A steel structure anti-compression support frame

A technology of support frame and steel structure, applied in the direction of building structure, construction, etc., can solve the problems of weak support frame structure, reduced compressive performance, loose bolts, etc., to ensure stability, enhance compressive stability, Avoid loosening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

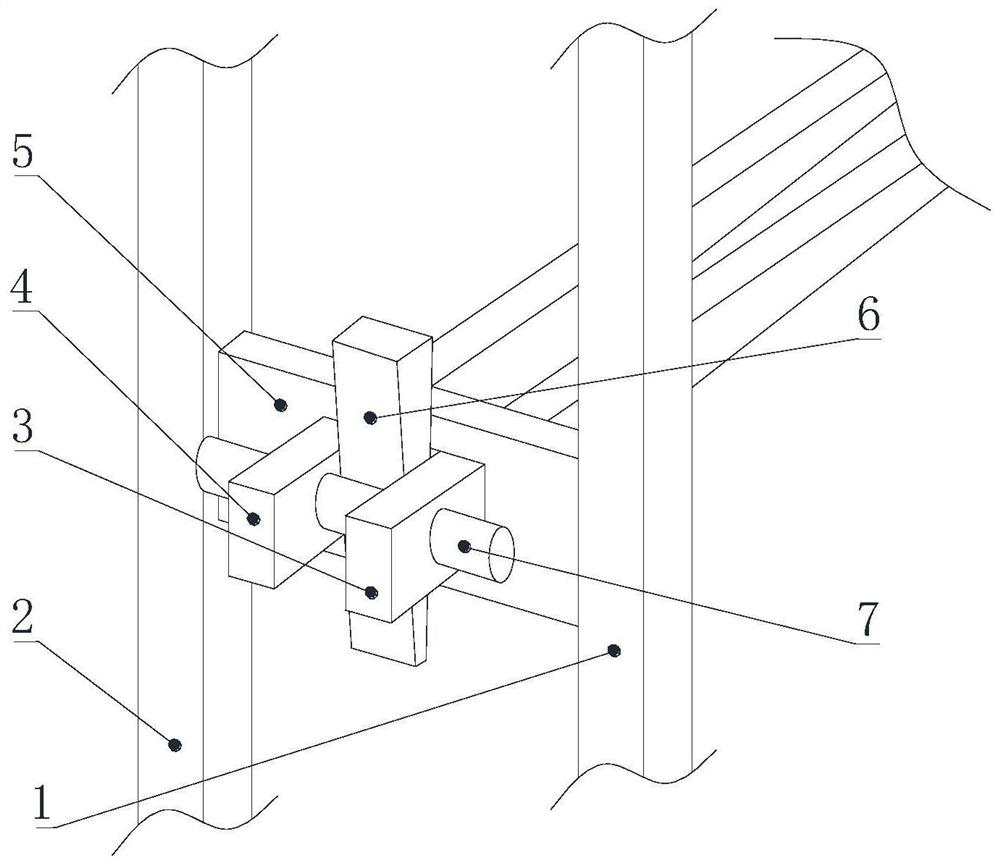

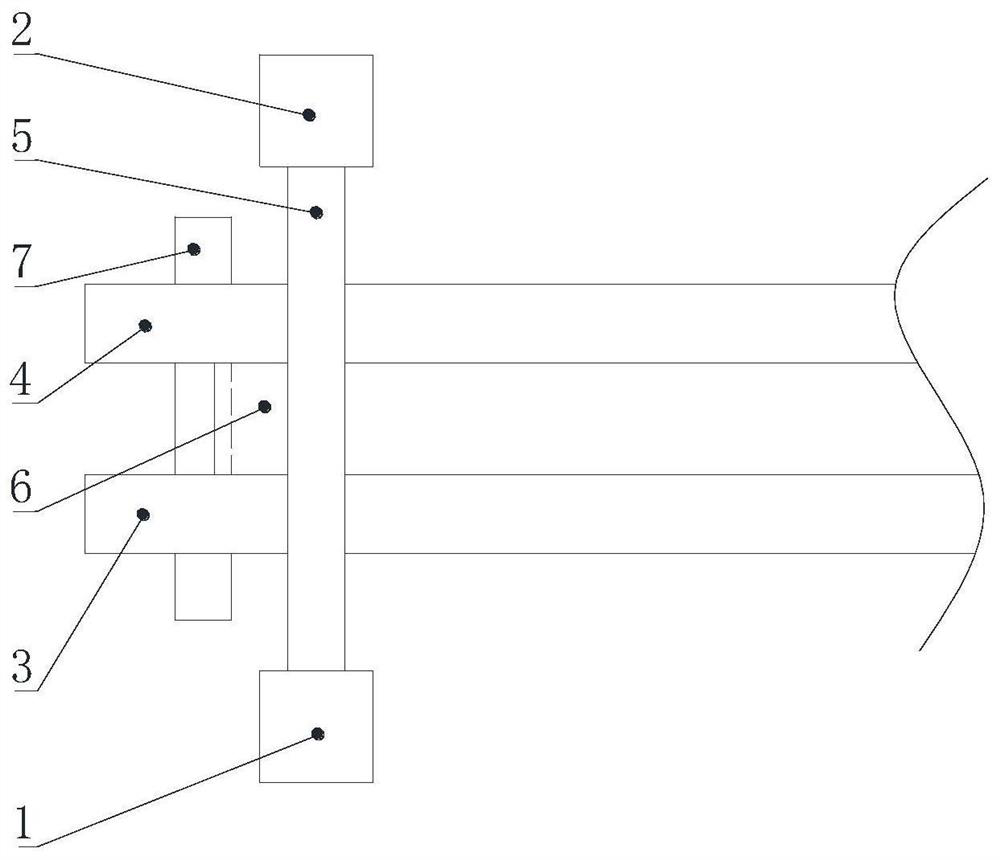

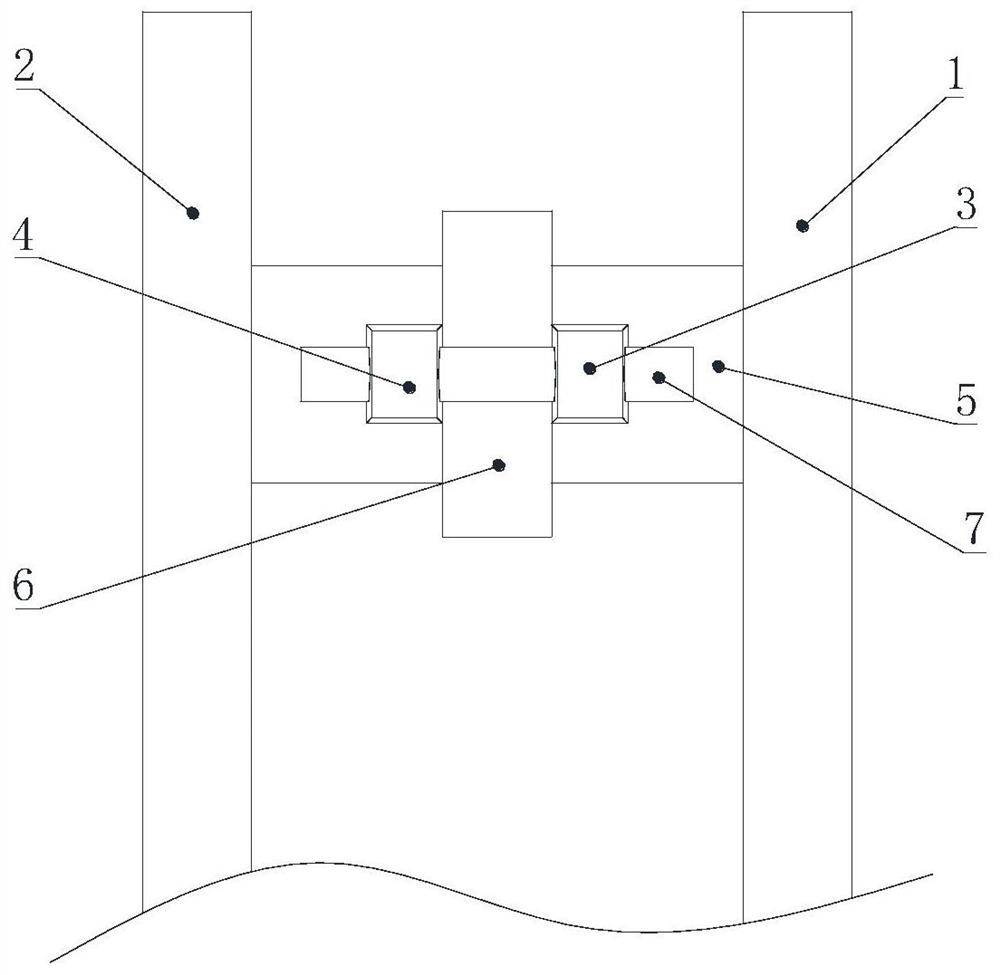

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0034] Such as Figure 1-4 As shown, a steel structure anti-compression support frame includes a first column 1, a second column 2, a connecting plate 5, a first beam 3, a second beam 4, a connecting column 7 and a positioning wedge 6, the first column 1 and The second column 2 is collectively referred to as a column, and the columns are used in pairs. The first column 1 and the second column 2 are arranged in parallel, and the first column 1 and the second column 2 are connected by a connecting plate 5, and the connecting plate 5 There are through holes on the top, and the first beam 3 and the second beam 4 perpendicular to the first column 1 and the second column 2 are arranged in the through hole. The first beam 3 and the second beam 4 are collectively called beams. A crossbeam 3 and a second crossbeam 4 are arranged in parallel, and the first crossbeam 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com