Roller lathe composite tool rest

A technology of composite tool rest and roll lathe, applied in the field of machine tools, can solve the problems of reducing precision, time-consuming and laborious card installation, etc., and achieves the effect of reliable card installation, satisfying the function of copying and cutting, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

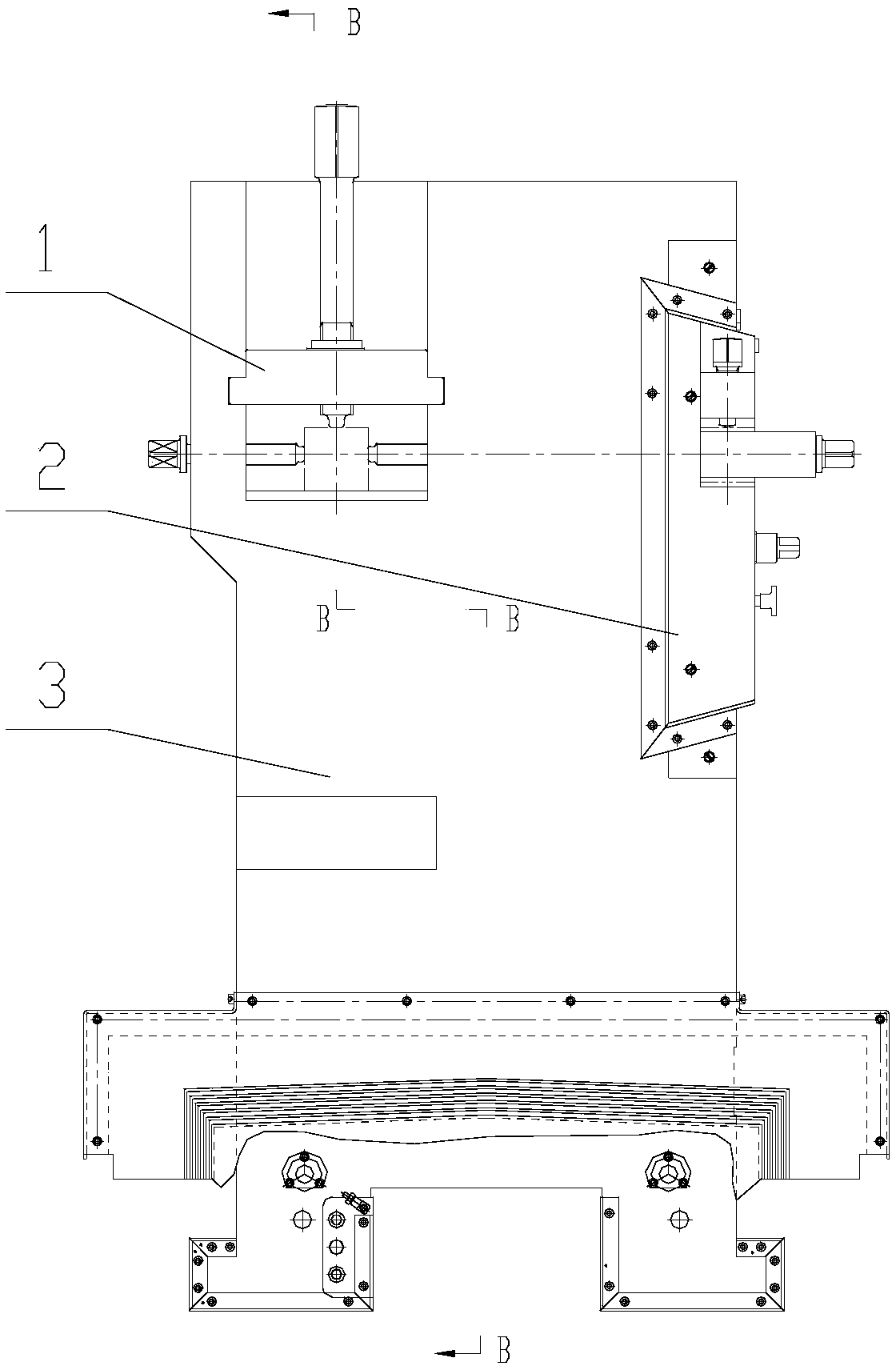

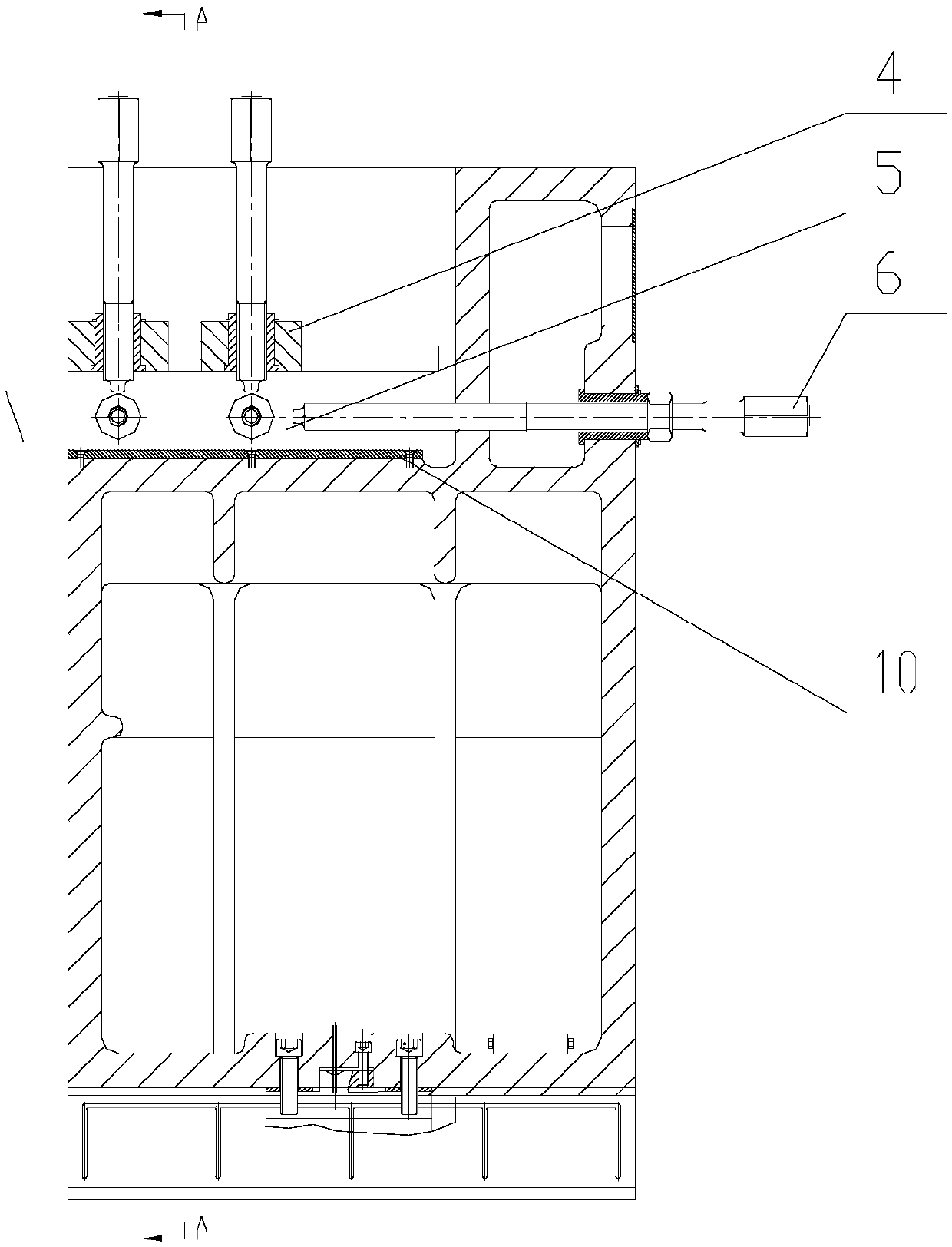

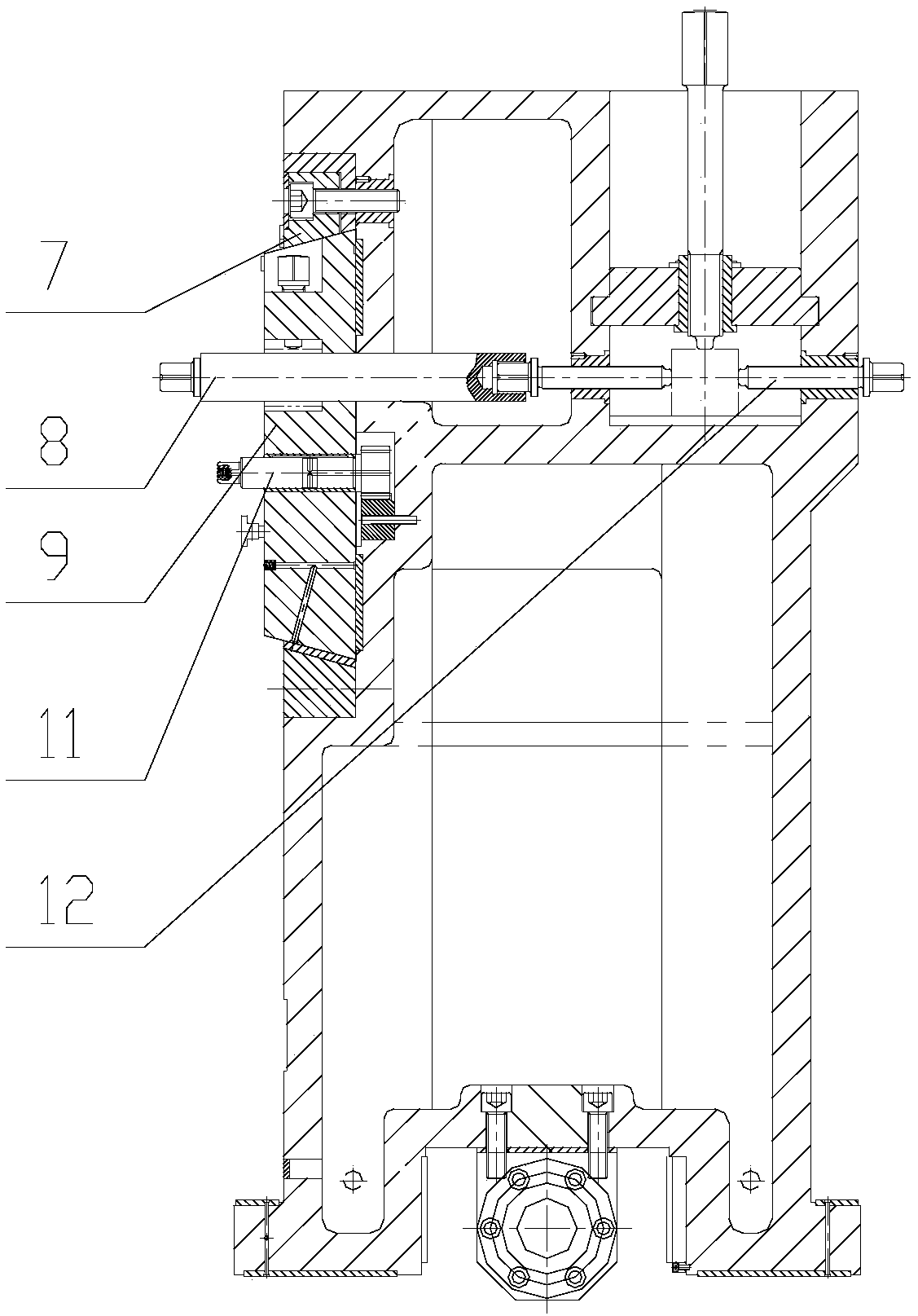

[0014] The present invention will be further described below in conjunction with accompanying drawing:

[0015] Depend on Figure 1 to Figure 3 As shown, a composite tool holder for a roll lathe includes a tool holder body 3 on which a profiling tool clamping mechanism 1 and a standard tool clamping mechanism 2 are respectively fixed, wherein the profiling tool clamping mechanism 1 It is used to clamp the profiling tool, and the standard tool clamping mechanism 2 is used to clamp the standard tool. The clamping mechanism 1 of the profiling tool comprises a radial clamping mechanism 4, a tool adjusting rod 6, a central adjustment pad 10 of the profiling tool, an axial clamping mechanism 12 of the profiling tool and a profiling tool 5, the radial clamping The tightening mechanism 4 is located at the top of the profiling tool 5, and the radial clamping mechanism 4 includes two ejector rods. On the cutter 5, thereby clamping the Y-axis direction of the profiling cutter 5. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com