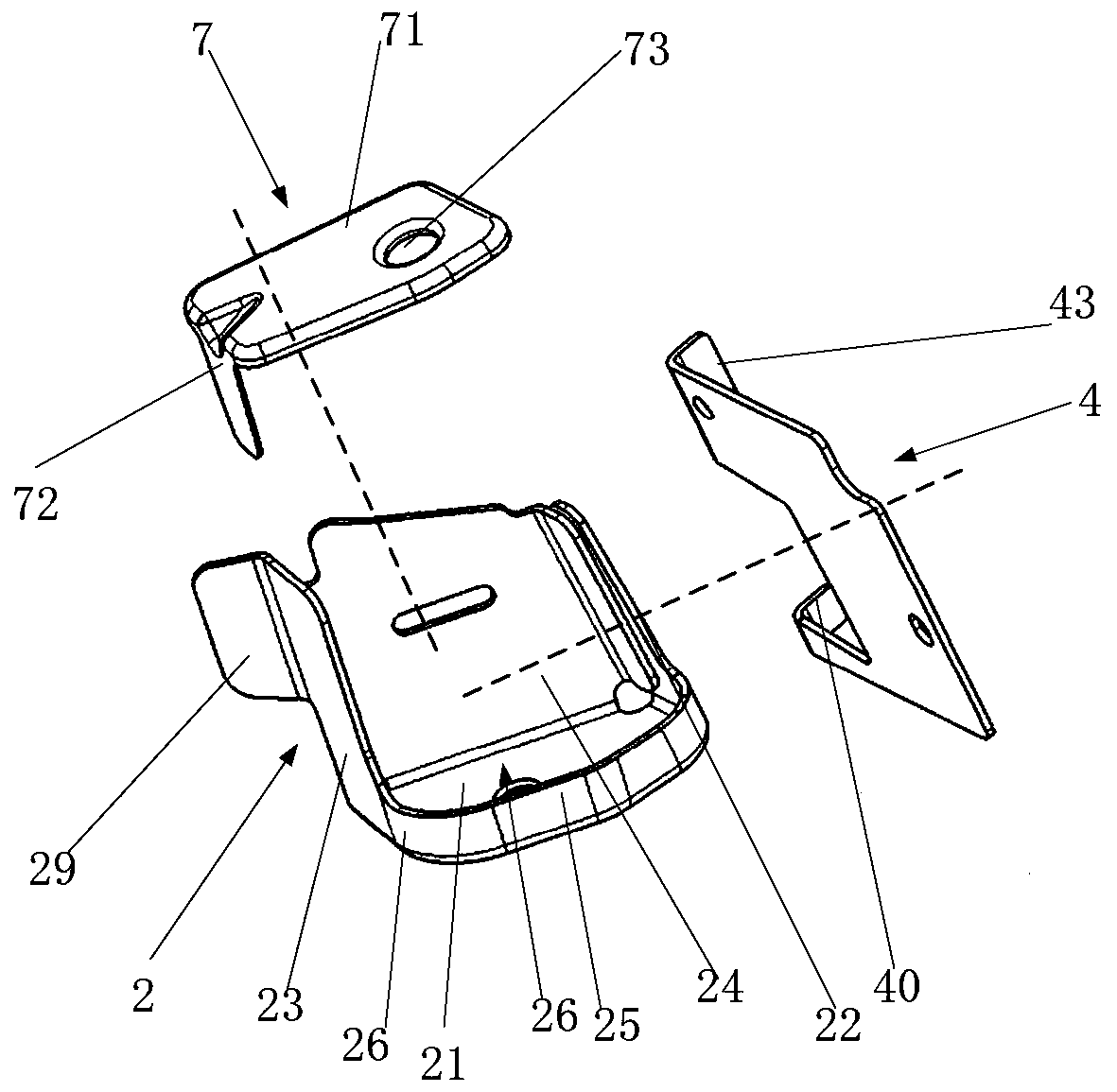

Plastic clamping part

InactiveCN105545888AInhibit sheddingRealize positioning connectionShrinkage connectionsEngineeringSlide plate

The invention discloses a plastic clamping part. The plastic clamping part comprises a mother part and a son part; the mother part and the son part are both produced by plastics; the mother part consists of an upper plate, a lower plate and a side surrounding plate arranged between the upper plate and the lower plate; recess grooves are inwards formed in two sides of the side surrounding plate; a clamping groove is formed among the upper plate, the lower plate and the side surrounding plate; the son part includes a tail part for connecting with a schoolbag belt and a clamping part for inserting in the clamping groove; hook parts matched with the recess grooves are arranged on two sides of the clamping part; two upper slide plates are arranged on the upper wall surface of the clamping groove; an upper chute is formed between the two upper slide plates; two lower slide plates are arranged on the lower wall surface of the clamping groove; a lower chute is formed between the two lower slide plates; an upper slide block is arranged on the upper surface of the clamping part; and a lower slide block is arranged on the lower surface of the clamping part. On the one hand, the plastic clamping part can prevent deviation between the son part and the mother part, and on the other hand, the plastic clamping part can quickly realize positioning connection; and the plastic clamping part is convenient for operation, popularization and application.

Owner:ANHUI HUACAI PLASTIC CO LTD

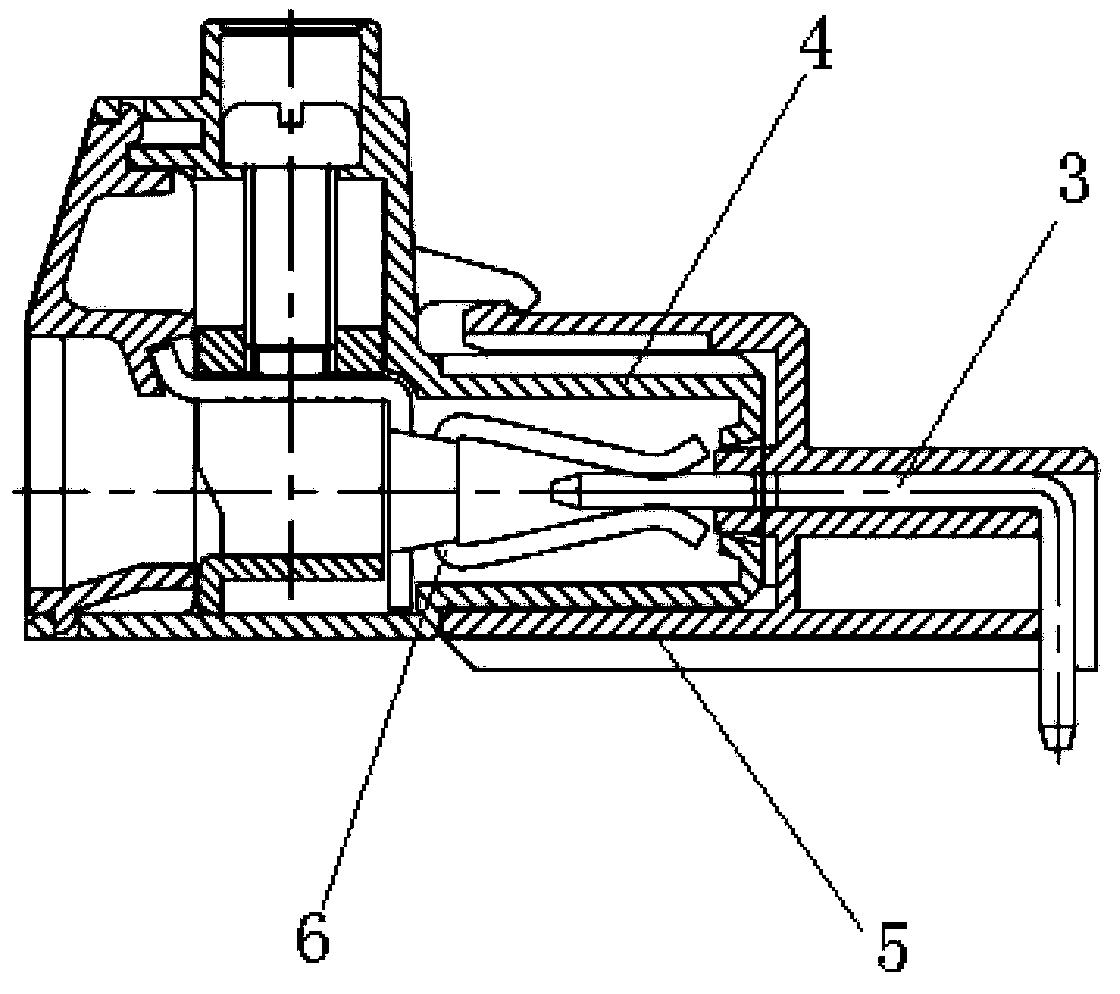

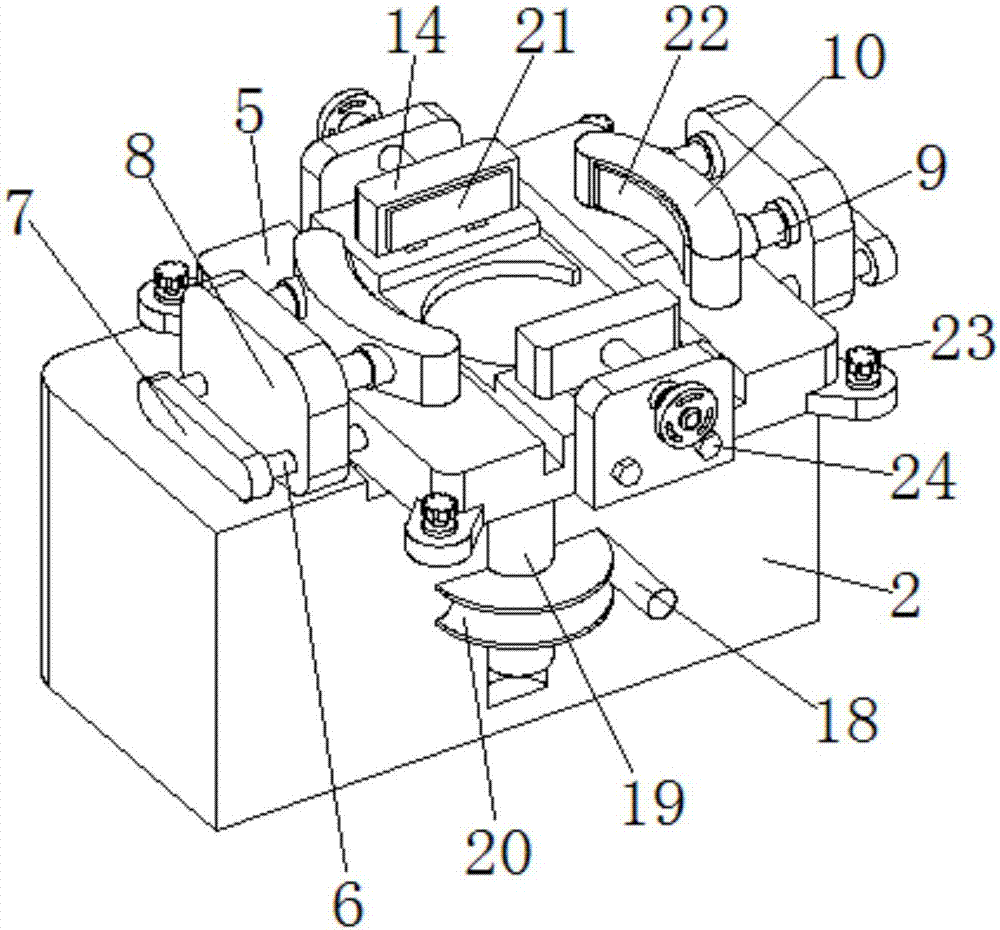

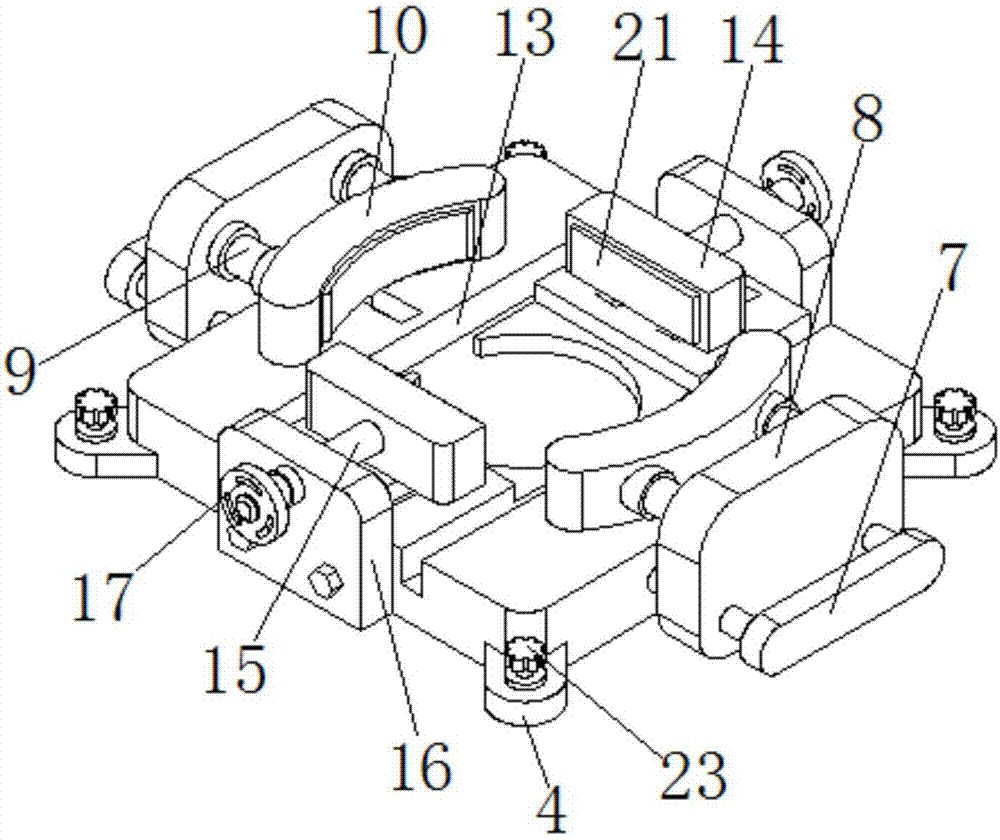

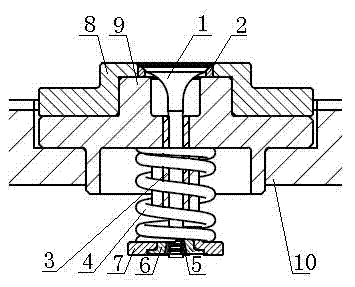

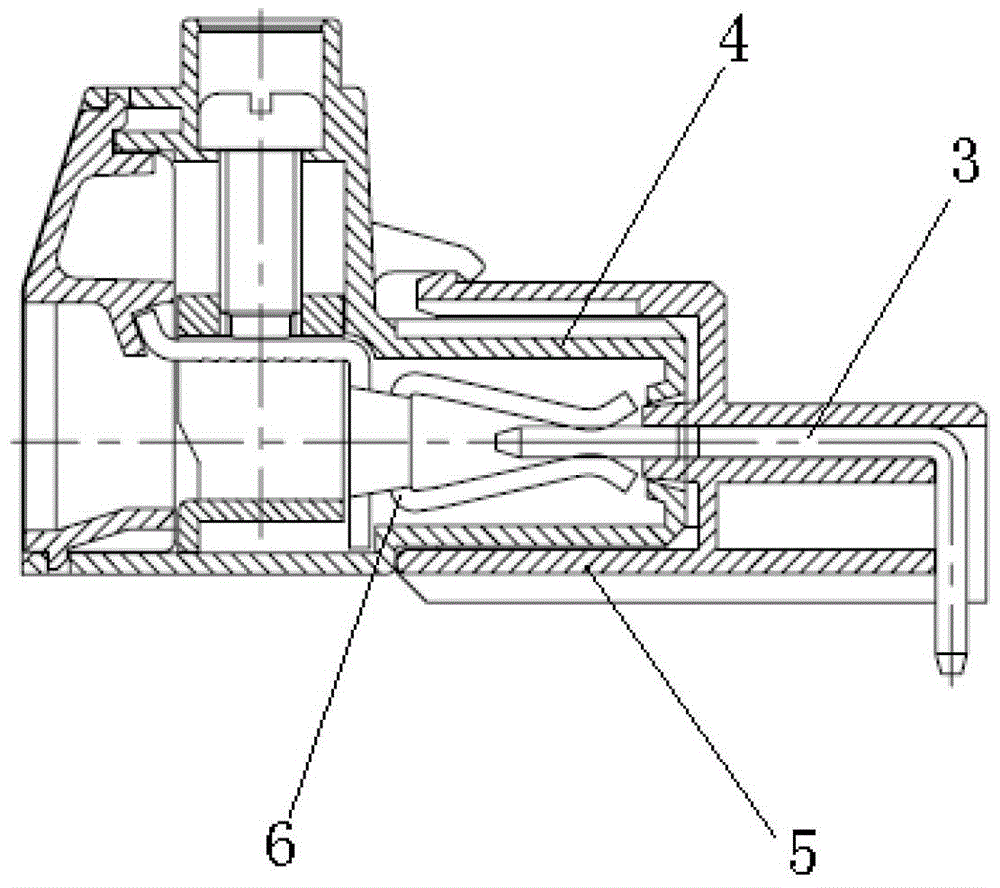

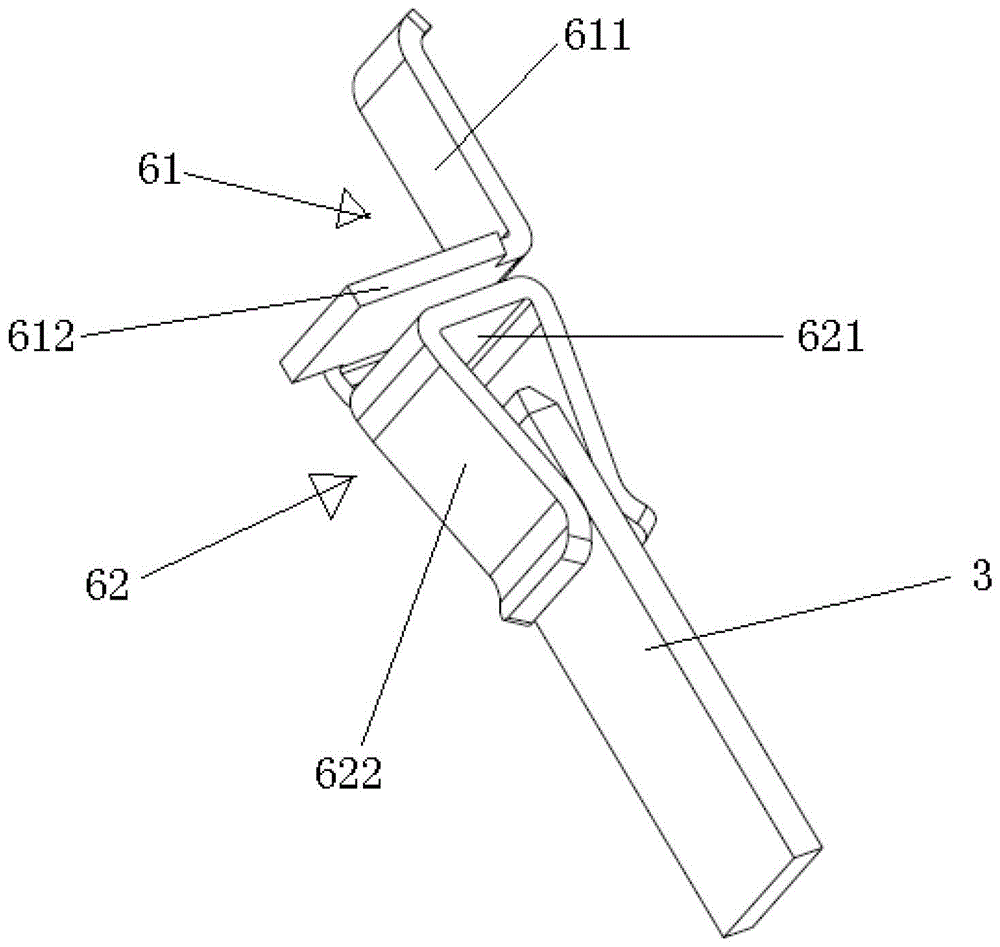

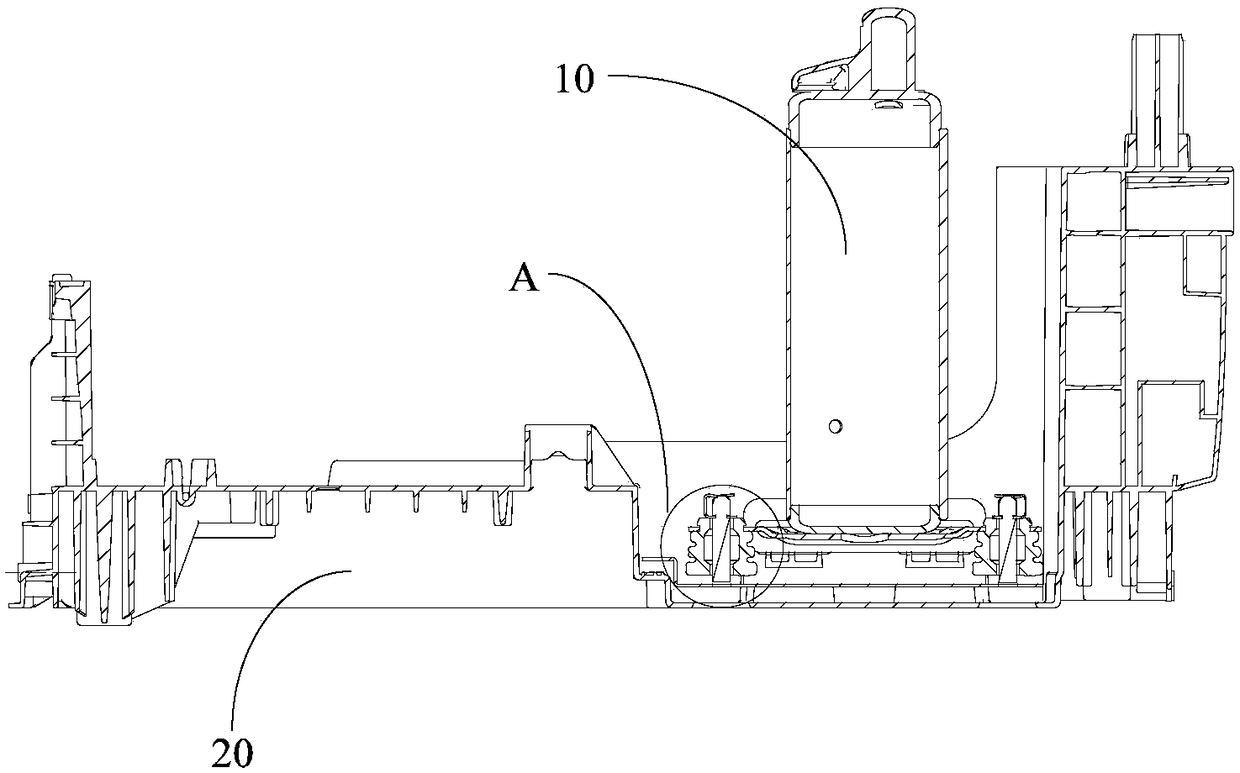

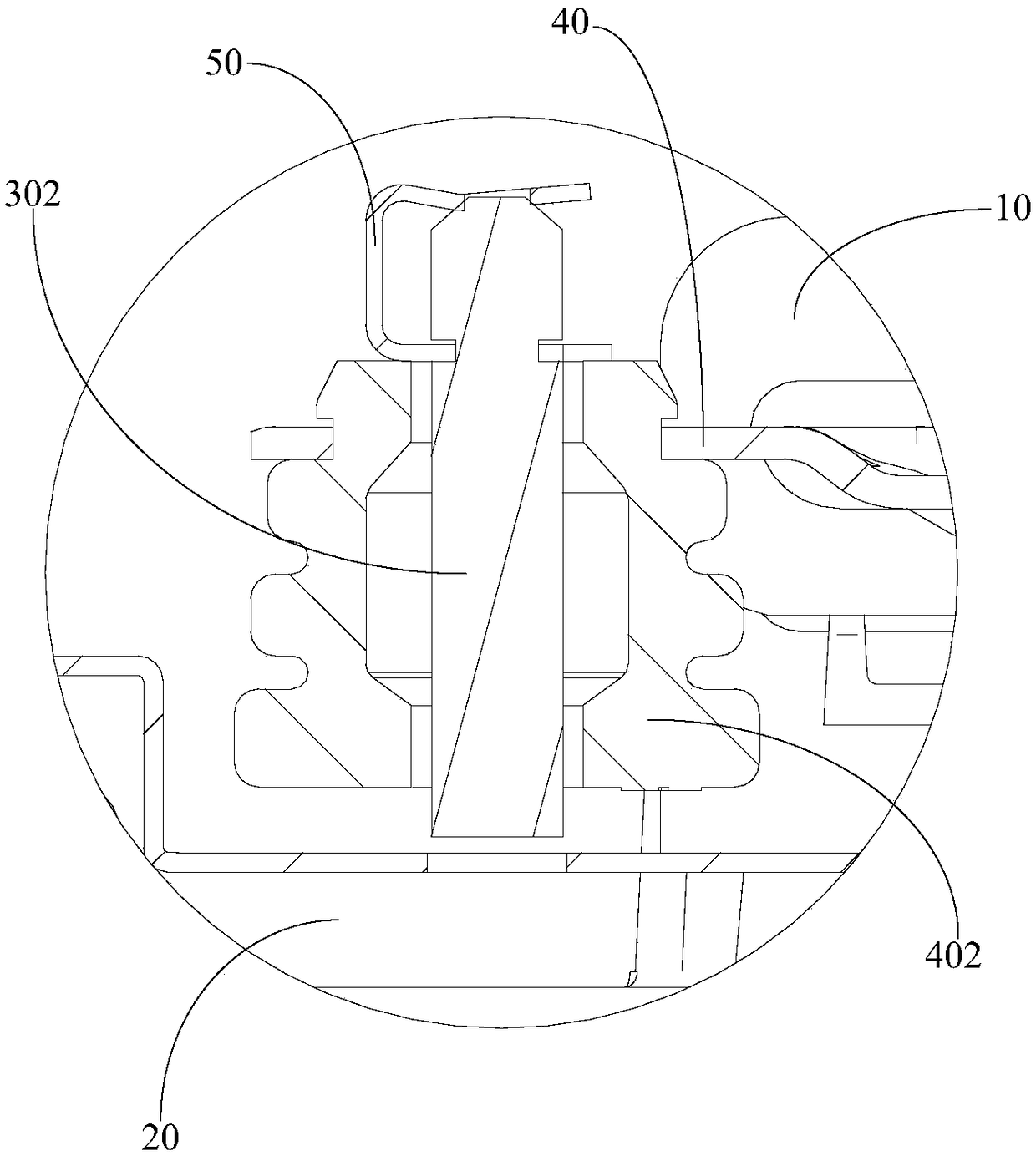

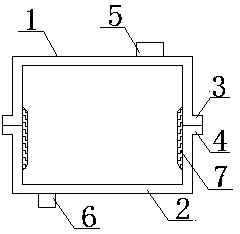

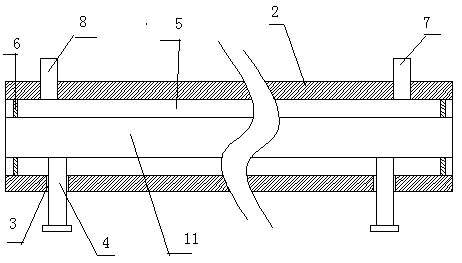

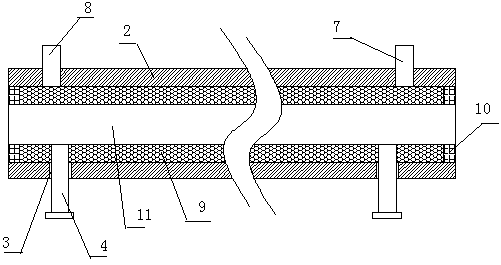

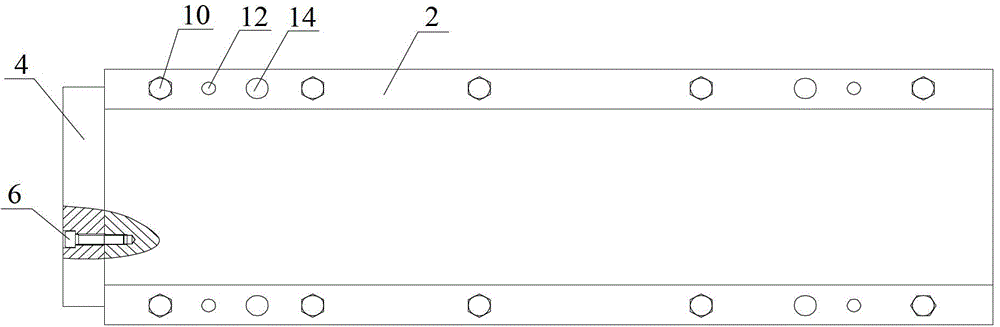

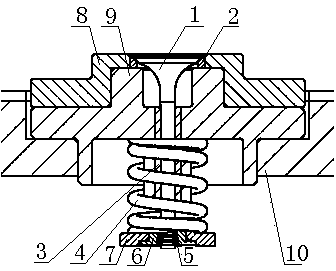

Mounting structure for frictional wear test for valve mechanism of engine

ActiveCN102778350AEasy to processRealize positioning connectionMachine part testingEngine testingTest sampleEngineering

The invention discloses a mounting structure for frictional wear test for a valve mechanism of an engine. The mounting structure mainly comprises parts including a valve (1), a seat ring (2), a guide tube (3), a spring (4), a lock clamp (5), an inner spring seat (6), an outer spring seat (7), an upper mounting disc (8), a lower mounting disc (9), a support box (10) and the like. The valve (1) and the seat ring (2) are main assessment test samples for the test, the lock clamp (5) is the part for matching the valve (1) with the seat ring (2), the upper mounting disc (8), the lower mounting disc (9) and the outer spring seat (7) are reusable main parts of the mounting structure, and the guide tube (3) and the inner spring seat (6) are transitional connectors for fittingly mounting the gas valve and the seat ring with the main parts. The mounting structure is a combined type structure and is easy to process; coaxiality of the guide tube and a seat ring hole is high; and the mounting structure is convenient and speedy to assemble and disassemble and high in universality, and can be used for valve-seat ring tests in multiple schemes.

Owner:NO 70 INST OF CHINA NORTH IND GRP

Enclosure component of fabricated underground structure and connecting structure of enclosure component and arched plate

PendingCN110359488AGood building visual effectGood structural durabilityArtificial islandsUnderwater structuresClerestoryBuilding construction

The invention belongs to the technical field of underground construction building, and particularly relates to an enclosure component of a fabricated underground structure. A supporting face used forsupporting an arched plate is arranged on an enclosure component body. A first connecting part at least partially embedded into the enclosure component body is arranged on the supporting face, and thefirst connecting part comprises a first connecting plate used for being connected with the arched plate in a locating manner. The invention further provides a connecting structure of the enclosure component of the fabricated underground structure and the arched plate. The connecting structure comprises the arched plate and the enclosure component. An arc prefabricated part is supported on the enclosure component, and the arc prefabricated part and the enclosure component body are connected through a cast-in-place structure. A second connecting part is arranged at one end of the arc prefabricated part and is connected with the first connecting plate in a locating manner. The first connecting part on the enclosure component and the second connecting part on the arched plate are connected inthe locating manner, the arc prefabricated part and the enclosure component body are connected in a cast-in-place manner, a three-hinged arch stable structure is formed, and the effect of undergroundcolumn-free arch top large space can be achieved conveniently.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Ornament connecting piece for sofa

InactiveCN103032432ARealize positioning connectionPromote withdrawalFurniture joiningEngineeringOrnaments

Owner:WANFUGE FURNITURE KUSN

Low cost high current clip terminals for electrical connectors

ActiveCN104143718BImprove connection reliabilityImprove conductivityCoupling contact membersElectricityPower flow

The invention discloses a low-cost, high-current clip terminal for an electrical connector, which includes a terminal body and an elastic clip, and the elastic clip includes an integrally formed connecting piece with high electrical conductivity and elasticity and two opposing clamping pieces , the two clamping pieces are integrally connected to the connecting piece at the same end, the terminal body includes an integrally formed conductive plate with high conductivity and two oppositely disposed jaw pieces, one end of one of the jaw pieces is integrally connected to the conductive plate; The elastic clamping piece is positioned and sleeved between the two clamping pieces, the connecting piece faces the conductive plate and closely contacts the clamping piece, and the two clamping pieces can elastically clamp the metal insert to be connected. The present invention changes the integral structure with only one clamping point, and forms a multi-point contact clip structure, which can effectively improve the connection reliability of the clip terminal, and can reduce the size of the elastic contact part of the clip terminal, thereby reducing the The consumption of highly elastic copper materials saves production costs.

Owner:DINKLE M&E CHINA

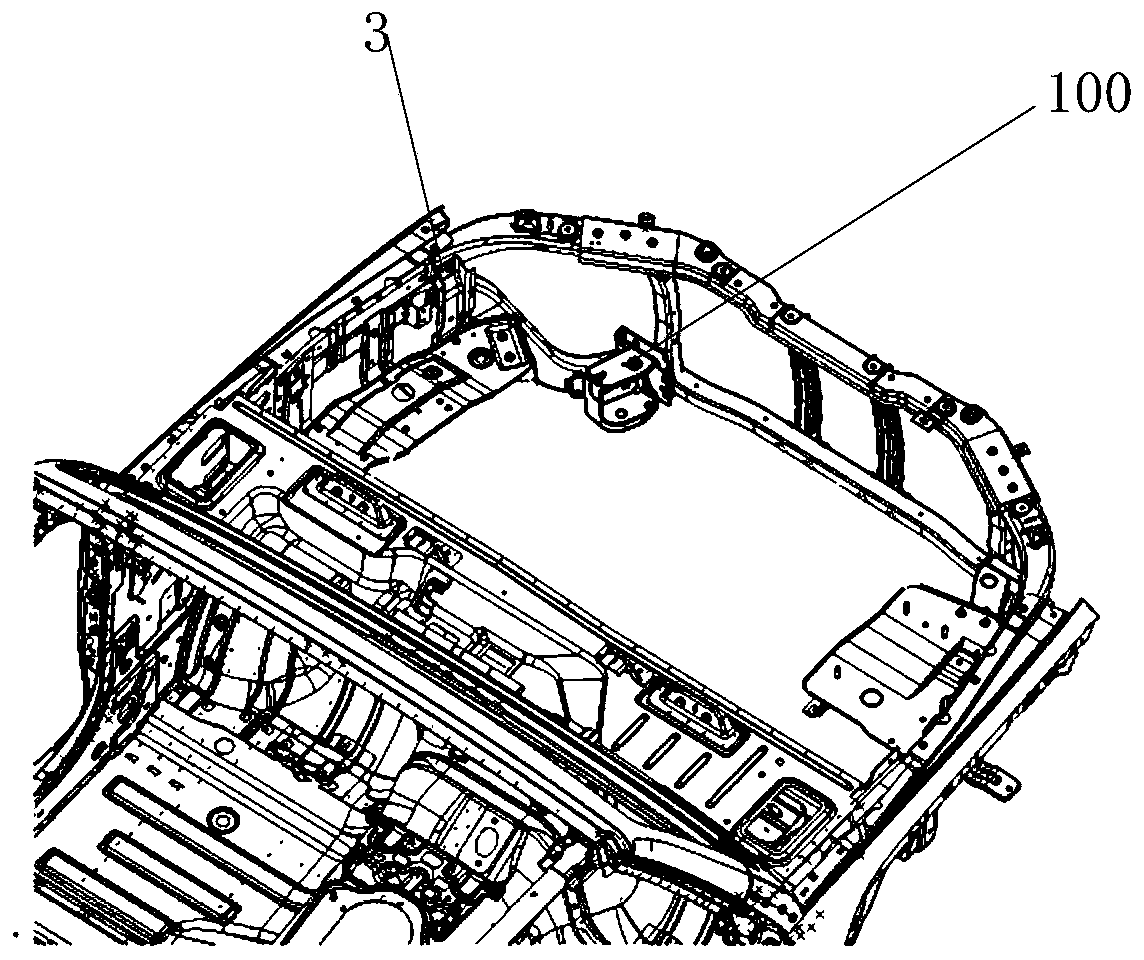

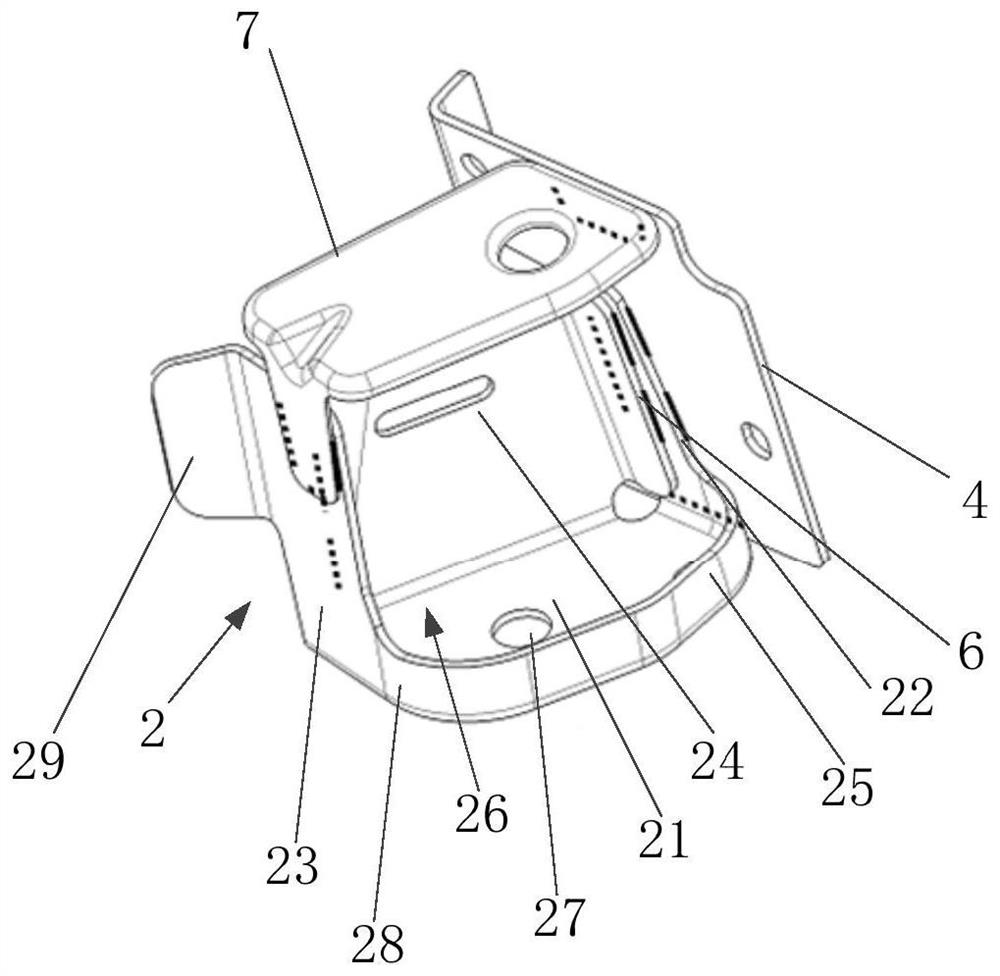

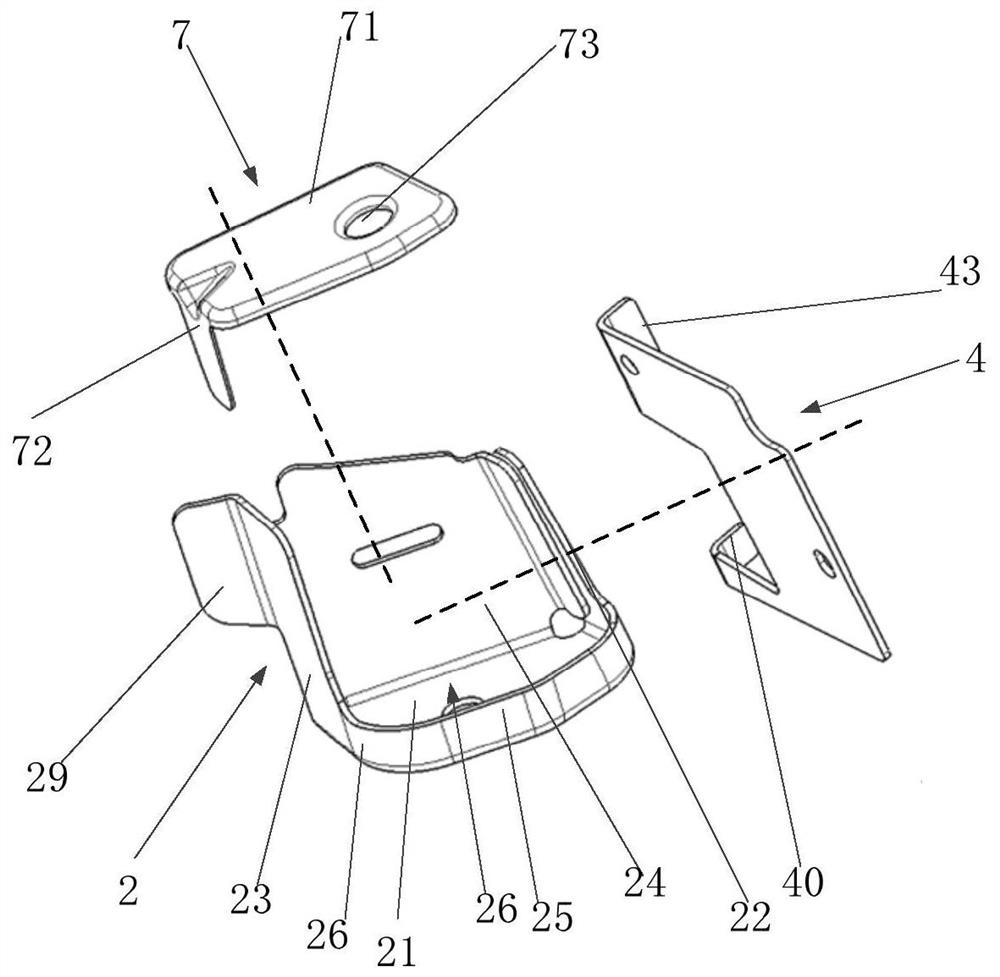

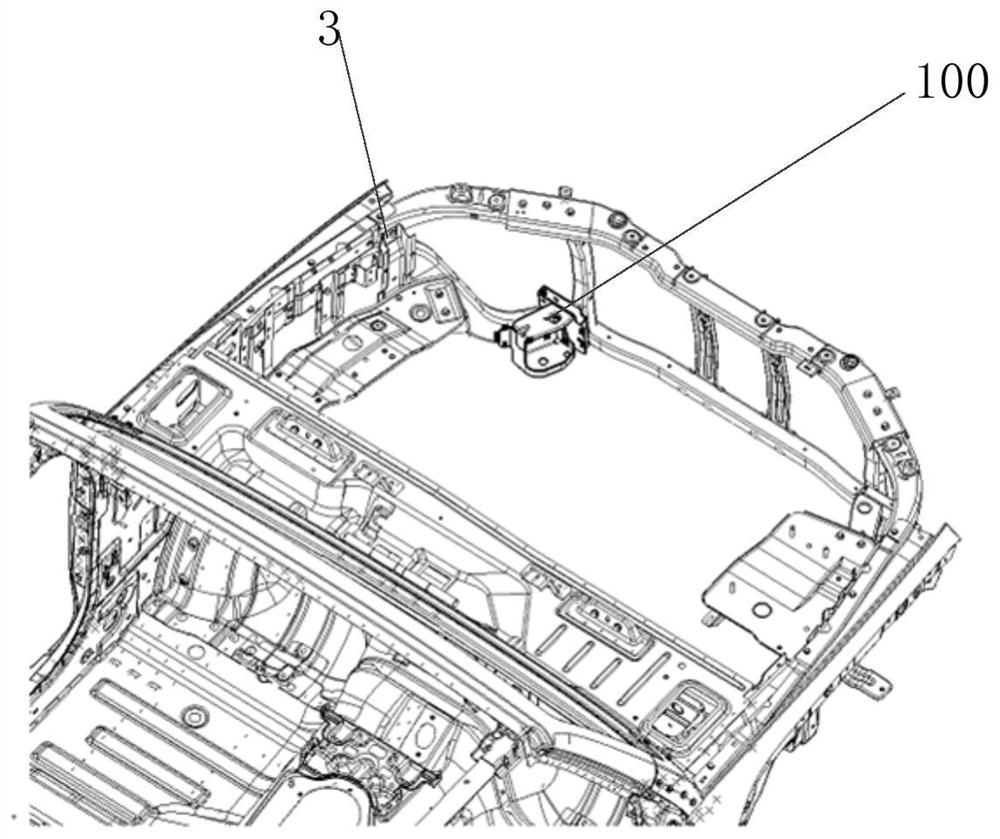

Vehicle body end fixing structure for vehicle body suspension and vehicle with same

ActiveCN110588794AMiniaturizationEasy to installVehicle body-frame connectionsSuperstructure subunitsWeight lightAutomotive engineering

Owner:BAIC GRP ORV CO LTD

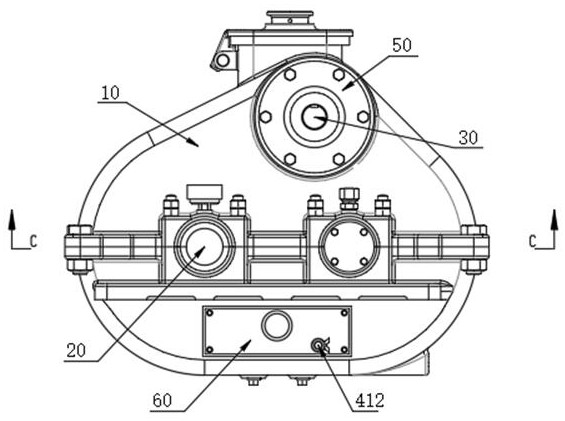

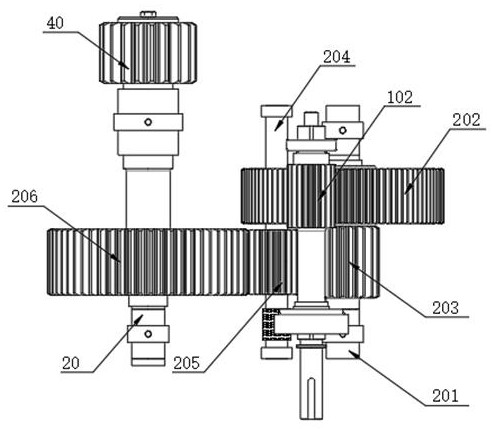

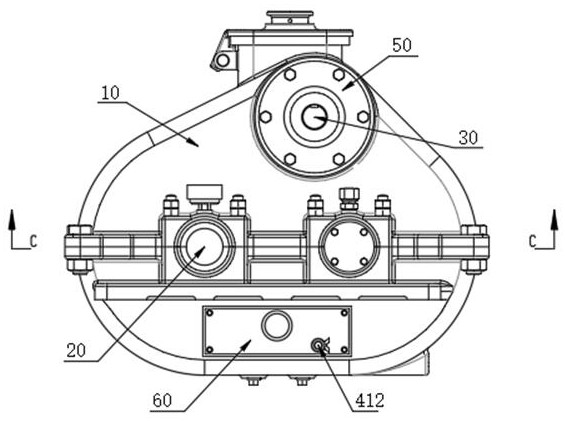

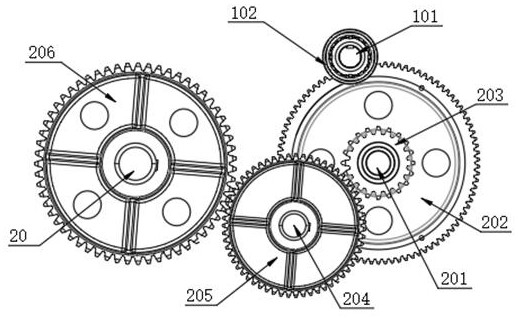

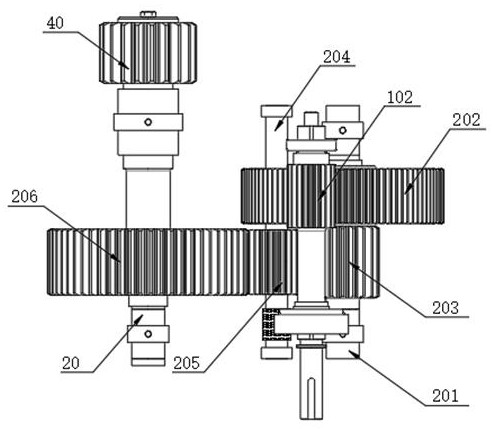

A pumping unit deceleration device with safety protection function

ActiveCN113374833BWith security protection functionChange speedGearboxesToothed gearingsMotor speedDrive shaft

Owner:SHENGLI OIL FIELD HIGHLAND GASOLINEEUM EQUIP +1

Body end fixing structure of body suspension and vehicle having same

ActiveCN110588794BMiniaturizationEasy to installVehicle body-frame connectionsSuperstructure subunitsSuspension (vehicle)Control theory

Owner:BAIC GRP ORV CO LTD

Magnetic core for high-frequency high-impedance ignition coil

ActiveCN111863398AImprove stabilityRealize positioning connectionTransformersTransformers/inductances magnetic coresIgnition coilStructural engineering

The invention provides a magnetic core for a high-frequency high-impedance ignition coil, which is characterized in that a first end cover is provided with a non-circular first positioning through hole, and a second end cover is provided with a non-circular second positioning through hole; positioning parts are arranged at the two ends of the positioning column, the positioning rod is arranged inthe through hole in a penetrating mode, the positioning head abuts against the first end cover, the fixing part abuts against the second end cover, and the fixing part is connected with the other endof the positioning rod; the two positioning parts of the magnetic column respectively extend into the first positioning through hole and the second positioning through hole; the positioning connectionamong the magnetic column, the first end cover and the second end cover is realized; a positioning rod of the positioning piece is arranged in the through hole of the magnetic column in a penetratingmanner; and the positioning head of the positioning rod is propped against the first end cover, and the other end of the positioning rod is propped against the second end cover through the fixing part, so that the magnetic column, the first end cover and the second end cover are connected through the positioning piece, the connection strength among all parts of the magnetic core is improved, andthe purpose of improving the operation stability of the magnetic core is achieved.

Owner:ANHUI HUALIN MAGNETIC TECH

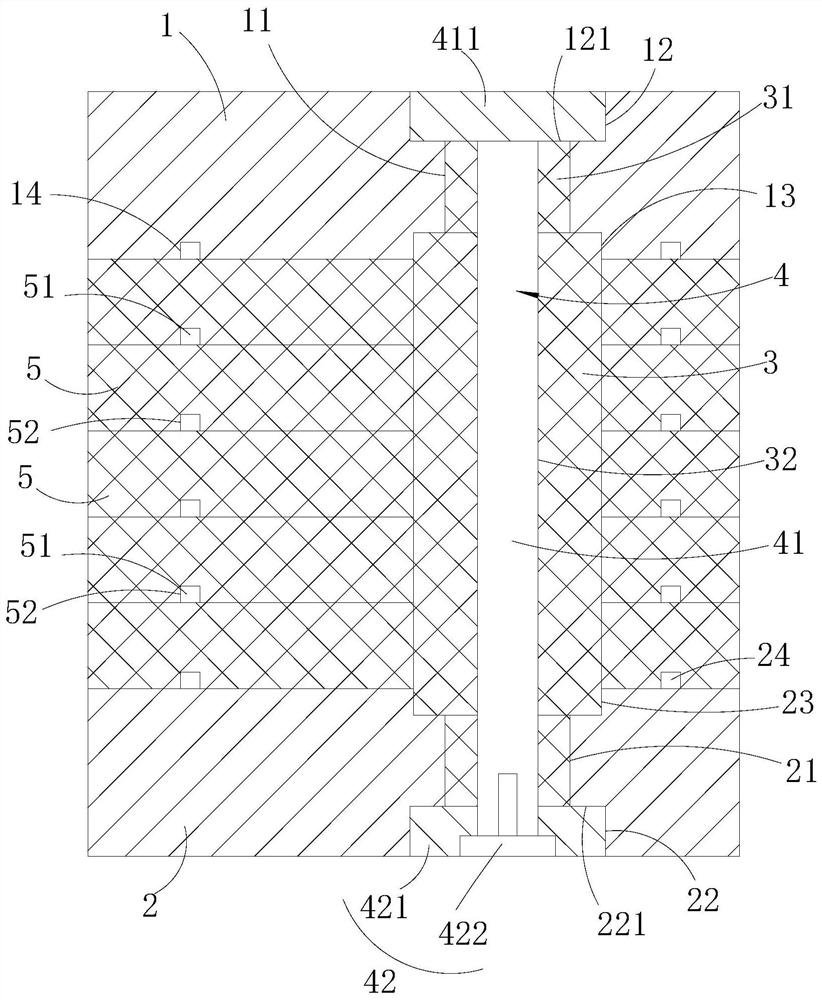

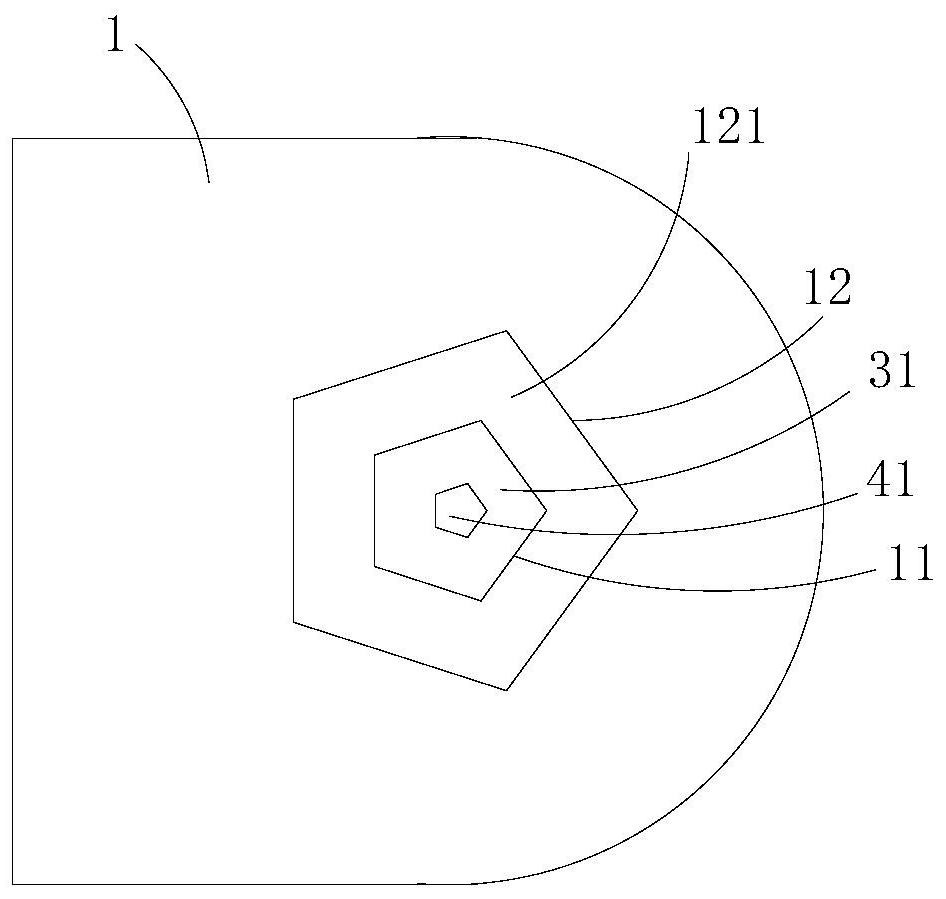

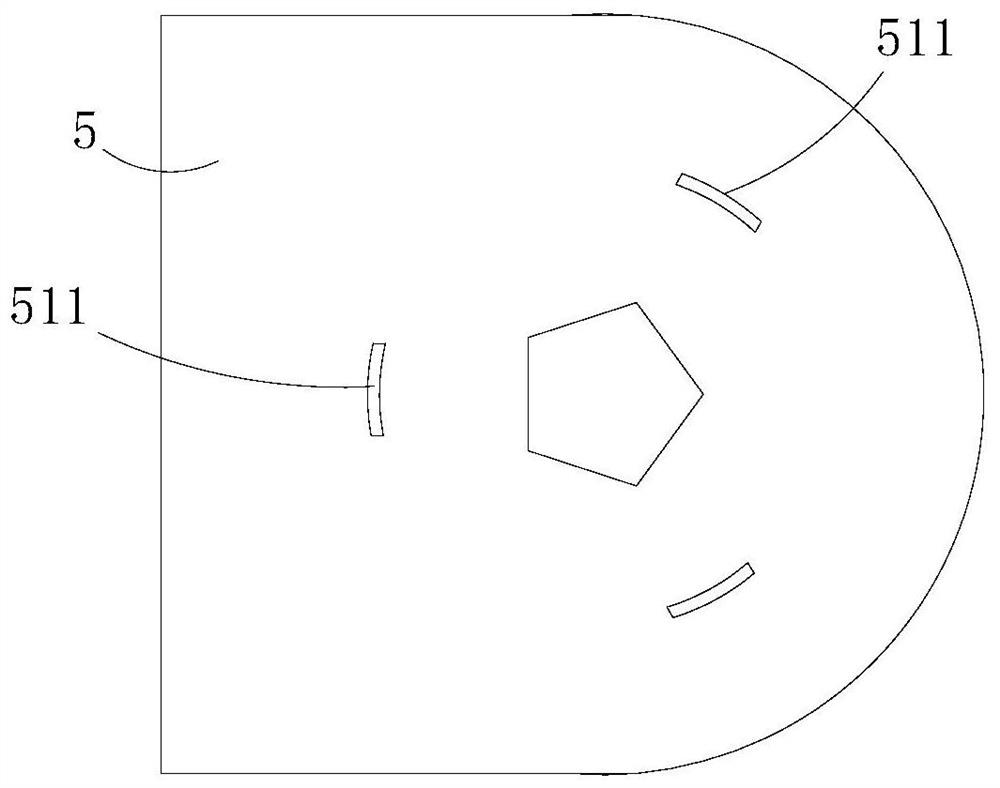

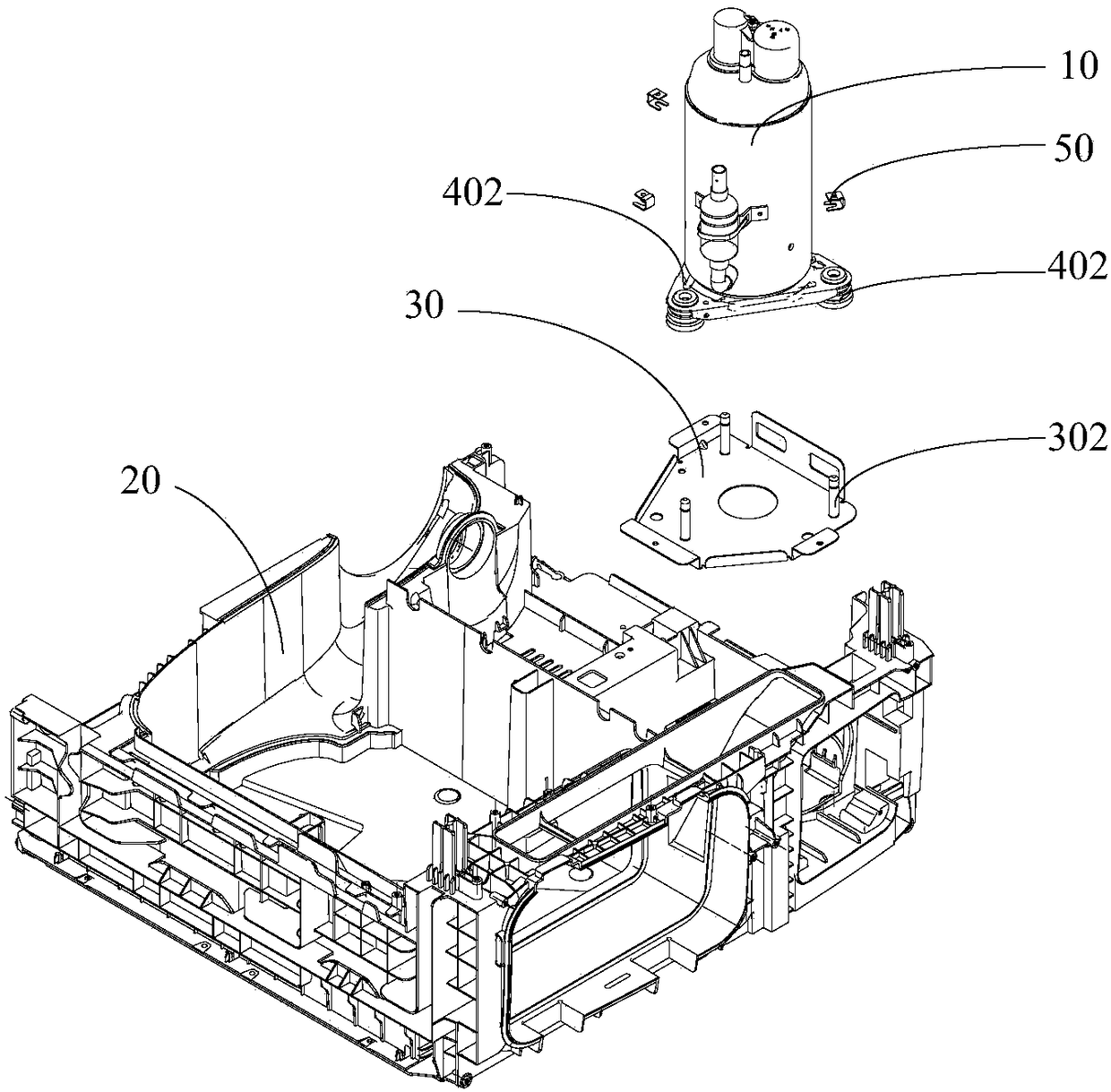

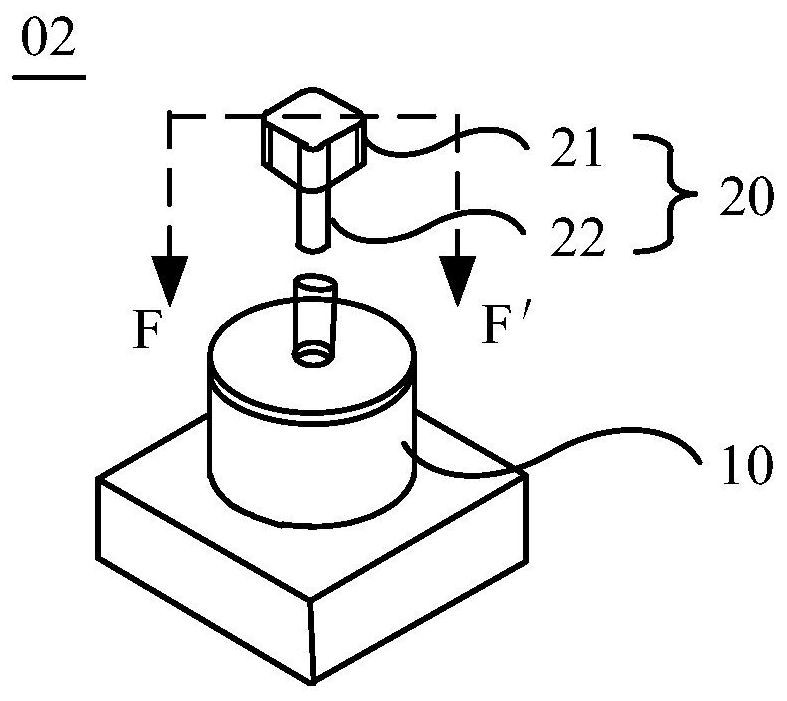

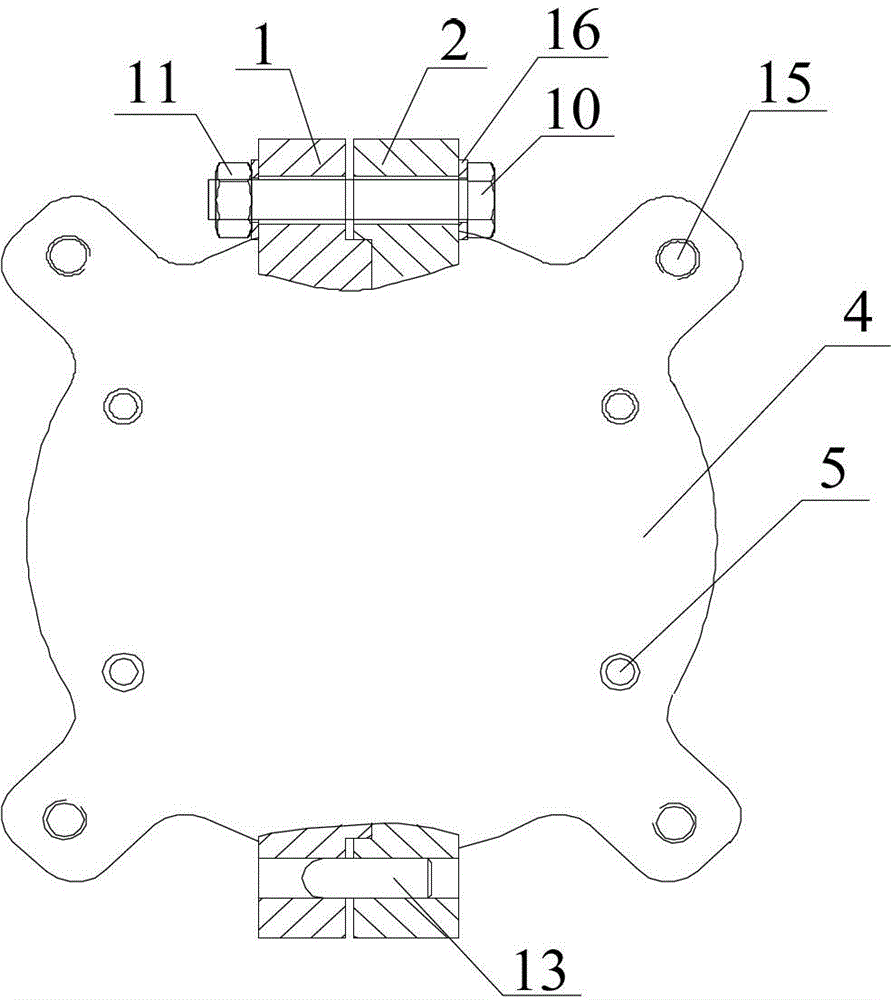

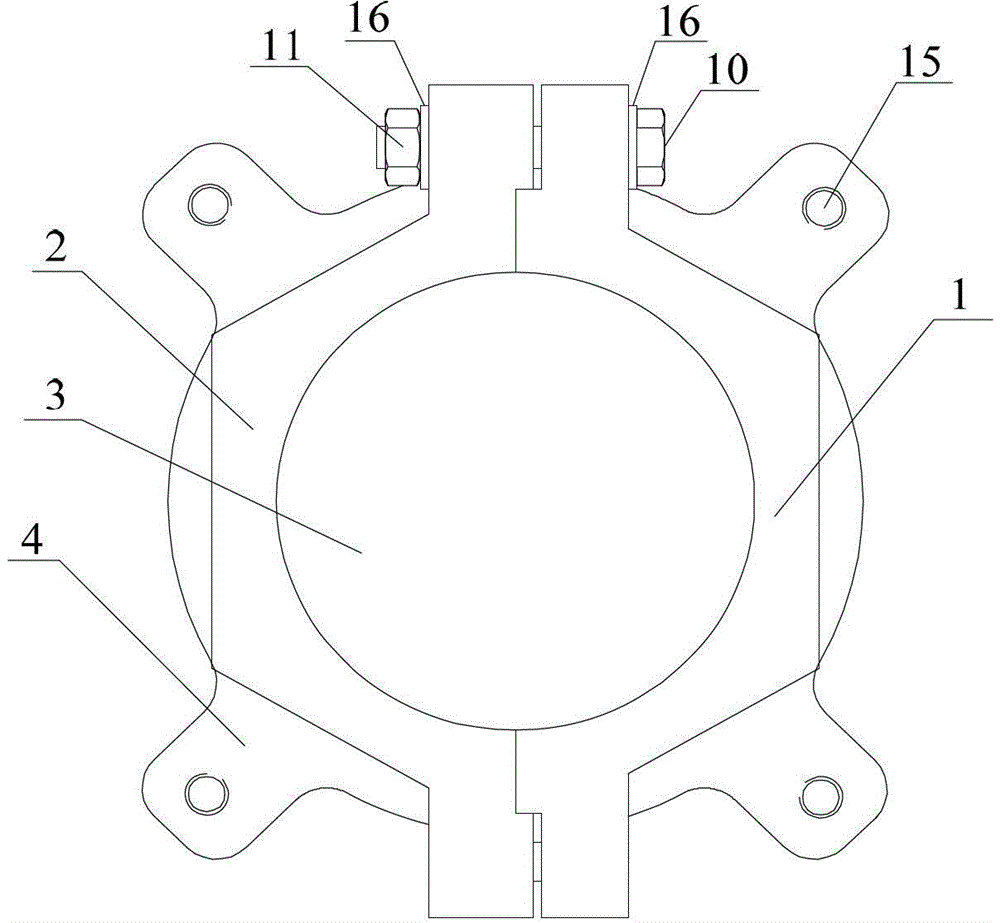

Mounting assembly of compressor and clothes treatment device

ActiveCN108589215AIncrease productivityImprove assembly reliabilityTextiles and paperLaundry driersEngineering

The invention provides a mounting assembly of a compressor and a clothes treatment device. The mounting assembly of the compressor comprises a base and a switching part, wherein the base is arranged at the bottom of the compressor; the switching part is fixedly connected with a fixing seat of the compressor; when the bottom of the compressor is detachably connected to the switching part, the compressor is mounted at the fixing seat of the compressor. By means of the technical scheme, an existing fixed connection mode adopting nuts and gaskets is replaced, the assembling efficiency is greatly improved, and the abnormal risk caused by nut loosening due to running of the compressor can be prevented.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Looseness preventing diesel tank of diesel engine

InactiveCN104141570AHigh strengthGuaranteed uptimeMachines/enginesLiquid fuel feedersFuel tankDiesel engine

The invention relates to the technical field of diesel engines, in particular to a looseness preventing diesel tank of a diesel engine. The looseness preventing diesel tank comprises an upper tank body, a lower tank body, an upper connecting edge, a lower connecting edge, a diesel inlet and a diesel outlet, wherein a positioning plate is arranged on the upper tank body. The positioning plate made of an elastic metal material is arranged on the upper tank body, so that the positioning connection is realized, the looseness is effectively prevented, the assembly difficulty is largely reduced, the manpower and the material are decreased, the whole strength of the diesel tank is largely enhanced, and the normal operation of the diesel engine is guaranteed.

Owner:CHANGZHOU YINGHUANGGUAN IMPORTS & EXPORTS

Oil pumping unit speed reducer with safety protection function

ActiveCN113374833AWith security protection functionChange speedGearboxesToothed gearingsDrive shaftGear wheel

The invention discloses an oil pumping unit speed reducer with a safety protection function, and relates to the technical field of oil pumping equipment for petrochemical engineering. The oil pumping unit speed reducer comprises a machine shell, a speed reduction shaft is rotatably arranged in the machine shell, a first transmission wheel drives a first transmission shaft to rotate, and a second transmission wheel on the surface of the first transmission shaft and the first transmission wheel synchronously rotate, so that a brake protection wheel is driven to rotate in the machine shell, a third transmission wheel rotates in the machine shell through mutual meshing between the brake protection wheel and the third transmission wheel, and a speed reduction gear outputs rotation of the speed reduction shaft; and the first transmission wheel, the second transmission wheel, the third transmission wheel and the brake protection wheel are matched with one another, so that matched transmission of multiple stages of gears is completed, the rotating speed and torque of a motor are changed, the efficiency of the motor is effectively improved, large torque can be obtained with small power consumption, and the energy consumption of the oil pumping unit in the using process is reduced.

Owner:SHENGLI OIL FIELD HIGHLAND GASOLINEEUM EQUIP +1

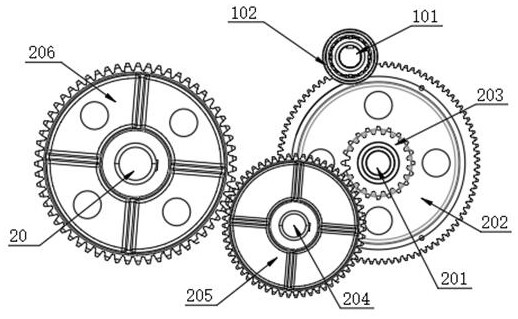

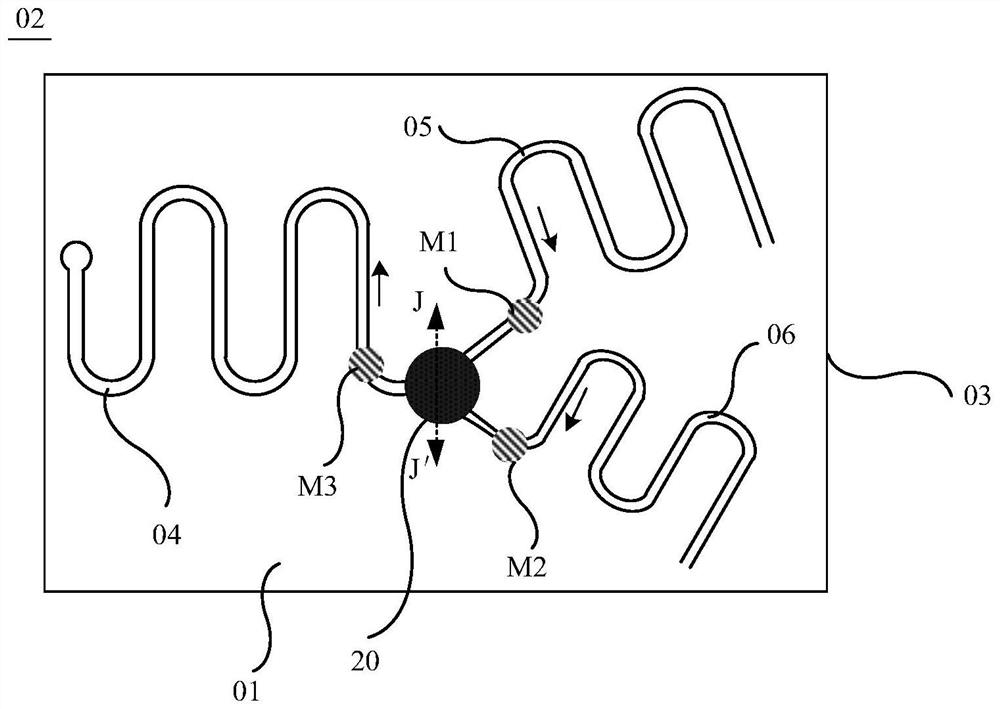

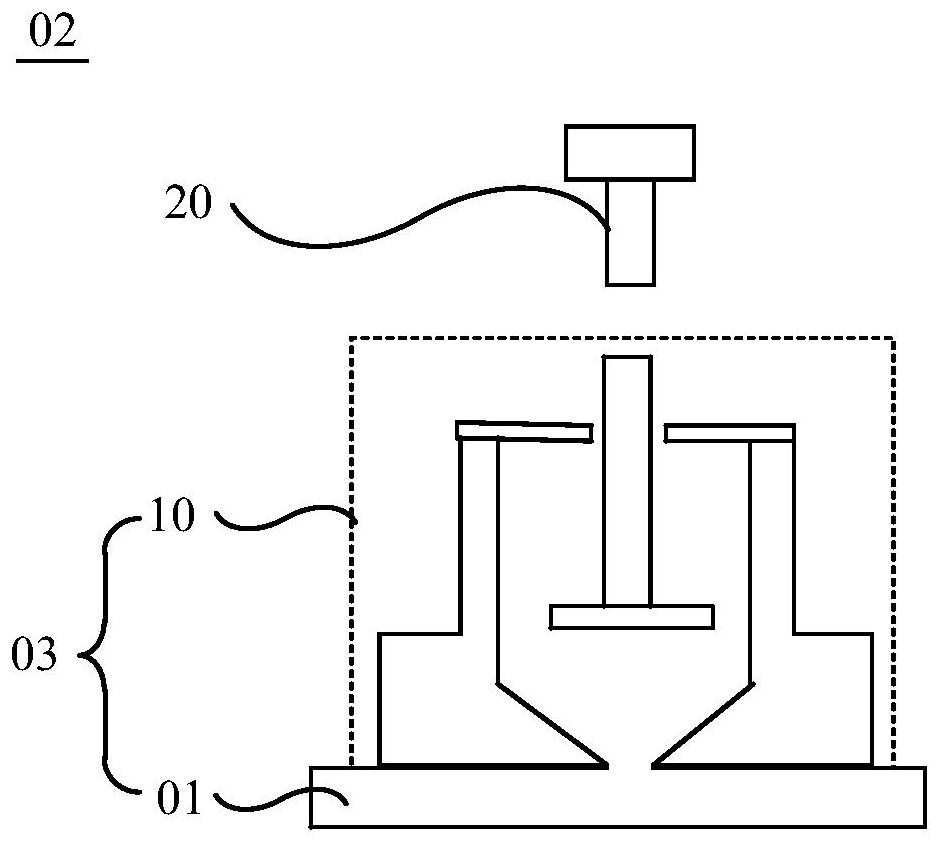

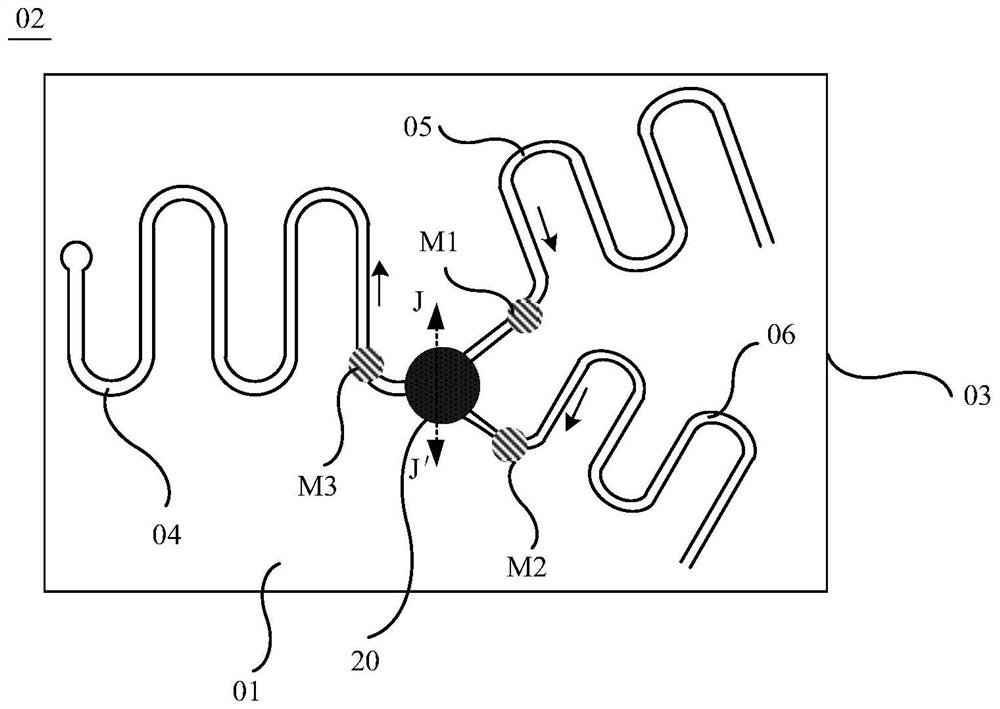

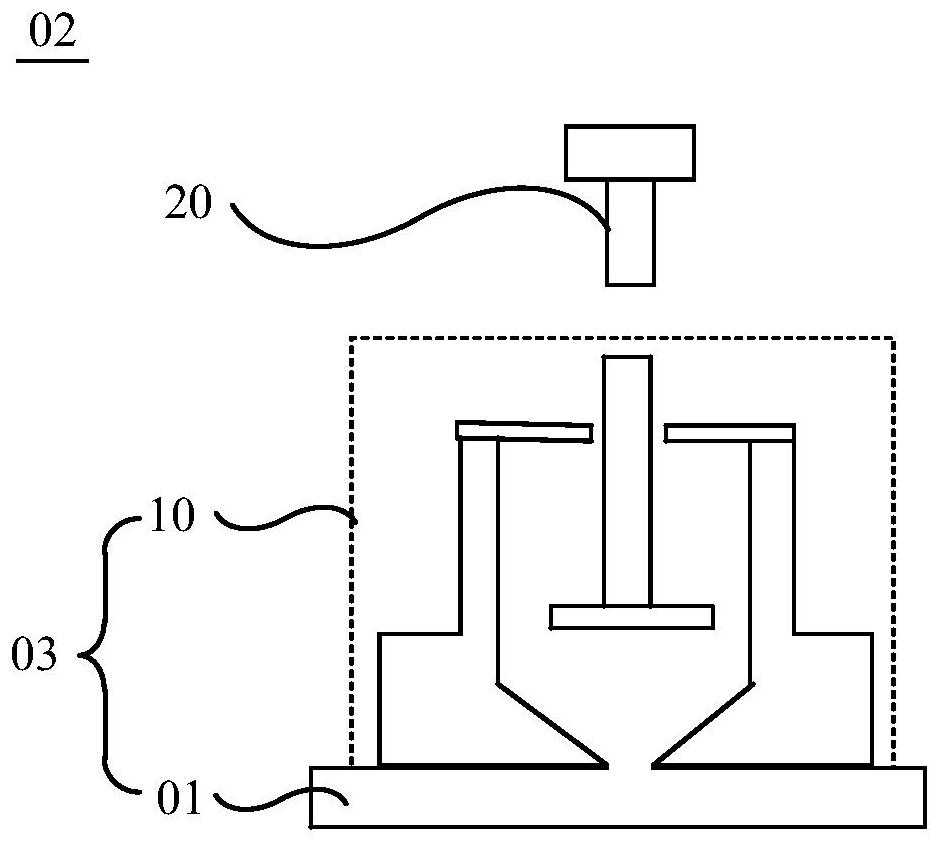

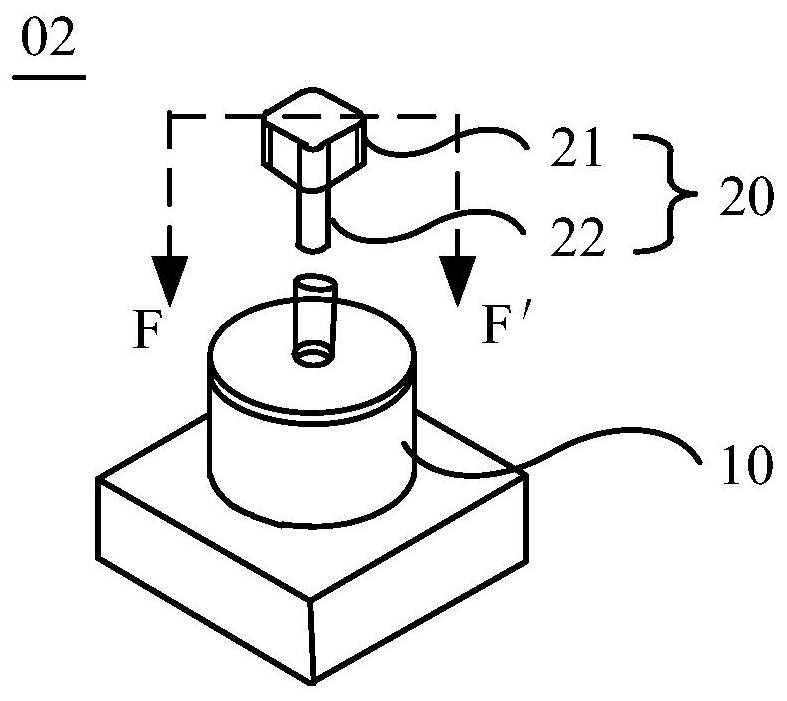

Microfluidic device, stirring system and stirring method

ActiveCN112844503BRealize positioning connectionLow costMixing methodsTransportation and packagingEngineeringAgitator

The embodiments of the present application provide a microfluidic device, a stirring system and a stirring method, which relate to the field of biotechnology, have a simple structure, are easy to manufacture, and can prevent cross-contamination of liquids in the microfluidic device. The above-mentioned microfluidic device includes a microfluidic chip, a stirring cavity, a first cover plate and a stirrer. The microfluidic chip includes at least two inflow microchannels and at least one outflow microchannel. The stirring cavity includes a stirring cavity for accommodating the liquid to be stirred, and the stirring cavity has a first opening and a liquid inlet and outlet that are oppositely arranged, and the liquid inlet and outlet are communicated with at least two inflow microchannels and at least one outflow microchannel. The first cover plate covers the first opening and is connected with the stirring cavity, and the first cover plate is provided with a first installation hole. The agitator includes a blade and a connecting piece. The blade is arranged in the stirring cavity and is connected with the first end of the connecting piece. The second end of the connecting piece passes through the first installation hole and is detachably connected with the driving device. The driving device is used for driving connection. Pieces rotate.

Owner:BOE TECH GRP CO LTD +1

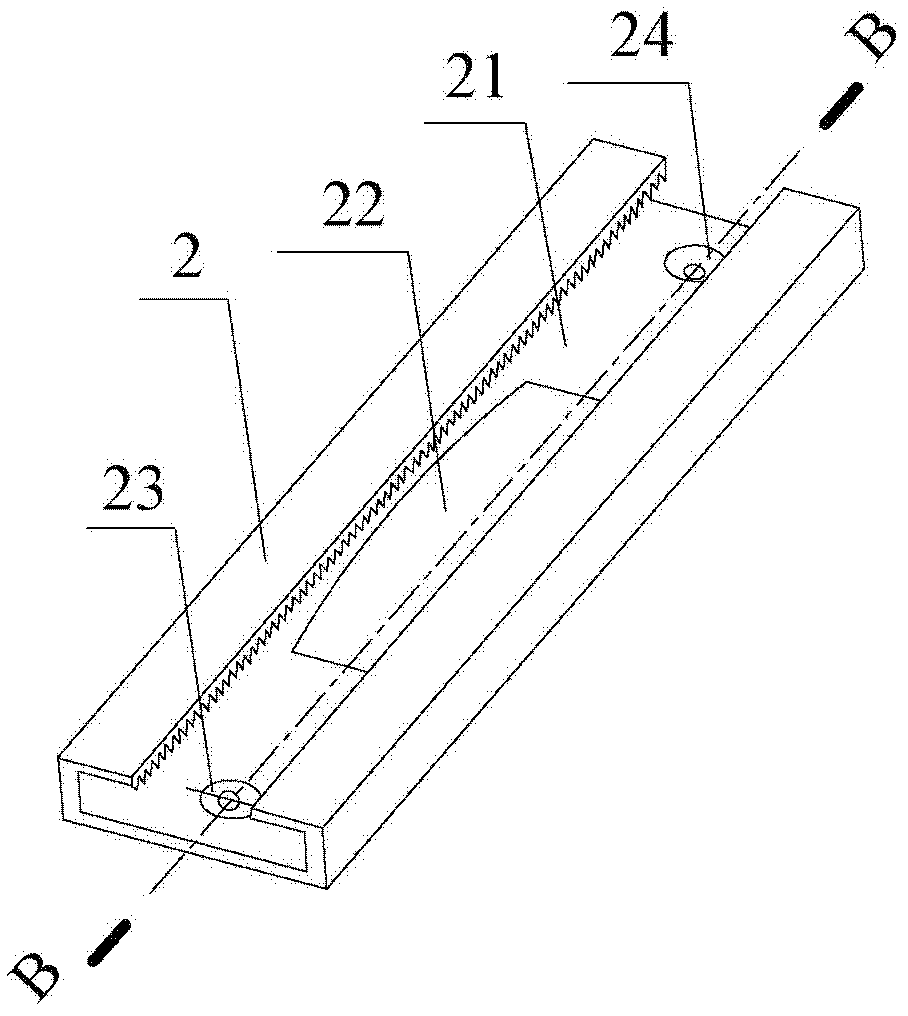

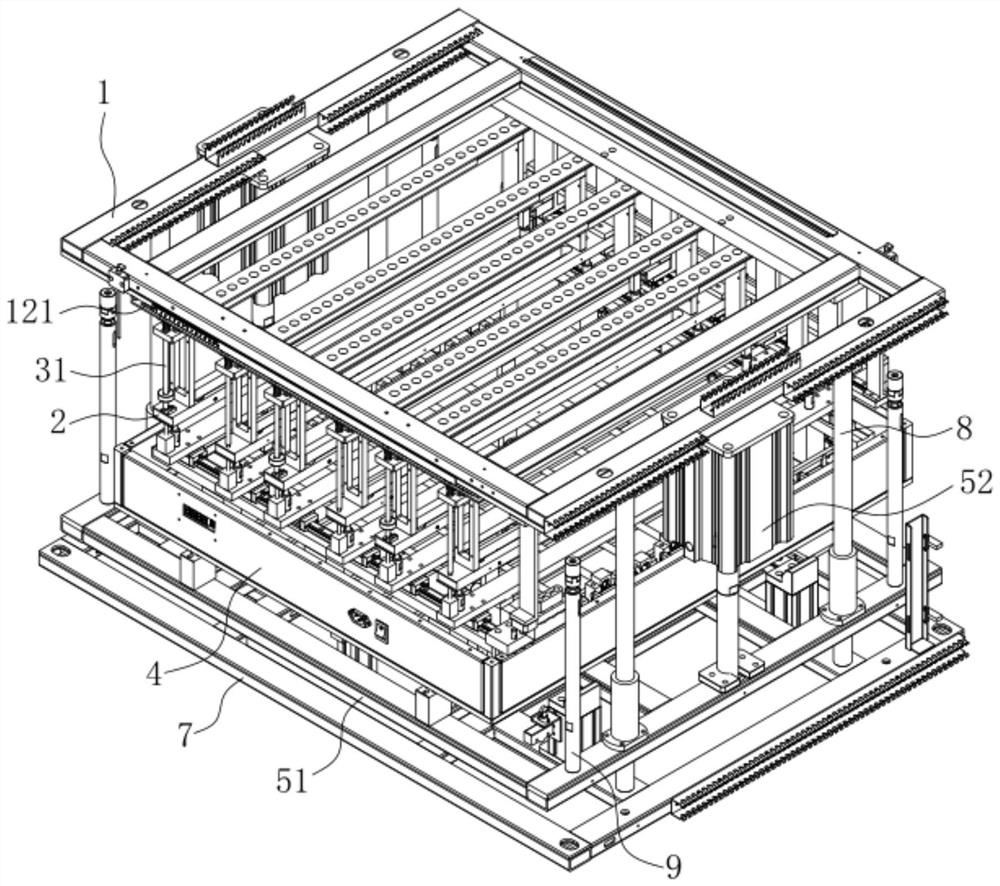

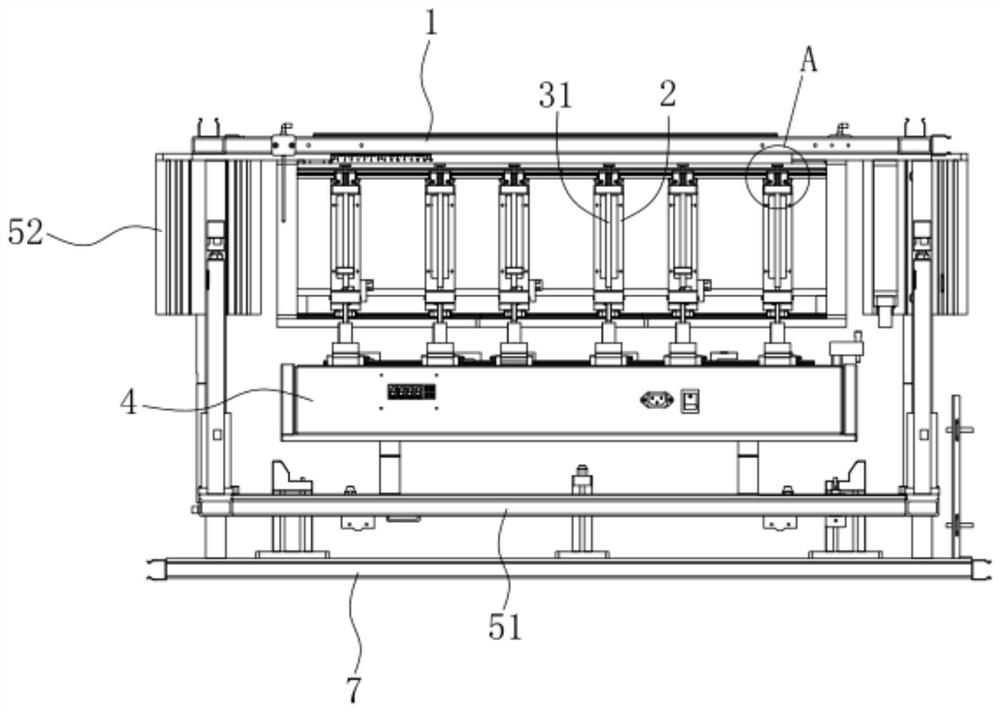

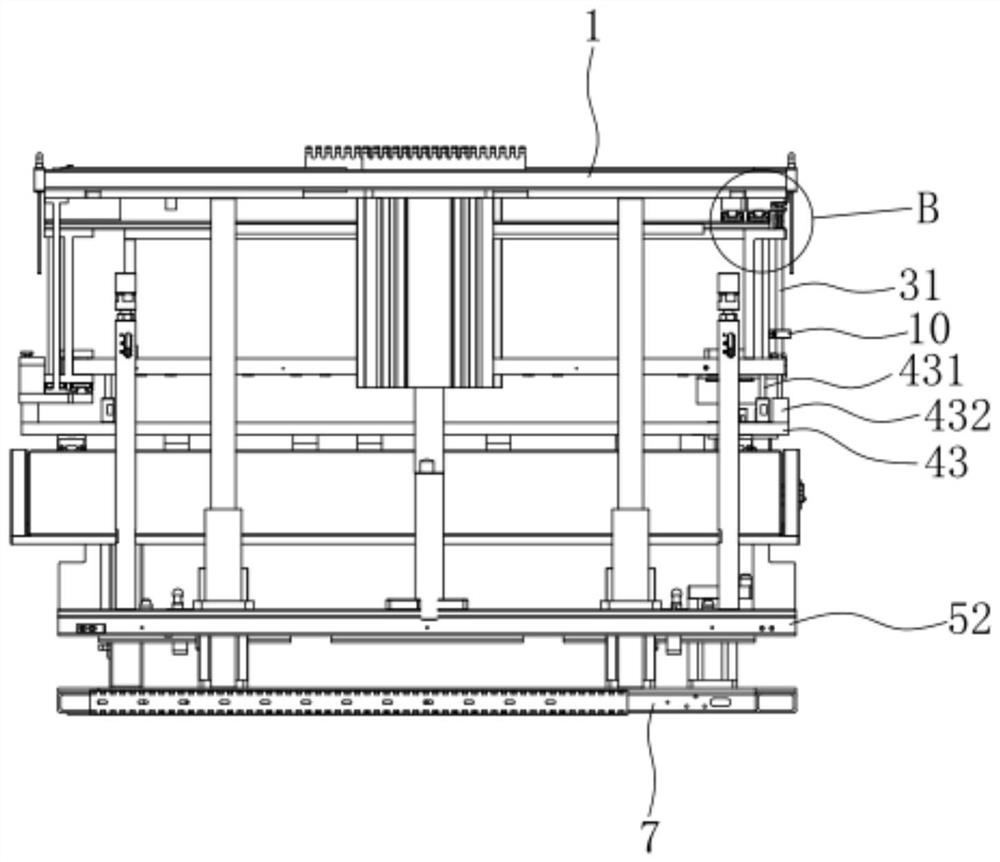

A rapid adjustment mechanism for the distance between a probe module and a formed needle bed

ActiveCN111044920BAchieve lock positioningImprove spacing adjustment efficiencyElectrical measurement instrument detailsElectrical testingEngineeringMechanical engineering

The invention discloses a probe module interval rapid adjusting mechanism and a formation needle bed, and the probe module interval rapid adjusting mechanism comprises an upper layer frame, a probe fixing frame, a pressing assembly and a positioning and adjusting tool. An upper guide rail and an installation frame are separately arranged on the two opposite sides of the upper layer frame, and theinstallation frame is provided with a through groove arranged in the same direction as the upper guide rail; two ends of the probe fixing frame are respectively connected to the corresponding upper guide rails in a sliding manner; the pressing assembly comprises an ejector rod movably mounted on the probe fixing frame and in the through groove in a sliding manner, a pressing plate which is connected to the periphery of the ejector rod and located between the installation frame and the probe fixing frame, and an elastic piece which sleeves the ejector, is elastically supported between the pressing plate and the installation frame, and drives the pressing plate to press the probe fixing frame through an elastic force so that the probe fixing frame can be locked on the upper layer frame; andthe positioning and adjusting tool jacks up the ejector rod under the effect of a jacking mechanism, so that the probe fixing frame is in an unlocked state capable of freely sliding in the through groove. The formation needle bed can adjust the positions of multiple groups of probe fixing frames at the same time, and has the advantages of high adjusting efficiency and low labor intensity.

Owner:GUANGDONG HYNN TECH CO LTD

A box-shaped ecological block for ecological slope protection

InactiveCN105544466BReduce usageReduce weightCoastlines protectionVegetative propogationEconomic benefitsWater flow

The invention discloses box-type ecological building blocks used for ecologically protecting a slope. The box-type ecological building blocks comprise building block single bodies. A packing groove is formed in the center of each building block single body. The four inner side faces of each packing groove are all provided with water through grooves. Circular-arc steps are evenly arranged at the corners of each packing groove from top to bottom. Guiding sliding grooves are formed in the two side edges of the top face of each building block single body. Limiting protrusions are arranged on the two side edges of the bottom face of each building block single body. A rectangular limiting groove is formed in one side of each building block single body, and a rectangular clamping block is arranged on the other side of the corresponding building block single body. Every two adjacent building block single bodies are fixedly connected through connecting pipes. The box-type ecological building blocks are simple in structure and high in practicability. The slope protection function of existing ecological building blocks is achieved, and water flow can also be maintained in a flowing state, so that scour of the water flow to the building blocks is reduced and the overall stability and strength are improved. Meanwhile, usage quantities of materials are reduced, and the weight of each building block single body is reduced, so that transportation is facilitated, the manufacturing cost is reduced and the economic benefits are remarkable.

Owner:浙江景昌建设有限公司

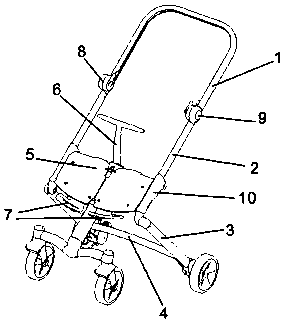

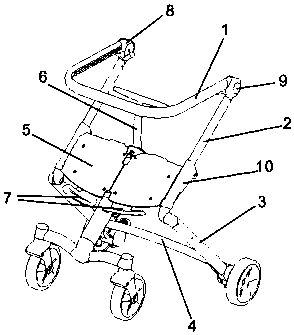

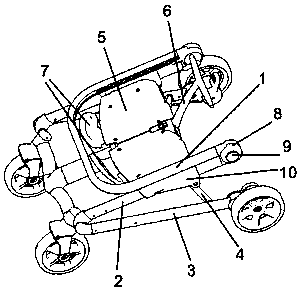

foldable stroller

InactiveCN106184333BEasy to operateRealize positioning connectionCarriage/perambulator with multiple axesEngineeringMechanical engineering

Owner:邝双发

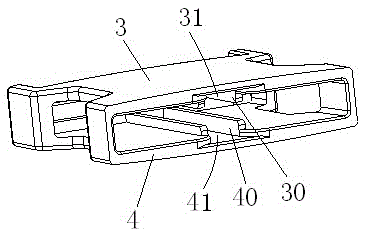

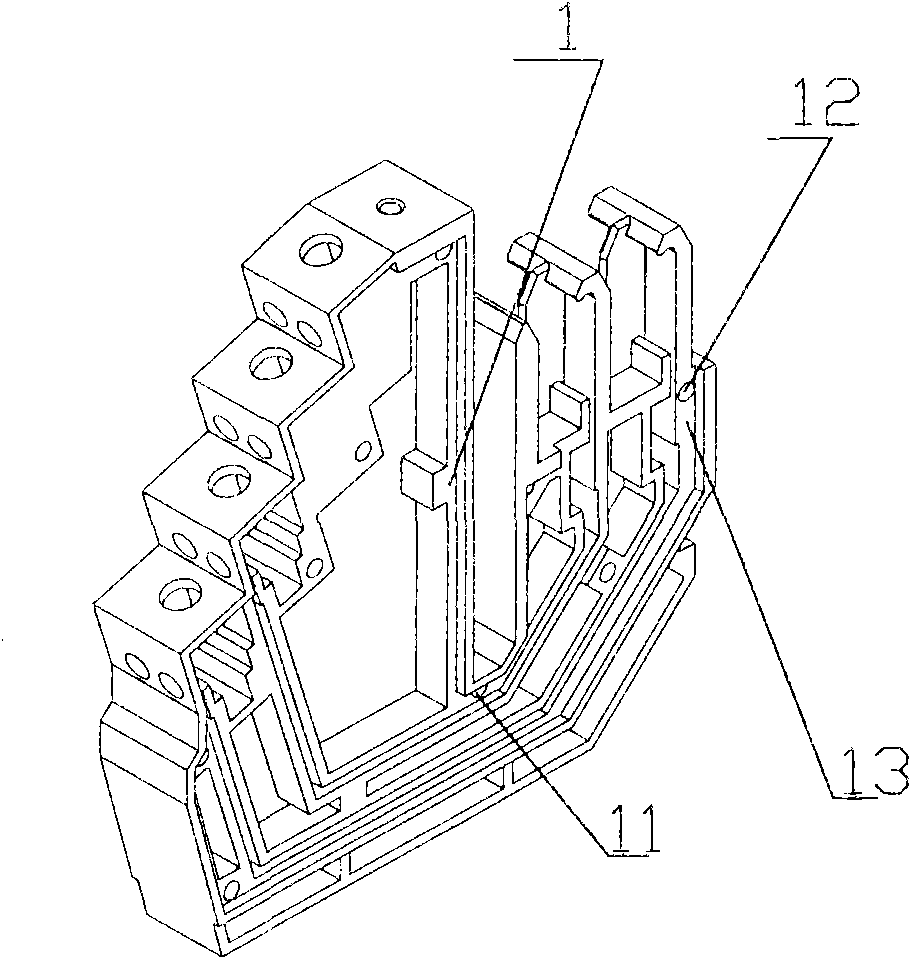

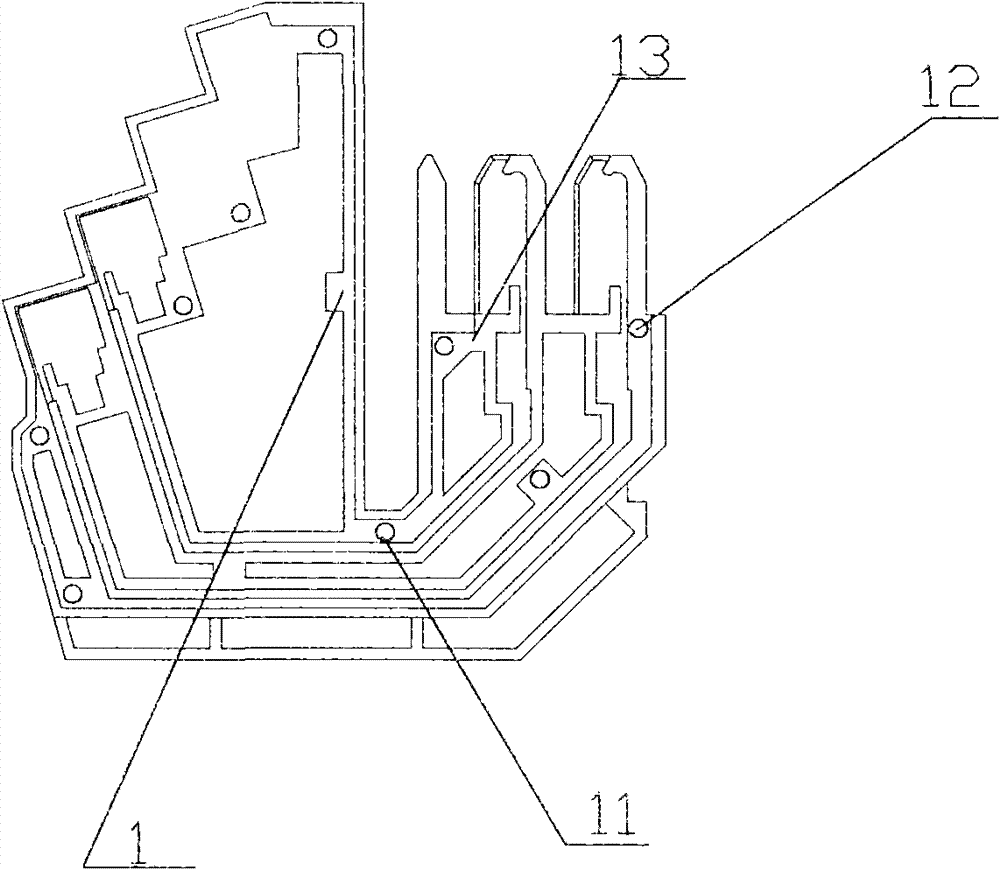

Positioning structure for contact plate group in fixed contact of circuit breaker

InactiveCN102254751BEasy to assembleEasy to installProtective switch detailsCircuit-breaking switch contactsEngineeringCircuit breaker

The invention discloses a positioning structure for a contact plate group in a fixed contact of a circuit breaker. The positioning structure comprises contact plates. Conductive plates used for conduction are arranged in the contact plates. A plurality of contact plates are horizontally laminated to form the contact plate group which is fixedly arranged in a contact holder of the fixed contact. The positioning structure further comprises cover plates. Each cover plate has a shape in fit with that of the contact plate, and is arranged between two adjacent contact plates. The two sides of the cover plate are provided a positioning pin respectively. Positioning holes in fit with the positioning pins are formed at the positions, corresponding to the positioning pins on the cover plates, of the contact plates, and are formed on the two sides of each contact plate. Due to the adoption of the structure, the contact plate group in the fixed contact of the circuit breaker can realize positioning connection among the contact plates by the positioning pins on the cover plates between every adjacent two of the plurality of contact plates forming the contact plate group and the positioning holes at corresponding positions on the contact plates, avoids sliding displacement among the contact plates, ensures connection stability and reliability in the working of the circuit breaker and simultaneously brings convenience to the assembly and mounting of the fixed contact.

Owner:CIXI SHUOBO ELECTRICAL APPLIANCE SCI & TECH

Microfluidic device, stirring system and stirring method

ActiveCN112844503ARealize positioning connectionLow costRotary stirring mixersTransportation and packagingEngineeringAgitator

The embodiment of the invention provides a microfluidic device, a stirring system and a stirring method, relates to the technical field of biology, and is simple in structure, easy to manufacture and capable of preventing cross contamination of liquid in the microfluidic device. The microfluidic device comprises a microfluidic chip, a stirring cavity, a first cover plate and a stirrer. The micro-fluidic chip comprises at least two inflow micro-channels and at least one outflow micro-channel. The stirring cavity comprises a stirring cavity used for containing liquid to be stirred, the stirring cavity is provided with a first opening and a liquid inlet and outlet which are oppositely arranged, and the liquid inlet and outlet is communicated with the at least two inflow micro-channels and the at least one outflow micro-channel. The first cover plate covers the first opening and is connected with the stirring cavity, and a first mounting hole is formed in the first cover plate; the stirrer comprises a blade and a connecting piece, wherein the blade is arranged in the stirring cavity and connected with the first end of the connecting piece, the second end of the connecting piece penetrates through the first mounting hole and is detachably connected with the driving device, and the driving device is used for driving the connecting piece to rotate.

Owner:BOE TECH GRP CO LTD +1

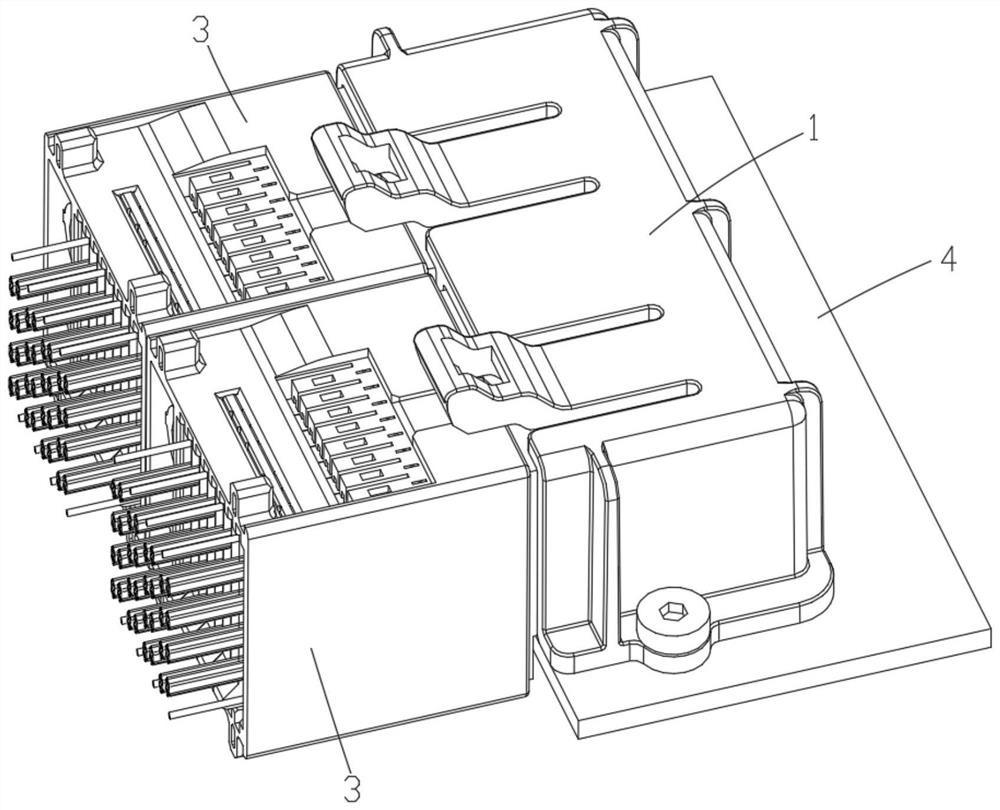

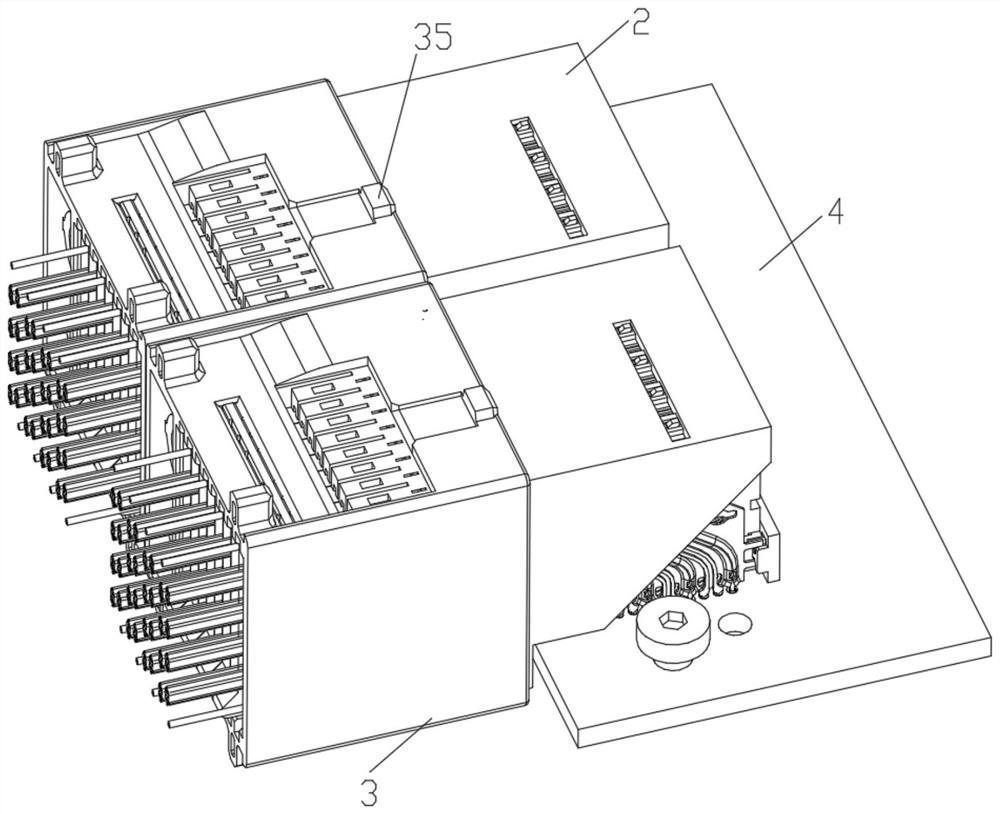

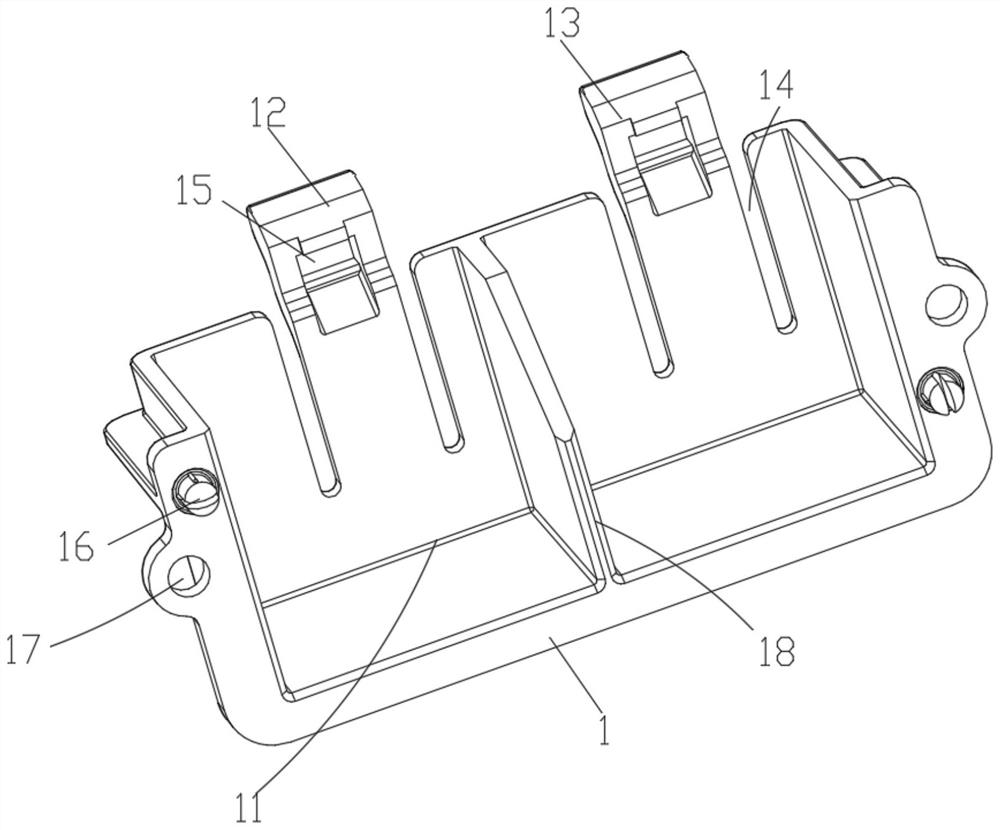

High-speed backboard connector with locking function

PendingCN113285299AAchieve lockingSimple structureSecuring/insulating coupling contact membersCoupling contact membersStructural engineeringMechanical engineering

The invention provides a high-speed backboard connector with a locking function, which comprises a mainboard, a mainboard connector, a cable connector and a locking outer cover matched with the mainboard, the mainboard connector and the cable connector, wherein the mainboard connector is inserted into the mainboard; the locking outer cover is provided with an installation groove used for installing a mainboard connector, and the locking outer cover is further provided with a first elastic arm and a second elastic arm which are used for being matched with a cable connector. The connection of the mainboard, the mainboard connector and the cable connector is realized through the locking outer cover, and the locking of the mainboard, the mainboard connector and the cable connector is realized at the same time; the mainboard connector and the cable connector are positioned and connected through guide columns and guide holes; the mainboard connector is installed in the containing groove of the outer cover, meanwhile, the elastic arm is connected with the hanging table of the cable connector in a clamped mode, interlocking of the mainboard connector and the cable connector is achieved, and meanwhile disassembly is convenient.

Owner:FCI CONNECTORS DONGGUAN

Glass fiber reinforced plastic stern shaft sleeve and bearing connecting joint

InactiveCN110949648ARealize positioning connectionImprove connection strengthWater acting propulsive elementsPropulsive transmissionGlass fiberEngineering

The invention relates to the technical field of glass fiber reinforced plastic stern shaft sleeves, in particular to a glass fiber reinforced plastic stern shaft sleeve and bearing connecting joint. The glass fiber reinforced plastic stern shaft sleeve and bearing connecting joint includes a ship body; a strip-shaped tail shaft sleeve is arranged at the lower end of the ship body; bearing positioning groups are respectively arranged at the front end part and the rear end part below the tail shaft sleeve; each bearing positioning set is composed of two positioning threaded sleeves and a positioning bolt. The positioning screw sleeves are pre-embedded in the tail shaft sleeve; the two positioning threaded sleeves are symmetrically arranged on the left side and the right side below the tail shaft sleeve. The axes of the two positioning screw sleeves form an angle of 120 degrees; positioning bolts are arranged in the positioning threaded sleeves; the positioning bol penetrate into the tailshaft sleeve to support and position the bearing; an injection molding cavity is formed between the outer wall of the bearing and the inner wall of the tail shaft sleeve, the two ends of the injection molding cavity are blocked and sealed through detachable plasticine layers, a liquid injection hole and an exhaust hole which are communicated with the injection molding cavity are formed in the twoends of the upper side of the outer wall of the tail shaft sleeve respectively. The glass fiber reinforced plastic stern shaft sleeve and bearing connecting joint has the advantages of being simple in structure, convenient to install, high in stability and connection strength.

Owner:WEIHAI ZHONGFU XIGANG SHIP

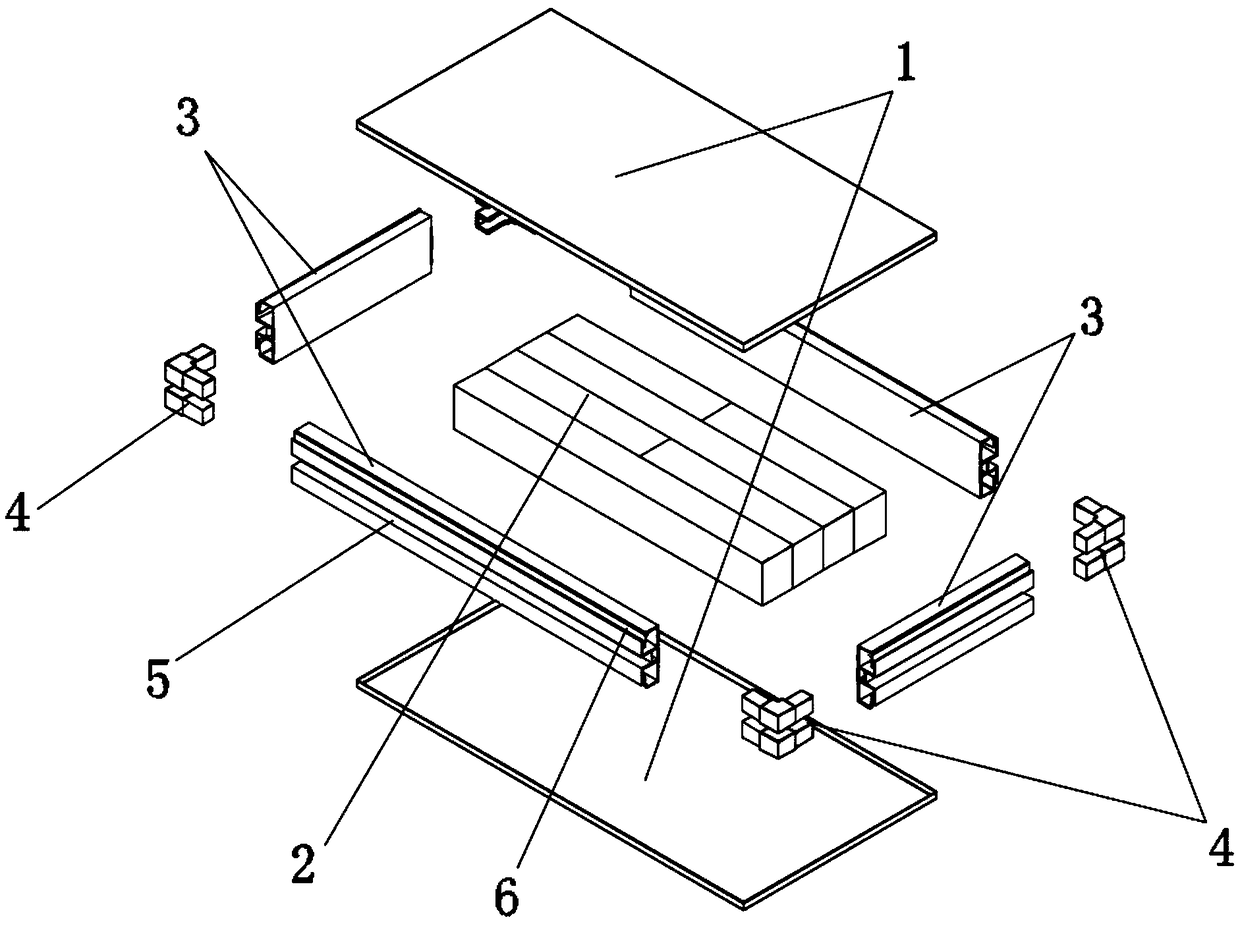

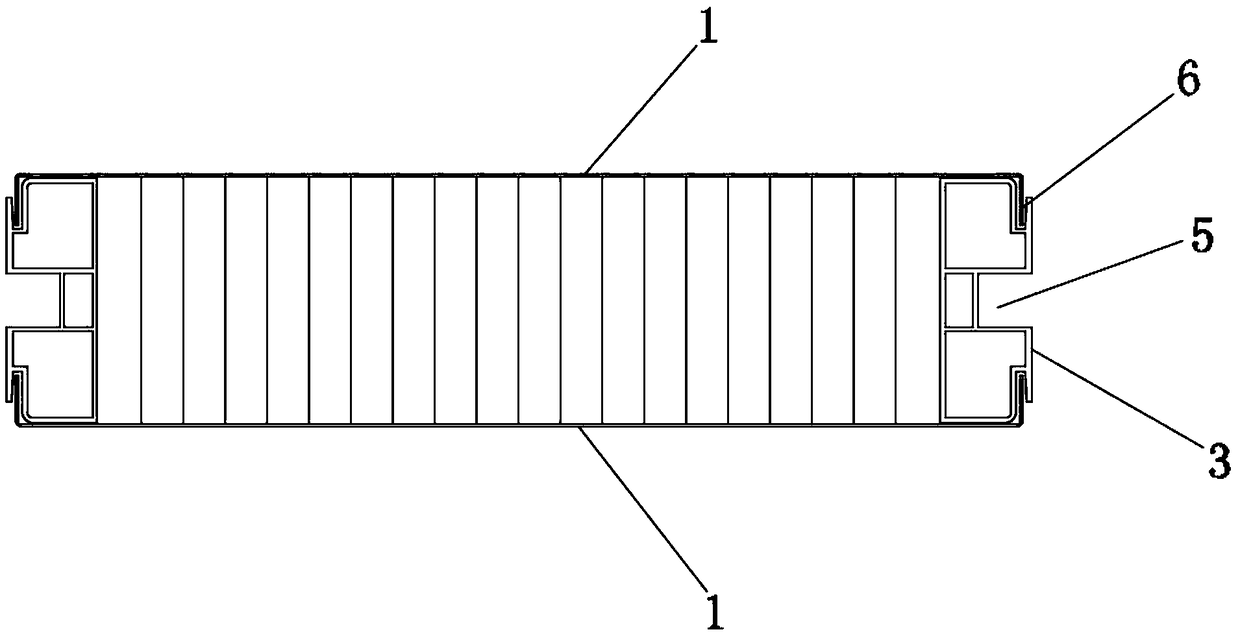

Glue-leak-free sandwich panel with grooved frame

The invention relates to the field of sandwich panels, in particular to a glue-leak-free sandwich panel with a grooved frame. The sandwich panel comprises panel bodies and core materials, wherein thecore materials are clamped and fixed between the two panel bodies. The glue-leak-free sandwich panel is characterized in that the fixing frame is fixedly connected between the two panel bodies; the fixing frame is composed of four frame strips; adjacent frame strips are connected through connecting members; the core materials are located in the fixing frame; the outer end faces of the four frame strips of the plate bodies are provided with recesses for the connection of the two identical sandwich panels; the four sides of each panel body are flanged; and the connecting members are provided with positioning grooves for inserting the flanged sides of the plate bodies. The frame is formed through the joggling of the connecting members and the frame strips, so that the core materials are completely enclosed between the two panel bodies and prevented from being exposed; the positioning connection between the sandwich panels is realized through the recesses of the outer end surfaces of the connecting members; and the four flanged sides of each plate body is clamped into the positioning grooves of the connecting members so that the overflowing of glue can be reduced.

Owner:辰峰洁净系统科技(昆山)有限公司

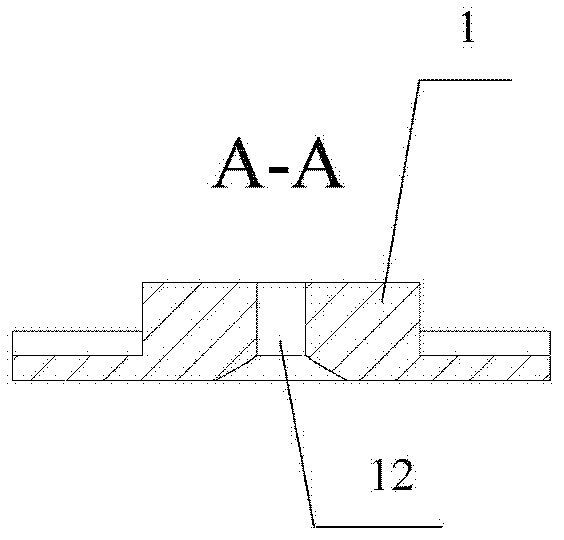

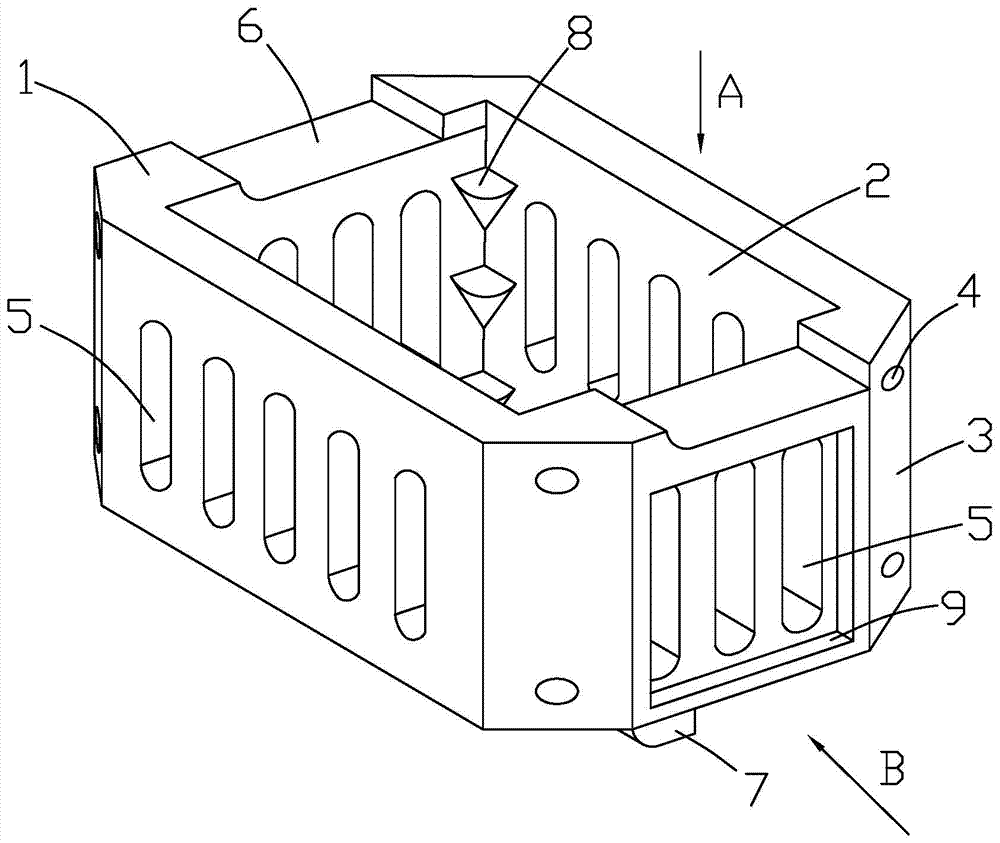

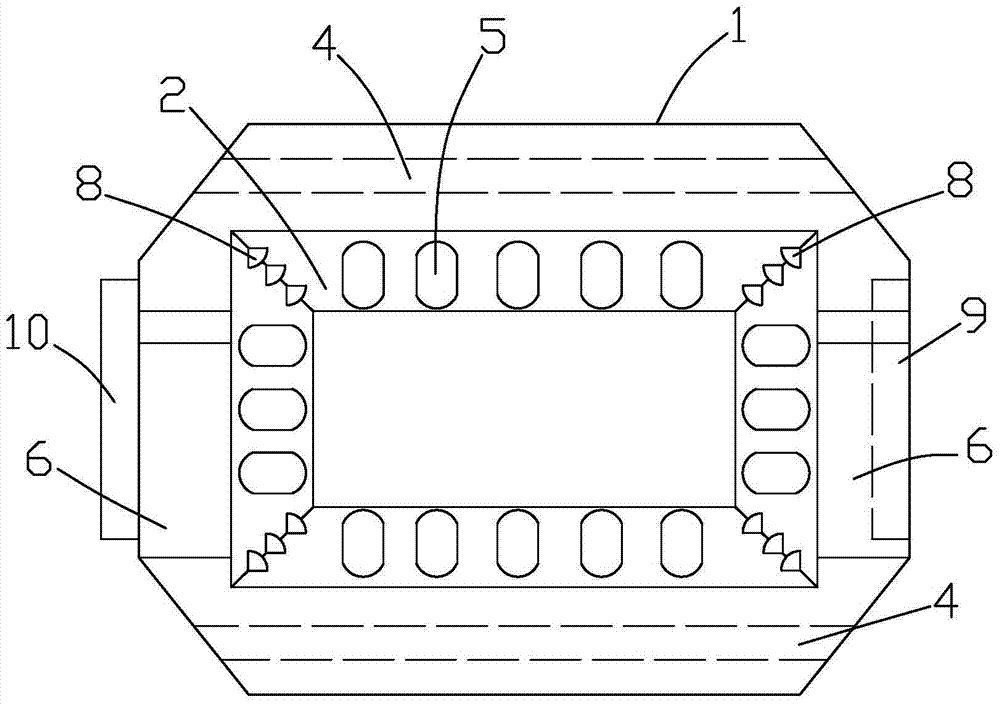

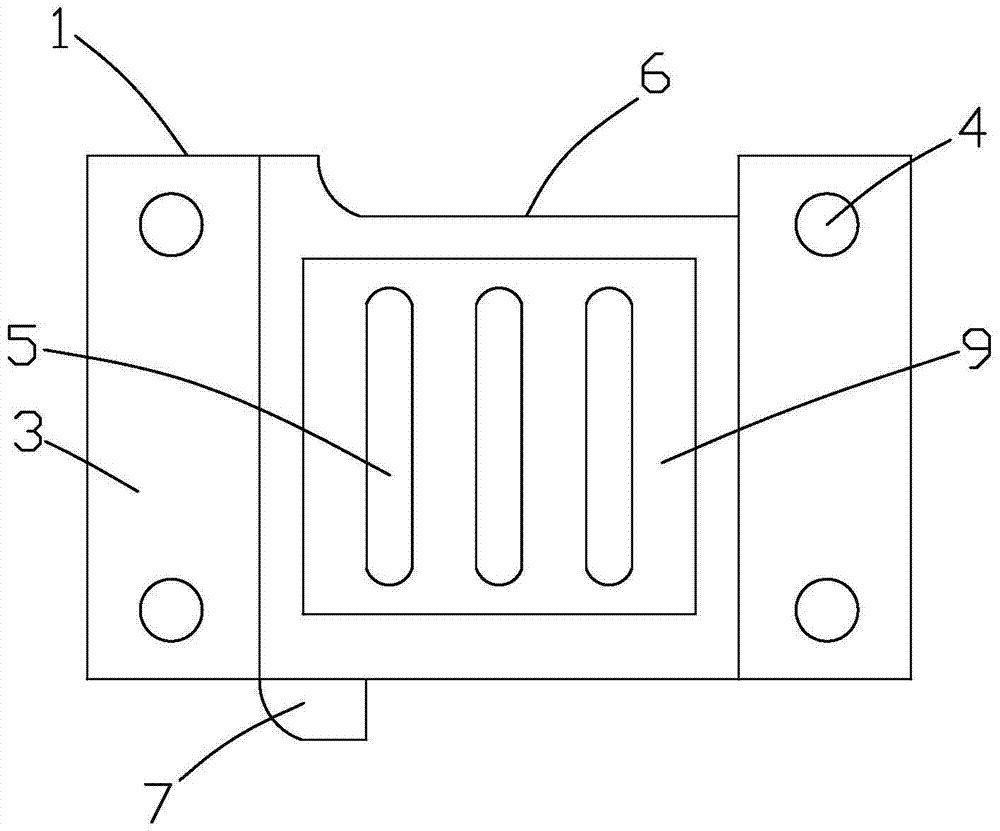

Technological opening-closing bomb mould for explosive loading of warhead

ActiveCN103073368BFacilitate direct observation of surface qualityFirmly connectedExplosive working-up apparatusLeft halfMaterials science

The invention discloses a technological opening-closing bomb mould for explosive loading, and relates to a technological opening-closing bomb mould for explosive loading of a warhead. The mould is characterized in that the mould mainly comprises a mould body, wherein an opening is formed at one end of the mould body; a mould cavity is formed in the mould body; the mould body comprises a left half mould (1) and a right half mould (2) that are matched and movably connected with each other; each half mould is provided with a cavity (3); and the cavity (3) of the left half mould (1) and the cavity (3) of the right half mould (2) form the mould cavity together. The mound is simple in structure and low in cost; the warhead can be subjected mould opening, detection of the explosive loading quality of the warhead can be facilitated, and the mould is suitable for popularization and application.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Mounting structure for frictional wear test for valve mechanism of engine

ActiveCN102778350BEasy to processRealize positioning connectionMachine part testingEngine testingTest sampleEngineering

The invention discloses a mounting structure for frictional wear test for a valve mechanism of an engine. The mounting structure mainly comprises parts including a valve (1), a seat ring (2), a guide tube (3), a spring (4), a lock clamp (5), an inner spring seat (6), an outer spring seat (7), an upper mounting disc (8), a lower mounting disc (9), a support box (10) and the like. The valve (1) and the seat ring (2) are main assessment test samples for the test, the lock clamp (5) is the part for matching the valve (1) with the seat ring (2), the upper mounting disc (8), the lower mounting disc (9) and the outer spring seat (7) are reusable main parts of the mounting structure, and the guide tube (3) and the inner spring seat (6) are transitional connectors for fittingly mounting the gas valve and the seat ring with the main parts. The mounting structure is a combined type structure and is easy to process; coaxiality of the guide tube and a seat ring hole is high; and the mounting structure is convenient and speedy to assemble and disassemble and high in universality, and can be used for valve-seat ring tests in multiple schemes.

Owner:NO 70 INST OF CHINA NORTH IND GRP

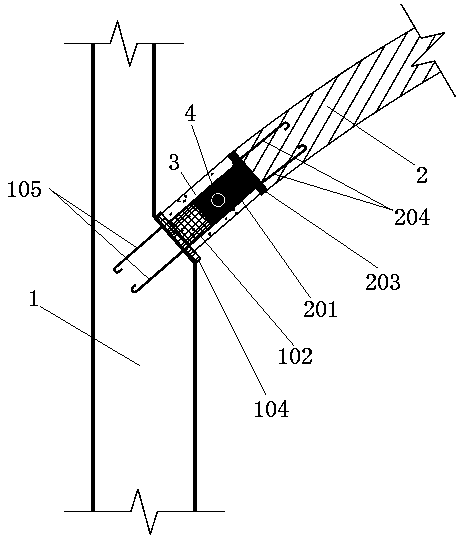

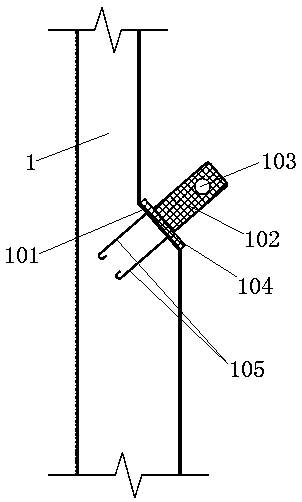

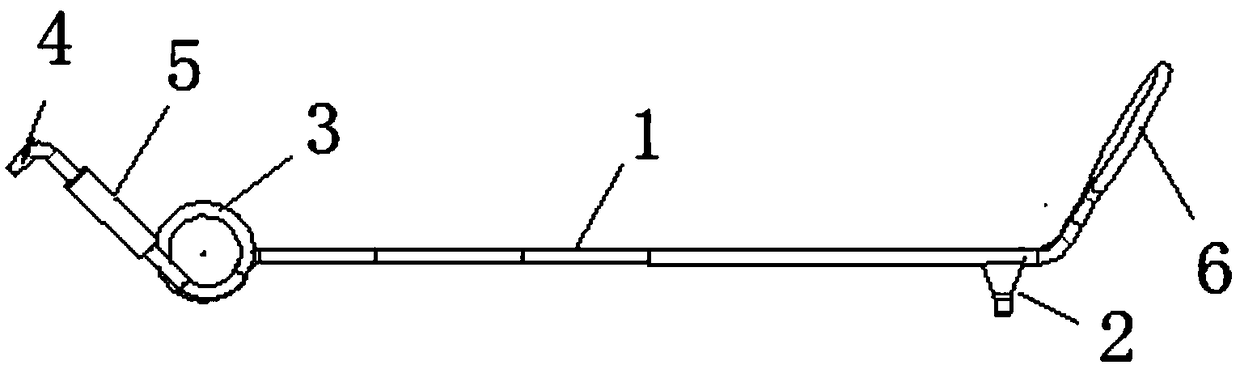

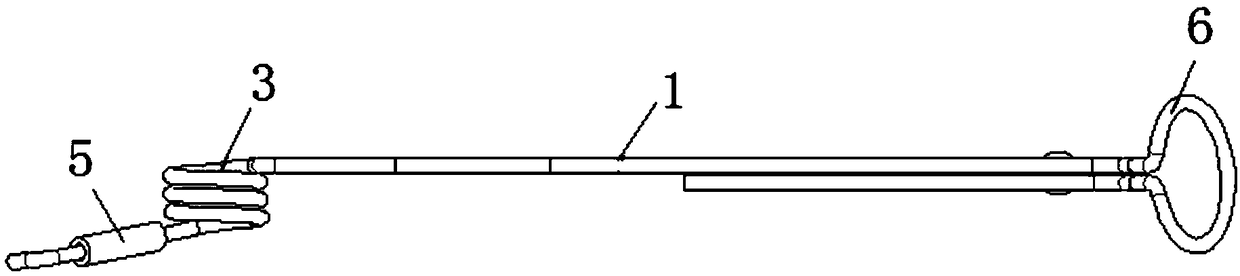

Four-door universal tool for processing electrophoresis before coating

InactiveCN108842178ARealize positioning connectionGuaranteed opening angleElectrophoretic coatingsElectrophoresisHooking

The invention discloses a four-door universal tool for processing electrophoresis before coating. The tool comprises a connecting rod, positioning structures and a hooking and tensioning mechanism, wherein the positioning structures are arranged at the two ends of the connecting rod, and the hooking and tensioning mechanism can be deformed to form a tensioning force; and one end of the connectingrod is connected to a vehicle body in a hooked mode through the hooking and tensioning mechanism, and the other end is connected to a vehicle door in a positioning mode through a positioning structure. According to the tool, the vehicle door can be firmly connected to the vehicle body, so that the opening angle of the vehicle door and the vehicle body is guaranteed.

Owner:CHERY COMML VEHICLE ANHUI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com