A kind of preparation method and application of polyvinyl chloride

A technology of polyvinyl chloride and polymerization method, applied in the direction of organic chemistry, etc., can solve problems such as the migration of plasticizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

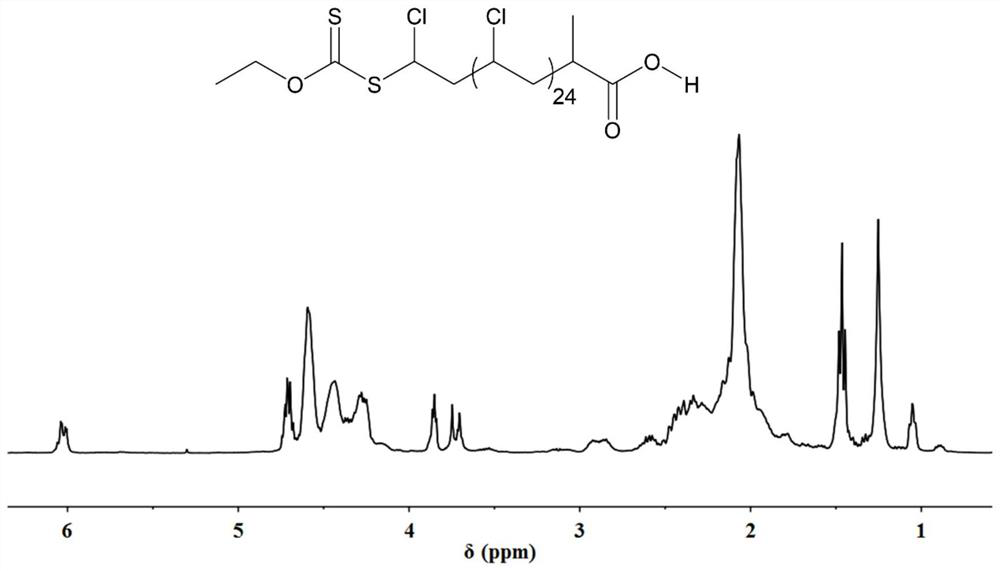

[0031] In the autoclave, add THF solvent (23.1g, 320.0mmol), VC monomer (20.0 g, 320.0mmol), the molar ratio of THF solvent and VC monomer is 1:1, linear xanthate RAFT reagent RAFT- 1 (2.7g, 11.5mmol), the molar ratio of monomer and corresponding RAFT reagent is 28:1, the initiator AIBN (0.20g, 1.2mmol), the molar ratio of RAFT reagent and initiator is 9.5:1, at 50℃ Under reaction 60h, after the product is precipitated in methanol, the linear PVC (structural formula and NMR 1 H NMR spectrum see figure 1 ). The degree of polymerization n of PVC in the present embodiment 1 =24.

Embodiment 2

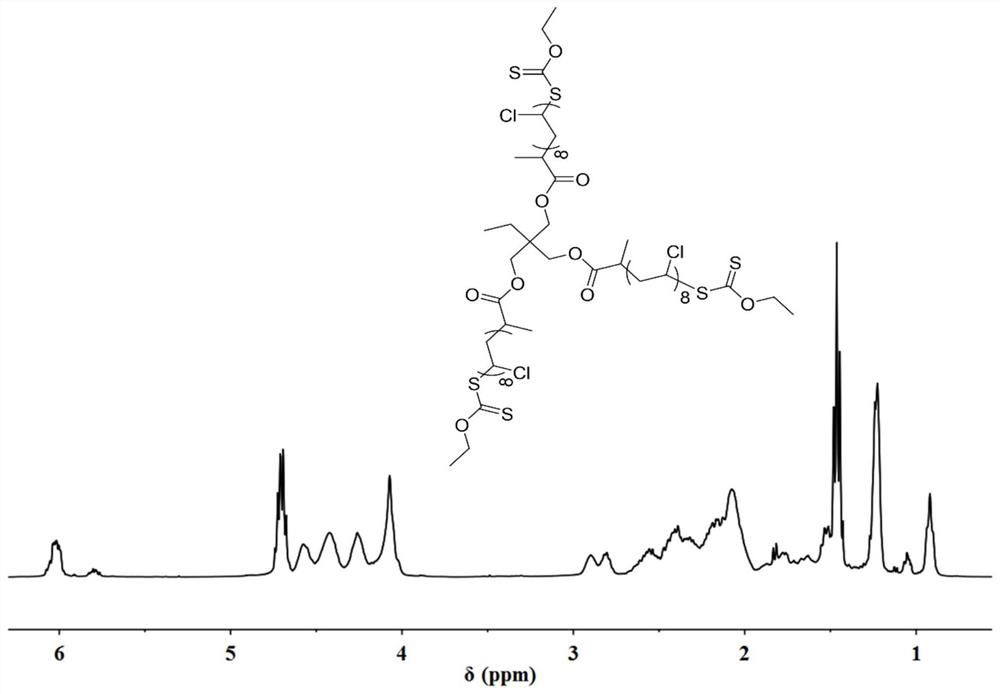

[0033] Add dioxane solvent (114.5g, 1.3mol), VC monomer (26.6 g, 425.6mmol) in the autoclave, the molar ratio of dioxane solvent and VC monomer is 3.1:1, three-arm star Xanthate RAFT reagent RAFT-2 (10.6g, 16.0mmol), the molar ratio of monomer and corresponding RAFT reagent is 26.6:1, initiator ABVN (0.45g, 1.6mmol), the molar ratio of RAFT reagent and initiator The ratio is 10:1, react at 60°C for 24h, and precipitate the product in methanol to obtain a three-arm star-shaped linear PVC with a low degree of polymerization (structural formula and NMR 1 H NMR spectrum see figure 2 ). The degree of polymerization n of the three-arm star-shaped PVC in the present embodiment 2 =8.

Embodiment 3

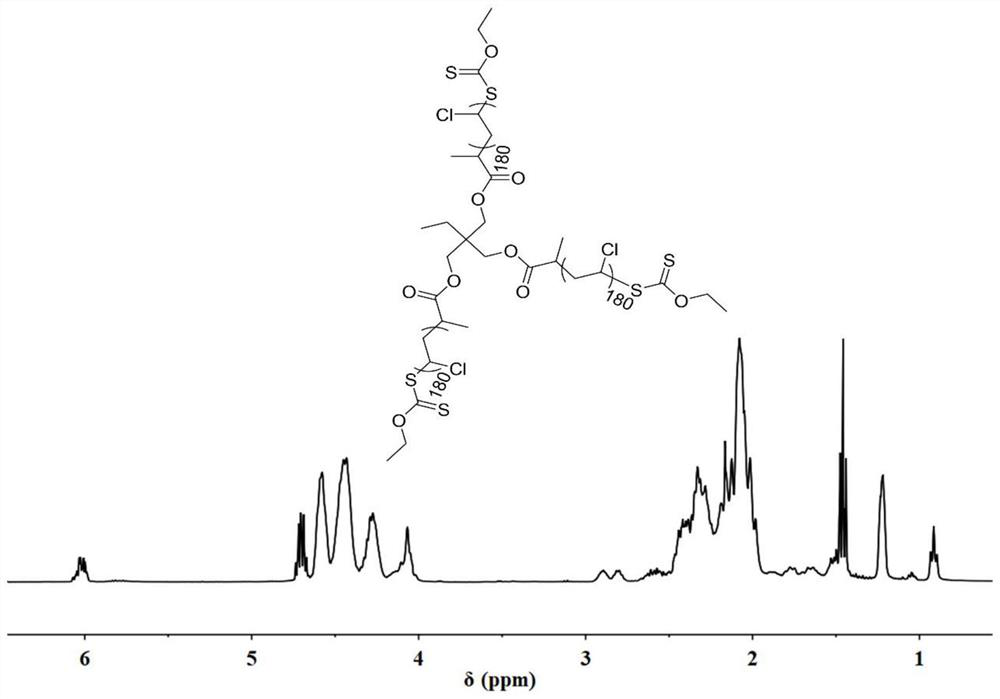

[0035]Add dioxane solvent (114.5 g, 1.3 mol), VC monomer (68.8 g, 1.1 mol) in the autoclave, the molar ratio of dioxane solvent and VC monomer is 1.2:1, three-arm star Xanthate RAFT reagent RAFT-2 (11.2g, 18.0mmol), the molar ratio of monomer and corresponding RAFT reagent is 61.1:1, initiator ABVN (2.3g, 9.0mmol), the molar ratio of RAFT reagent and initiator The ratio is 2:1, react at 60°C for 30h, and precipitate the product in methanol to obtain a three-armed star-shaped PVC. The degree of polymerization n of the three-arm star-shaped PVC in the present embodiment 2 =18.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap