Separation method of chloropentafluoroethane and pentafluoroethane

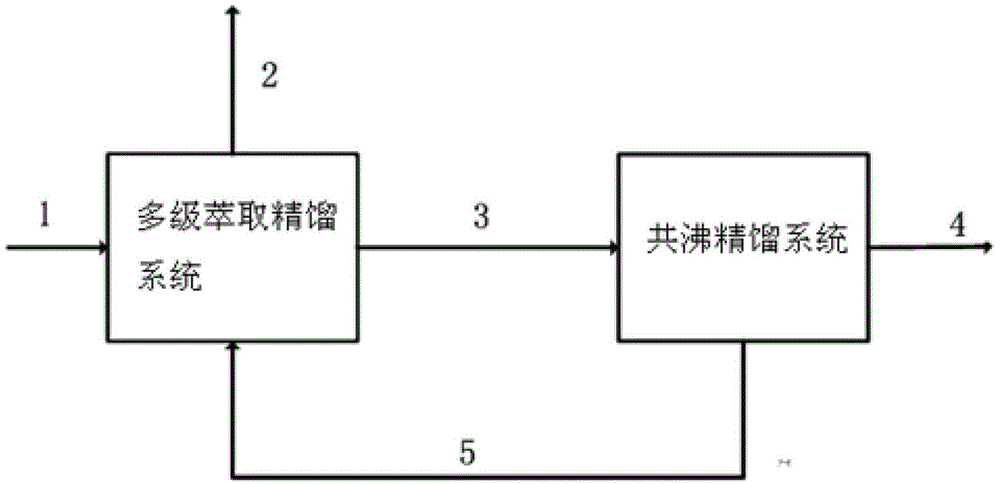

A technology of monochloropentafluoroethane and pentafluoroethane, which is applied in the field of separation of monochloropentafluoroethane and pentafluoroethane, can solve uneconomical problems, reduce energy consumption, optimize process flow, and stabilize The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

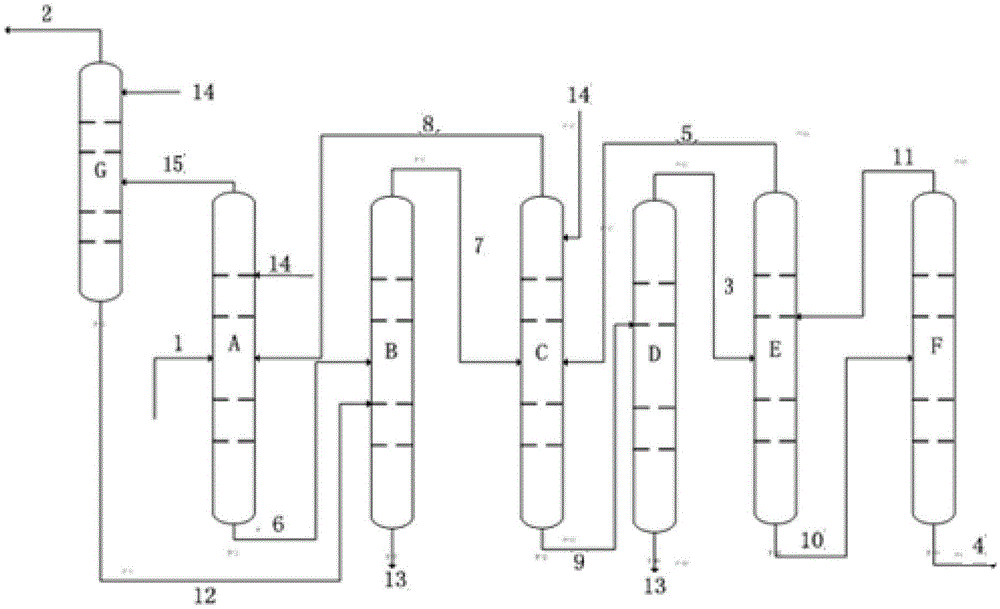

[0037] This embodiment provides a method for separating a mixture of chloropentafluoroethane and pentafluoroethane according to the above-mentioned process flow, and the raw materials and process conditions are as follows:

[0038] (1) In the mixture of chloropentafluoroethane and pentafluoroethane to be separated: the content of chloropentafluoroethane is 1wt%, the content of pentafluoroethane is 98.5wt%, tetrafluoroethane and its The homologue content is 3 / h;

[0039] (2) Extractant: petroleum hydrocarbon;

[0040] (3) Parameter setting of the primary extractive distillation column: the feed rate of the mixture of chloropentafluoroethane and pentafluoroethane to be separated is 2.4~2.6m 3 / h, the throughput of extractant is 8~11 m 3 / h, pressure 0.8~1.2MPa, return flow 4~7 m 3 / h;

[0041] Parameter setting of the secondary extractive distillation column: the feed rate of the mixture containing chloropentafluoroethane and pentafluoroethane is 0...

Embodiment 2

[0047] This embodiment provides a method for separating a mixture of chloropentafluoroethane and pentafluoroethane according to the above-mentioned process flow, and the raw materials and process conditions are as follows:

[0048] (1) In the mixture of chloropentafluoroethane and pentafluoroethane to be separated, the content of chloropentafluoroethane is 1.5 wt%, the content of pentafluoroethane is 98 wt%, tetrafluoroethane and its Congener content 3 / h;

[0049] (2) Extractant: petroleum ether (C 3 -C 6 ethers);

[0050] (3) Parameter setting of the primary extractive distillation column: the feed rate of the mixture of chloropentafluoroethane and pentafluoroethane to be separated is 2.4~2.6m 3 / h, the throughput of the extractant is 7~9m 3 / h, pressure 1.2~1.4 MPa, return flow 5~8 m 3 / h ;

[0051] Parameter setting of the secondary extractive distillation column: the feed rate of the mixture 7 containing chloropentafluoroethane and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com