Bluetooth module production test system and method

A technology for production testing and modules, applied in the field of Bluetooth, can solve the problems of high testing cost and cumbersome testing process, and achieve the effect of optimizing the testing process, reducing the high price and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

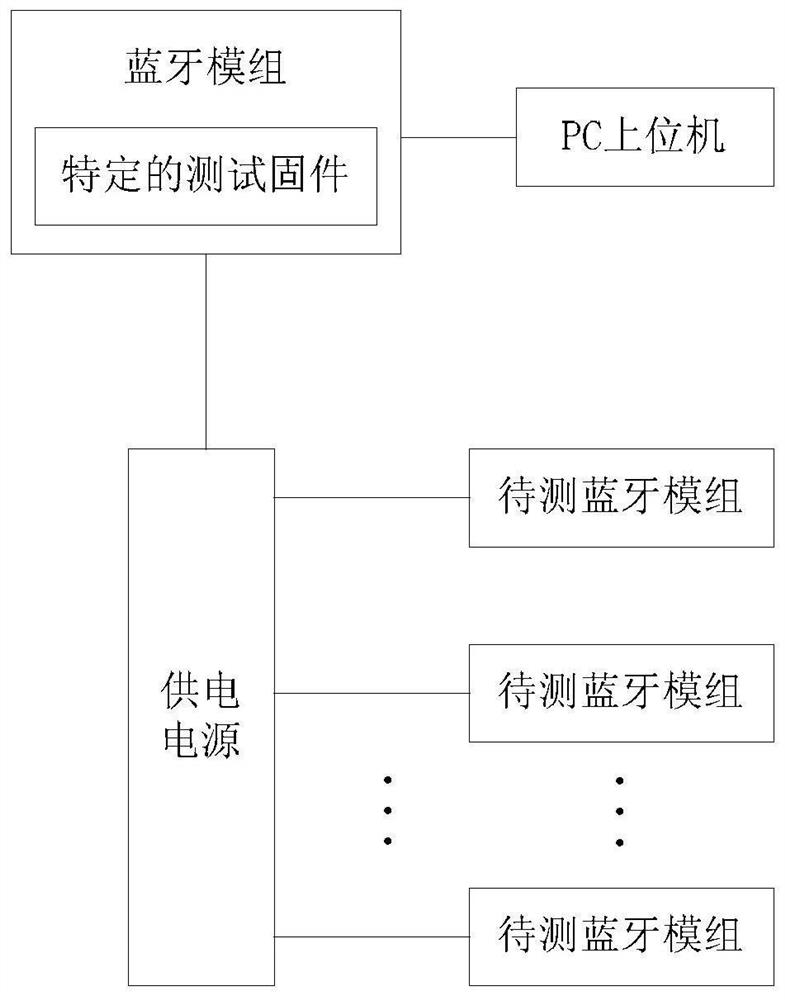

[0032] The bluetooth module production test system of the embodiment of the present invention includes the bluetooth module to be tested, and also includes the bluetooth module, a power supply and a PC host computer, wherein the bluetooth modules to be tested are all used to connect with the power supply, and the bluetooth modules are respectively It is connected with the power supply and PC host computer, and the Bluetooth module is programmed with specific test firmware; the power supply is used when it is respectively connected with the Bluetooth module and the Bluetooth module to group for power supply; the Bluetooth module to be tested is used to broadcast the Bluetooth broadcast packet in real time when the power supply is connected, and the Bluetooth broadcast packet includes the MAC address and signal strength value of the corresponding Bluetooth module to be tested; the Bluetooth module is used to pass The specific test firmware grabs the broadcast bluetooth broadcast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com