Electromagnetic MEMS micromirror

A micromirror and electromagnetic technology, applied in the field of electromagnetic MEMS micromirrors, can solve the problems of difficult combination of MEMS micromirrors, unsuitable for mass production, insufficient electromagnetic driving force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

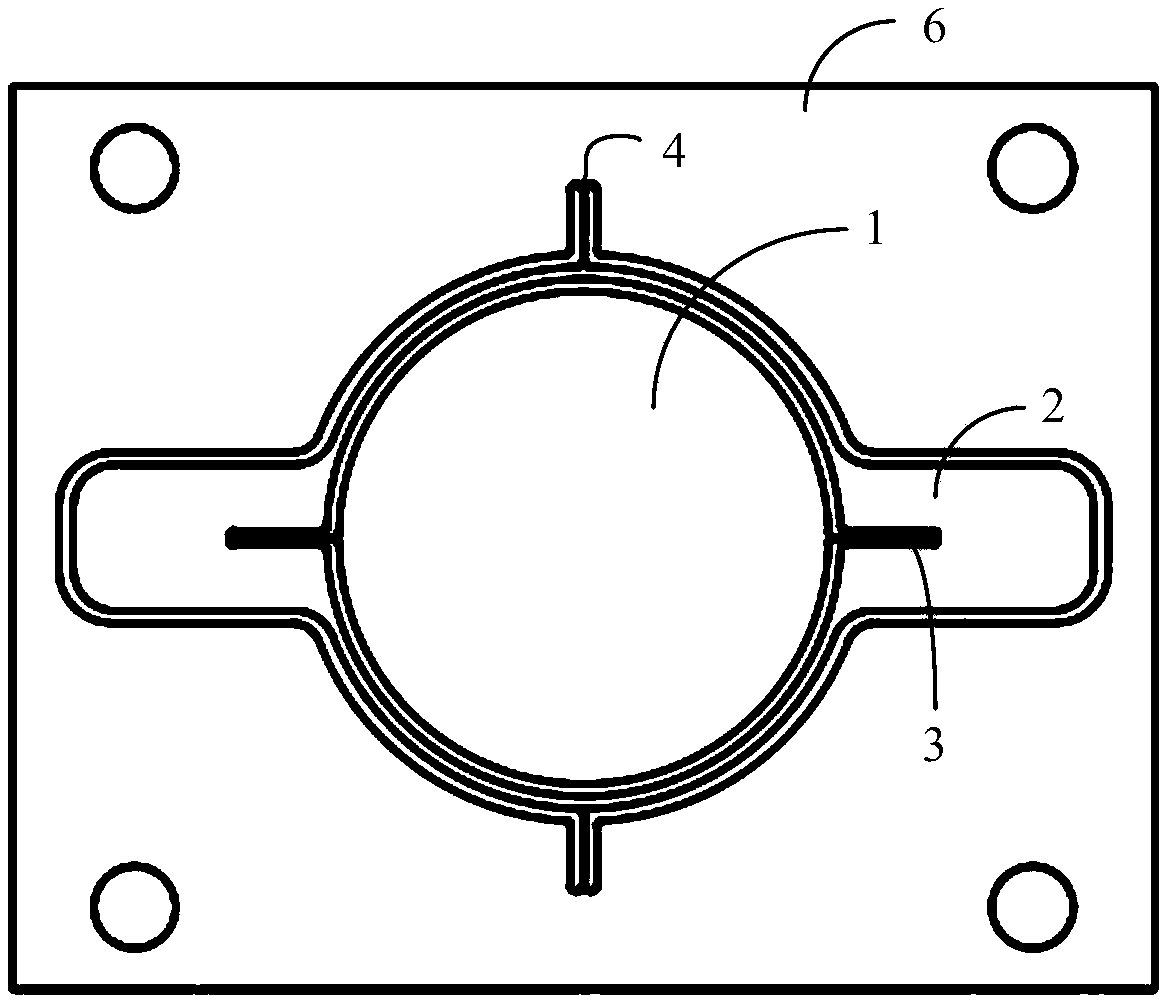

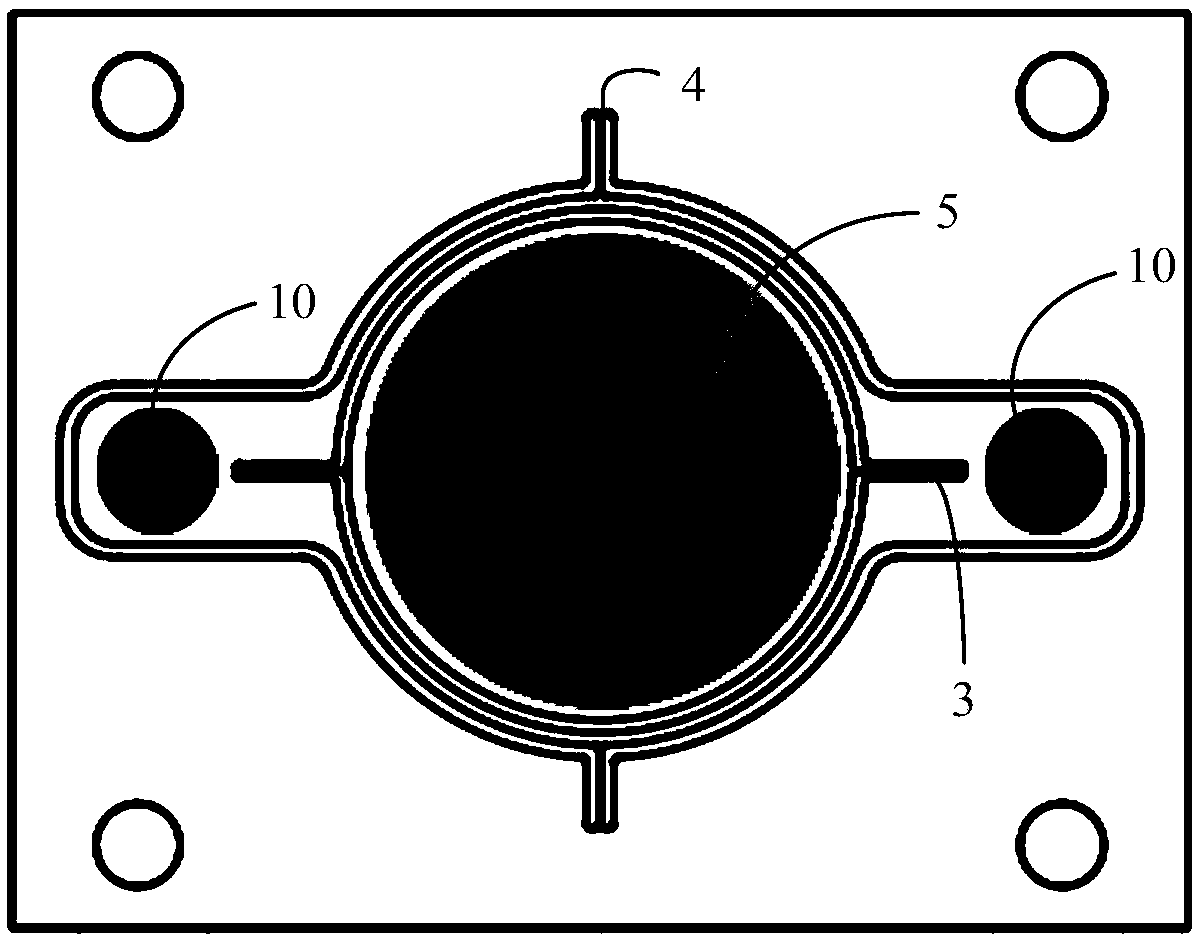

[0031] Such as Figure 2-3 As shown, the electromagnetic MEMS micromirror includes a frame 2, and a mirror 1 is also arranged in the frame 2. The mirror 1 is connected to the inside of the frame 2 through a first rotating shaft 3, and a second rotating shaft 4 is arranged outside the frame 2, and the back of the mirror 1 is arranged There is a soft magnetic film 5. The outside of the frame 2 is connected to the base plate 6 through the second rotating shaft 4 , and the directions of the first rotating shaft 3 and the second rotating shaft 4 are arranged to cross. The frame 2, the first rotating shaft 3 and the second rotating shaft 4 are all made of single crystal silicon.

[0032] The monocrystalline silicon material has a simple structure and fewer internal defects. The internal damping of the rotating shaft structure is small during motion, and the Q value (that is, the quality factor) is greatly improved, which can reach 1000; when the rotating shaft structure is composed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap