Explosion-proof device on smelting furnace

An explosion-proof device and smelting furnace technology, applied in the field of smelting furnaces, can solve problems affecting the normal operation of heating furnaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

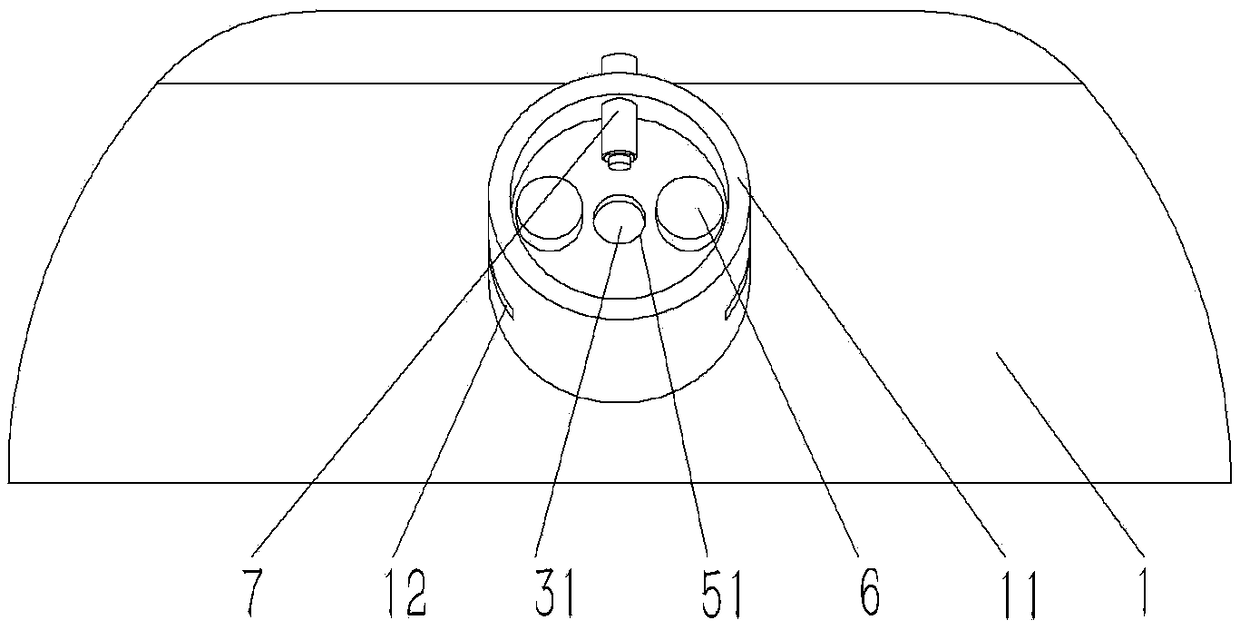

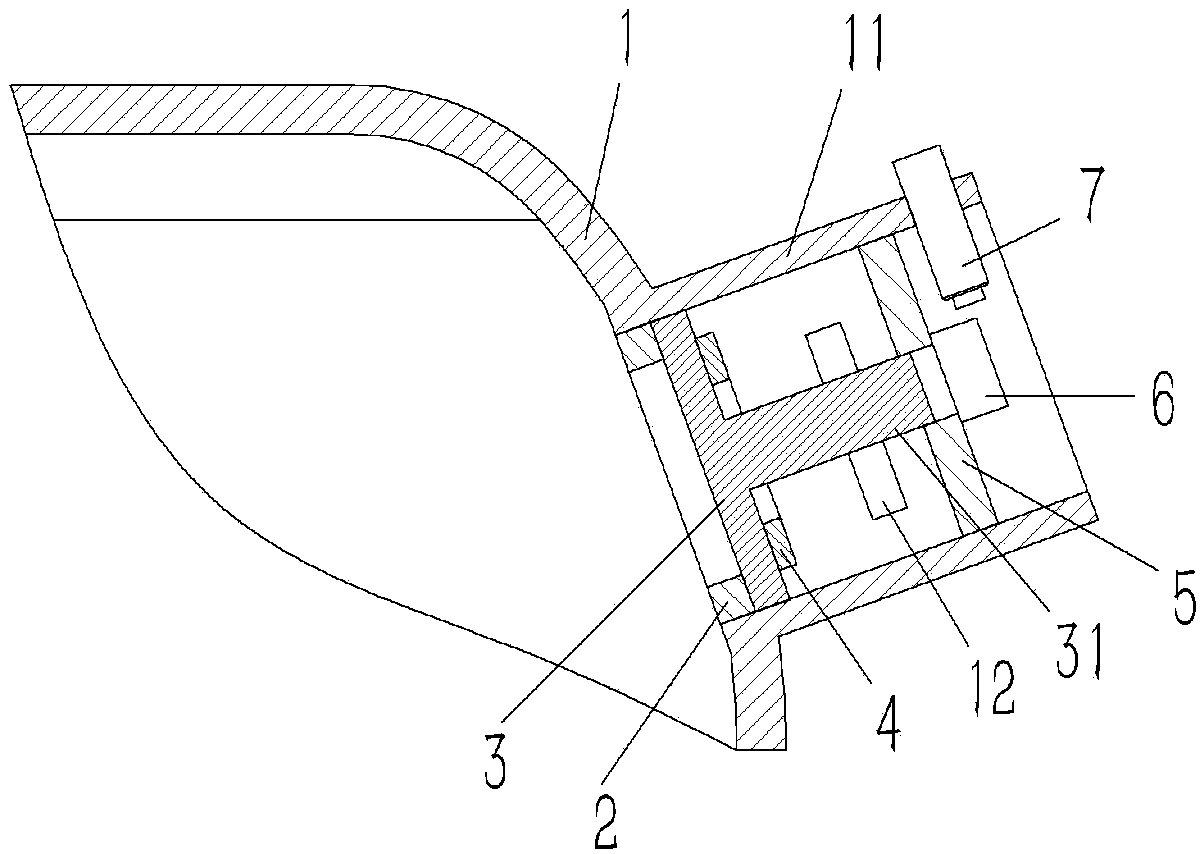

[0014] Example: see figure 1 , 2 As shown, an explosion-proof device on a smelting furnace comprises a furnace body 1 of the smelting furnace, a pressure relief hole is formed on the furnace body 1, and an explosion-proof pipe 11 communicating with the pressure relief hole is formed on the outer wall of the furnace body 1, and the explosion-proof The lower end of the tube 11 is plugged and fixed with a retaining ring 2, and an explosion-proof cover 3 is inserted in the explosion-proof tube 11. The lower end surface of the explosion-proof cover 3 is pressed against the retaining ring 2, and the outer wall of the explosion-proof cover 3 is against the inner wall of the explosion-proof tube 11. Above, the center of the upper end surface of the explosion-proof cover 3 is formed with a guide column 31, and the explosion-proof tube 11 on the upper side of the guide column 31 is inserted and fixed with a positioning plate 5, and the center of the positioning plate 5 is formed with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com