A Dune Imitation Microstructure with Efficient Air Drag Reduction Function and Its Optimal Design Method

A high-efficiency air and optimized design technology, applied in the field of surface drag reduction, can solve problems such as poor air drag reduction effect and large wind resistance on the smooth surface of aircraft, so as to achieve efficient design methods, good pertinence and flexibility, and alleviate excessive energy consumption. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

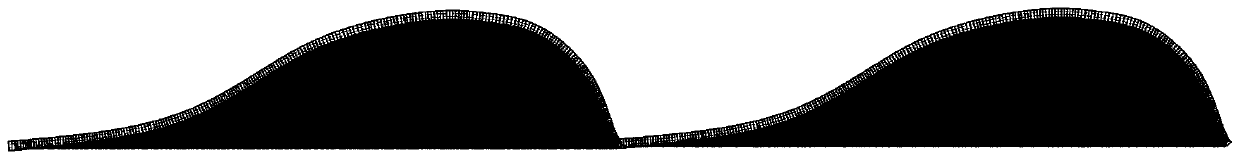

[0034] The design method of the dune-like microstructure with high-efficiency air drag reduction function of the present invention is as follows:

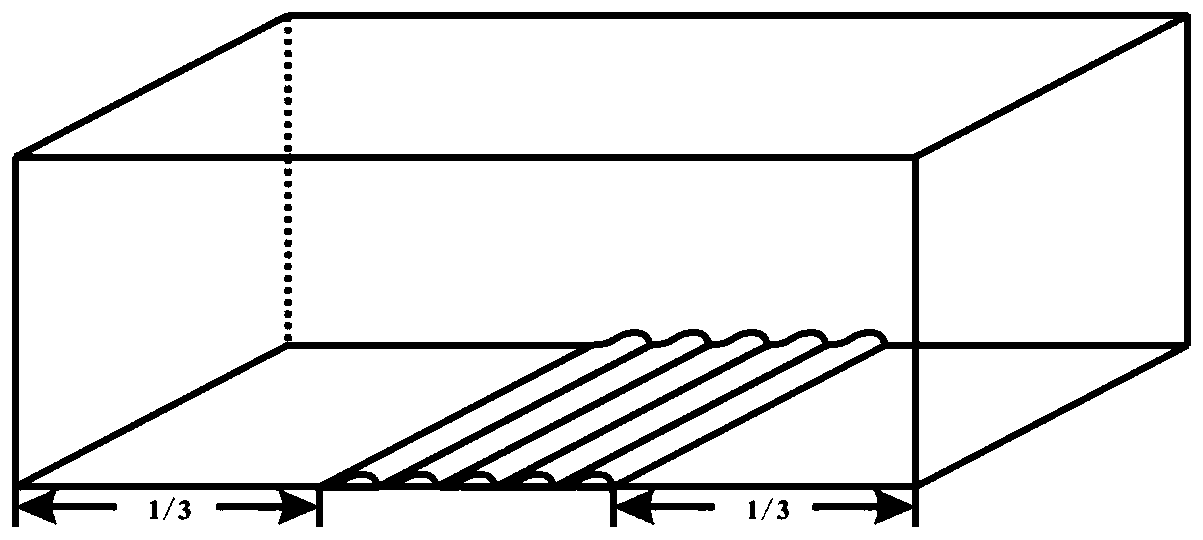

[0035] In the first step, a geometric model of the flow field with an area size of 15mm×15mm×45mm is established. A buffer zone of 15mm length is set in the front and back sections of the flow field area, and 15mm is reserved in the middle area to arrange the microstructure array.

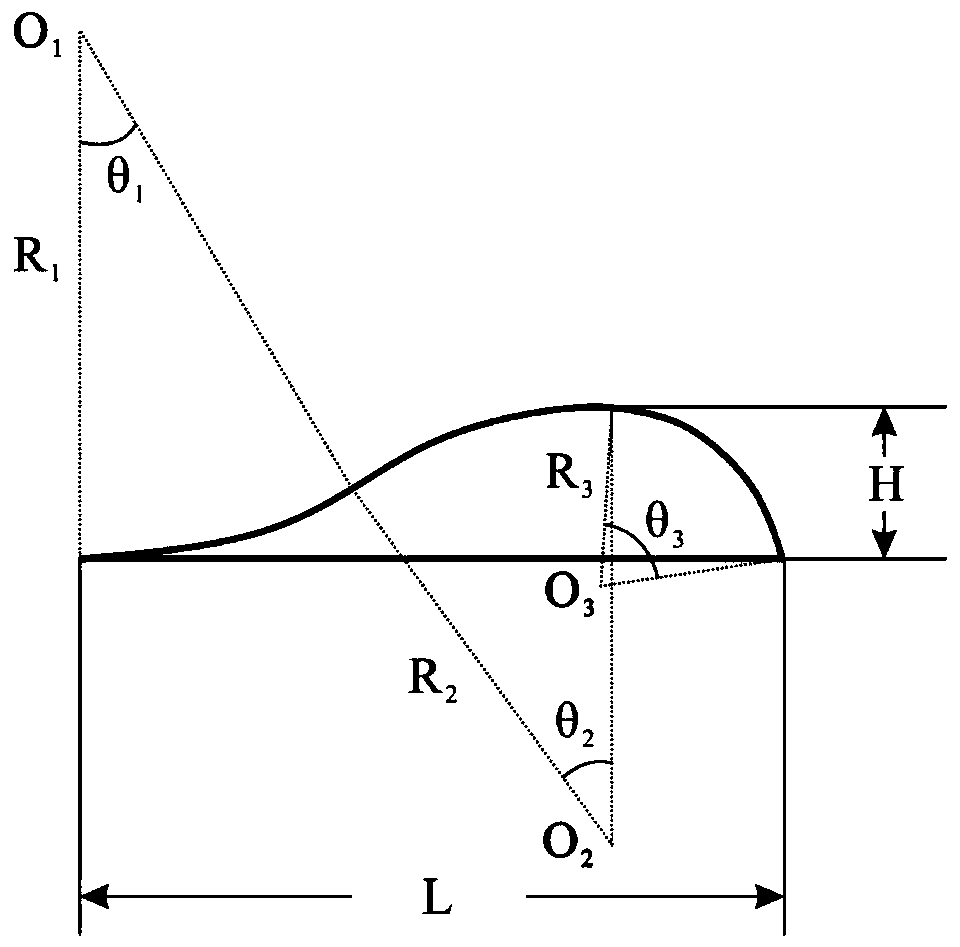

[0036] The second step is to establish a geometric model of the dune-like microstructure. The height H is set to 40μm, the length L is set to 200μm, and the first arc center is O 1 Located at the left end of the microstructure bottom surface and perpendicular to the vertical line of the bottom surface, corresponding to the central angle θ 1 Set to 25°, the second arc circle center O 2 Located at the highest point of the microstructure and perpendicular to the vertical line of the bottom surface, corresponding to the central angle θ 2 Set to 30°, the third arc ...

Embodiment 2

[0043] The design method of the dune-like microstructure with high-efficiency air drag reduction function of the present invention is as follows:

[0044] In the first step, a geometric model of the flow field with an area size of 15mm×15mm×45mm is established. A buffer zone of 15mm length is set in the front and back sections of the flow field area, and 15mm is reserved in the middle area to arrange the microstructure array.

[0045] The second step is to establish a geometric model of the imitated sand dune microstructure. The height H is set to 50μm, the length L is set to 250μm, and the center of the first arc is O 1 Located at the left end of the microstructure bottom surface and perpendicular to the vertical line of the bottom surface, corresponding to the central angle θ 1 Set to 20°, the second arc circle center O 2 Located at the highest point of the microstructure and perpendicular to the vertical line of the bottom surface, corresponding to the central angle θ 2 Set to 25°...

Embodiment 3

[0052] The design method of the dune-like microstructure with high-efficiency air drag reduction function of the present invention is as follows:

[0053] In the first step, a geometric model of the flow field with an area size of 15mm×15mm×45mm is established. A buffer zone of 15mm length is set in the front and back sections of the flow field area, and 15mm is reserved in the middle area to arrange the microstructure array.

[0054] The second step is to establish a geometric model of the dune-like microstructure. The height H is set to 60μm, the length L is set to 300μm, and the center of the first arc is O 1 Located at the left end of the microstructure bottom surface and perpendicular to the vertical line of the bottom surface, corresponding to the central angle θ 1 Set to 30°, the second arc circle center O 2 Located at the highest point of the microstructure and perpendicular to the vertical line of the bottom surface, corresponding to the central angle θ 2 Set to 35°, the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com