Positioning structure on top of high-pressure liquid ammonia pump cylinder

A positioning structure, high-pressure liquid technology, applied in variable displacement pump components, liquid fuel engines, components of pumping devices for elastic fluids, etc. problem, to achieve the effect of simple and reliable positioning structure, avoid positioning failure, and increase positioning depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

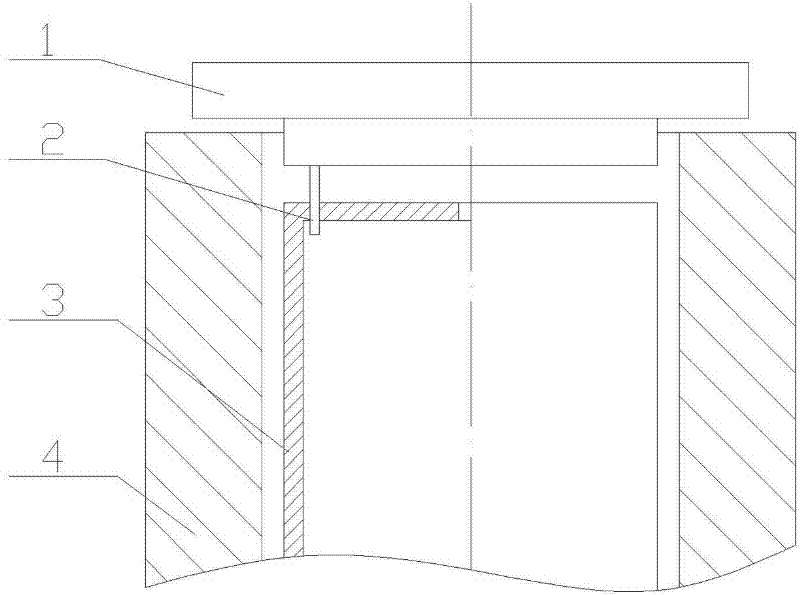

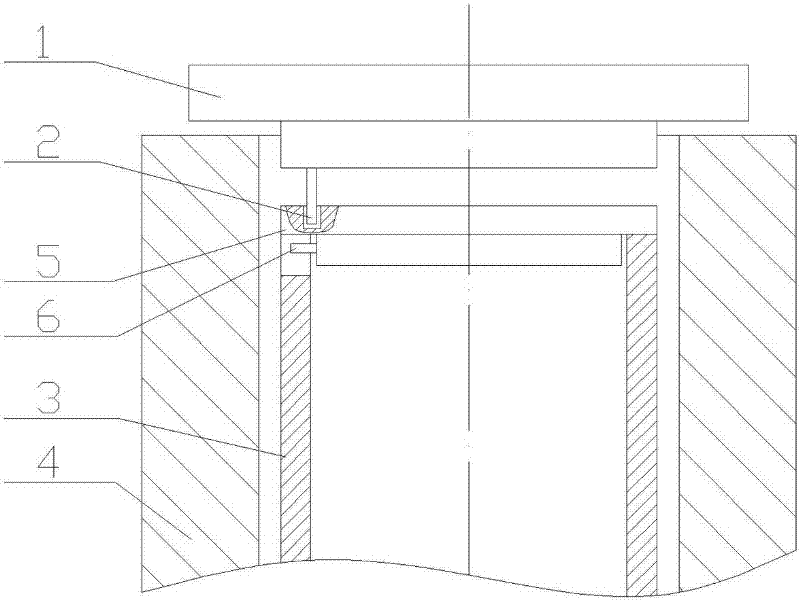

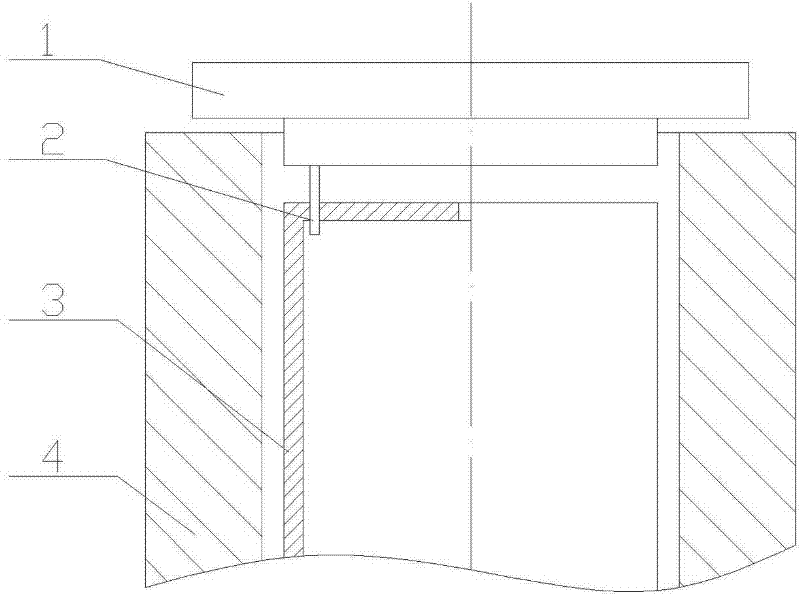

[0013] Such as figure 1 As shown, the top positioning structure of the high-pressure liquid ammonia pump cylinder includes an outlet valve sleeve 3 installed in the cylinder 4 and a top flange 1 fixed on the cylinder 4 . There is an upper end surface on the outlet valve sleeve 3, and a pin hole is eccentrically arranged on the upper end surface. A positioning pin 2 is arranged on the lower surface of the top flange 1, and the length of the positioning pin 2 ensures that it can completely pass through the pin hole on the outlet valve sleeve 3 and exceed a certain length. The outlet valve sleeve 3 is installed in the cylinder body 4. After the positioning pin 2 on the top flange 1 is inserted into the pin hole on the outlet valve sleeve 3, the top flange 1 is fixed on the cylinder body 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com