Heat exchanger structure and assembly process thereof

An assembly process and heat exchanger technology, applied in heat exchange equipment, lighting and heating equipment, tubular components, etc., can solve problems such as product quality decline, cost increase, and poor brazing, to ensure welding quality, improve Product quality, the effect of improving welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

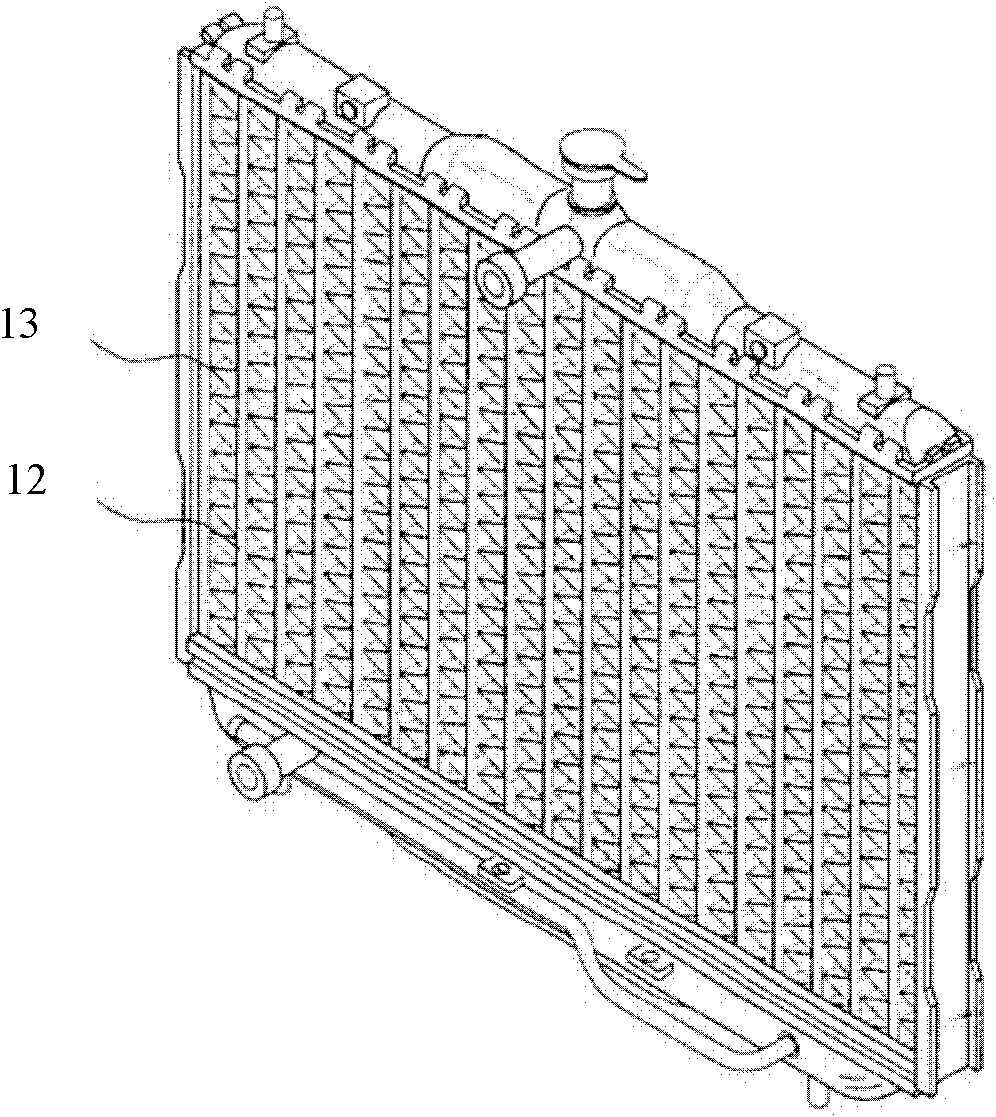

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

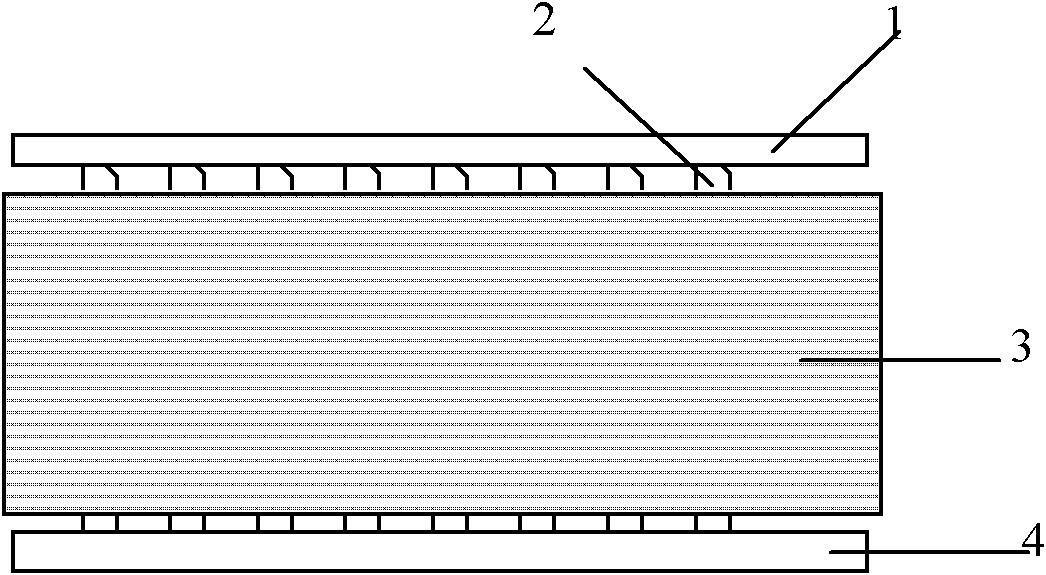

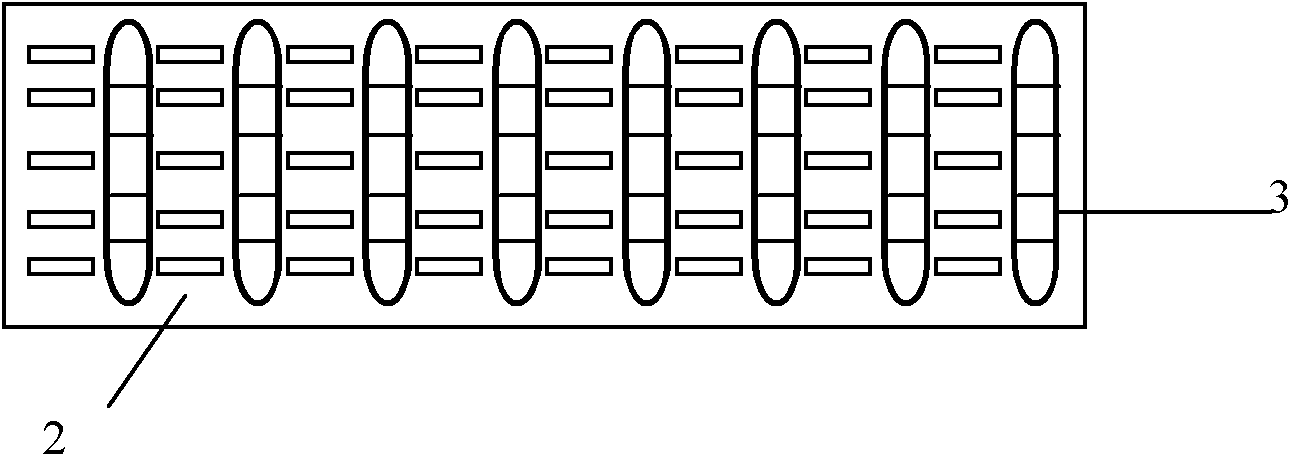

[0032] Such as Figure 4-8 Shown is the first embodiment of the present invention, as shown in the figure, the fin 13 is a rectangular aluminum sheet, on which a plurality of groups of punching holes 31 are evenly spaced, and the punching holes 31 are set along the length direction of the rectangular fin , the punched hole 31 is conducive to the circulation of air flow in it to enhance the heat dissipation effect of the radiator. Between the two groups of punching holes 31 is provided a rounded rectangular pipe groove 32 , the width of the pipe groove 32 is slightly larger than the thickness of the flat tube 22 , so that the flat pipe 22 can enter the pipe groove 32 smoothly.

[0033] Further, flanges are provided around the duct groove 32 to limit the distance between two adjacent fins 13 .

[0034] as attached Figure 5 As shown, the flat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com