screw pump

A screw pump and screw technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve problems such as difficult alignment, cumbersome installation, and difficulty in pushing a bush or multiple bushes to the end of the screw, etc. , to achieve the effect of gap equalization compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

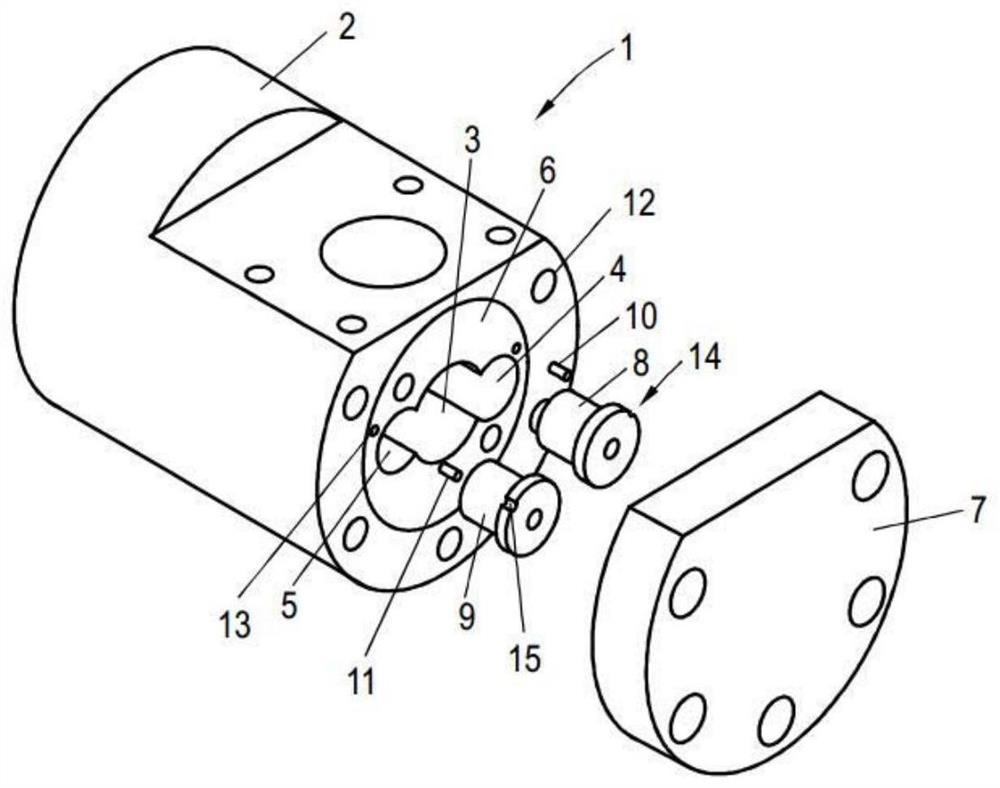

[0037] figure 1 A partially exploded view of a screw pump 1 according to the invention is shown. Shown is a housing 2 in which a first hole 3 for fixing the drive screw is formed in the middle of the housing 2 and two additional holes 4, 5 laterally offset from the first hole 3 are formed in the housing, Each additional hole accommodates an idler screw which engages the drive screw. The screw is not shown therein. The bores 4 , 5 for fastening the idler screws extend as far as they are directly flush with the end face 6 of the housing 2 .

[0038] Also shown is a housing cover 7 which is tightly screwed onto the housing 2 by means of suitable fastening screws to close it.

[0039] Also shown are two bushings 8,9, which are part of the hydraulic thrust compensation system, by which the two idler screws are axially supported. The design and function of the bushings 8,9 will be further discussed next. Two pins 10,11 are used to fix the bushing in place non-rotatably; one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com