Mounting structure for frictional wear test for valve mechanism of engine

A technology of friction and wear test and gas distribution mechanism, which is applied in the direction of engine testing, machine/structural component testing, mechanical component testing, etc. It can solve the problems of high cost and long cycle, and achieve simple structure, strong versatility, The coaxiality is easy to guarantee the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

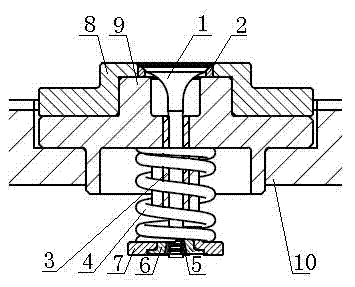

[0026] An installation body structure used for friction and wear tests of engine valve mechanism, mainly including valve, seat ring, guide tube, spring, lock clip, spring inner seat, spring outer seat, installation upper plate, installation lower plate, support box, etc. Parts, of which the valve and seat ring are the main test samples for the test; the lock clip is the part provided to match the valve and seat ring; the upper plate, the lower plate and the spring outer seat are the main parts of the reusable installation body; the conduit, The spring inner seat is a transition piece used to match the installation of the valve-seat ring and the main body parts;

[0027] There is a cylindrical boss on the upper part of the lower plate, and two inner and outer cylindrical bosses on the lower part. The upper boss of the lower plate is positioned and connected with the upper plate with a small fit gap. Positioning connection with small fit clearance; the seat ring processed by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com