Four-door universal tool for processing electrophoresis before coating

A pre-treatment and tooling technology, applied in the direction of electrophoretic plating, coating, electrolytic coating, etc., can solve the problems of complex tooling, poor ergonomics, inconvenient management, etc., to improve work efficiency, reduce development costs, and open and close angles controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

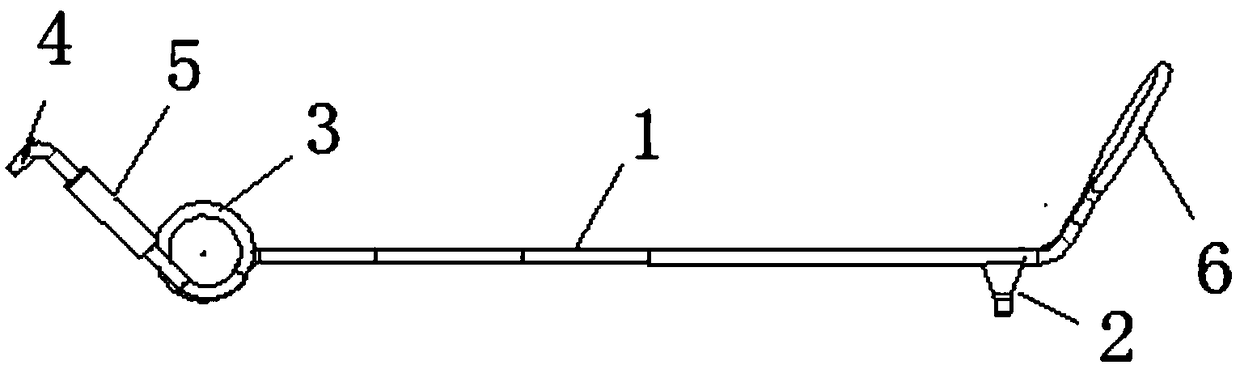

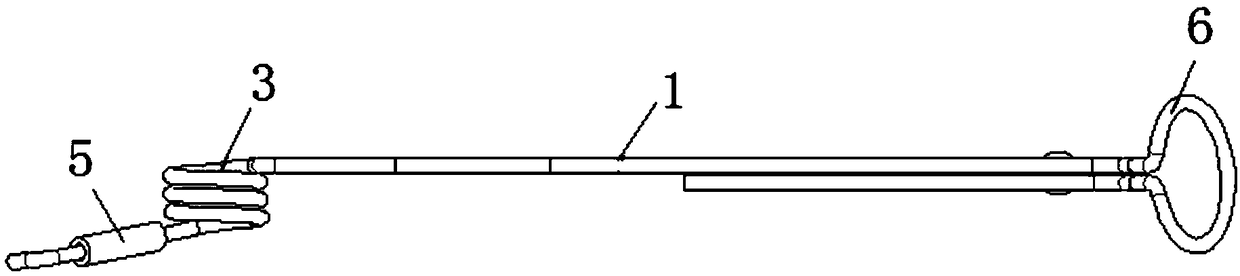

[0024] like Figure 1 to Figure 2 As shown, a four-door general-purpose tooling for pre-painting electrophoresis, including a connecting rod 1, positioning structures respectively arranged at both ends of the connecting rod 1 and a hooking and tensioning mechanism that can be deformed to form a tensioning force, one end of the connecting rod 1 The hooking and tensioning mechanism is hooked and connected with the vehicle body, and the other end is positioned and connected with the car door through a positioning structure.

[0025] Wherein, the positioning structure is the positioning pin 2 . Locating pin 2 is concentrically located with the locating hole of the car door, and the locating pin is the benchmark of the whole frock. The positioning pin 2 is preferably a lower circle upper cone structure, the lower circle upper cone structure includes a circular column for connecting the positioning hole of the car door and a tapered structure arranged on the circular column for fit...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that the connecting rod is a telescopic rod, and the purpose is to adjust the distance between the hook and the positioning pin according to the structure of different vehicle models. The telescopic rod can adopt two sleeve rods that are nested with each other. The inner sleeve rod is provided with multiple positioning holes in the axial direction, and the outer sleeve rod is provided with elastic positioning protrusions, which cooperate with different positioning holes through the elastic positioning protrusions. Realize the telescopic adjustment of two sets of rods. Of course, the connecting rod can also be an electric push rod, the positioning pin is arranged at the telescopic end of the electric push rod, and the hook and the spring are arranged at the tail end of the electric push rod.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com