Battery cold-press shaping machine capable of continuously working

A shaping machine and cold-pressing technology, applied in sustainable manufacturing/processing, climate sustainability, non-aqueous electrolyte batteries, etc., can solve problems such as labor consumption and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below with reference to the accompanying drawings. The description in this section is only exemplary and explanatory and should not have any limitation on the scope of protection of the present invention. .

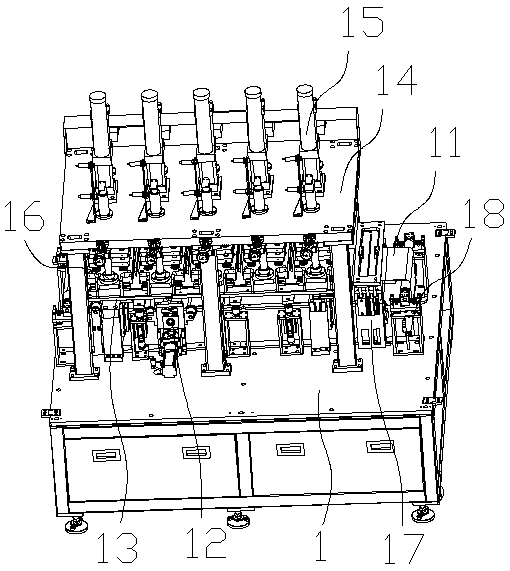

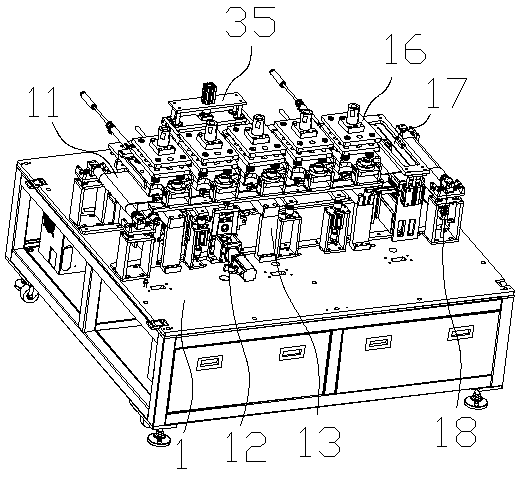

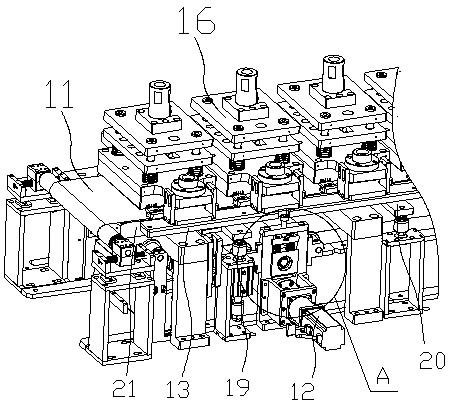

[0022] Such as Figure 1-3 As shown, the specific structure of the present invention is: a continuous working battery cold press shaping machine, including a power distribution control box 1, and the power distribution control box 1 is provided with a cold press belt 11 and a belt feeder that cooperate with each other. The device 12, and the power distribution control 1 is also provided with a cold press frame 14, the cold press frame 14 is provided with a cold press cylinder 15, below the cold press cylinder 15 is connected with the product on the cold press belt 11 For the cold press 16, the cold press ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com