Cooling system with adjustable internal heat exchanger

A technology for internal heat exchangers, cooling systems, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as limiting IHX performance, achieve constant conditions, low flow rate, and improve flow control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

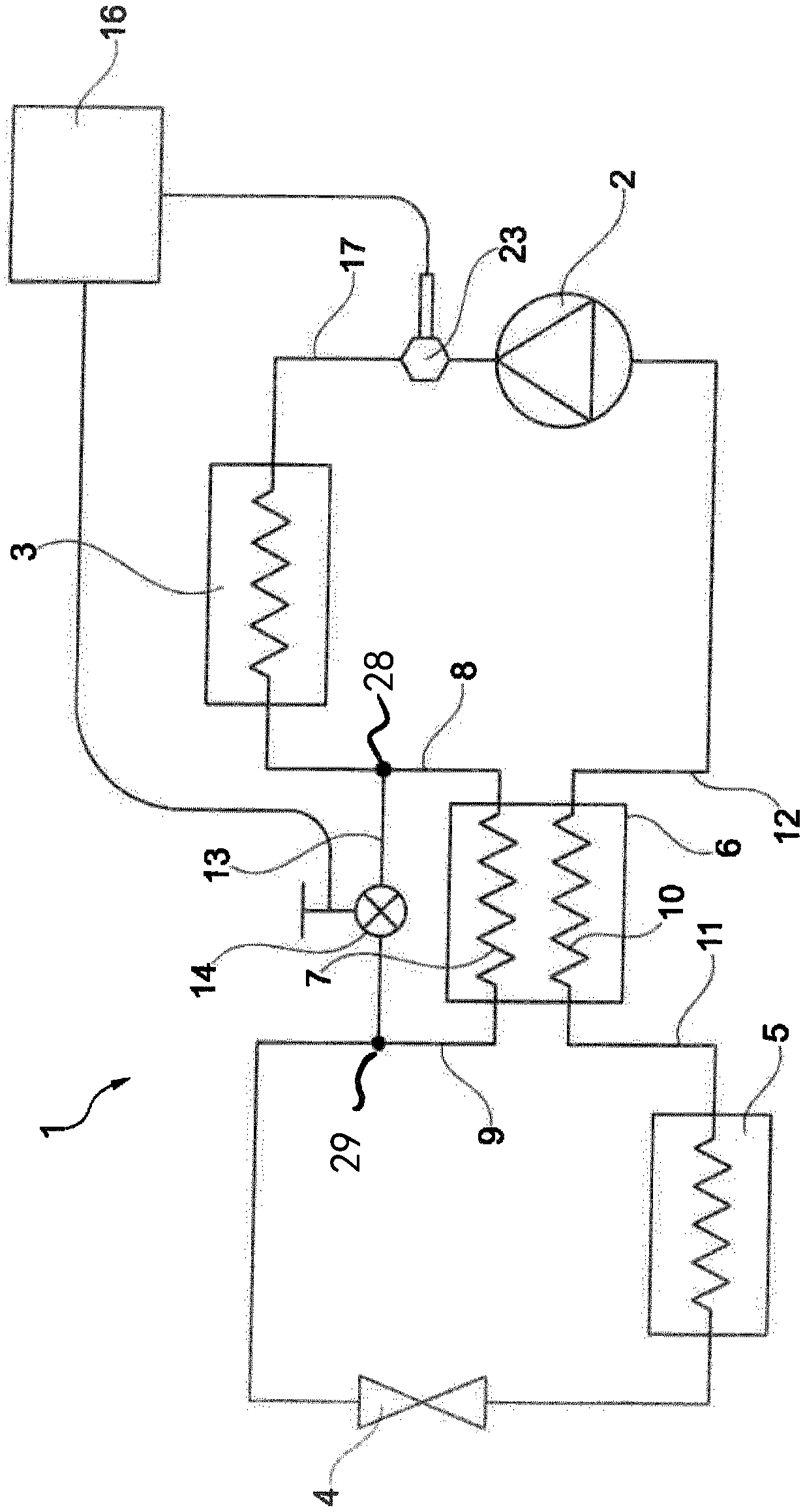

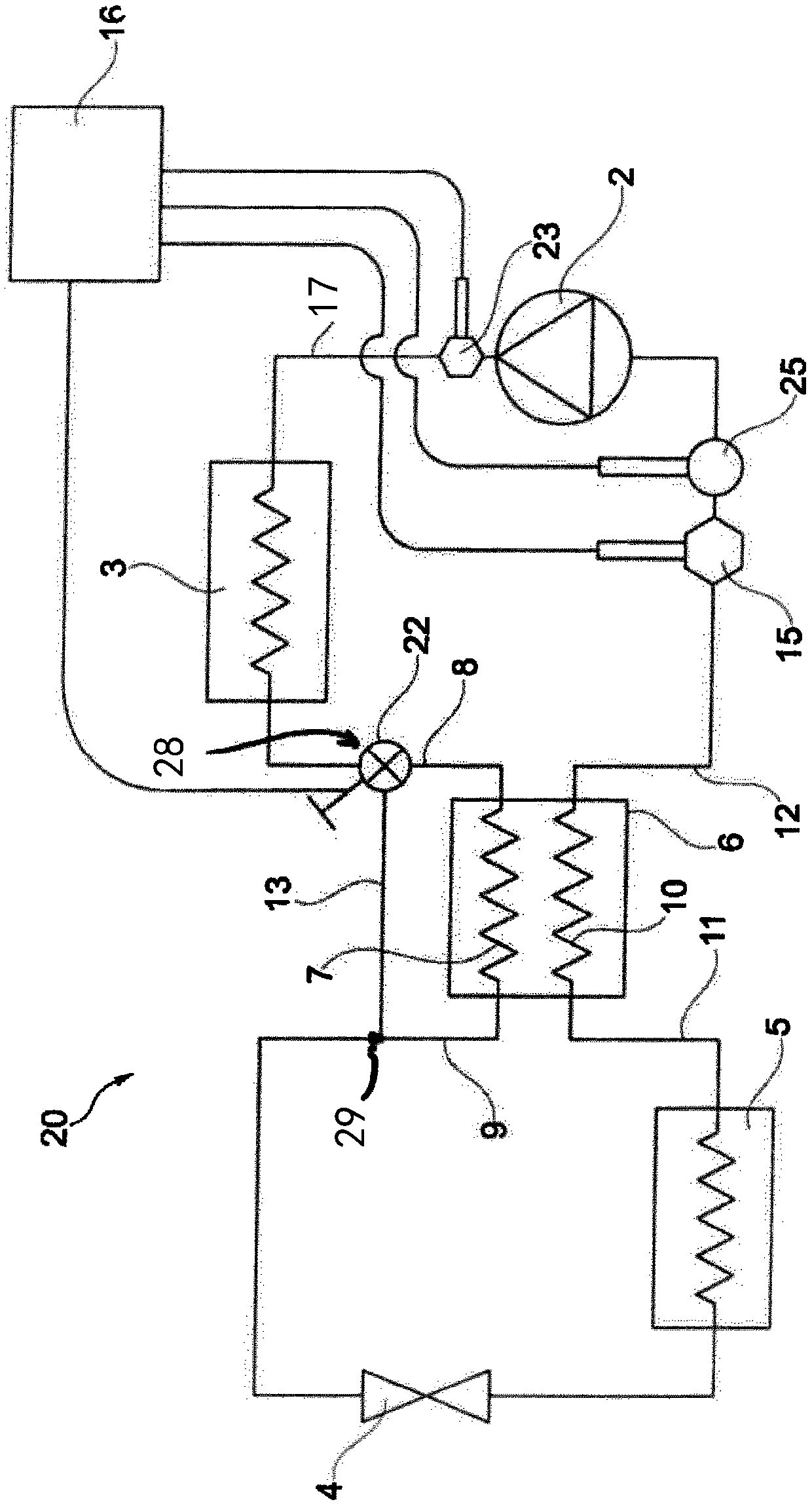

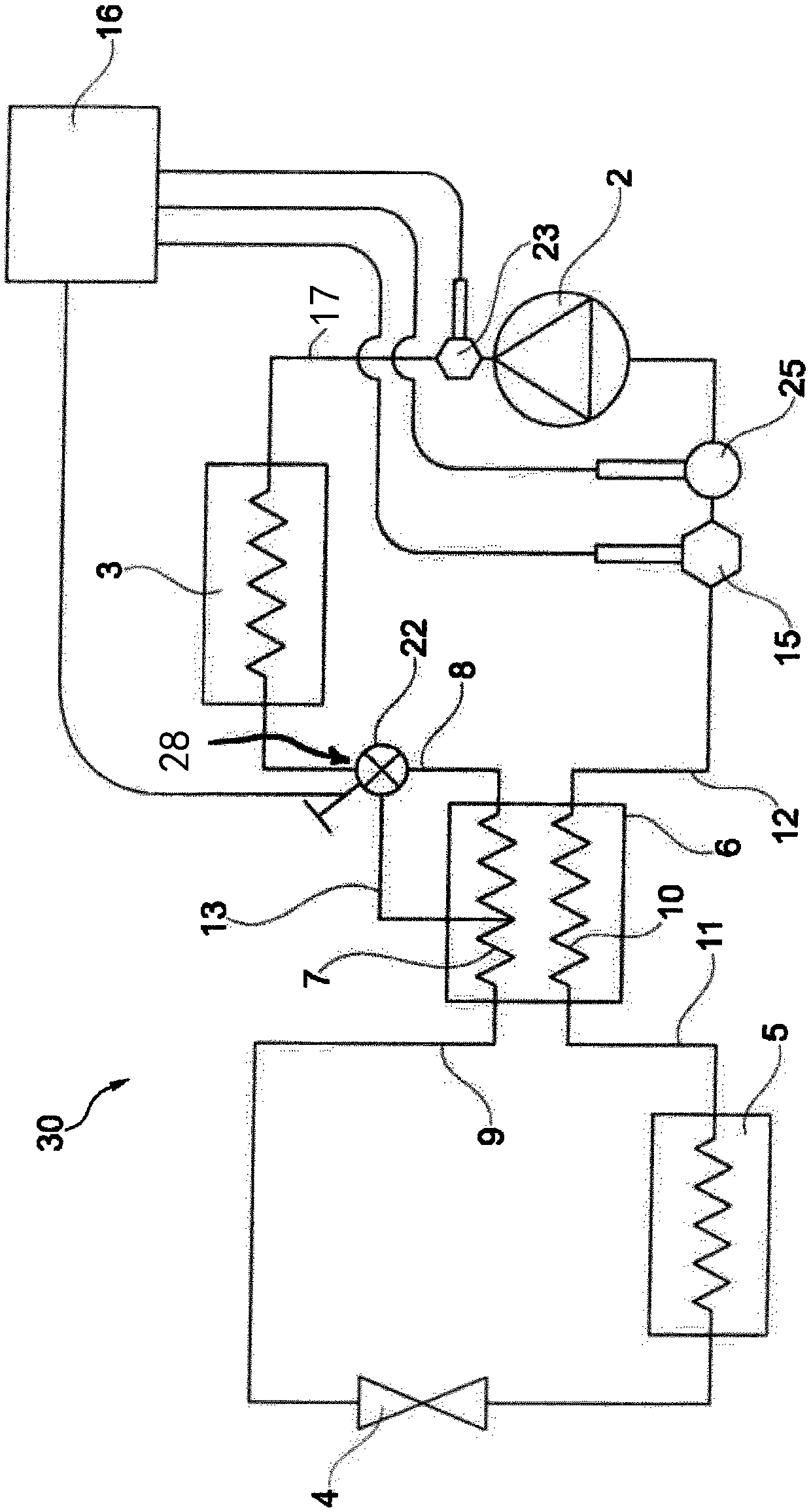

[0064] figure 1 A cooling system 1 is schematically shown comprising a compressor 2 , a condenser 3 , an expansion valve 4 and an evaporator 5 connected in sequence by fluid lines in a circuit.

[0065] In order to further improve the cooling system 1, the internal heat exchanger 6 is provided with a first conduit 7 arranged in the lines 8, 9 between the condenser 3 and the expansion valve 4, and a first conduit 7 arranged between the evaporator 5 and the compressor 2 Second conduit 10 in lines 11 , 12 .

[0066] Furthermore, a bypass fluid line 13 with a controllable valve 14 is arranged between the line 8 and the line 9 , ie between the two ends of the first conduit 7 of the internal heat exchanger 6 . The bypass fluid line 13 is arranged between the inlet connection 28 and the outlet connection 29 .

[0067] The fluid line 8 between the condenser 3 and the first conduit 7 of the internal heat exchanger 6 is permanently open. The first conduit 7 of the internal heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com