Laser active detecting device based on MEMS (micro-electromechanical system) two-dimensional scanning mirror array

A technology of two-dimensional scanning mirror and active detection, which is applied in the direction of measuring device, electromagnetic wave re-radiation, radio wave measurement system, etc., can solve the problems of complex structure, low scanning speed and low work efficiency, and achieve high scanning frequency and high scanning efficiency. Effects with a large range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

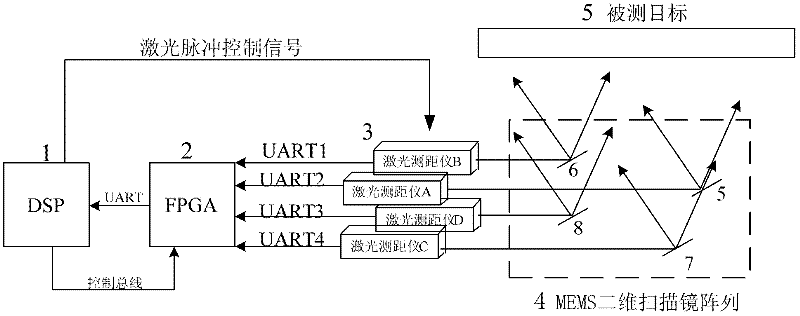

[0018] The DSP signal processing circuit 1 generates a laser pulse control signal to control the laser rangefinder array 3 to emit pulsed laser light. After the laser beam is scanned by the micromechanical (MEMS) two-dimensional scanning mirror array 4, it is irradiated on the detected target 5, and the laser beam is scanned. After being reflected back to the laser rangefinder, the laser rangefinder measures the distance of the measured target according to the time difference between the emitted laser pulse and the received laser pulse, and the DSP signal processing circuit 1 uses the control bus to control the FPGA logic circuit 2 to connect the micromachines ( MEMS) two-dimensional scanning mirror array 4 sets of laser range finder, read the measurement results into the DSP signal processing circuit 1, DSP signal processing circuit 1 sorts and generates the four sets of measurement results of the micromechanical (MEMS) two-dimensional scanning mirror array A 3D laser image of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com